Composition for foaming material with high rebound resilience and preparation method thereof

A technique for foaming materials and compositions, which is applied in the field of compositions for high-resilience foaming materials and its preparation, and can solve problems such as reduced service performance, poor wear resistance, and poor resilience of foaming materials, and reduce interfacial tension , The process is simple, the effect of improving the resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

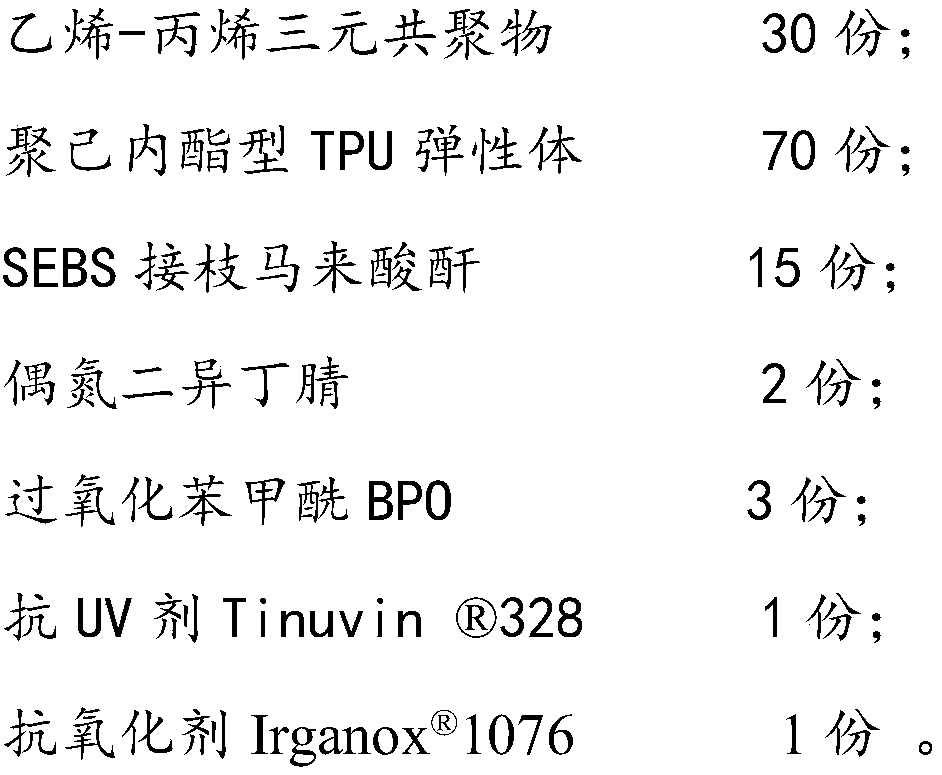

[0033] A composition for foaming materials with high resilience, comprising the following components in parts by weight:

[0034]

[0035] Prepare the foamed product as follows:

[0036] 1) Base material preparation: in the process of adopting the one-step method known in the art to produce TPU, EVA-1, EVA-2, EVA grafted maleic anhydride are added in the extruder by side feeding screw, control extruding screw The temperature is 100-190°C, the temperature of the die head is controlled at 150°C, and the base material is obtained through extrusion and granulation;

[0037] 2) Preparation of high-resilience foaming material: mix the base material prepared in step 1), 0.1 part of azodicarbonamide, and 0.01 part of DCP through a high-mixer and put them into the product mold. The temperature of the flat vulcanizer is 100 ° C , molded and foamed for 1 minute, and then cooled the mold to 5° C. to obtain the final high-resilience foamed product material.

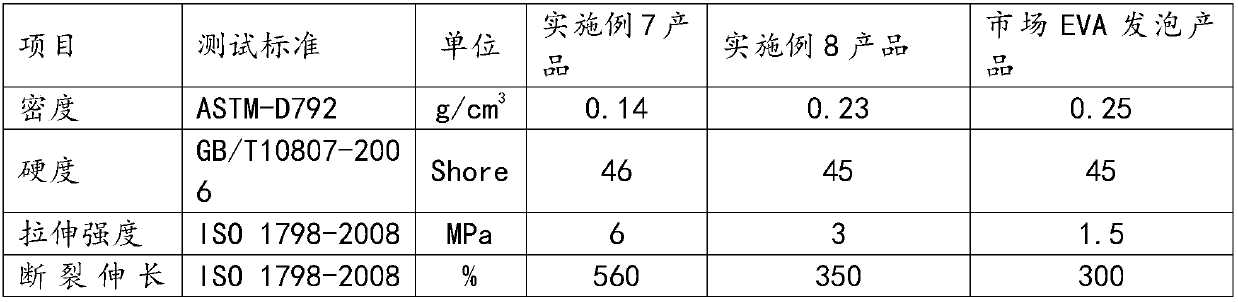

[0038] The physical prope...

Embodiment 2

[0040] A composition for foaming materials with high resilience, comprising the following components in parts by weight:

[0041]

[0042] Prepare the foamed product as follows:

[0043]1) Base material preparation: in the process of adopting the one-step method known in the art to produce TPU, EVA-1, EVA-2, EVA grafted maleic anhydride are added in the extruder by side feeding screw, control extruding screw The temperature is 100-190°C, the temperature of the die head is controlled at 150°C, and the base material is obtained through extrusion and granulation;

[0044] 2) Preparation of high-resilience foaming material: mix the base material prepared in step 1), 1 part of azodicarbonamide, and 0.05 part of DCP through a high-speed mixer and put them into the product mold. The temperature of the flat vulcanizer is 100 °C , molded and foamed for 1 minute, and then cooled the mold to 5° C. to obtain the final high-resilience foamed product material.

[0045] The physical pro...

Embodiment 3

[0047] A composition for foaming materials with high resilience, comprising the following components in parts by weight:

[0048]

[0049]

[0050] Prepare the foamed product as follows:

[0051] 1) Preparation of base material: adopt the one-step method known in the art to produce TPU particles, then add TPU particles and EVA-1, EVA grafted maleic anhydride to a twin-screw extruder after mixing with a high mixer, and control extrusion The temperature of the screw is 100-190°C, the temperature of the die head is controlled at 150°C, and the base material 1 is obtained by extrusion and granulation; then the base material 1 and EVA-2 are mixed by a high-speed mixer and added to the twin-screw or internal mixer , mixed uniformly and then extruded and granulated to obtain the final base material 2;

[0052] 2) Preparation of high-resilience foaming material: base material 2 prepared in step 1), 1.5 parts of azodicarbonamide, 0.1 part of DCP are mixed uniformly by a high-mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com