Low-molecular-weight narrow-distribution styrene-maleic anhydride copolymer and preparation method thereof

A technology of maleic anhydride and low molecular weight, which is applied in the field of low molecular weight narrow distribution styrene-maleic anhydride copolymer and its preparation, and can solve problems affecting the health of operators, large odor, and large odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a kind of preparation method of low molecular weight narrow distribution styrene-maleic anhydride copolymer, comprises the following steps:

[0026] Mix styrene, maleic anhydride and an initiator, polymerize the resulting mixture, and devolatilize the resulting reaction material to obtain a low-molecular-weight narrow-distribution styrene-maleic anhydride copolymer and an extraction material; Post-processing;

[0027] The temperature of the polymerization reaction is 130-300°C; the polymerization reaction is carried out in a tubular reactor with a static mixer;

[0028] The initiator is a thermal decomposition type initiator, and the thermal decomposition type initiator includes an organic peroxide type initiator and an azo type initiator;

[0029] Described organic peroxide initiator comprises benzoyl peroxide, lauroyl peroxide, di-tert-butyl peroxide, dicumyl peroxide, tert-butyl peroxybenzoate or diisopropyl peroxydicarbonate ester;

[0030]...

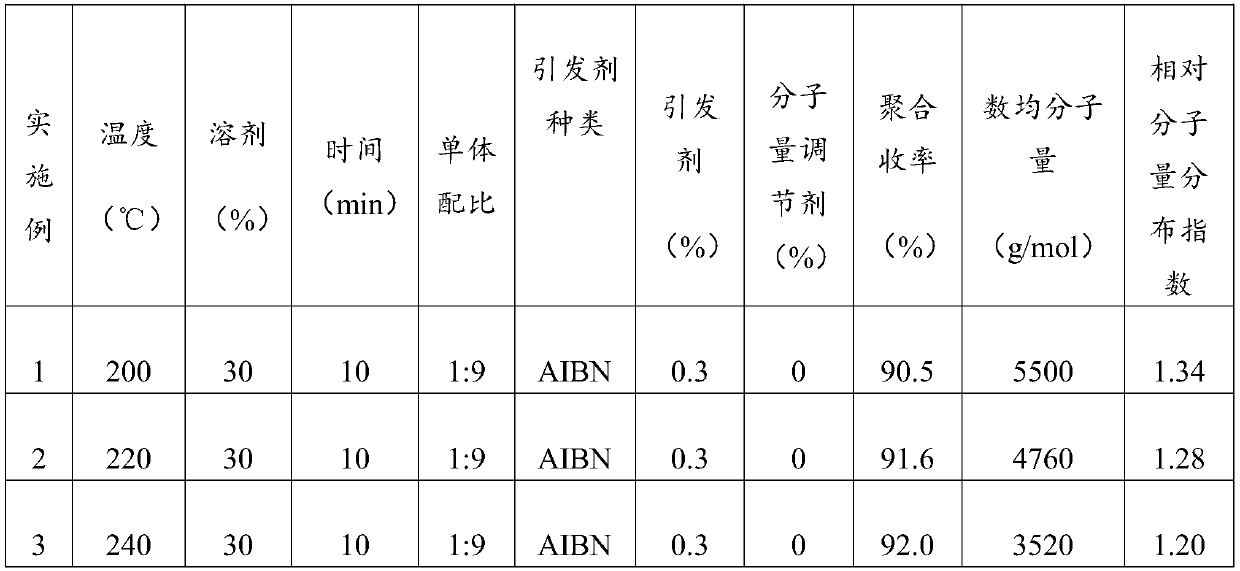

Embodiment 1

[0046] Material ratio: reaction solvent cyclohexanone 30kg, accounting for 30% of the total mass of all materials; maleic anhydride to styrene molar ratio 1:9, maleic anhydride 6.6kg, styrene 63.4kg; initiator azobisisobutyl Nitrile 0.21kg, the quality of described initiator accounts for 0.3% of the total mass of maleic anhydride and styrene.

[0047] Preparation of copolymer: Add styrene, maleic anhydride, initiator and reaction solvent into the monomer mixing reactor, exhaust the air with nitrogen and mix until the maleic anhydride dissolves, and then send the resulting mixture to In the tubular reactor at 200°C, the residence time of the mixed material is 10min, and the obtained reaction material is transported to the devolatilizer for devolatilization to obtain low molecular weight narrow distribution styrene-maleic anhydride copolymer and the exfoliated material; The low molecular weight narrow distribution styrene-maleic anhydride copolymer obtained by volatilization is ...

Embodiment 2

[0049] The only difference from Example 1 is that the residence time of the mixed material in the tubular reactor at 220° C. is 10 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com