Foaming agent with low gas liquid ratio foam for common heavy oil reservoir and injection method thereof

A heavy oil reservoir and foaming agent technology, applied in chemical instruments and methods, earthwork drilling and production, and drilling compositions, etc., can solve the fouling of injection production system, difficulty in emulsification of produced fluid, and adverse effects on oil field production And other problems, to achieve the effect of high oil washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

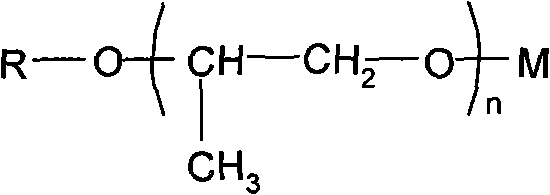

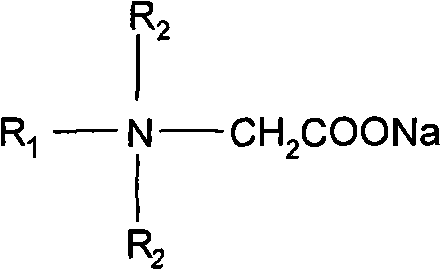

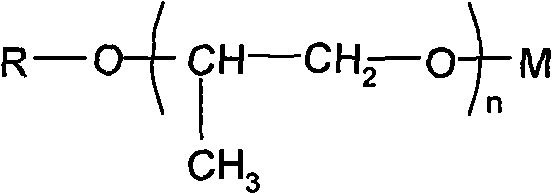

[0024] Polyoxypropylene nonylphenol ether sodium sulfate-5 (component 1) and tetradecyl betaine (component 2) were compounded in different proportions to form a foaming agent, and the foaming volume and half-life of the system were measured. As well as the interfacial tension with pile 106-15-X18 heavy oil (viscosity 325mPa.s at 50°C), the results are shown in Table 1. It can be seen that after the two surfactants are compounded, the foam stability is increased by nearly 2 times, and the interfacial tension has reached an ultra-low value.

[0025] The performance of table 1 blowing agent

[0026]

Embodiment 2

[0028] Polyoxypropylene nonylphenol ether sodium ethyl sulfonate-3 (component 1) and lauryl betaine (component 2) were compounded in different proportions, and the foaming volume and liquid separation of the compound system were measured. See Table 2 for the half-life and the interfacial tension with Shengli Chenzhuang 13-15 heavy oil (viscosity 1600mPa.s at 50°C). It can be seen that after the two surfactants are compounded at a mass ratio of 1:1 to 1:4, the foam volume and foam half-life increase, and the interfacial tension reaches an ultra-low value.

[0029] The performance of table 2 blowing agent

[0030]

Embodiment 3

[0032] The drag coefficient is the ratio of the pressure difference of the fluid passing through the porous medium to the water drive pressure difference. The larger the resistance coefficient, the stronger the plugging ability of the fluid to the porous medium, and the larger the sweep coefficient.

[0033] The foaming agent is composed of 0.04% polyoxypropylene nonylphenol ether sodium sulfate-5 and 0.06% myristyl betaine. The gas flow is controlled by the gas mass flow meter SFC4000 produced by Swiss SENSIRION company, and the permeability is 3.340μm 2 Nitrogen and foaming agent solution were injected into the epoxy resin cemented artificial rock core at the same time, and the resistance coefficient of the foam generated at different gas-liquid ratios was measured, and compared with the partially hydrolyzed polyacrylamide with a molecular weight of 18 million, it was found that the gas-liquid ratio was The resistance coefficient produced by the foam of 0.125:1 is comparabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com