Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Play a capacity-increasing role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition for foaming material with high rebound resilience and preparation method thereof

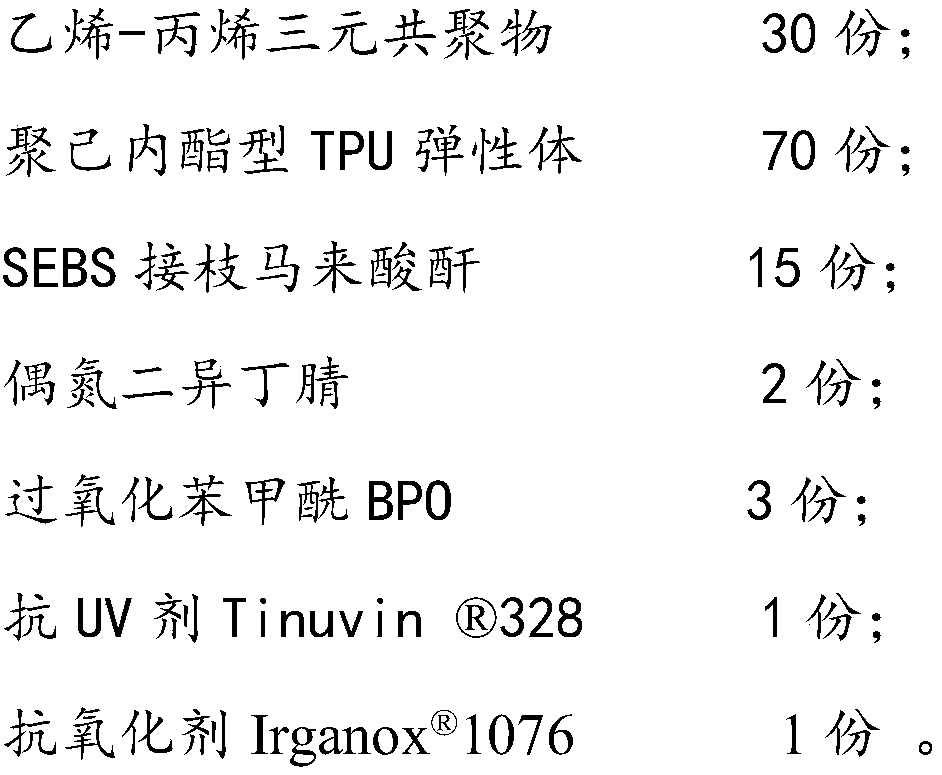

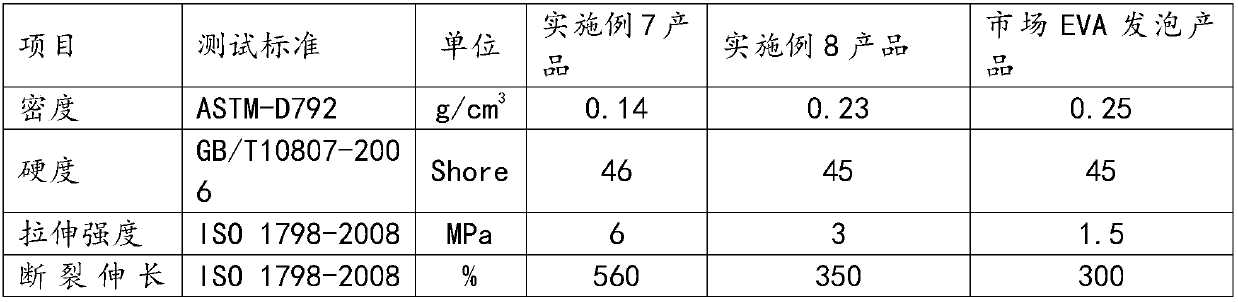

The invention relates to a composition for foaming material with high rebound resilience and a preparation method thereof. The composition is prepared from the following components in parts by weight: 5 to 95 parts of alkene polymer, 5 to 95 parts of TPU (thermoplastic polyurethane) elastomer, 0.1 to 45 parts of compatilizer, 0.1 to 10 parts of foaming agent, 0.01 to 5 parts of crosslinking agent, 0 to 5 parts of crosslinking additive, and 0 to 10 parts of other additive. The composition has the advantages that by utilizing the comptilzier with polarity groups or double active groups, the interface tension between the alkene polymer and TPU is reduced, an alkene polymer / TPU IPN (inter-penetrating polymer network) structure is formed, and the problem of compatibility between two types of materials is solved; by successfully introducing the TPU component into the alkene polymer, the excellent resilience of TPU is utilized, and the rebound resilience, compression permanent deformation and the like of the alkene polymer are greatly improved.

Owner:MIRACLL CHEM

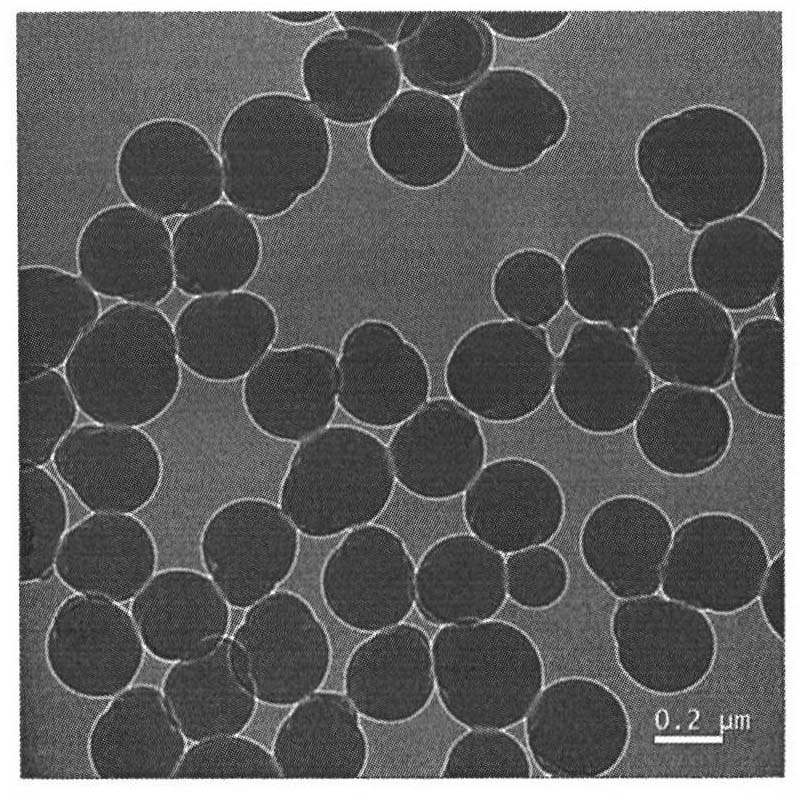

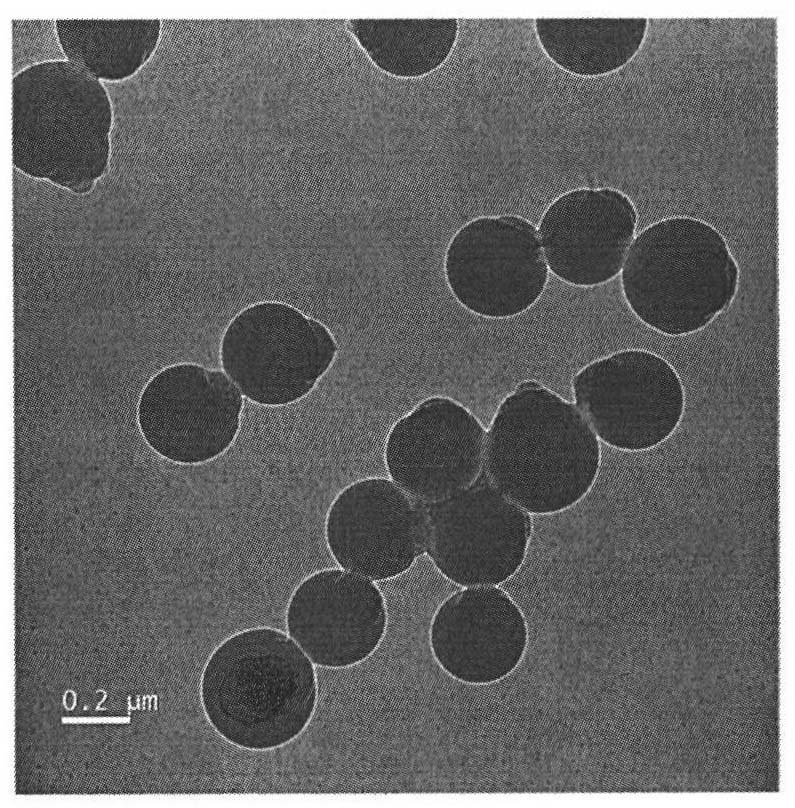

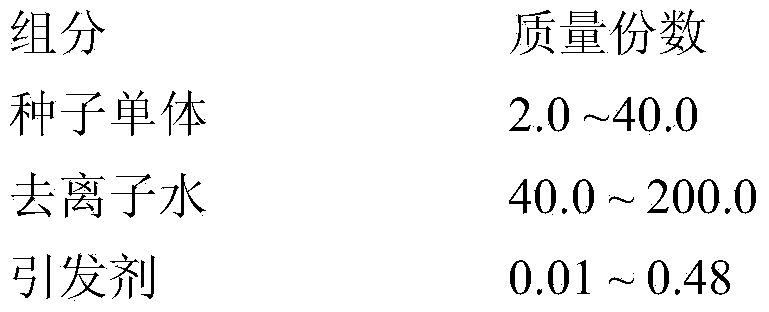

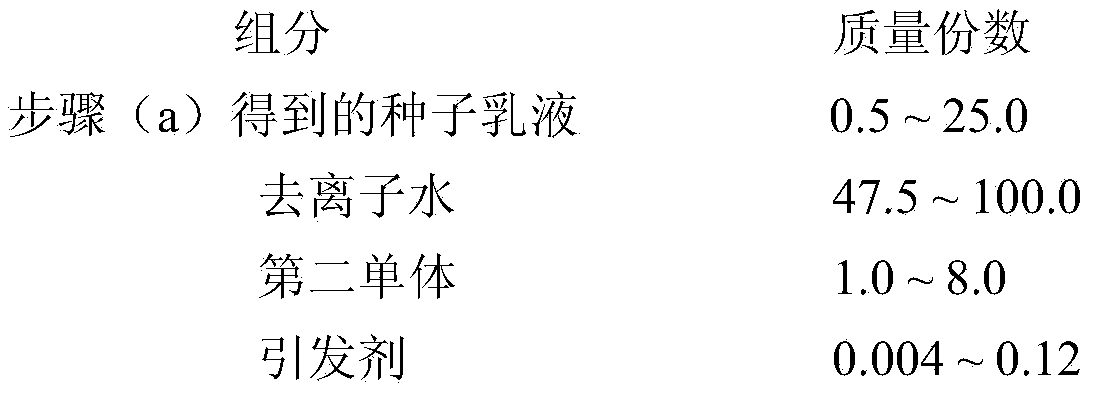

Preparation method of Janus-structure composite emulsion particle

The invention relates to a preparation method of a Janus-structure composite emulsion particle. The method comprises the following steps: adding deionized water into a PVDF seed emulsion, performing ultrasonic dispersion for 1 hour, pouring the dispersed emulsion into a reactor equipped with a reflux condensing tube, a stirring device, and a nitrogen introducing port, starting stirring and continuously introducing nitrogen, after 15 min, heating the reaction system, adding monomers, introducing cooling water into the reflux condensing tube; when the system is heated to a reaction temperature, adding an initiator, performing a polymerization reaction at a reaction temperature of 20-80 DEG C for 1-8 hours; drying the emulsion at a reduced pressure and a low temperature to obtain a constant weight so as to obtain the Janus-structure composite particle. Through the selection of PVDF seeds with different particle sizes, the seed monomer mass ratio and the polymerization time, the invention can effectively control the form and the size of the composite particle. The invention is widely applicable to various fields in polymer blending modification, such as compatilizers, self-cleaned coatings, and the like.

Owner:HEBEI UNIV OF TECH

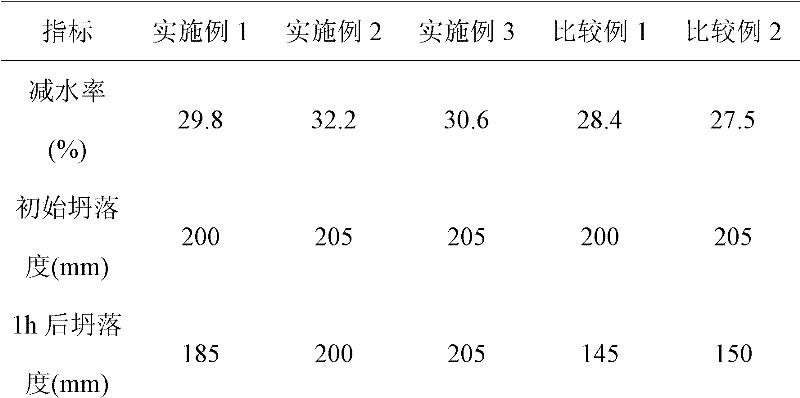

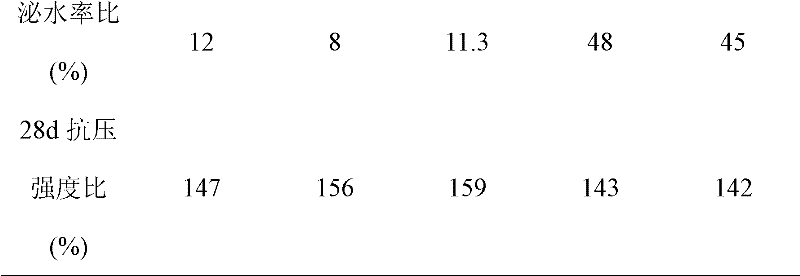

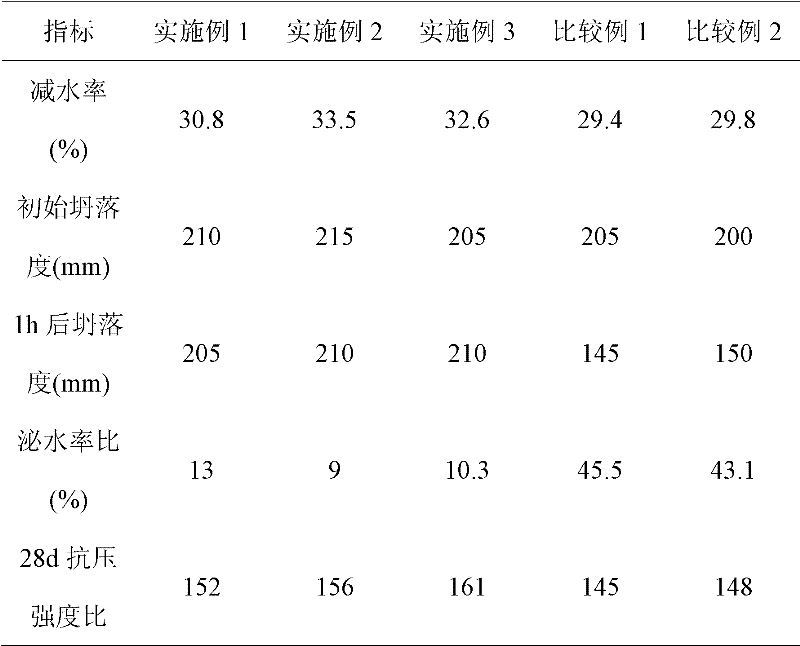

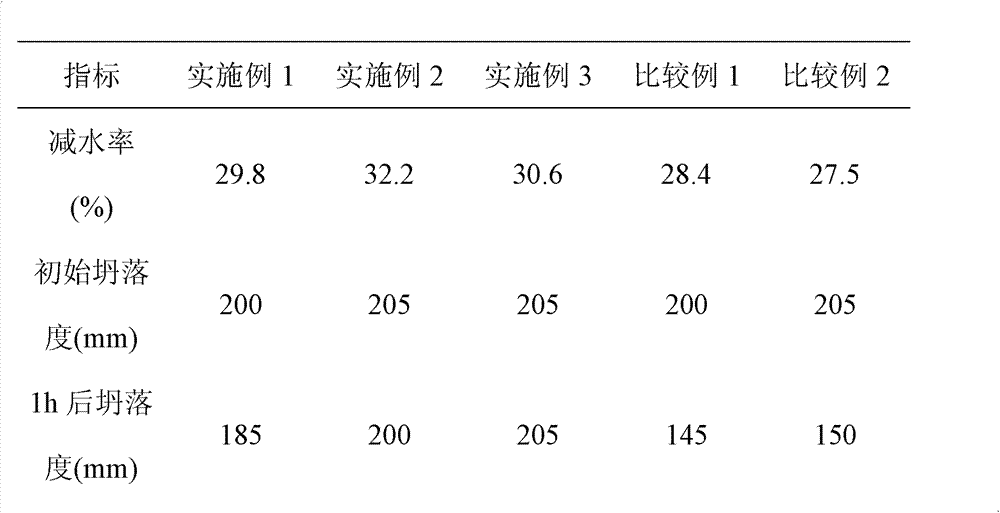

Polycarboxylene high-performance water reducing agent and preparation method thereof

The invention provides a polycarboxylene high-performance water reducing agent, which is obtained by copolymerization of following monomer components: ester macro monomer, ether macro monomer, micro-molecule monomer and bulking agent. The invention also discloses a preparation method of the polycarboxylene high-performance water reducing agent. The polycarboxylene high-performance water reducing agent of the invention not only can show good adaptability for different concrete construction materials, but also reduces usage of a retarder, improves water-reducing rate, and has good bleeding rate and compressive strength rate. The product has more stable quality; the shortcomings that the polycarboxylene product in the prior art has single type and narrow adaptability is overcome.

Owner:湖北恒利建材科技有限公司

Natural fiber-reinforced styrene maleic anhydride copolymer composition and preparation method thereof

The invention relates to a natural fiber-reinforced styrene maleic anhydride copolymer composition and a preparation method thereof. The composition comprises the following components in percentage by weight: 10-50 percent of a styrene maleic anhydride copolymer, 10-40 percent of a rubber elastomer, 5-25 percent of a styrene acrylonitrile copolymer, 5-40 percent of natural fibers and 0.1-1.5 percent of a processing aid. The preparation method comprises the following steps of: premixing the components in a high-speed mixer for 3-10 minutes according a certain proportion; leading out; and putting into a screw compressor for extruding and granulating to obtain a product. Compared with the prior art, the invention has the advantages that: a natural fiber-reinforced styrene maleic anhydride copolymer is adopted, so that a prepared product has excellent mechanical performance; and compared with a glass fiber-reinforced product, the prepared product has the advantages of light weight, safety, comfort and degradability.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

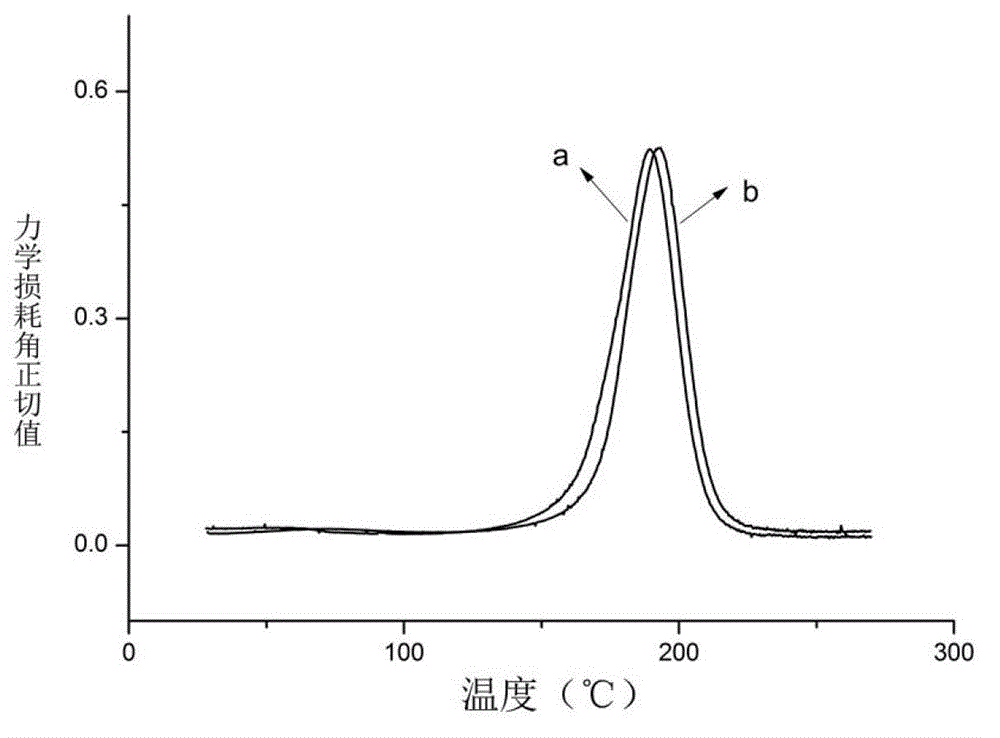

Method for decreasing acrylic ester rubber glass-transition temperature

Owner:BEIJING UNIV OF CHEM TECH

Composite material combining PVC (Polyvinyl Chloride) elastomer with super high molecular weight and fluorubber and preparation method thereof

ActiveCN102061047AImprove aging resistanceImprove flame retardant performanceInsulating bodiesEthylenediamineElastomer

The invention discloses a composite material combining PVC (Polyvinyl Chloride) elastomer with super high molecular weight and fluorubber. The composite material is prepared from the following raw materials in parts by weight: 50-90 parts of fluorubber, 9-30 parts of PVC elastomer with super high molecular weight and 1-20 parts of nanometer carbon black with surface modified by a silane coupling agent, wherein the silane coupling agent is N'-vinyl benzyl-N-trimethoxysilane propyl ethylenediamine salt. The invention modifies the surface of the nanometer carbon black by adopting the silane coupling agent VTSD and realizes a nanometer carbon black / PVC / fluorubber multi-phase composite structure with uniform dispersion in mixing rubber so that the modified nanometer carbon black effectively reinforces PVC / fluorubber. The invention also discloses a preparation method of the composite material, and the method is simple, easy to control and suitable for industrial production.

Owner:杭州顺和轨道交通新材料有限公司

In-situ compound type core-shell toughener and preparation method thereof

InactiveCN104804129AHigh apparent densityGood impact modification propertiesApparent densityCore shell

The invention provides an in-situ compound type core-shell toughener and a preparation method thereof, and belongs to the technical field of plastic modifying. The core-shell toughener comprises the following components in parts by weight: 180 to 270 parts of soft monomer, 30 to 120 parts of hard monomer, 1.5 to 6 parts of multi-activity monomer, and 1.5 to 3 parts of inorganic matter; the soft monomer is acrylic monomer. The invention also provides the preparation method of the in-situ compound type core-shell toughener. The in-situ compound type core-shell toughener has the advantages that the impact modifying property is good, and the apparent density is higher; after proofing by experiment results, the maximum apparent density value is 0.45g / cm<3>.

Owner:GUANGZHOU XINBANG CHEM & TECH CO LTD

Gasoline detergent, preparation method and applications thereof

ActiveCN103571549AEasy to cleanReduce wearLiquid carbonaceous fuelsFuel additivesAlkaneCombustion chamber

The invention provides a gasoline detergent, a preparation method, and applications thereof. The gasoline detergent comprises polyether amine with a surface activity, a gasoline octane value improver, and alkane solvent naphtha, wherein by taking the volume percentage of the gasoline detergent as the baseline, the volume percentage of the polyether amine is 30-70 vol%, the volume percentage of the gasoline octane value improver is 3-20 vol%, and the volume percentage of the alkane solvent naphtha is 25-60 vol%. The gasoline detergent can more effectively remove the carbon deposition on the oil nozzle, combustion chamber, and intake valve of a motor, improves the economic profit of fuel combustion, reduces the gasoline consumption, prevents the motor wear, prolong the service life of the motor, and decreases the maintenance fee. The cost of the gasoline detergent is low, because an ideal effect can be achieved by using only a few amount of the gasoline detergent.

Owner:BYD CO LTD

Epoxy nanocomposite with controllable phase structure and based on polyhedral oligomeric silsesquioxanes (POSS)

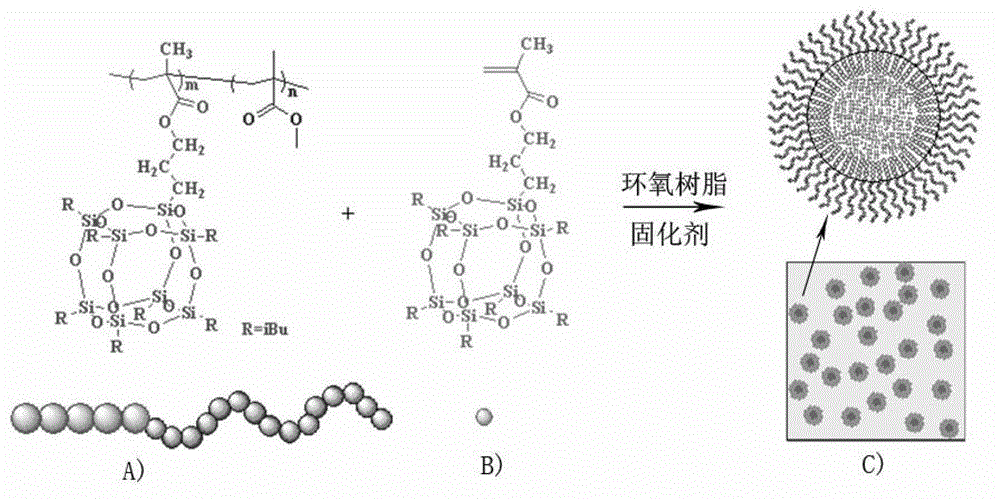

The invention discloses an epoxy nanocomposite based on polyhedral oligomeric silsesquioxanes (POSS) and a preparation method of the epoxy nanocomposite based on the POSS and relates to the epoxy nanocomposite with a controllable phase structure capable of improving effect and based on the POSS. The preparation method includes the following steps of allocating a POSS monomer, a chain transfer agent and an initiating agent in a solution according to the measuring amount through a reversible addition-fragmentation chain transfer (RAFT) method, conducting freeze thaw and degassing through liquid nitrogen, charging argon shield to enable the mixture to react, and obtaining PMAiBuPOSS; further allocating PMAiBuPOSS, Methl Methacrylate monomer (MMA) and an initiating agent in a solution, and obtaining POSS base block copolymer , namely, PMAiBuPOSS-b-PMMA, through the RAFT; conducting melt blending on the POSS monomer, epoxy resin, the prepared POSS base block copolymer to obtain blend precursor of the POSS and the epoxy, adding in a curing agent, fully stirring, dissolving the mixture the curing agent, pouring the blend into a die, conducting temperature programming and curing, and obtaining the nanocomposite with the controllable phase structure and based on the POSS.

Owner:XIAMEN UNIV

Water-absorbent rubber made from hydrophilic fiber and preparation method of water-absorbent rubber

ActiveCN106117664AImprove hydrophilicityHigh equilibrium water absorptionLiquid repellent fibresFiberNitrile rubber

The invention relates to water-absorbent rubber made from hydrophilic fiber and a preparation method of the water-absorbent rubber. The water-absorbent rubber is prepared from raw materials including, by weight, 100 parts of nitrile rubber, 1.5 parts of an active agent A, 5 parts of an active agent B, 1.5 parts of an antiager, 40 parts of a reinforcing filler, 1.5 parts of a vulcanizing accelerator A, 1.5 parts of a vulcanizing accelerator B, 1.5 parts of a vulcanizing agent, 40-80 parts of water-absorbent resin, 1-10 parts of the hydrophilic fiber and 0-10 parts of a bulking agent. The invention further relates to the preparation method of the water-absorbent rubber. The water-absorbent rubber is high in water absorption rate, good in mechanical property and capable of being widely applied to the field of sealing materials high in rubber absorption property and mechanical property requirements.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

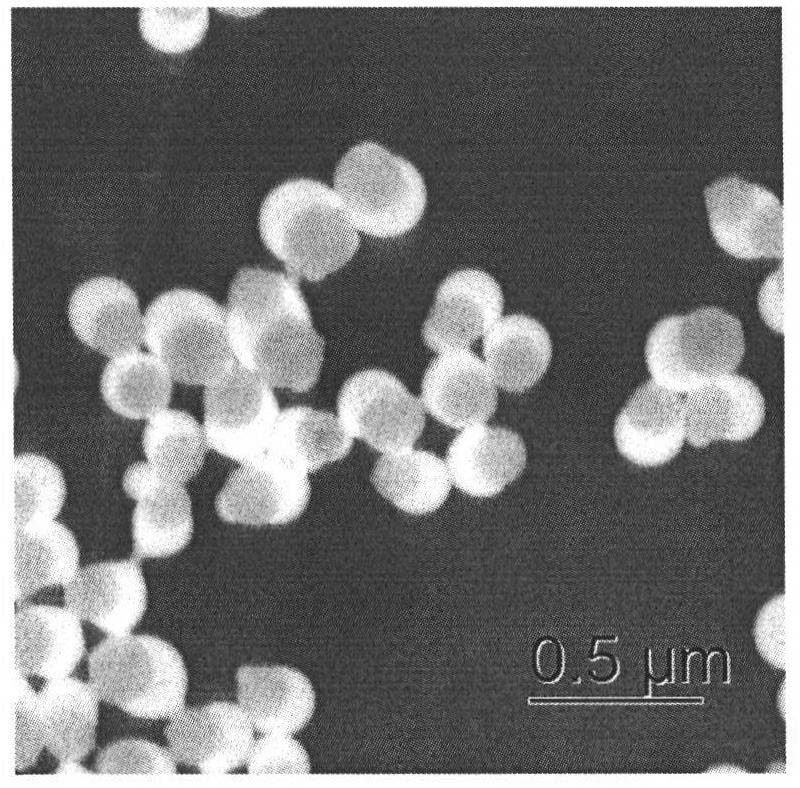

Method for preparing anisotropic composite particles

The invention relates to a method for preparing anisotropic composite particles. According to the method, firstly, a primary seed emulsion is prepared, then, primary seed particles are coated by hydrophilic monomers so as to form hydrophilic layers, a series of polymer seeds with the hydrophilic layers of different thickness can be synthesized through adjusting the amount of the hydrophilic monomers, then, the polymer seeds are swelled by monomers incompatible with the polymer seeds, and the occurrence of phase separation is facilitated due to the introduction of the hydrophilic layers, so that a series of anisotropic composite particles with different microcosmic morphologies can be prepared. According to the method, soap-free seed emulsion polymerization is adopted, and different from the traditional methods that highly-crosslinked seeds and various organic solvents are adopted as dispersion phases, water is adopted as a dispersion phase, so that non-crosslinked composite particles can be prepared, the separation and further processing of the composite particles are facilitated, the separation treatment is facilitated, and the method is clean and environment-friendly and is beneficial to further large-scale production.

Owner:TIANJIN QUANDA TECH

High-strength shape-memory 3D (three dimensional) printing bioplastics and preparation method

InactiveCN106928671AImprove mechanical propertiesHigh tensile modulusAdditive manufacturing apparatusCross-linkBiocompatibility Testing

The invention discloses high-strength shape-memory 3D (three dimensional) printing bioplastics. The high-strength shape-memory 3D printing bioplastics are prepared by compounding PLLA (Poly-L-lactic acid), PCL and CaCO3, wherein the PLLA accounts for 25 to 80 percent of the total mass of the material. The PCL accounts for 17 to 72 percent of the total mass of the material, the CaCO3 accounts for 3 percent of the total mass of the material, the high-strength shape-memory 3D printing bioplastics are prepared by virtue of fused deposition molding; the PLLA and the PCL are blended, so that the mechanical strength of the PCL is improved, good biocompatibility is ensured; by virtue of machining or radiation cross-linking treatment, the PLLA has the shape memory characteristics; after the PLLA is blended and extruded with the PCL, the shape memory property of the material can also be maintained; by adding little CaCO3, not only can a capacity increasing effect be achieved and the performance degradation caused by the mixing be avoided, the mechanical strength of the material can be further improved; and moreover, the invention also discloses a preparation method of the high-strength shape-memory 3D printing bioplastics. The method is easy in operation, low in technological conditions and low in requirement on production equipment, capable of being widely popularized, and wide in application prospect.

Owner:GUANGZHOU SUN SHING BIOTECH CO LTD

Preparation method of PP/PET microfiber reinforced blend

InactiveCN106366452AIncrease capacity synergyPlay a capacity-increasing roleGlycidyl methacrylateDiallyl phthalate

The invention provides a preparation method of a PP / PET microfiber reinforced blend. The PP / PET capacity-increase blend is preapred with PP as the continuous phase, PET as the dispersing phase and diallyl phthalate and glycidyl methacrylate cograft PP graft PP-g-(DAP-co-GMA) as the novel compatibilizer; the dispersing, orienting and fiber forming of PET in the blend are achieved through a proper processing method, the structure is much stored in subsequent products, and therefore the aim of reinforcing PP through PET microfiber in situ is achieved. By means of the method, the mechanical performance of PP can be remarkably improved, and the method has great important significance in expanding the application field of PP.

Owner:CHANGZHOU UNIV HUAIDE COLLEGE

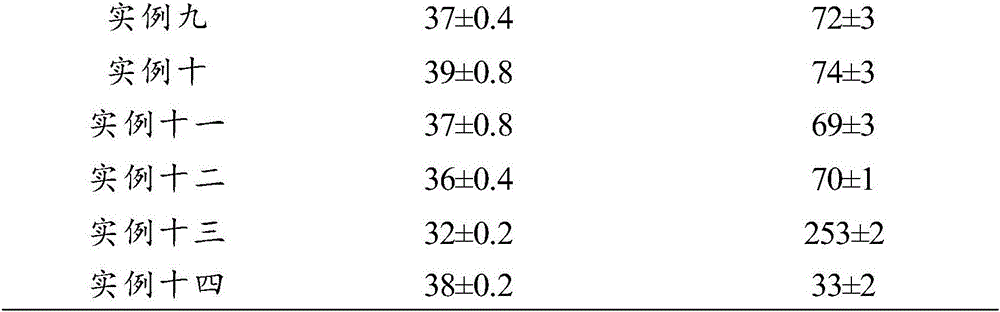

Preparation method of form-adjustable anisotropic asymmetric emulsion particles

The invention discloses a preparation method of form-adjustable anisotropic asymmetric emulsion particles. The method comprises steps as follows: adding a PVDF (polyvinylidene fluoride) seed emulsion to a reaction container equipped with a mechanical stirring and reflux condensing tube and a nitrogen introduction port, performing ultrasonic dispersion for 40 min, adding monomers and an initiator, meanwhile, starting stirring, continuously feeding nitrogen, adding ligands and a catalyst after 1.5 h, performing vacuum pumping and nitrogen feeding operations simultaneously, and then performing polymerization at the reaction temperature of 20-50 DEG C for 1-7 h; then performing decompression and low-temperature drying on the emulsion until the emulsion is constant in weight so as to prepare the anisotropic asymmetric emulsion particles. The catalyst is metallic copper. According to the method, the anisotropic asymmetric particles are successfully prepared through seed emulsion polymerization and SET-LRP (single electron transfer-living radical polymerization), and forms and sizes of the emulsion particles can be effectively controlled through selection of different seed monomer mass ratios, polymerization reaction temperatures and catalyst sizes.

Owner:HEBEI UNIV OF TECH

Cement grinding aid as well as preparation method and application method thereof

The invention discloses a cement grinding aid as well as a preparation method and an application method thereof. The cement grinding aid comprises the following raw materials in parts by weight: 5-15 parts of triethanolamine, 5-20 parts of honey, 1-5 parts of sodium gluconate, 1-5 parts of N-sulfo-glucosamine potassium salt, 5-10 parts of C1-C3 alcohol and 40-100 parts of water. The invention aims to provide the cement grinding aid that the grain composition of cement added with the cement grinding aid is reasonable after powdering, the fineness of cement is appropriately reduced, the strength of grinded cement can be improved, and the comprehensive effect is relatively good.

Owner:HANGZHOU LIPING IND & TRADE CO LTD

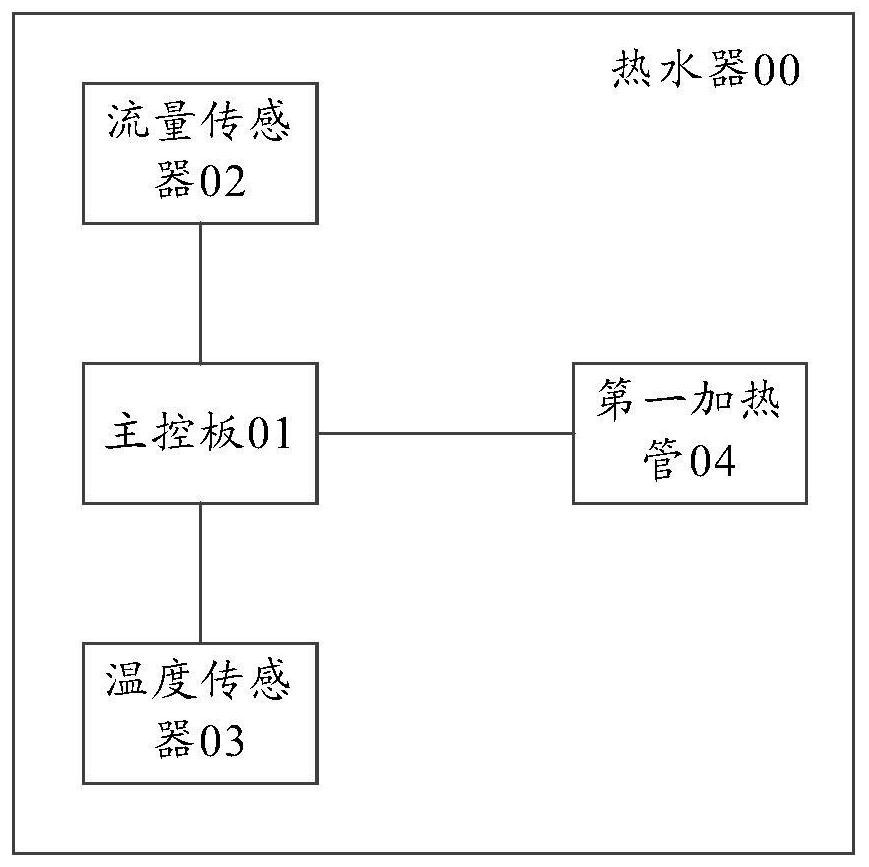

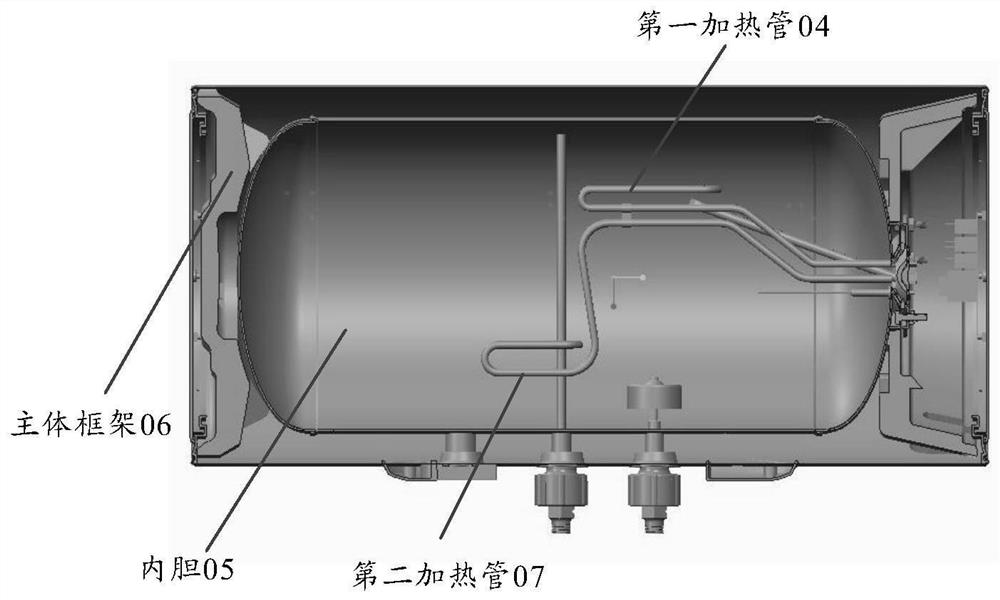

Water heater and capacity increasing control method thereof

InactiveCN112944669AHigh outputPlay a capacity-increasing roleWater heatersThermodynamicsEngineering

The embodiment of the invention provides a water heater and a capacity increasing control method thereof, relates to the technical field of electronics, and aims to improve the heating efficiency of the water heater and increase the hot water output quantity. The method comprises the following steps: starting a capacity increasing mode, and determining the water outlet flow or the water inlet flow of the water heater; when the water outlet flow or the water inlet flow is larger than or equal to a set value, setting the heating temperature of the water heater to be a first target temperature, wherein the first target temperature is greater than a set temperature, and the set temperature is an actually-set heating temperature of the water heater; and if a first temperature is smaller than the first target temperature, starting a first heating pipe, so that the water temperature in the water heater reaches the first target temperature, wherein the first temperature is the temperature of a water heater inner container. The capacity increasing control method is used for hot water capacity increasing of water heaters.

Owner:GUANGDONG HISENSE HOME APPLIANCES CO LTD

Polycarboxylene high-performance water reducing agent and preparation method thereof

The invention provides a polycarboxylene high-performance water reducing agent, which is obtained by copolymerization of following monomer components: ester macro monomer, ether macro monomer, micro-molecule monomer and bulking agent. The invention also discloses a preparation method of the polycarboxylene high-performance water reducing agent. The polycarboxylene high-performance water reducing agent of the invention not only can show good adaptability for different concrete construction materials, but also reduces usage of a retarder, improves water-reducing rate, and has good bleeding rate and compressive strength rate. The product has more stable quality; the shortcomings that the polycarboxylene product in the prior art has single type and narrow adaptability is overcome.

Owner:湖北恒利建材科技有限公司

Impact-resistant antistatic sealing barrel and preparation method thereof

The invention discloses an impact-resistant antistatic sealing barrel and a preparation method thereof, and relates to the field of plastic products. The preparation method comprises the following steps: polymerizing a layer of polyaniline on the surface of graphite oxide, electrostatically adsorbing zinc ions on the surfaces of the graphite oxide and the polyaniline, reducing the graphite oxide into graphene through hydrazine hydrate, and reducing the zinc ions into elemental zinc to obtain a graphene-polyaniline-zinc mixture; performing melt blending on ultra-high density polyethylene and polypropylene, then adding the prepared graphene-polyaniline-zinc mixture, performing oxygen radiation by gamma rays after mixing, adding a dispersing agent and a lubricating agent, and uniformly stirring to obtain conductive plastic, taking the graphene-polyaniline-zinc mixture as a composite conductive agent, the ultrahigh-density polyethylene as a reinforcing material and polypropylene as a matrix, and carrying out extrusion granulation and blow molding by to obtain the impact-resistant antistatic sealing barrel. The impact-resistant antistatic sealing barrel prepared by the invention has excellent antistatic capability and relatively good impact resistance.

Owner:常州优洁包装材料有限公司

Anisotropic particle preparation method based on change of hydrophilicities of non-crosslinked seeds

The invention relates to an anisotropic particle preparation method based on change of hydrophilicities of non-crosslinked seeds. The method comprises the steps: firstly a series of polymer seeds having different surface hydrophilicities are prepared and then are swollen with monomers incompatible with the polymer seeds; according to different phase separation degrees of polymers which are induced by different interfacial tensions and incompatible with the seeds, the degree of phase separation is controlled, composite particles with controllable morphologies are obtained, and thus a series of anisotropic composite particles having different micro morphologies are successfully synthesized. The method adopts the soap-free emulsion polymerization, takes water as a reaction medium, is different from a conventional method adopting highly crosslinked seeds and various organic solvents as a dispersion phase, can prepare the non-crosslinked composite particles, and is conducive to separation and further processing. The synthesis process is simple and feasible, is clean and environmentally friendly, is easy for large-scale production, moreover, has universality, and is applicable to other polymer systems incompatible with each other.

Owner:HEBEI UNIV OF TECH

Soft environment-friendly polyvinyl chloride film with self-cleaning properties

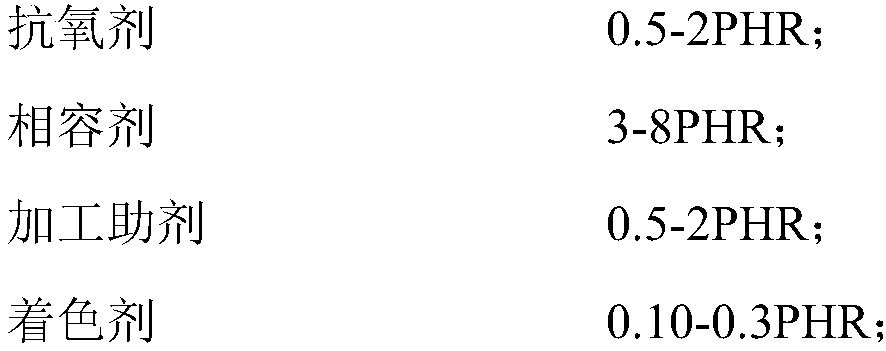

InactiveCN109880249ANot self-cleaningGuaranteed anti-fouling, self-cleaning and weather resistanceAntioxidantPlasticizer

The invention relates to a soft environment-friendly polyvinyl chloride film with self-cleaning properties, which comprises the following components: 100 parts by mass of polyvinyl chloride resin; 10-30 PHR of PVDF resin; 33-62 PHR of a main plasticizer; 4-13 PHR of an auxiliary plasticizer; 2.2-4 PHR of a stabilizer; 0.3-1 PHR of a light stabilizer; 0.5-2 PHR of an antioxidant; 3-8 PHR of a compatilizer; 0.5-2 PHR of a processing aid; and 0.10-0.3 PHR of a coloring agent; the stabilizer is a calcium zinc stearate stabilizer; and the compatilizer is chlorinated polyethylene CPE. Based on the lotus leaf effect principle, the compatilizer chlorinated polyethylene CPE is used for carrying out compatibility modification on a PVDF / PVC blended film, so that the compatibility of a blended systemis improved; the calcium zinc stearate stabilizer can further reduce the surface energy of the film and improve the hydrophobicity of the material surface.

Owner:TIANJIN TIANSU SCI & TECH GROUP

Super-soft and super-fluffy spun-bonded non-woven fabric and preparation method thereof

ActiveCN112095230AImprove anti-oxidative aging performanceGood anti-ultraviolet aging performanceConjugated synthetic polymer artificial filamentsNon-woven fabricsLow-density polyethylenePolyurethane elastomer

The invention discloses a super-soft and super-fluffy spun-bonded non-woven fabric and a preparation method thereof. The super-soft and super-fluffy spun-bonded non-woven fabric is prepared from the following raw materials in parts by weight: 55-65 parts of polyethylene glycol terephthalate, 25-32 parts of polyurethane elastomers, 7-10 parts of polyethyleneglycol adipate, 5-7 parts of linear low-density polyethylene, 9-12 parts of metallocene linear low-density polyethylene and 4-6 parts of oxidized polyethylene. According to the super-soft and super-fluffy spun-bonded non-woven fabric, on thepremise that the mechanical property and durability are guaranteed, the softness of the super-soft and super-fluffy spun-bonded non-woven fabric is far superior to that of common PET non-woven fabric, the fluffy comfort degree of the super-soft and super-fluffy spun-bonded non-woven fabric is far superior to that of the common PET non-woven fabric, the air permeability is high and good, the disability is high, and the elasticity is good; the good waterproof performance is achieved; and the comprehensive performance index is excellent, the comprehensive use performance is good, and the marketapplication prospect is wide.

Owner:FUJIAN GUAN HONG IND

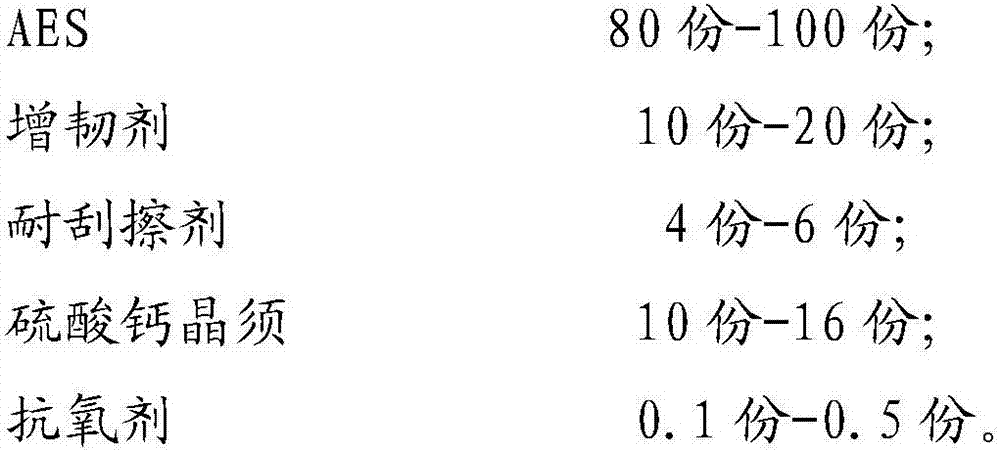

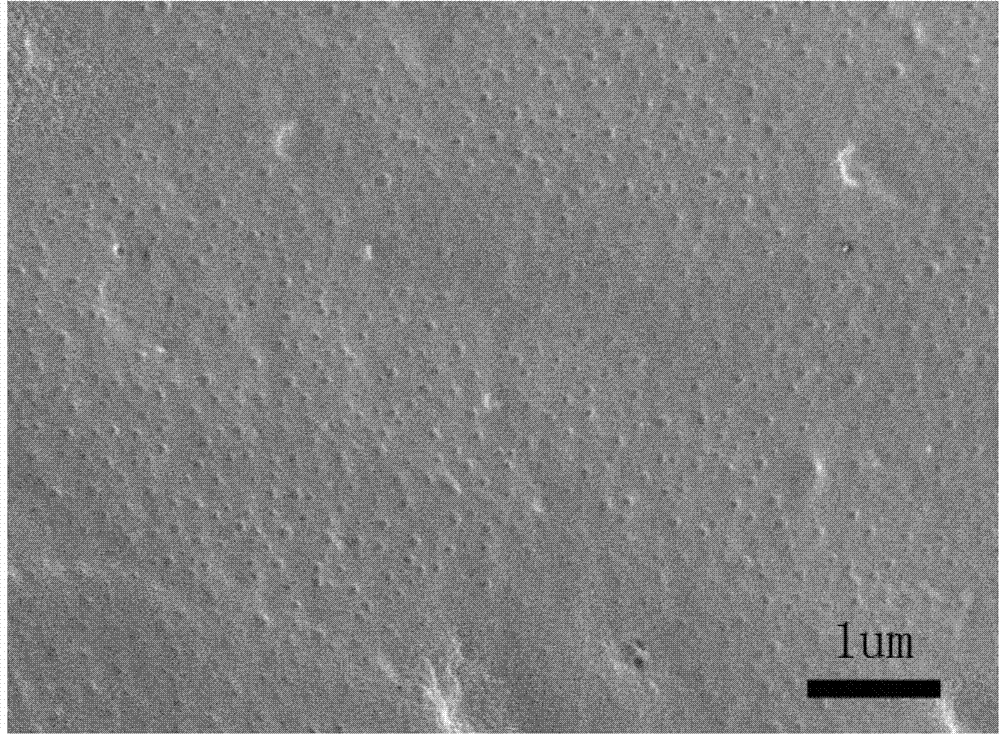

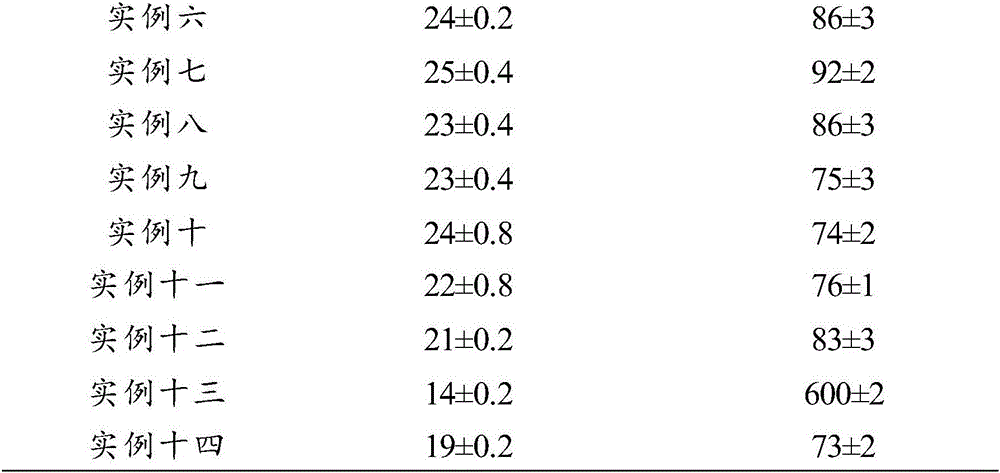

An AES composite material and a preparing method thereof

The invention relates to an AES composite material and a preparing method thereof. The AES composite material includes, by weight, 80-100 parts of AES, 10-20 parts of a flexibilizer, 4-6 parts of an anti-scraping agent, 10-16 parts of calcium sulfate whisker and 0.1-0.5 part of an antioxidant. Functions of the calcium sulfate whisker mainly are that (1) the whisker has a wear resistant characteristic so that anti-scraping performance of the AES composite material is further improved, and (2) the whisker has a highly ordered atom arrangement structure which is close to a perfect crystal structure, bonding strength of valence bonds among atoms is high, and the whisker has high strength and a high modulus, and therefore the AES composite material modified by the whisker has excellent mechanical performance.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Preparation method of heat-conducting graphene-rubber composite

The invention provides a preparation method of a heat-conducting graphene-rubber composite. Microspheres are prepared from graphene nanoplatelets and SiO2 by spray drying and then mixed with EPDM, and3-methacryloxypropyltrimethoxysilane is added in the mixing process and plays a compatibilization role by bridging between graphene / SiO2 and EPDM interface, so that graphene and an EPDM matrix bond better; further, scribing and drawing are performed by three continuous open mills with different rotation speeds, graphene is uniformly dispersed in the EPDM matrix to form a random network state, conduction of heat flow in the EPDM rubber matrix is facilitated, and accordingly, heat conductivity of the rubber composite is improved remarkably.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Epoxy nanocomposite with controllable phase structure and based on polyhedral oligomeric silsesquioxanes (POSS)

The invention discloses an epoxy nanocomposite based on polyhedral oligomeric silsesquioxanes (POSS) and a preparation method of the epoxy nanocomposite based on the POSS and relates to the epoxy nanocomposite with a controllable phase structure capable of improving effect and based on the POSS. The preparation method includes the following steps of allocating a POSS monomer, a chain transfer agent and an initiating agent in a solution according to the measuring amount through a reversible addition-fragmentation chain transfer (RAFT) method, conducting freeze thaw and degassing through liquid nitrogen, charging argon shield to enable the mixture to react, and obtaining PMAiBuPOSS; further allocating PMAiBuPOSS, Methl Methacrylate monomer (MMA) and an initiating agent in a solution, and obtaining POSS base block copolymer , namely, PMAiBuPOSS-b-PMMA, through the RAFT; conducting melt blending on the POSS monomer, epoxy resin, the prepared POSS base block copolymer to obtain blend precursor of the POSS and the epoxy, adding in a curing agent, fully stirring, dissolving the mixture the curing agent, pouring the blend into a die, conducting temperature programming and curing, and obtaining the nanocomposite with the controllable phase structure and based on the POSS.

Owner:XIAMEN UNIV

Method for decreasing acrylic ester rubber glass-transition temperature

Owner:BEIJING UNIV OF CHEM TECH

Preparing method for high-performance LLDPE/PET micro fiber enhanced blend

The invention provides a preparing method for a high-performance LLDPE / PET micro fiber enhanced blend. The LLDPE / PET compatibilization blend is prepared with LLDPE as a continuous phase, PET as a dispersion phase and DAP and GMA cograft LLDPE graft LLDPE-g-(DAP-co-GMA) as a novel bulking agent. Through the proper machining method, the PET dispersion phase in the blend is in orientation and fiber forming, more structures are stored in subsequent products, and the purpose of in-situ enhancement of LLDPE through the PET micro fiber is achieved. By means of the method, the mechanical performance of the LLDPE can be obviously improved, and an extremely important significance is achieved for widening the LLDPE application field.

Owner:CHANGZHOU UNIV HUAIDE COLLEGE

A kind of preparation method of high performance ldpe/pet microfiber reinforced blend

ActiveCN106519387BIncrease capacity synergyPlay a capacity-increasing roleLow-density polyethylenePolymer science

Owner:CHANGZHOU UNIV HUAIDE COLLEGE

A kind of in-situ composite core-shell structure toughening agent and preparation method thereof

InactiveCN104804129BHigh apparent densityGood impact modification propertiesApparent densityCore shell

The invention provides an in-situ compound type core-shell toughener and a preparation method thereof, and belongs to the technical field of plastic modifying. The core-shell toughener comprises the following components in parts by weight: 180 to 270 parts of soft monomer, 30 to 120 parts of hard monomer, 1.5 to 6 parts of multi-activity monomer, and 1.5 to 3 parts of inorganic matter; the soft monomer is acrylic monomer. The invention also provides the preparation method of the in-situ compound type core-shell toughener. The in-situ compound type core-shell toughener has the advantages that the impact modifying property is good, and the apparent density is higher; after proofing by experiment results, the maximum apparent density value is 0.45g / cm<3>.

Owner:GUANGZHOU XINBANG CHEM & TECH CO LTD

A method for preparing non-spherical particles based on changing seed hydrophilicity and cross-linking degree

The present invention is based on a method for preparing non-spherical particles by changing the hydrophilicity and crosslinking degree of seeds. This method first prepares a series of polymer seeds with different surface hydrophilicity and crosslinking degrees, and then is compared with them. Compatible monomers swell, different interfacial tensions induce different degrees of phase separation with their incompatible polymers, and the new polymer phase separates from the seeds under the joint action of interfacial tension and crosslinked seed elasticity , as a result, a series of non-spherical composite particles with different microscopic morphologies were successfully synthesized. The method of the invention adopts soap-free emulsion polymerization, uses water as a dispersed phase, can prepare non-spherical composite particles of different shapes, and is easy to separate and handle. The synthesis process is simple and easy, clean and environmentally friendly, easy for large-scale production, and has versatility, and is applicable to other polymer systems that are incompatible with each other.

Owner:HEBEI UNIV OF TECH

A kind of gasoline detergent, preparation method and application thereof

ActiveCN103571549BEasy to cleanReduce wearLiquid carbonaceous fuelsFuel additivesAlkaneCombustion chamber

The invention provides a gasoline detergent, a preparation method, and applications thereof. The gasoline detergent comprises polyether amine with a surface activity, a gasoline octane value improver, and alkane solvent naphtha, wherein by taking the volume percentage of the gasoline detergent as the baseline, the volume percentage of the polyether amine is 30-70 vol%, the volume percentage of the gasoline octane value improver is 3-20 vol%, and the volume percentage of the alkane solvent naphtha is 25-60 vol%. The gasoline detergent can more effectively remove the carbon deposition on the oil nozzle, combustion chamber, and intake valve of a motor, improves the economic profit of fuel combustion, reduces the gasoline consumption, prevents the motor wear, prolong the service life of the motor, and decreases the maintenance fee. The cost of the gasoline detergent is low, because an ideal effect can be achieved by using only a few amount of the gasoline detergent.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com