Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64 results about "Bone like apatite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

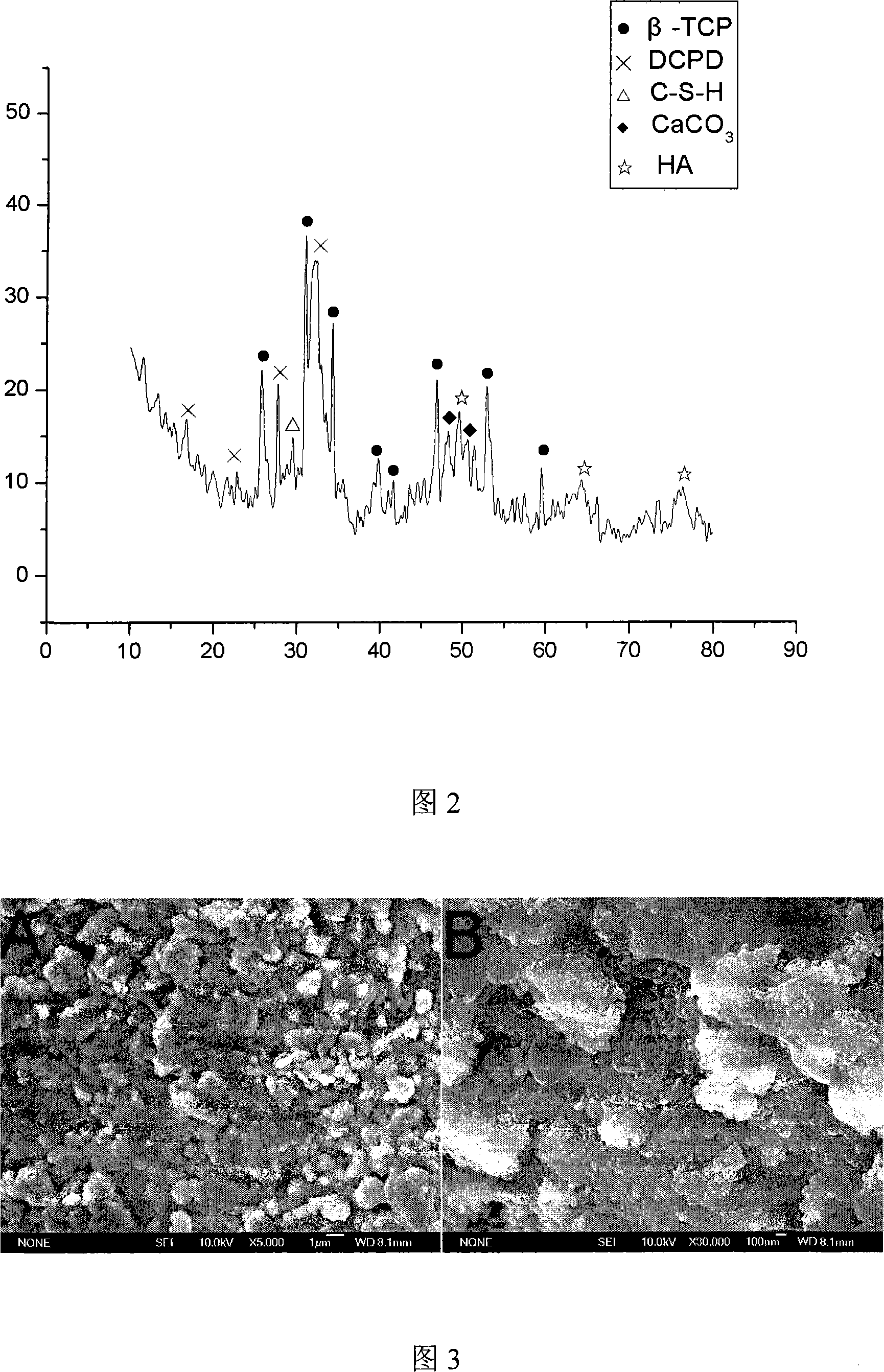

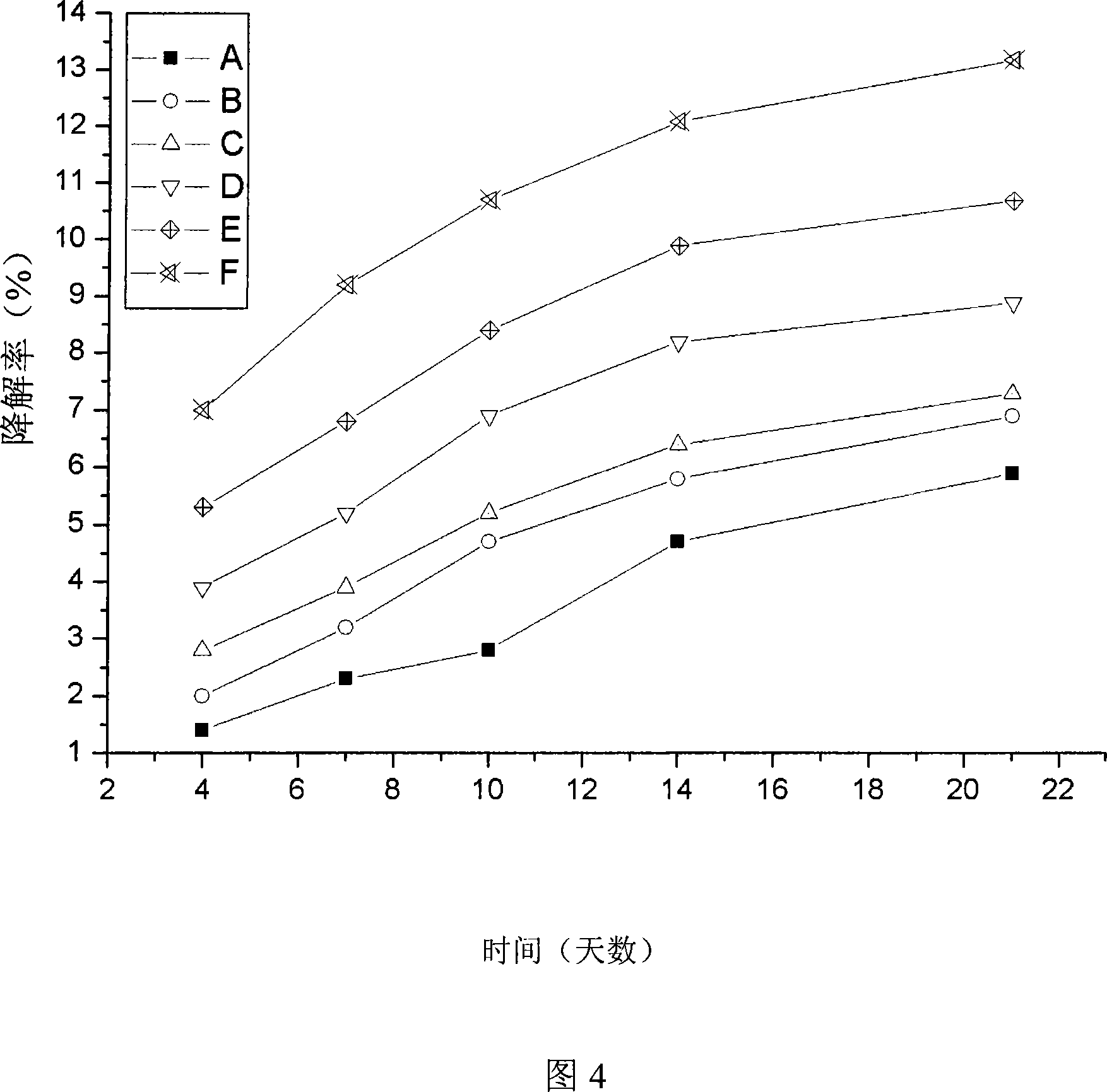

Complex self-curing material, method and application of bioactivity calcium phosphate/tricalcium silicate

InactiveCN101157045AImprove biological activityGood biocompatibilityPhysical/chemical process catalystsCalcium silicateCalcium biphosphate

The invention relates to human bone defect filling original position self-solidified bioactive material and the preparation method thereof. The material is bone / tooth defect repair material which is developed with bioactive calcium phosphate / tricalcium silicate composite powder and mixing liquid having the biological activity as raw materials. Compared with the prior material, the material of the invention has the advantages that the biological activity is excellent, the shaping is arbitrary, the material is self-solidified, no cytotoxicity exists, and the degradation is gradual, the degradation rate can be adjusted, and the effect of inducing bone-like apatite formation can be achieved; the biological activity is more excellent than that of the calcium phosphate calcium phosphate bone-like cement, and the preparation method is simple.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Bioactivity artificial joint material and preparation method thereof

InactiveCN1557503AImprove biological activityGood osteogenic effectJoint implantsCoatingsPhosphateCeramic coating

The present invention is one kind of artificial joint material with surface porous Ca-P bioactive ceramic coating layer and bone morphogenetic protein and its preparation process. The artificial joint material consists of metal substrate, one layer of double-layered porous Ca-P bioactive ceramic coating layer on the surface of the metal substrate, and bone morphogenetic protein covering the bioactive ceramic coating layer. The porous bioactive Ca-P ceramic coating layer comprises the non-crystal calcium phosphate base layer contacting with the metal substrate in 1-10 micron thickness and the crystalline bone-like apatite surface layer in 10-100 micron thickness. The preparation process includes machining artificial joint with titanium alloy, stainless steel or CO-Cr-Mo alloy; surface activating the artificial joint, two-step bionic deposition; and soaking the artificial joint inside mixed solution comprising bone morphogenetic protein and buffering phosphate solution.

Owner:SOUTHEAST UNIV +1

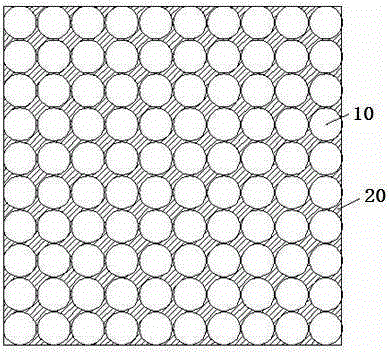

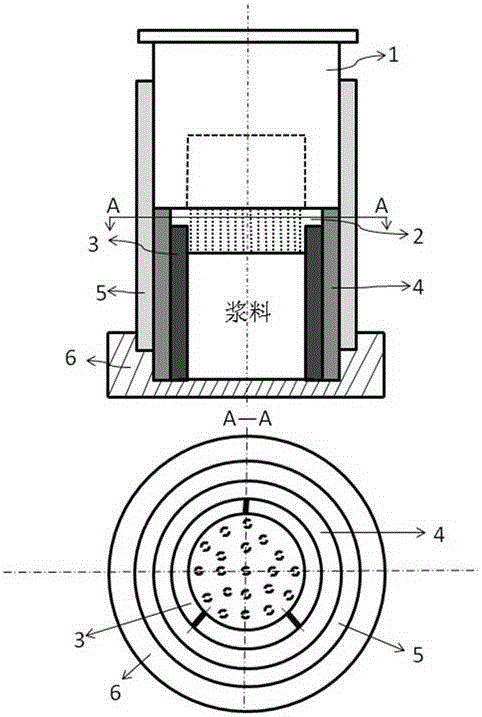

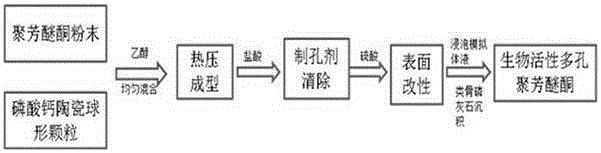

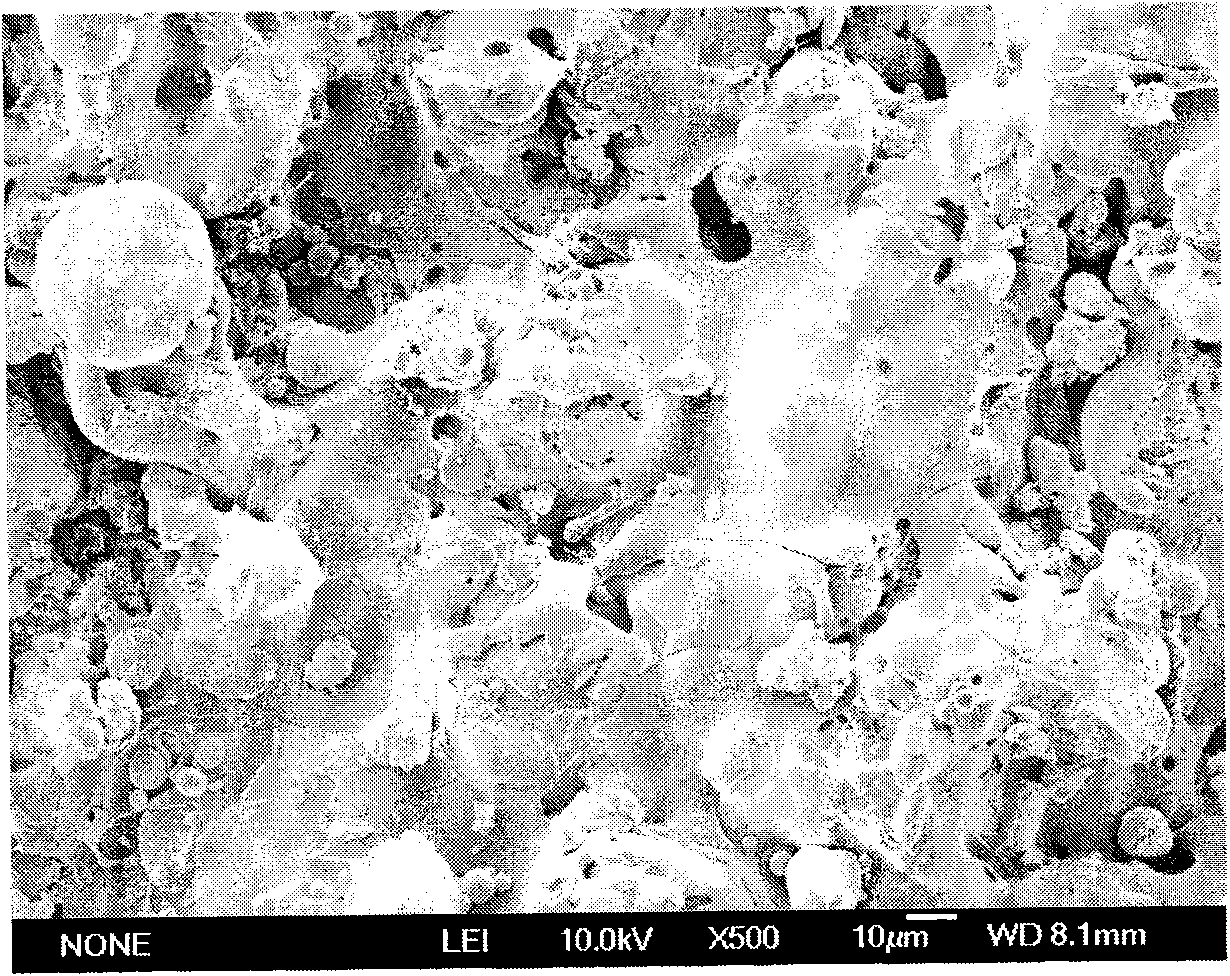

Porous polyaryletherketone material with bioactivity, and preparation method and application thereof

ActiveCN105233335AImprove the deposition effectOvercoming defects such as restricted bindingCoatingsProsthesisSpinal columnBiomedicine

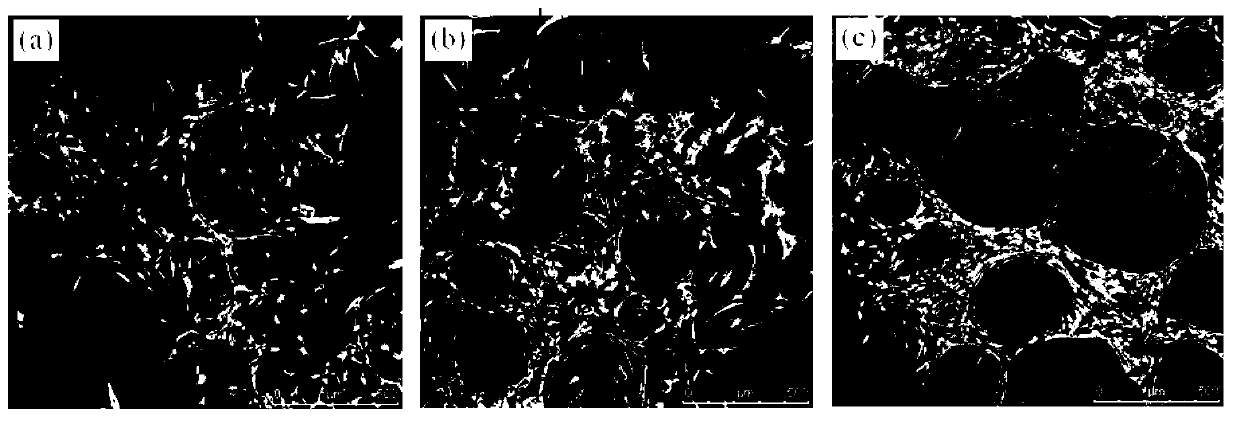

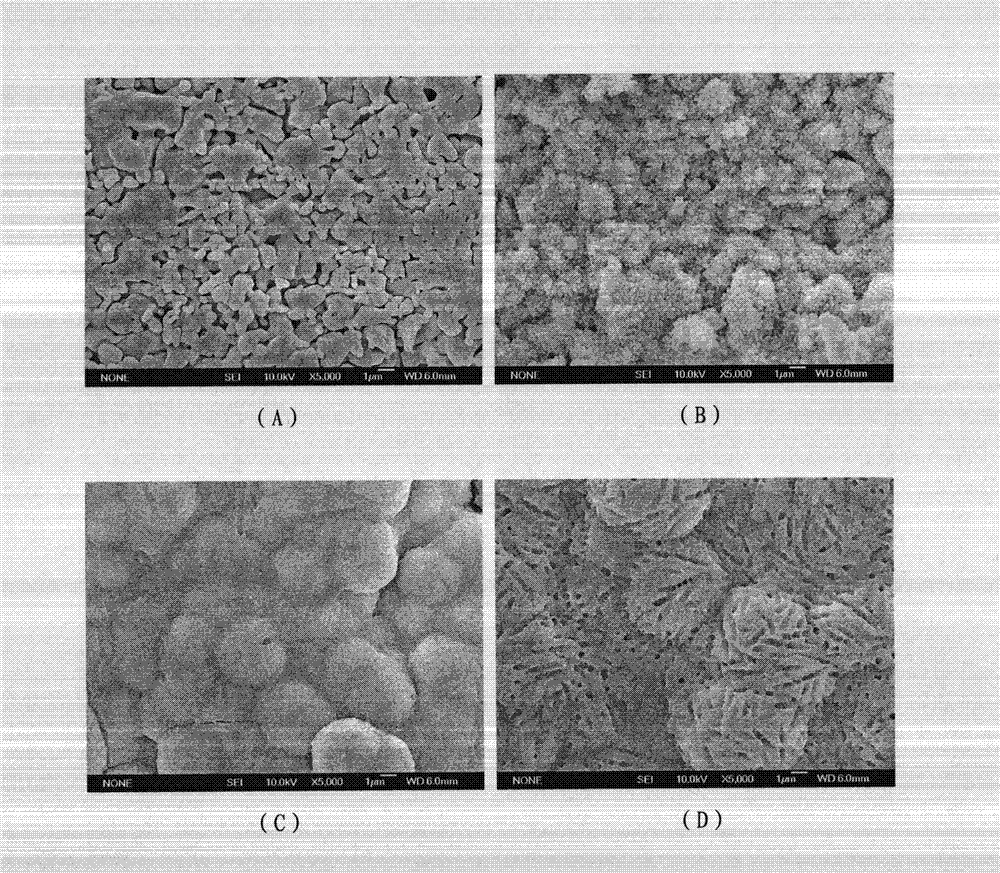

The invention discloses a porous polyaryletherketone (PAEK) material with bioactivity, and a preparation method and an application thereof, and belongs to the field of biomedical materials. The method comprises the following steps: carrying out wet uniform mixing on PAEK powder and a calcium phosphate ceramic (CPC) spherical particle pore forming agent to obtain a mixture, filling a die with the mixture, applying a pressure to make the hard pore forming agent be arranged in a close packing approximating manner and remove superfluous PAEK powder, heating the die to realize fusion molding of the PAEK powder under hot pressing in order to obtain a PAEK / CPC body, and immersing the PAEK / CPC body in diluted hydrochloric acid to remove the pore forming agent CPC in order to obtain the porous PAEK material; and processing through concentrated sulfuric acid, and immersing in a simulated body fluid to obtain the bioactive porous PAEK material with a surface bone like apatite layer. The method has the advantages of simple process and good repeatability, and the obtained bioactive material has completely three dimensional through macro-pores and abundant surface micro-pores, and easily adjustable macro-porous dimension and amount of porosity, and can be used to prepare bioactive materials with a gradient pore structure. The bioactive porous PAEK material can be used to restore bone defects, and is especially suitable for being used in interbody fusion cages for spinal column restoration.

Owner:SICHUAN UNIV

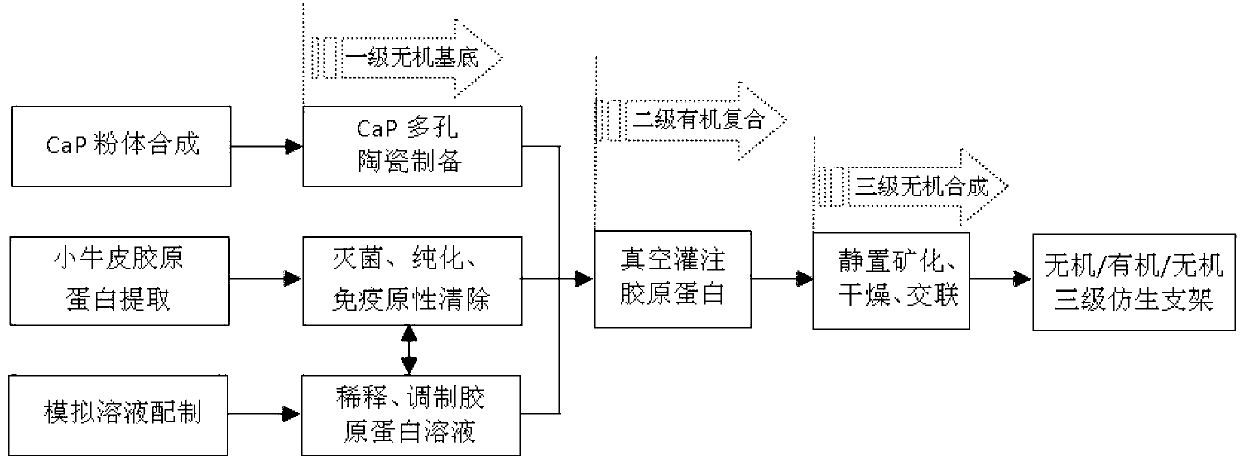

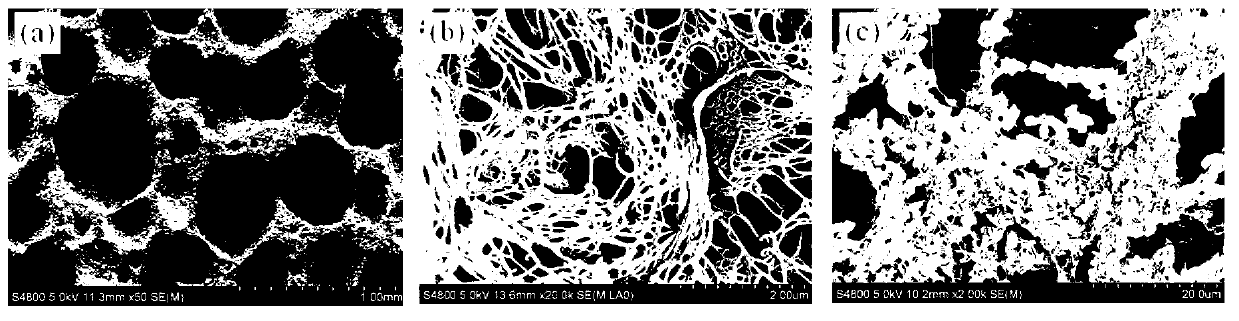

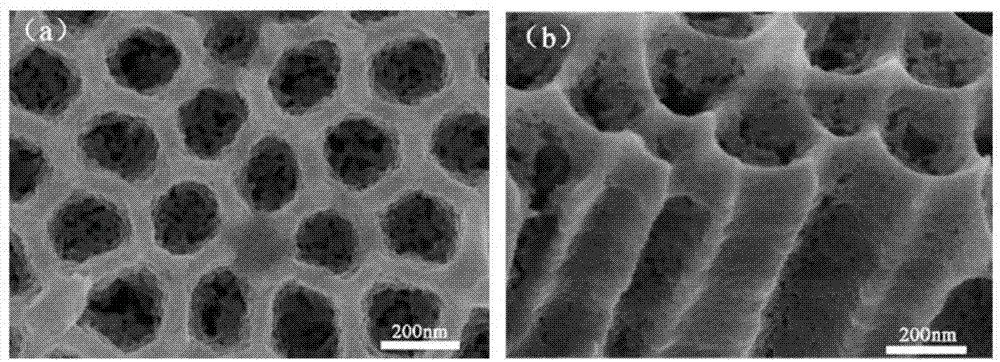

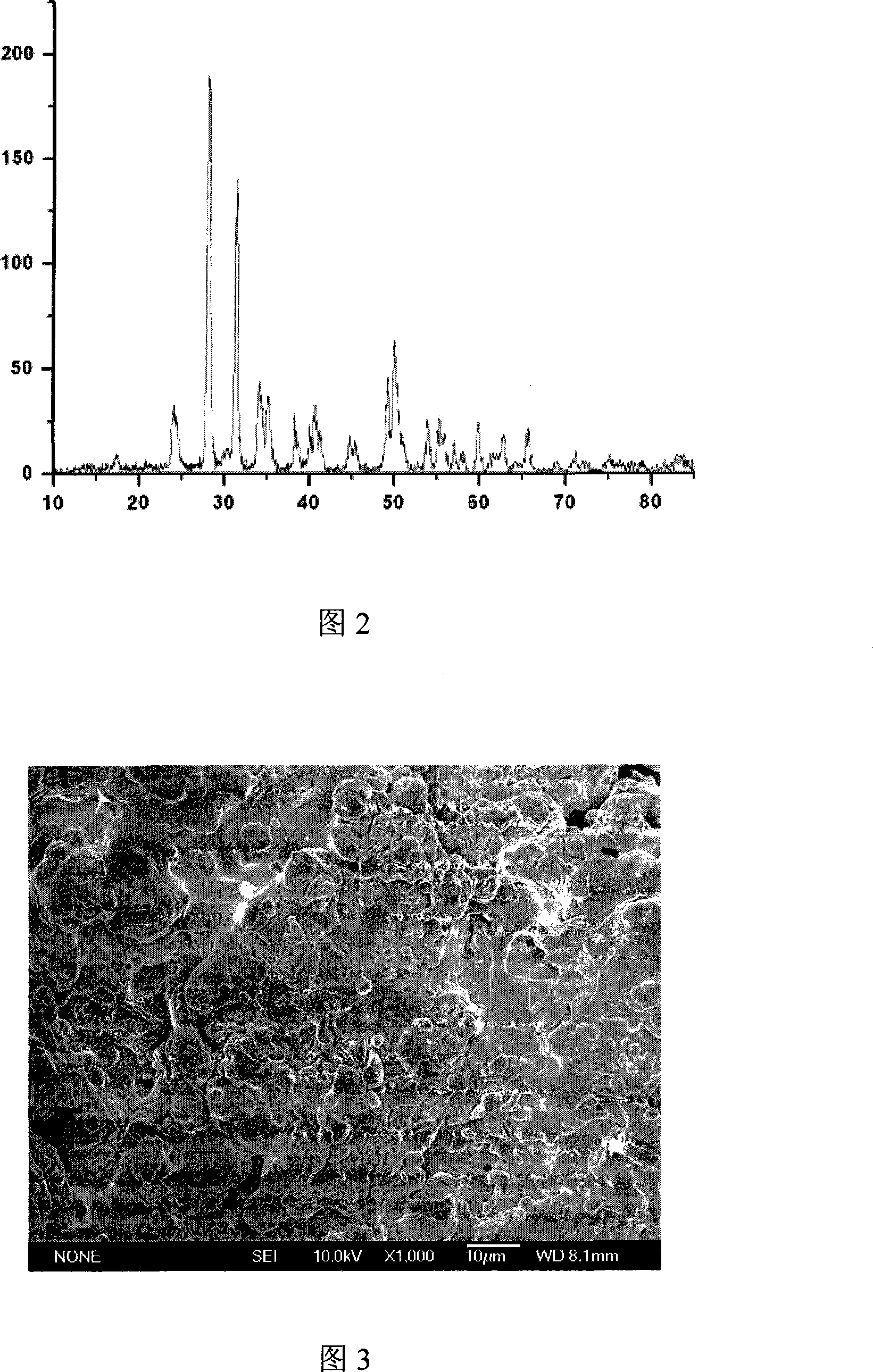

Calcium phosphate/collagen/bone-like apatite three-level bionic bone tissue engineering scaffold and preparation method thereof

InactiveCN103341206APromote repair and regenerationGood biocompatibilityProsthesisThree levelApatite

The invention provides a calcium phosphate / collagen / bone-like apatite three-level bionic bone tissue engineering scaffold and a preparation method thereof. The material of the scaffold possesses components similar to natural bone tissues, and an inorganic / organic / inorganic three-level bionic bone-like netted three-dimensional structure. The preparation method comprises: customizing a calcium phosphate ceramic which possesses a bionic porous structure similar to the natural bone micropore structure, filling collagen prepared by simulated body fluid (SBF) into the porous calcium phosphate ceramic base, low-temperature aging to simulate a biomineralization process, in-situ nucleating on the collagen organic macro-molecule matrix, and self-assembly crystallizing to form a third level bone-like apatite layer structure. The composite scaffold material has bionic material components and bionic microstructure both similar to the natural bone tissues, the mechanical properties and the biological activity of the material are substantially improved, and the composite scaffold material has a wide application prospect.

Owner:SICHUAN UNIV

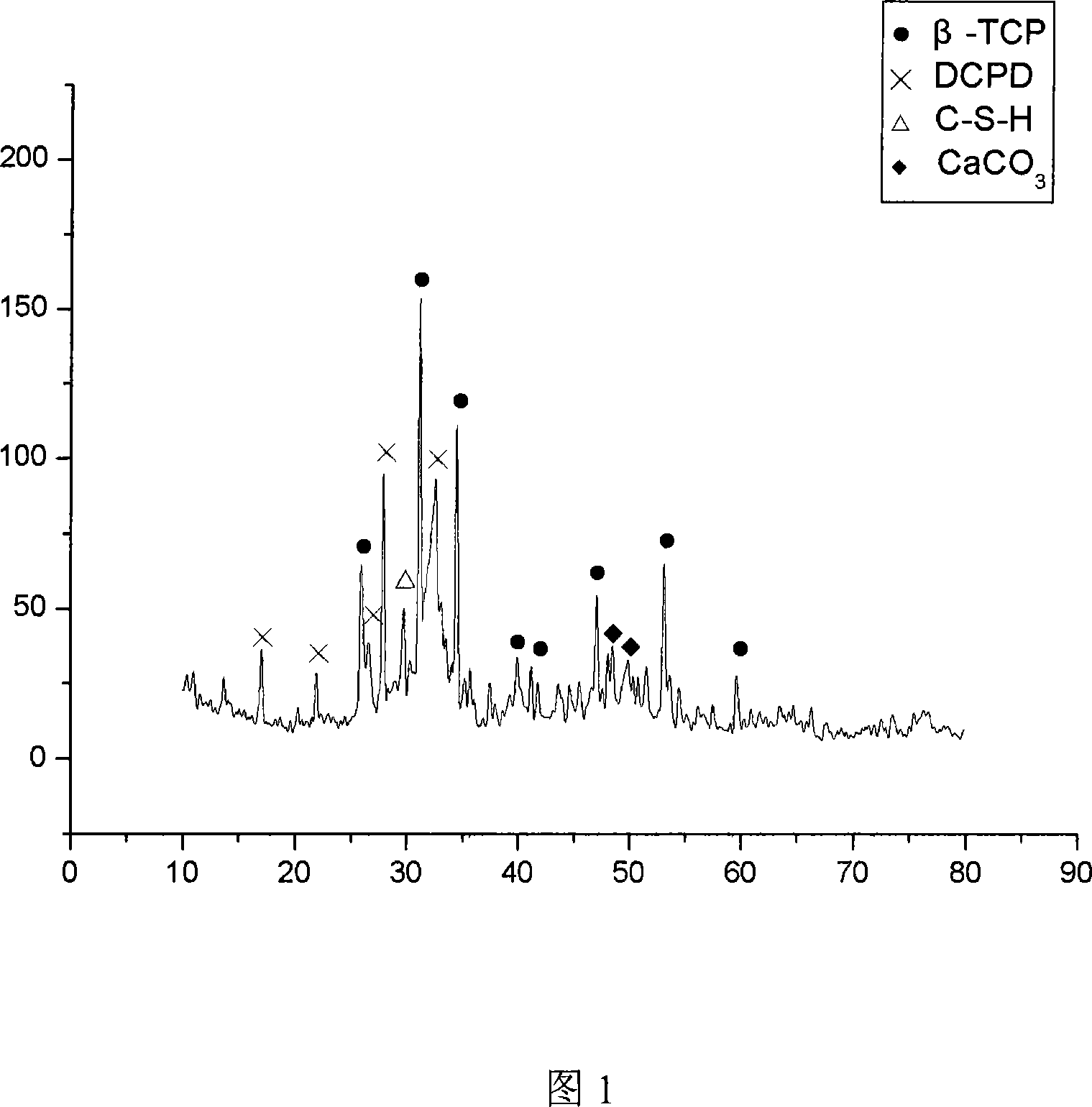

Hydrogen phosphate/tricalcium silicate composite self-curing material with biological activity, preparation and uses thereof

InactiveCN101428153AImprove biological activityGood biocompatibilityImpression capsDentistry preparationsApatitePhosphate

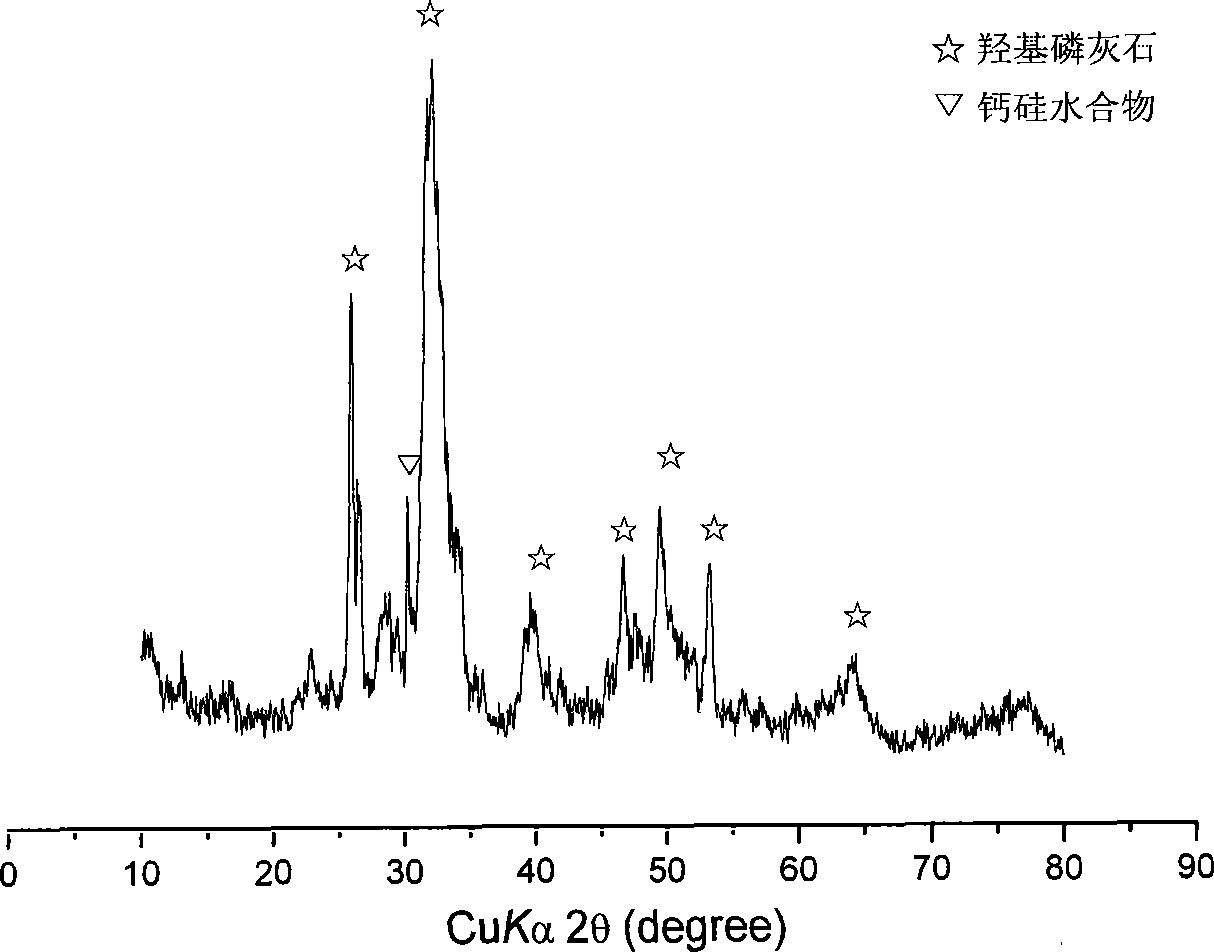

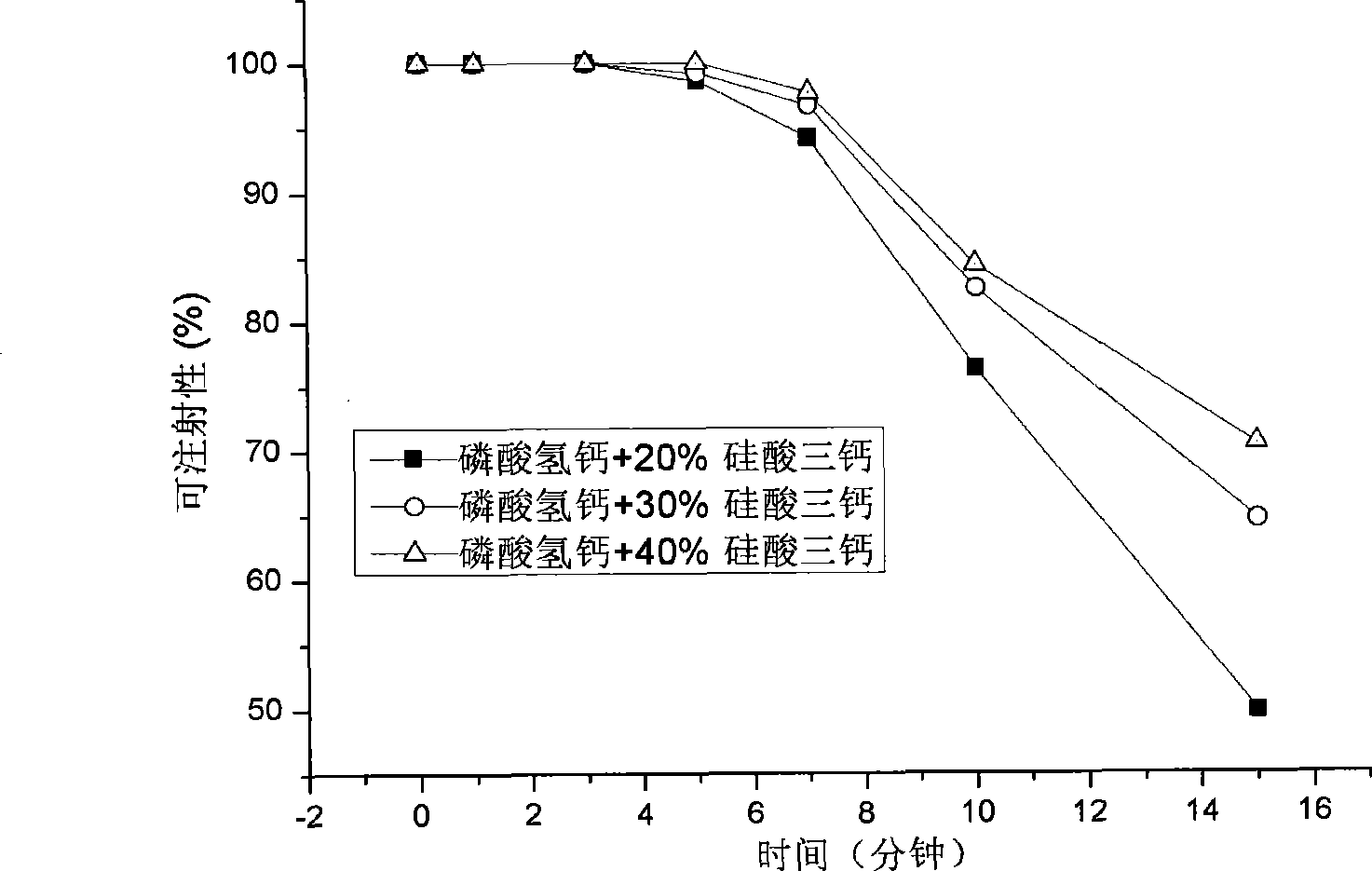

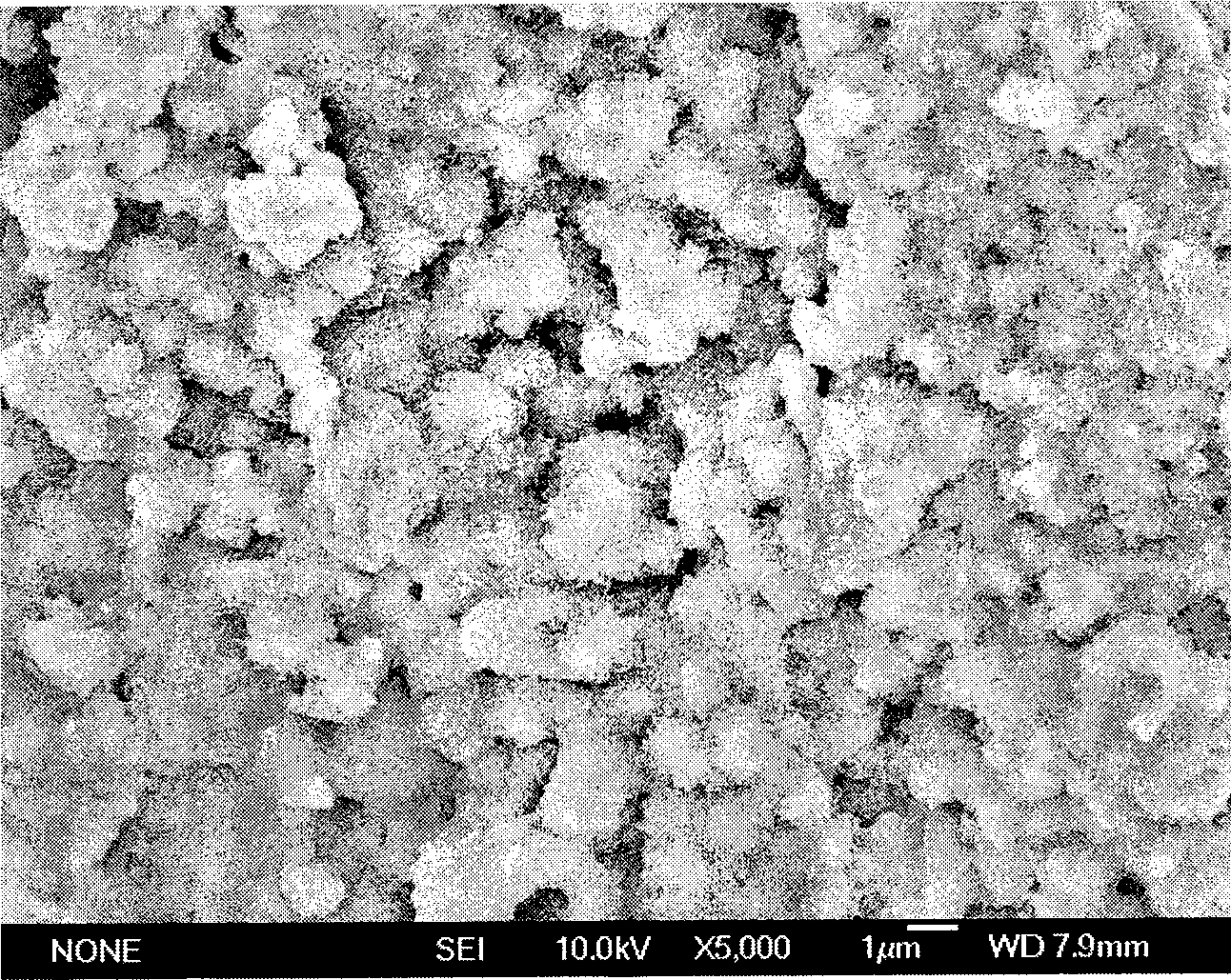

The invention relates to a bioactive dicalcium phosphate / tricalcium silicate compounded self-setting material and the preparation method and application thereof, and belongs to the field of medical biomaterials. The invention is a paste comprising a mixing liquid and bioactive dicalcium phosphate / tricalcium sulfate which are mixed with each other at a mass ratio of 0.5-1.5:1, with the percentage composition of the mass of tricalcium silicate in the composite powder equaling 1-50% and the selected mixing liquid being deionized water, a simulated body fluid, an inorganic salt solution, or an organic matter solution. Compared with the prior materials, the invention has the characteristics of relatively high strength, random moulding, self-setting and biological activity, and can achieve the effect of inducing the generation of bone-like apatite. Moreover, the ratio of mechanical property to biological activity of the material provided by the invention is similar to that of calcium phosphate bone / tooth defect recovery materials.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

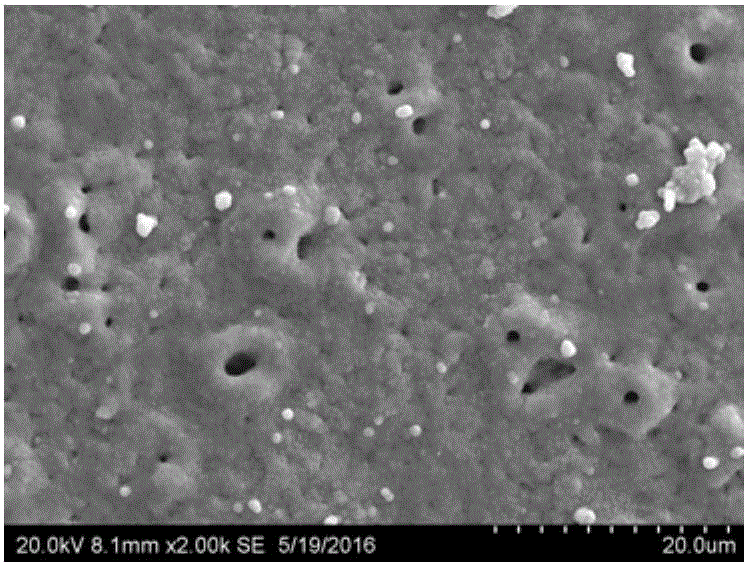

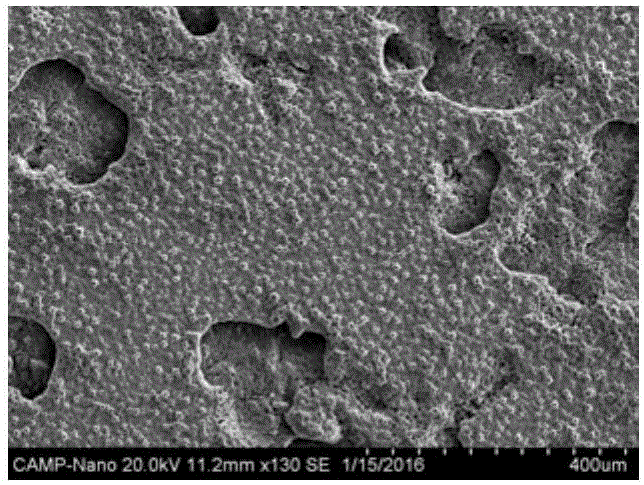

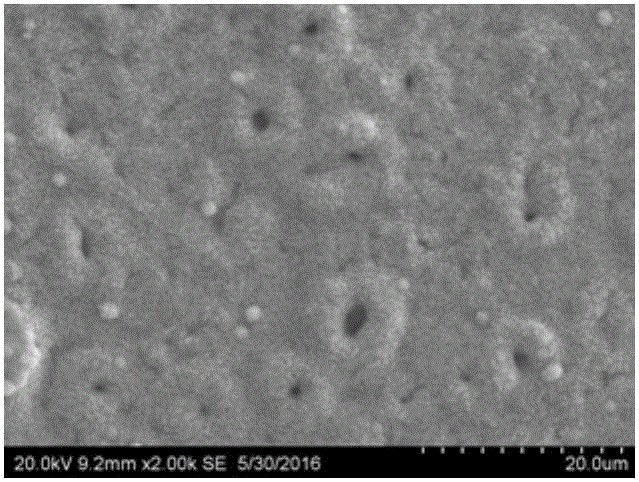

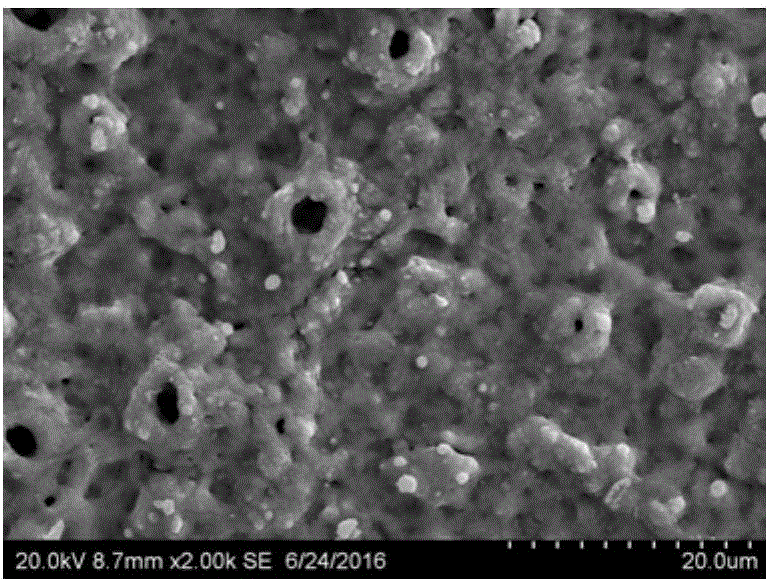

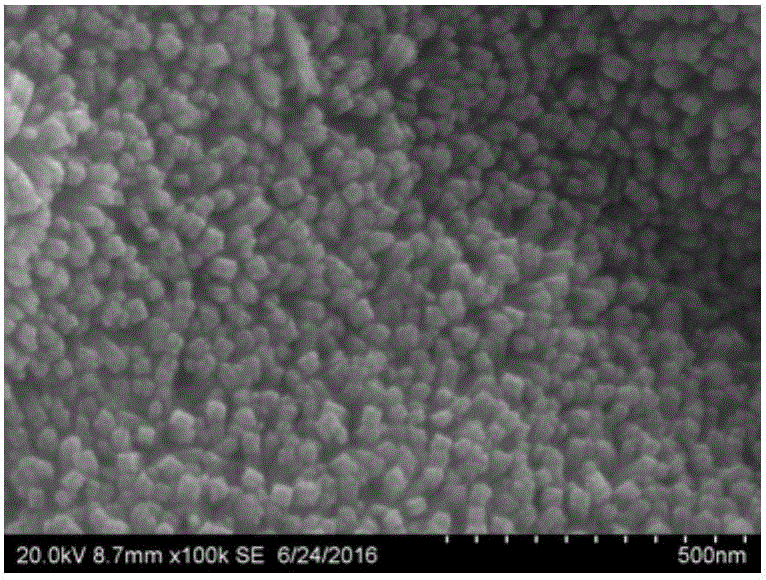

Preparation method of tin dioxide electroactive biological ceramic coating composited on surface of micro-arc oxidation titanium

ActiveCN106637347ACompact structureNot affected by porous structure morphologySurface reaction electrolytic coatingLiquid/solution decomposition chemical coatingTin dioxideParticulates

The invention discloses a preparation method of a tin dioxide electroactive biological ceramic coating composited on the surface of micro-arc oxidation titanium and relates to the technical field of metal surface modification. The method comprises the steps that a titanium sheet is put into a stainless steel tank containing an electrolyte for micro-arc oxidation; and a prepared micro-arc oxidation titanium sample is put into a reaction still so that nano-particulate tin dioxide can grow hydrothermally. The obtained electroactive biological ceramic coating has the structural and performance characteristics that the coating is a double-layer composite coating; an inner layer is composed of titanium dioxide and is of a microcosmic porous structure; and an outer layer is composed of tin dioxide and is in the nano-particulate state. No uncontinuous interface exists between the coating structure and a base body; bone-like apatite can be induced to be formed rapidly in a simulated body fluid environment; and good biological activity is achieved.

Owner:XI AN JIAOTONG UNIV

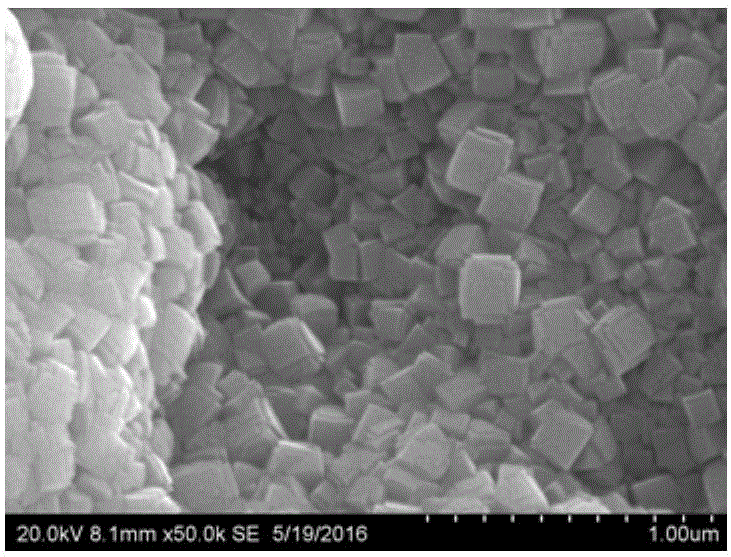

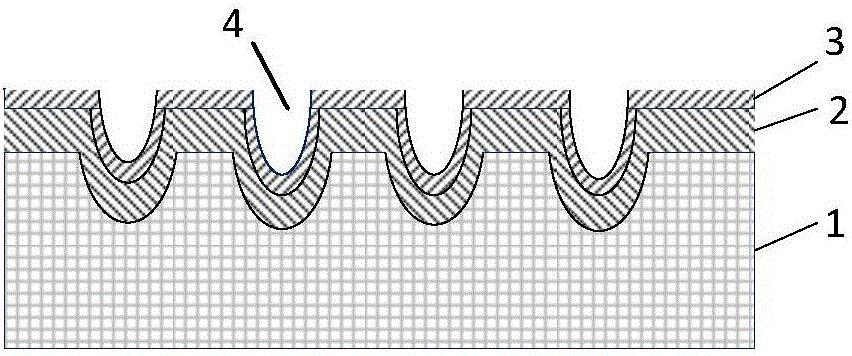

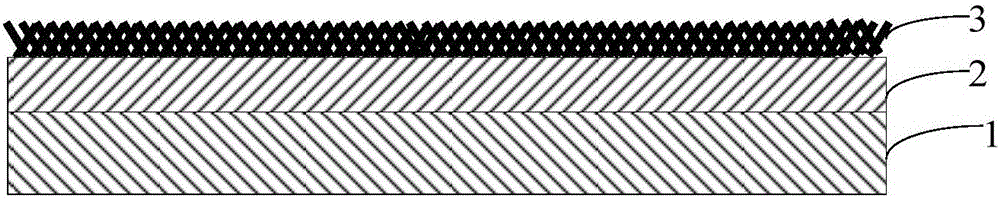

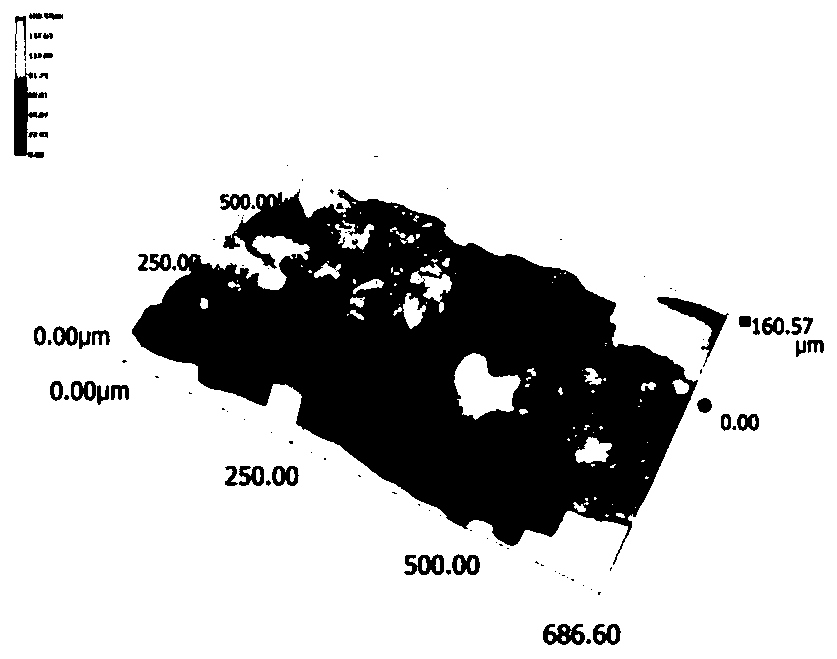

Preparation method of bioelectricity activity implant with multistage composite structure

ActiveCN106637346AHigh bonding strengthCompact structureSurface reaction electrolytic coatingLiquid/solution decomposition chemical coatingTin dioxidePlasma electrolytic oxidation

The invention discloses a preparation method of a bioelectricity activity implant with a multistage composite structure. A titanium sample is positioned in a stainless steel tank with electrolyte for corrosion microarc oxidation to generate a surface groove structure; the titanium sample with the groove performs general microarc oxidation; and the prepared microarc oxidation titanium sample with the groove in the surface is put in a reaction kettle for hydrothermal growth of nanorod tin dioxide. The obtained bioelectricity activity implant with the multistage composite structure has a three-grade surface structure of millimeter-stage grooves, micron-stage multiple holes and nanorods; the groove is formed in the surface of the sample macroscopically; microscopically, the surface of the sample is totally covered by a coating layer with a double-layer composite structure; the inner layer is titanium dioxide with a microscopic porous structure; and the surface layer is the nanorod tin dioxide. No discontinuous interface is formed between the coating layer structure and the matrix; bone-like apatite can be formed in a simulated body fluid environment through quick induction; and the bioactivity is excellent. The preparation method can be used for preparing the bioelectricity activity implant with the multistage composite structure.

Owner:XI AN JIAOTONG UNIV

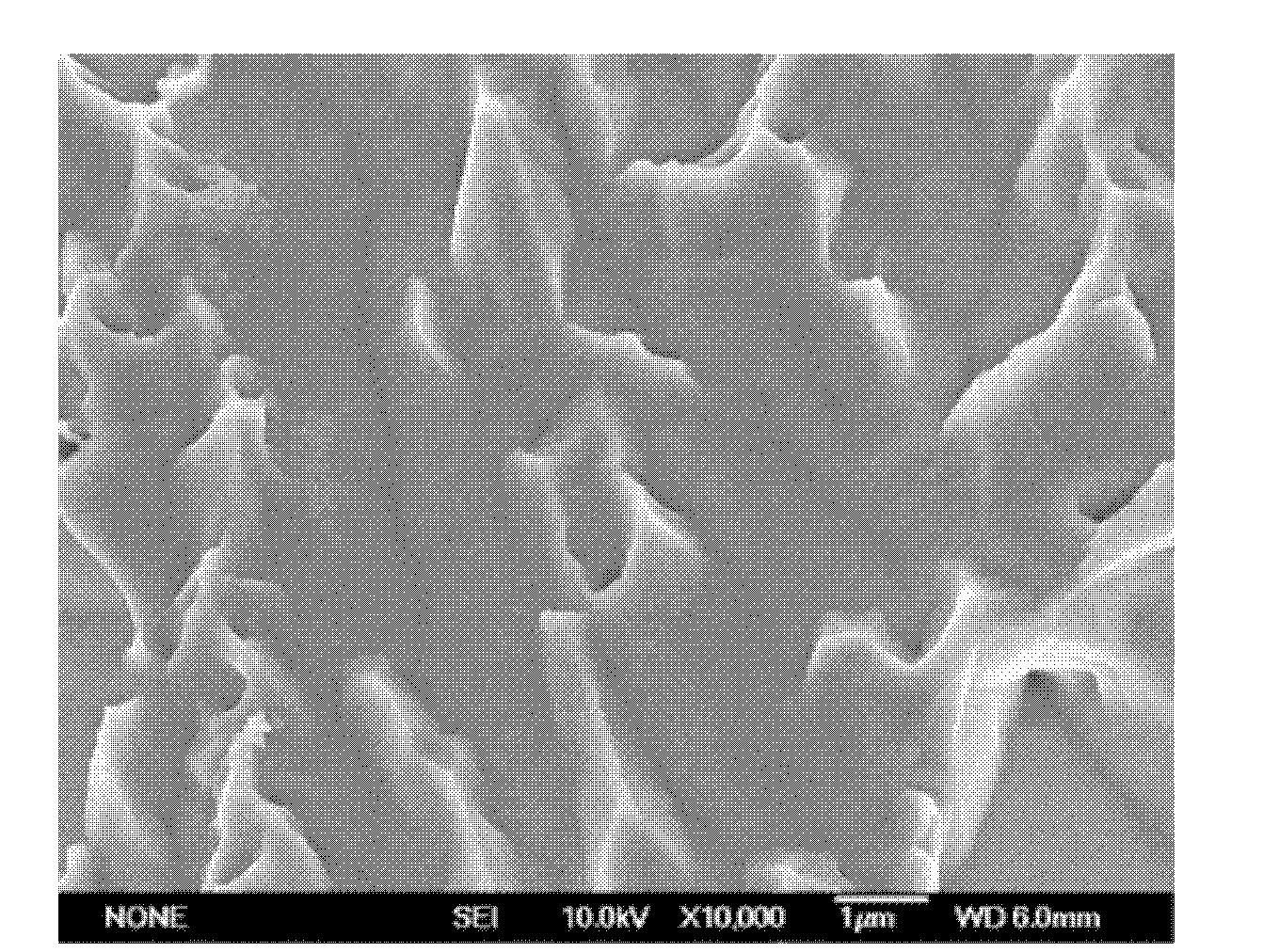

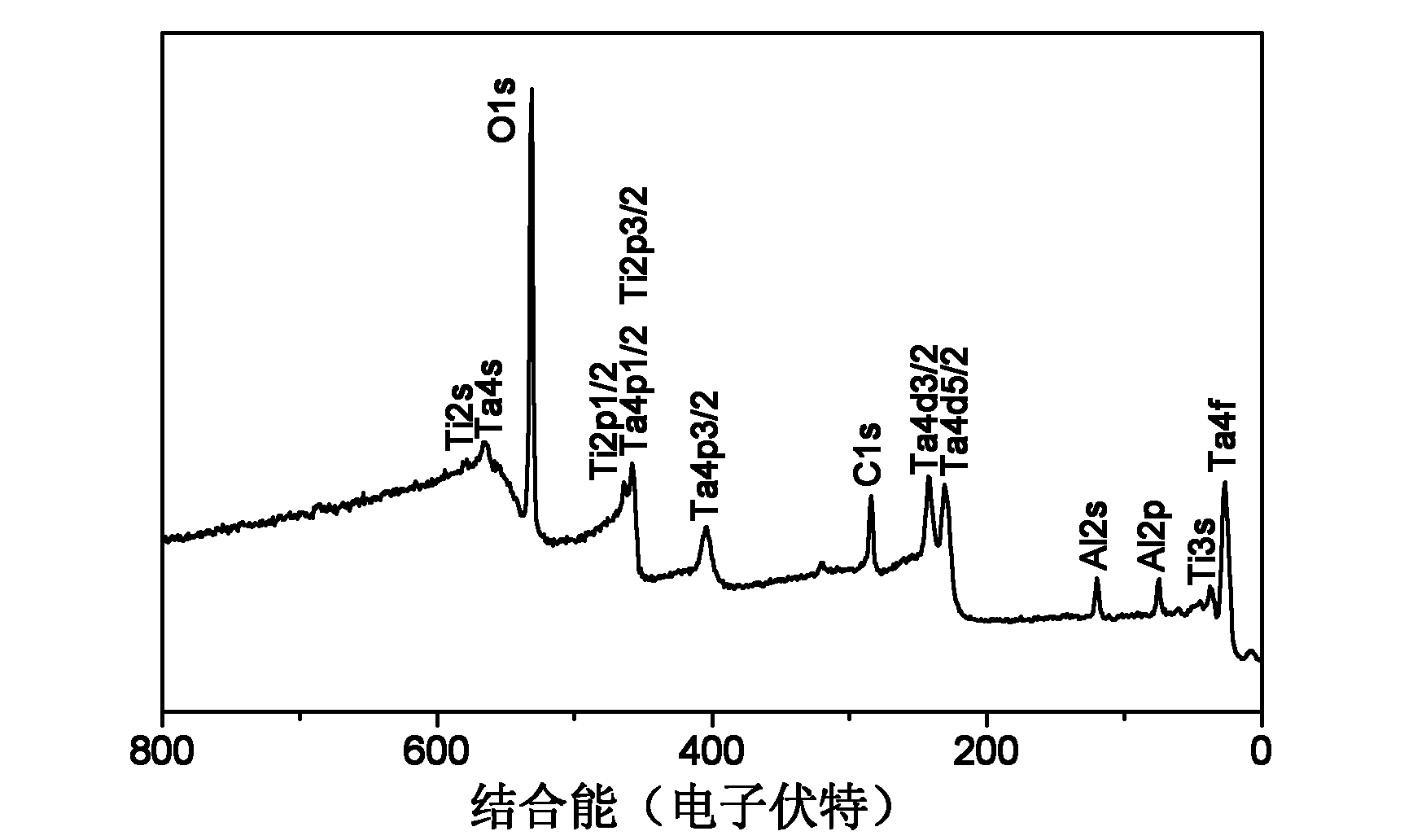

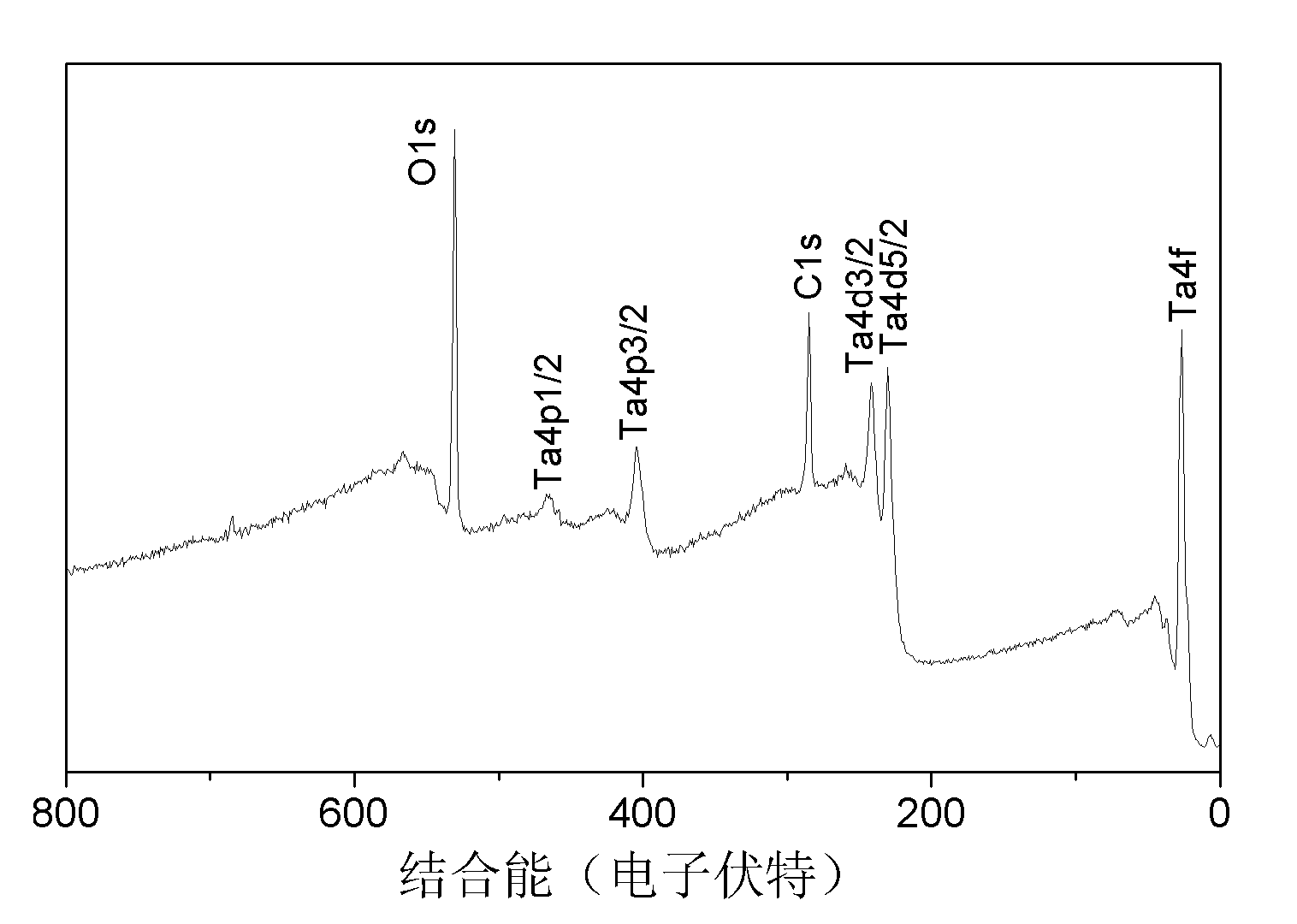

Method for modifying titanium surface

InactiveCN102181842ASolve solubilitySolve peelingVacuum evaporation coatingSputtering coatingTitanium metalApatite

The invention discloses a method for modifying titanium surface. The method comprises the following step of: performing tantalum ion implantation or plating on the titanium surface by using a plasma immersion ion implantation and deposition technology to obtain a tantalum and / or tantalum oxide modified layer. The titanium surface is modified, so that a high mechanical property of titanium can be preserved, the corrosion resistance and the bioactivity of a material can be improved, and high biocompatibility of the material can be kept; and the modified titanium surface which is subjected to tantalum ion implantation or plating is not required to be subjected to any aftertreatment, bone-like apatite can be induced to form and grow on the surface when the titanium surface is soaked in simulated body fluid, and an artificial bone substitutional material with high comprehensive performance can be obtained.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method of preparing titanium implant having bioelectricity activity by carrying out water-vapor treatment on tin-bearing microarc oxidation coating

ActiveCN106400087ACompact structureNot affected by porous structure morphologySurface reaction electrolytic coatingSolid state diffusion coatingTin dioxideNano structuring

The invention discloses a method of preparing a titanium implant having bioelectricity activity by carrying out water-vapor treatment on a tin-bearing microarc oxidation coating. A titanium sample is placed in a stainless steel tank filled with an electrolytic solution for microarc oxidation; then the titanium sample is placed in a reaction kettle for the water-vapor treatment, tin dioxide in a nano structure grows on the surface of the titanium sample, an electroactivity biological microarc oxidation coating which is in a microscope porous structure is obtained, and tin dioxide grows on the surface of the electroactivity biological microarc oxidation coating. No discontinuous interface exists between the coating and a substrate, bone-like apatite can be formed through rapid induction in a simulated body fluid environment, and the titanium implant has good bioactivity.

Owner:XI AN JIAOTONG UNIV

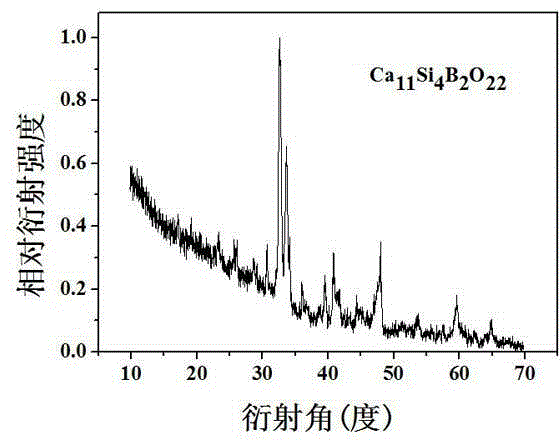

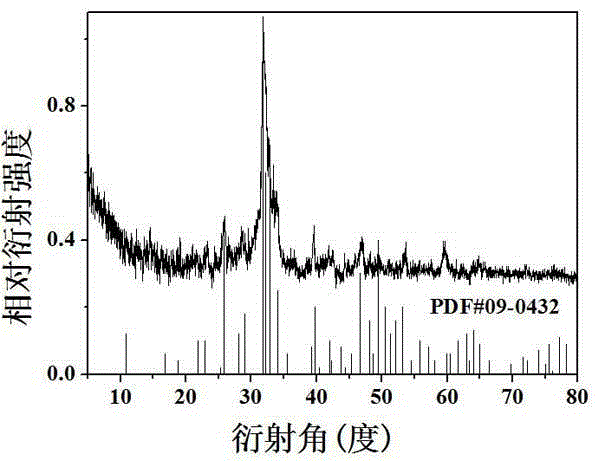

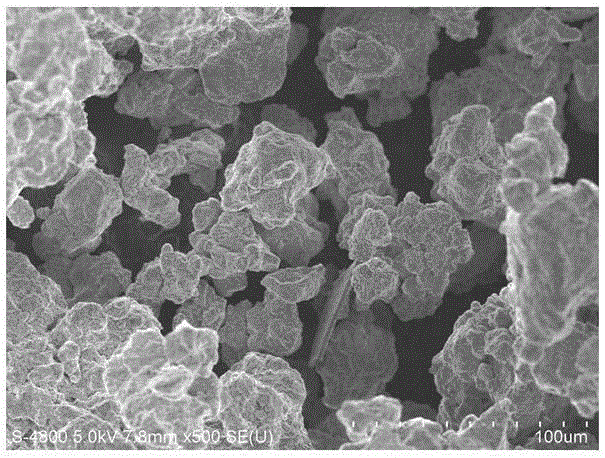

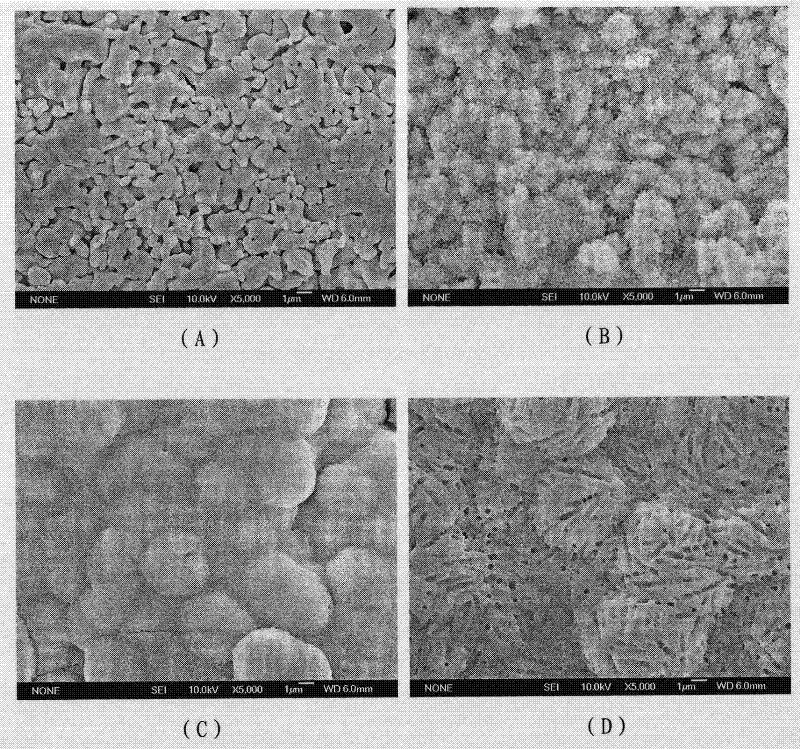

Calcium borate silicate biological material as well as preparation and application thereof

ActiveCN103819182AGood biocompatibilityNo side effectsImpression capsDentistry preparationsChemical synthesisApatite

The invention relates to a calcium borate silicate biological material as well as preparation method and application thereof. Pure-phase calcium borate silicate Ca11Si4B2O22 powder is synthesized by a solid-phase synthesis method or a wet chemical synthesis method; the calcium borate silicate powder is pressed and moulded to obtain a calcium borate silicate ceramic block; the calcium borate silicate powder or the calcium borate silicate ceramic block is soaked in a simulated body fluid (SBF) for certain time and mineralized; after a while, a bone-like apatite layer can deposit on the surface of the powder or the ceramic block; researches find that the thickness of mineralized hydroxyapatite increases along with the increase of the soaking time. The calcium borate silicate powder or the ceramic material prepared through the preparation method has good biological performance, is a biological and medical material with very high potential, and can be used as a bone tissue repairing and filling material and a tooth repairing material.

Owner:安徽(淮北)新型煤化工合成材料基地管理委员会科技服务中心

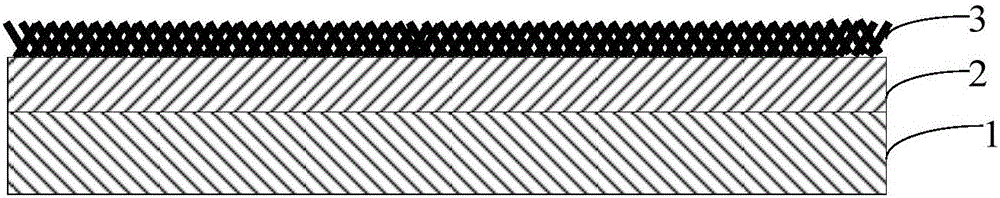

Composite film for guiding bone tissue regeneration and preparation method of composite film

The invention relates to a composite film for guiding bone tissue regeneration and a preparation method of the composite film. The composite film is a double-layer film, wherein a bottom-layer film is an L-lactide and caprolactone copolymer (L-PLCA) cast film with a compact structure, and the molar ratio of monomer components is (50:50) to (95:05); a surface layer is an L-PLCA and hydroxyapatite (HA) or tricalcium phosphate (beta-TCP) compound electrospinning film with a micropore structure, wherein the mass ratio of HA or beta-TCP in the electrospinning film is 10-50wt%, and the particle size of the electrospinning film can be nano-grade or micro-grade. The double-layer composite film is relatively good in mechanical performance and bone-like apatite deposition induction capacity, favorable in flexibility and capable of realizing performance regulation through regulating the molar ratio of L-PLCA, the content of the component HA or beta-TCP and the microstructure of the electrospinning film so as to be a novel degradable double-layer composite film capable of guiding bone tissue regeneration.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

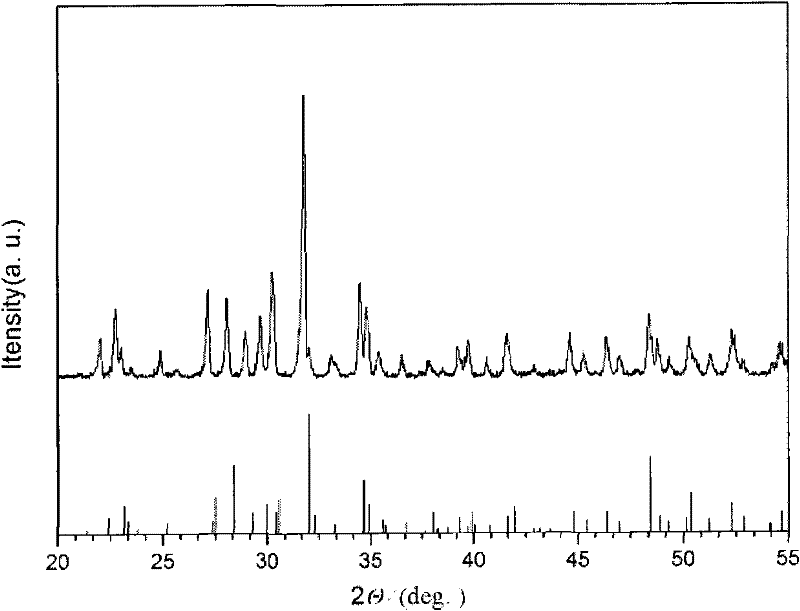

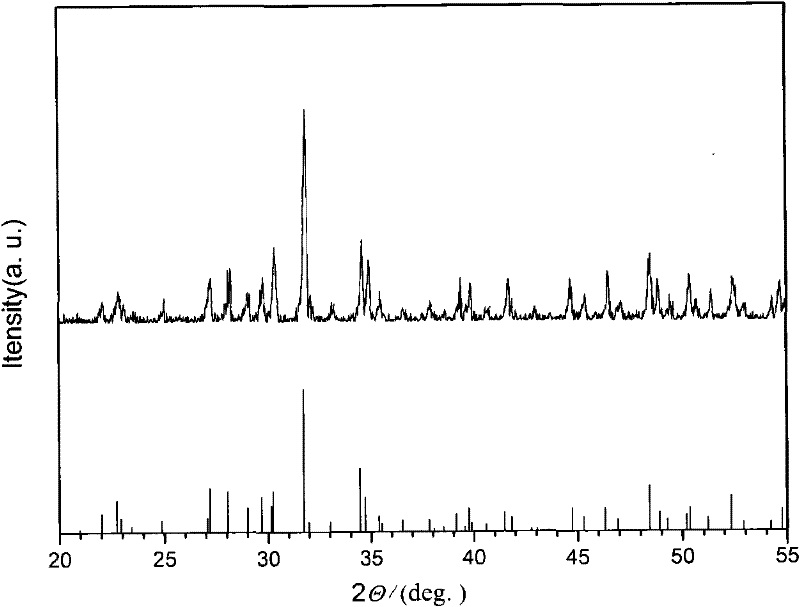

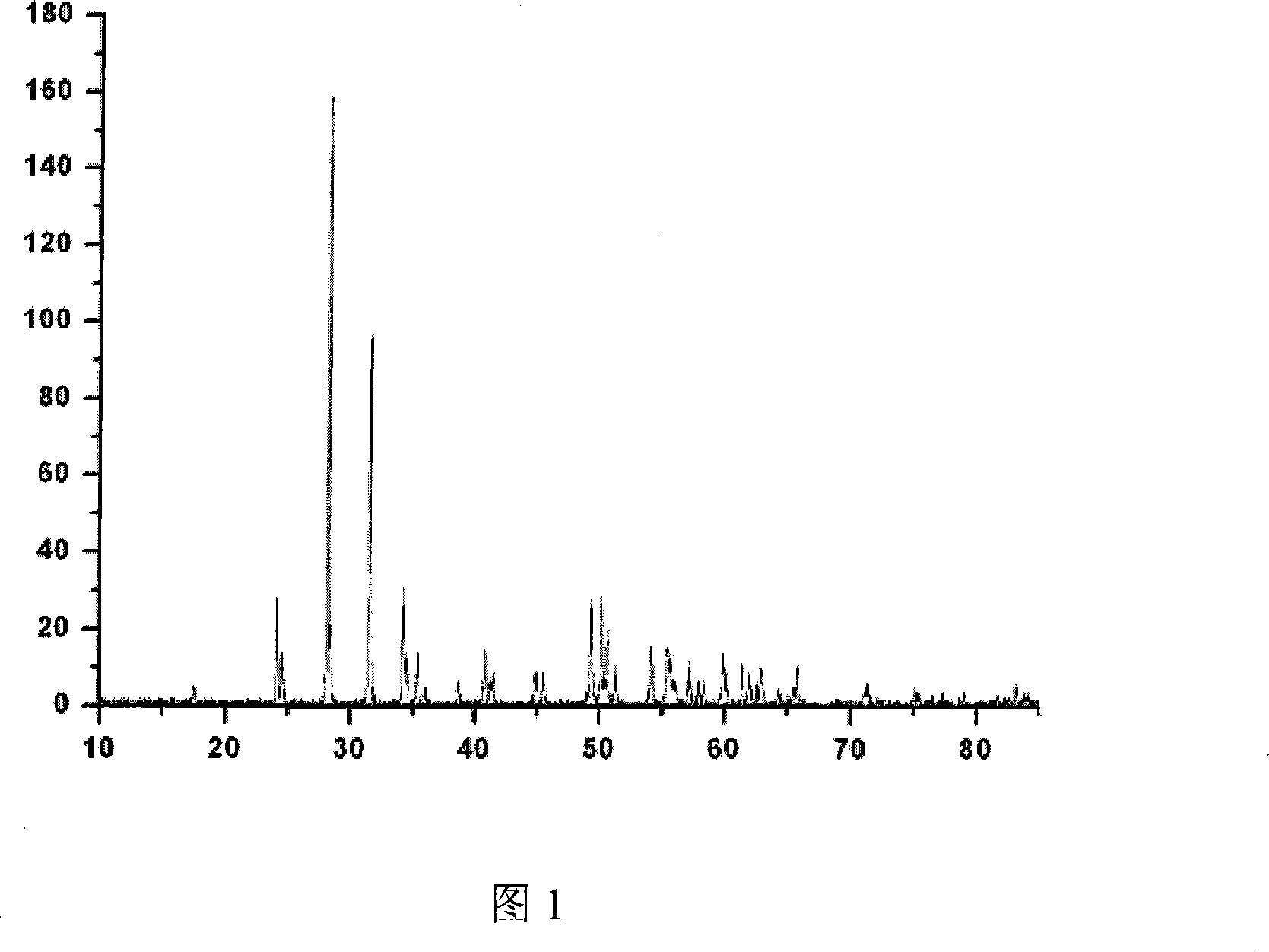

Calcium silicon phosphate biomaterial and its preparation method and use

ActiveCN102276247ASimple processLow costImpression capsDentistry preparationsCalcium biphosphateApatite

The invention relates to a calcium phosphate silicate biomaterial, and a preparation method and a purpose thereof. The calcium phosphate silicate biomaterial is characterized in that a soluble silicon source, a soluble phosphor source and a soluble calcium source are used as raw materials, and water is used as a solvent; a sol-gel method is employed to synthesize pure phase calcium phosphate silicate (Ca5(PO4)2SiO4) powder, which is compressed for moulding and sintered into a calcium phosphate silicate (Ca5(PO4)2SiO4) ceramic block. After soaking the Ca5(PO4)2SiO4 ceramic block in a simulated body fluid (SBF) for 1 day, bone-like apatite can be precipitated on a surface of the ceramic block, and the apatite layer becomes thicker with increasing of a soaking time. The Ca5(PO4)2SiO4 prepared in the invention has good biological performance, is a potential biological and medical material and can be used as a bone restoration and filling material and a restoration material in dentistry.

Owner:上海积力威尔生物科技合伙企业(有限合伙)

Calcium silicophosphate biomaterial, and preparation method and use thereof

The invention relates to a calcium silicophosphate biomaterial, and a preparation method and a use thereof. Pure-phase calcium silicophosphate (Ca5(PO4)2SiO4) powder is synthesized through adopting a sol-gel method and treating a soluble silicon source, a soluble phosphorus source and a soluble calcium source as raw materials and water as a solvent, and the calcium silicophosphate powder is subjected to compression molding and is sintered to obtain a calcium silicophosphate (Ca5(PO4)2SiO4) ceramic block. The surface of the ceramic is deposited with a bone-like apatite layer after the calcium silicophosphate (Ca5(PO4)2SiO4) ceramic block is immersed in a stimulation body fluid for 1 day, and the thickness of the apatite layer increases with the prolongation of the immersion time. The calcium silicophosphate (Ca5(PO4)2SiO4) material prepared in the invention has good biological performances, is a most potential biological and medical material, and can be used as a material for bone tissue restoration and filling, and dental restoration.

Owner:上海积力威尔生物科技合伙企业(有限合伙)

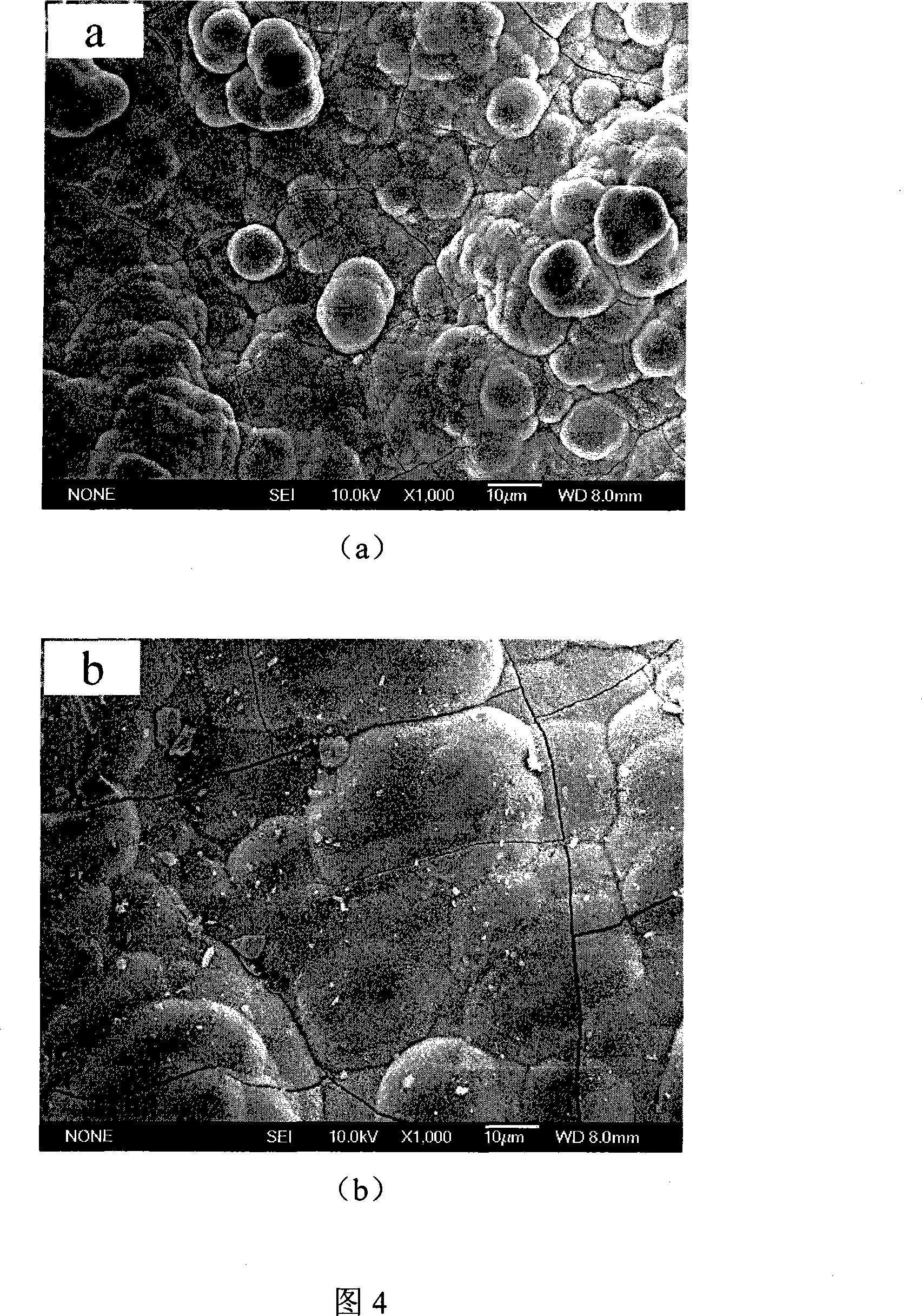

Surface activation method of dental implant

InactiveCN101773412AEvenly distributedPromote ingrowthDental implantsArtificial teethActivation methodTitanium alloy

A surface activation method of a dental implant comprises: putting a titanium implant in 1-3M of H2SO4 liquid, using the titanium or titanium alloy of the titanium implant as an anode and using a Pt material as a cathode to carry out anode oxidation by using an anode oxidation method, preparing an oxidation film with a three-dimensional spherical pore microstructure on a surface, and existing round pits in different sizes and with apertures of 100-200nm in local areas; and putting the titanium implant with the oxidized anode in 3-5M of NaOH alkali solution for processing and forming a titanium gel on the surface, wherein the enriched Ti-OH groups induce the generation of calcium phosphate crystal nucleuses to form a bone-like apatite layer. The invention uses the combination of the anode oxidation method and an alkali process method for preparing an active TiO2 coating layer on the surface of the titanium alloy, the implant processed by the anode oxidation method has good compatibility with bone, and bonding strength and bone sediment yield are both obviously higher than that of the unprocessed titanium, thereby greatly improving the clinic success ratio of the dental implant.

Owner:沈阳天贺新材料开发有限公司

Preparation method of bone inducing porous titanium artificial bone

The invention relates to a preparation method of bone inducing porous titanium artificial bone. The method comprises the following steps: a porous titanium block is processed into a required shape and is washed; the surface is activated; the porous titanium block is put into acid solution which is prepared by sulfuric acid, hydrochloric acid and deionized water to be processed and then is put into alkali solution of sodium hydroxide; or put into acid solution which is prepared by hydrofluoric acid, nitric acid and deionized water to be processed and is then put into hydrogen peroxide solution; or put into acid solution which is prepared by hydrofluoric acid, nitric acid and deionized water to be processed and is then put into hydrogen peroxide solution which contains tantalum pentachloride; the method is characterized in that the surface of the porous titanium can be activated uniformly without pre-depositing a calcium phosphate layer, when being soaked in simulated body fluid at 36.5DEG C, bone-like apatite can be induced to deposit in 28 days; and bone inductivity can be given to the porous titanium artificial bone. The bone inducing porous titanium artificial bone is used for repairing, replacing or reinforcing bone tissue and can reinforce the regeneration of the bone tissue and the interfacial bond of the implant site; and the process is simple and the operation is convenient.

Owner:SICHUAN UNIV

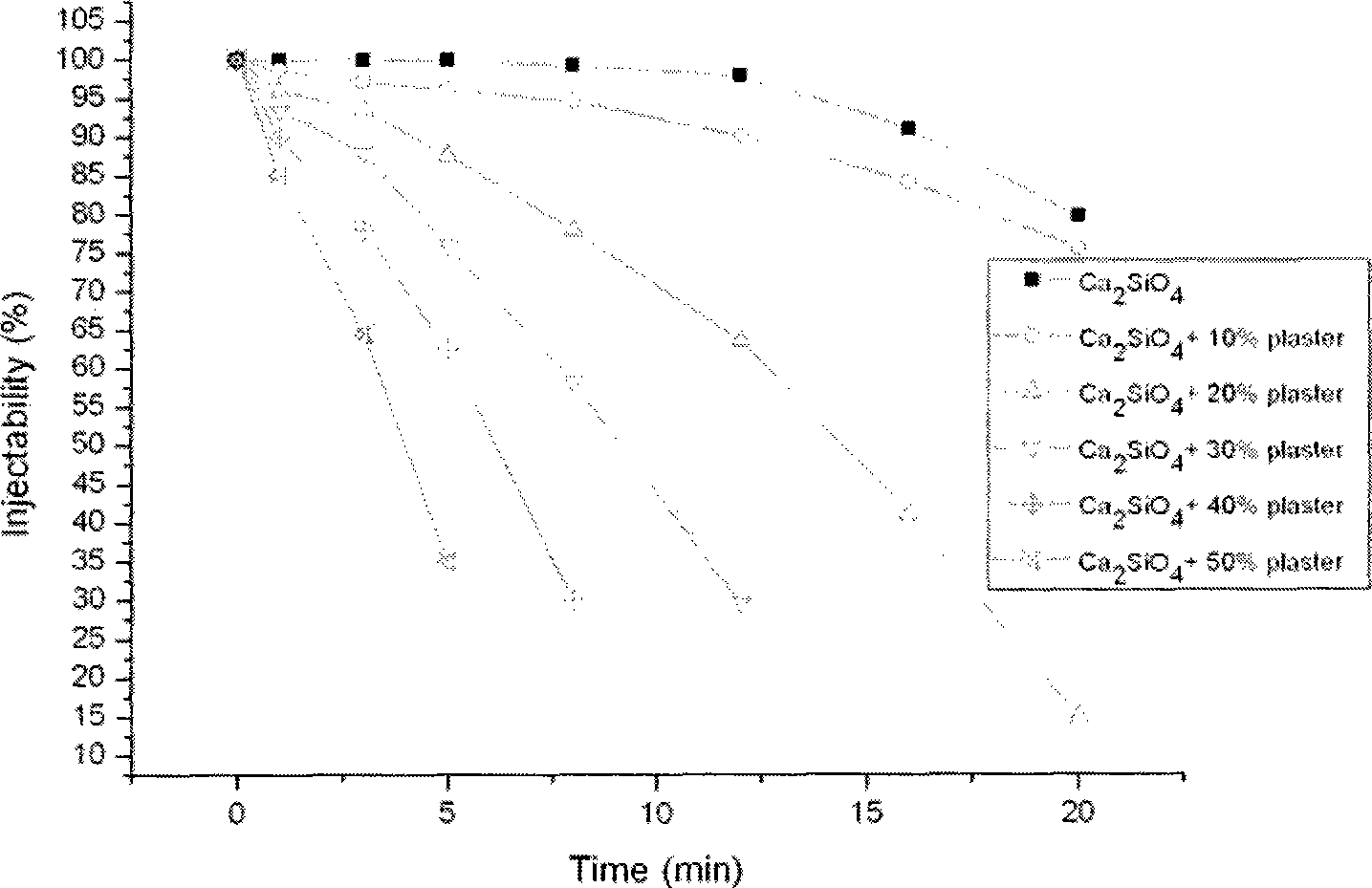

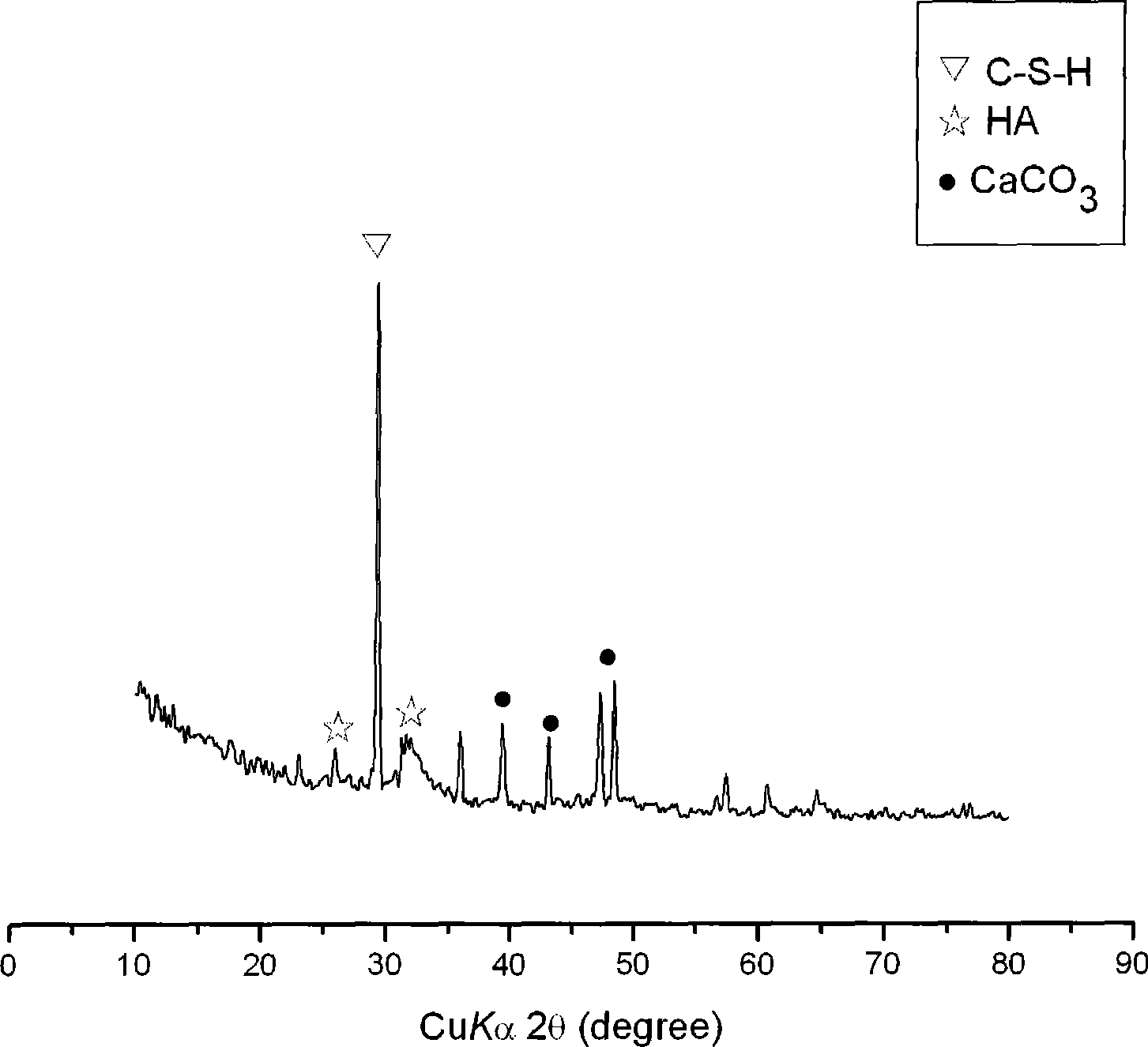

Composite self-curing material of dicalcium silicate, preparation and uses thereof

InactiveCN101428152AImprove biological activityGood biocompatibilityImpression capsDentistry preparationsCalcium silicateApatite

The invention relates to a dicalcium silicate compounded self-setting material as well as the preparation method and the application thereof, in particular to a human body hard tissue defect filling and recovery material, and belongs to the field of medical biomaterials. The invention is a paste comprising mixing liquid and dicalcium silicate / calcium sulfate hemihydrate which are mixed with each other at a mass ratio of 0.5-1.5:1, and the mixing liquid is selected from one of deionized water, a simulated body fluid, an inorganic salt solution, or an organic matter solution. Compared with the prior materials, the invention has the characteristics of excellent biological activity, random moulding, self-setting, non-cytoxicity, progressive degradation and adjustable degradation rate, and can achieve the effect of inducing the generation of bone-like apatite. Moreover, the material provided by the invention has better self-setting performance than pure calcium silicon-based or calcium sulfate self-setting bone recovery materials, the preparation method is simple.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

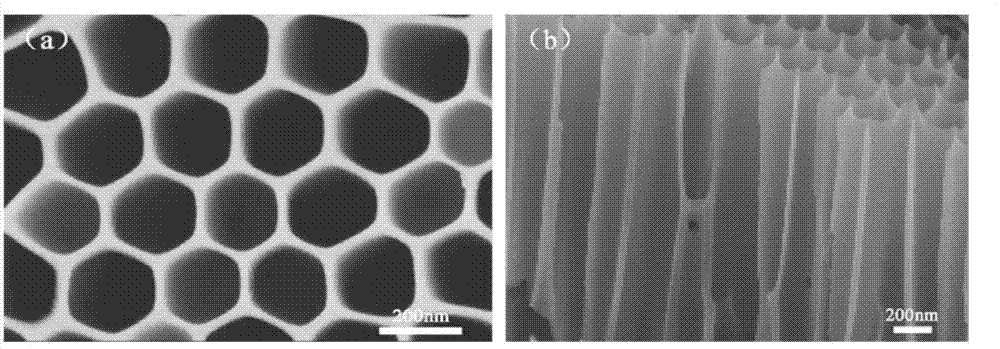

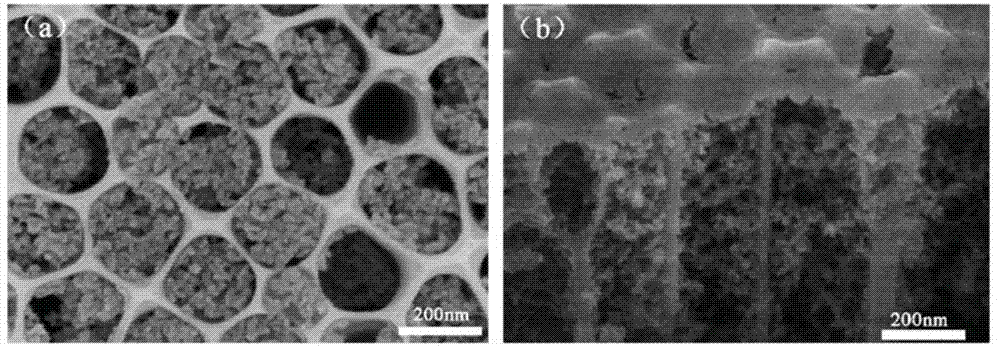

Preparation method for CaO-SiO2/PAA composite film material having biological activity

InactiveCN102793949ASpecial nanopore structureImprove biological activityProsthesisComposite filmApatite

The invention relates to a preparation method for a CaO-SiO2 / PAA (porous anodic alumina) composite film material having biological activities. The invention uses a sol-gel method to synthesize a binary system of silicate sol, and takes PAA as a matrix. The PAA matrix is placed in the sol. The sol is vacuumized for 1-3 hours. The PAA matrix is finally heated to get the CaO-SiO2 / PAA composite film. The composite film material obtained from the invention has a special nanopore structure and good biological activities. Experiments in vitro show that bone-like apatite is generated on the surface of the composite film soaked in a simulated body fluid (SBF) for a day. So, the preparation method is rapid, simple, efficient and suitable for the surface function modified design of biological materials.

Owner:DONGHUA UNIV

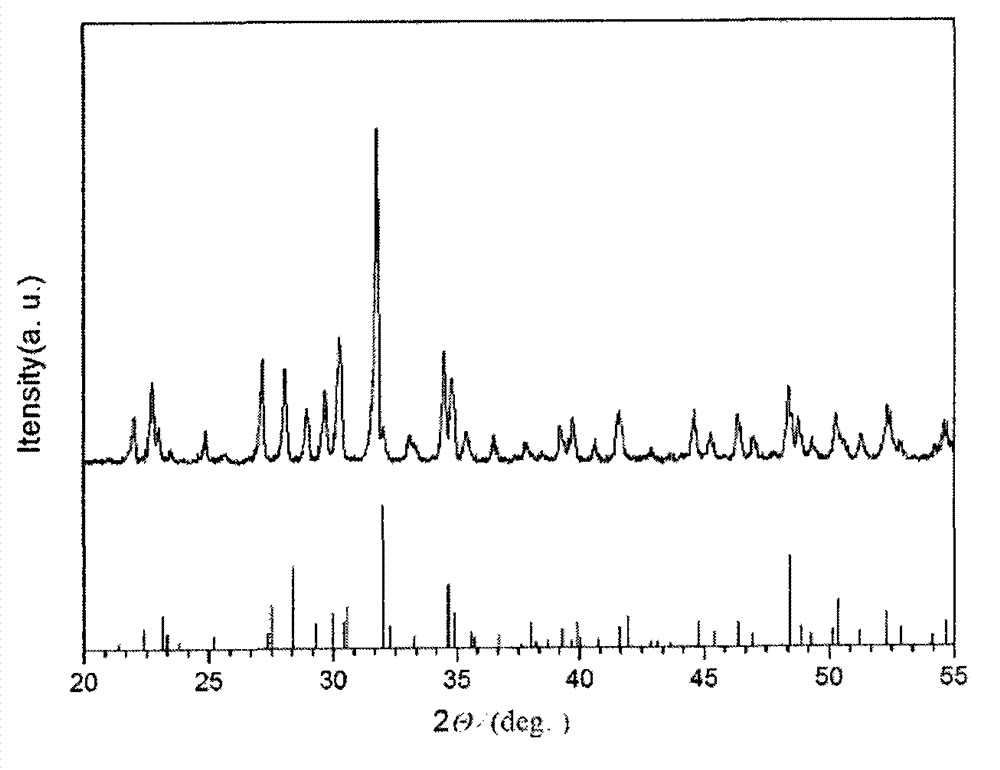

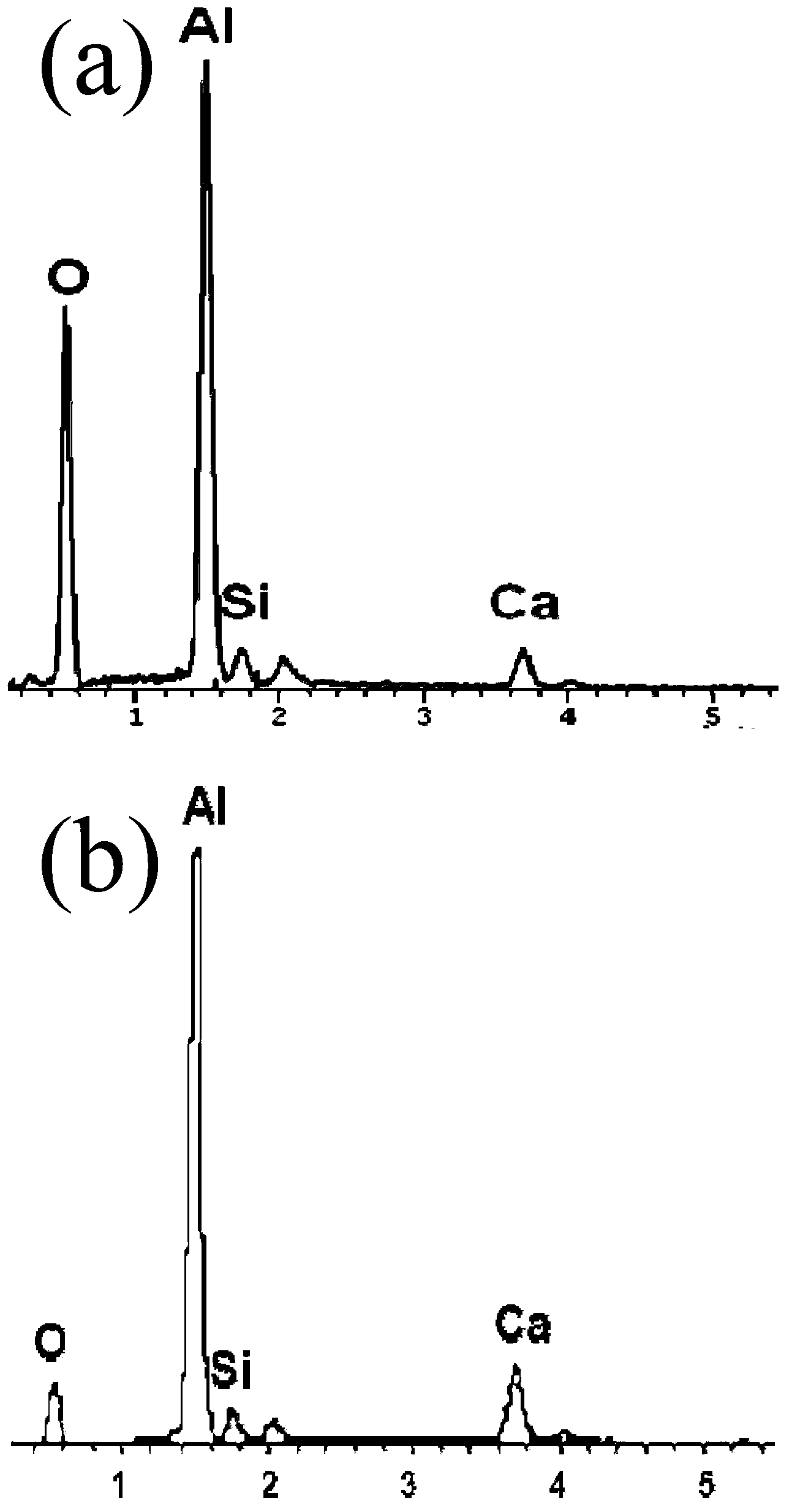

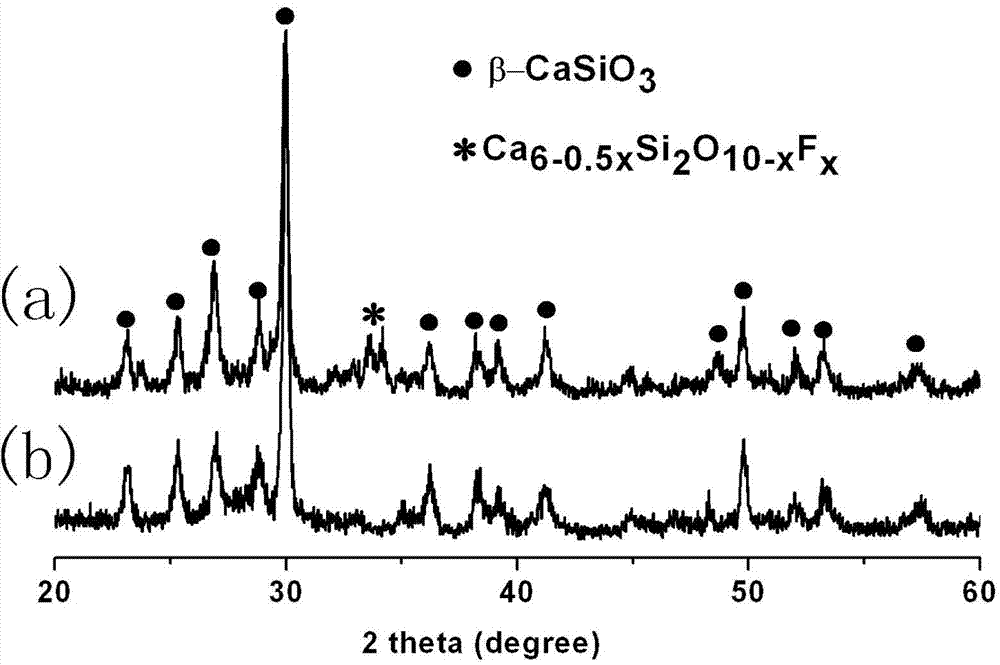

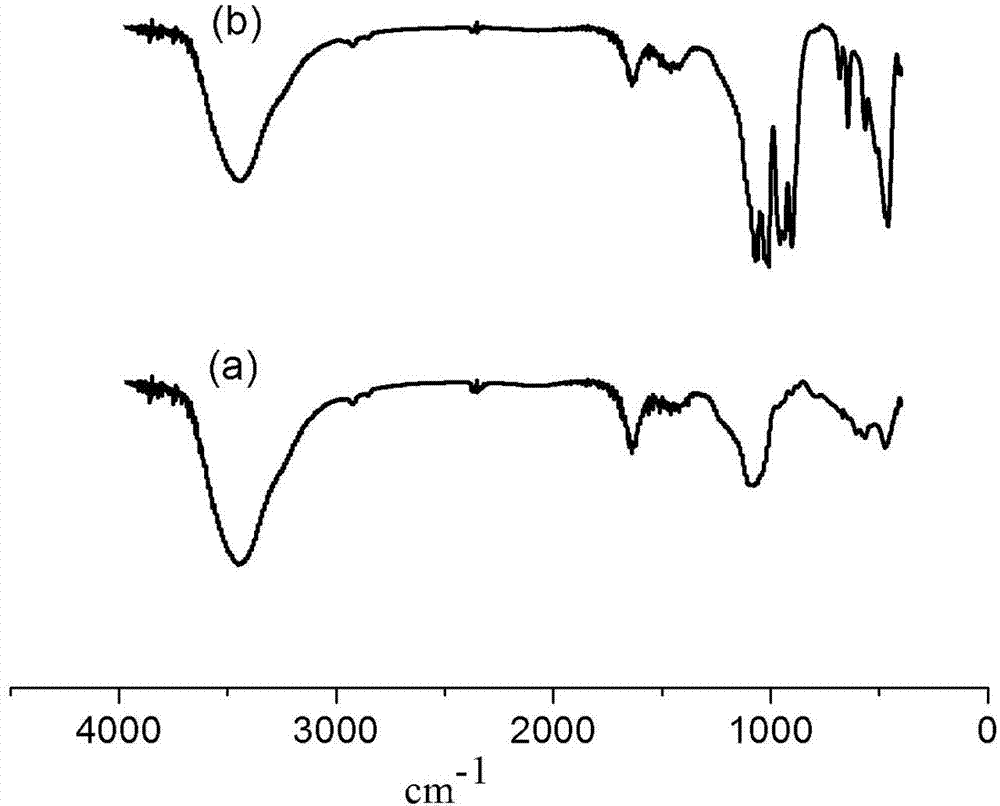

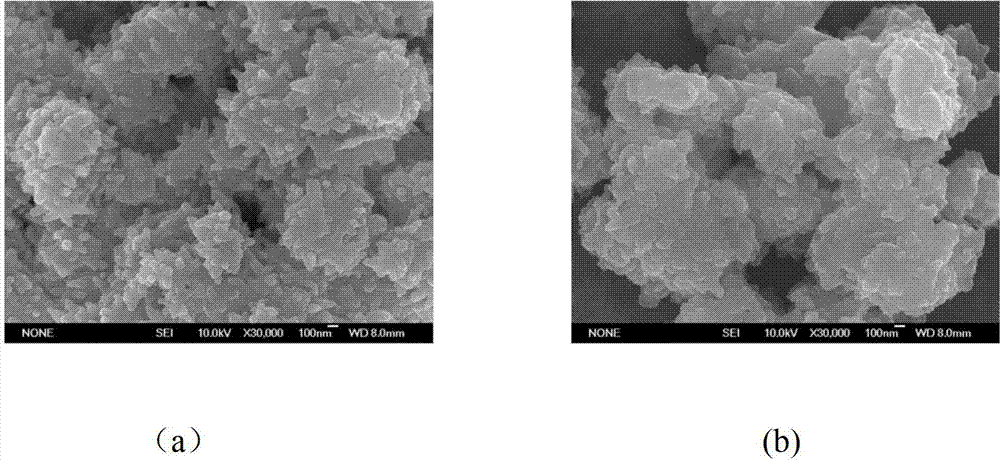

Fluoro-calcium silicate biological ceramic material and preparation method and application thereof

ActiveCN103030374APromote repairEasy to makeCosmetic preparationsImpression capsCalcium silicateApatite

The invention discloses a fluoro-calcium silicate biological ceramic material and a preparation method and application thereof. The fluoro-calcium silicate biological ceramic material is prepared by dipping mixed solution prepared by sodium silicate and alkali fluoride into calcium salt solution to generate precipitates, and filtering, washing, drying and forging the precipitates. The molar ratio of sodium silicate and fluoride is proportioned to prepare the fluoro-calcium silicate biological ceramic material with different fluorine-containing contents. Compared with the traditional sodium silicate biological ceramic, the prepared fluoro-calcium silicate biological ceramic has the advantage that bone-like apatite can be rapidly formed in a simulated body liquid environment, and can be used as a toothpaste additive and a hard tissue defect repairing material.

Owner:四川亿诺森生物科技有限公司

Self-degradation bioactive metal anchoring nail and preparation method thereof

InactiveCN101757695APromote bone repairEffective adjustment of degradation rateSurgeryCoatingsApatiteMechanical property

The invention relates to a self-degradation bioactive metal anchoring nail which belongs to the technical field of biomedicine. The self-degradation bioactive metal anchoring nail is made of magnesium or magnesium alloy, and the outer surface of the self-degradation bioactive metal anchoring nail can be optionally provided with a bone-like apatite coating. The magnesium alloy comprises the following components in percentage by mass: one or a plurality of 0.01-10% of Zn, 0.01-5% of Ca, 0.001-5% of Fe and 0.01-5% of Mn, and the balance of Mg. The invention basically ensures the biosafety. The magnesium or magnesium alloy matrix can be simultaneously provided with the bone-like apatite coating, thereby promoting the bone repair, enhancing the fixing strength, and overcoming the defects in the permanent implant metal anchoring nail and the degradable polymer anchoring nail. The self-degradation bioactive metal anchoring nail can better achieve the goals of healing and repairing of tendons and bone, achieve favorable tracing performance, and meet the requirements for comprehensive mechanical properties and biosafety of anchoring nail materials.

Owner:CHANGSHU MICROTUBE TECH

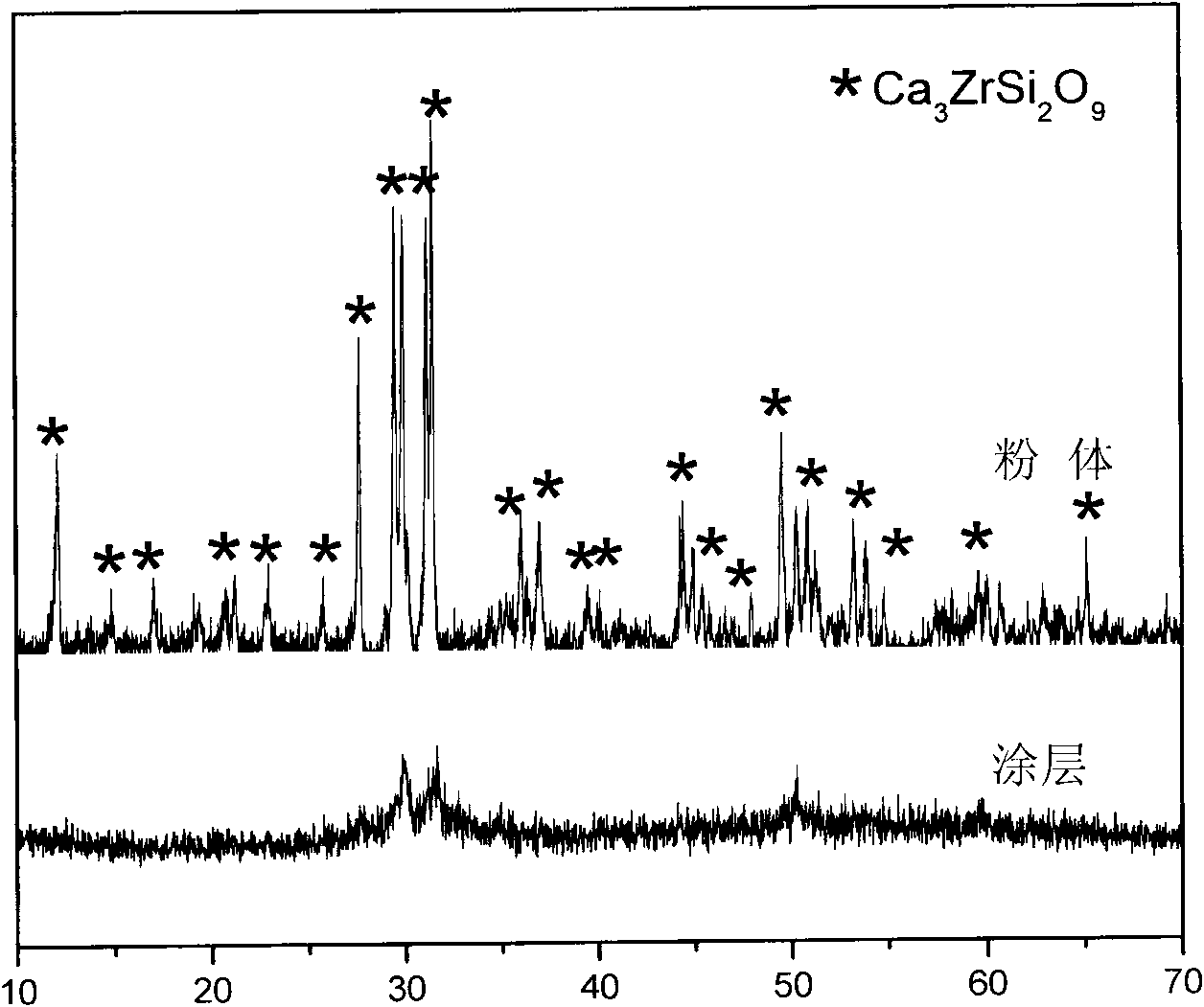

Bone substitute material for Ca3ZrSi2O9 coating-titanium alloy and preparation method of bone substitute material

InactiveCN102049065AGuaranteed service lifeHigh bonding strengthMolten spray coatingProsthesisTi 6al 4vTitanium

The invention relates to a bone substitute material for a Ca3ZrSi2O9 coating-titanium alloy and a preparation method of the bone substitute material. The bone substitute material is characterized in that medical titanium and titanium alloy (Ti-6Al-4V and the like) are taken as substrates, a Ca3ZrSi2O9 coating is deposited on the surfaces of the substrates and consists of Ca3ZrSi2O9 in a monoclinic system and a glass phase, the depth of the coating is 50-420 mu m. The preparation method comprises the following steps: synthesizing Ca3ZrSi2O9 powder; and then depositing the Ca3ZrSi2O9 coating on the titanium alloy substrate by using a plasma spraying technology, wherein the bond strength of the coating and the titanium alloy is 25-35 MPa. The provided coating can induce the formation of bone-like apatite in simulation body fluid, and has good bioactivity; and the bone substitute material can be degraded slowly in Tris-HCL buffer solution and has excellent long-term stability.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

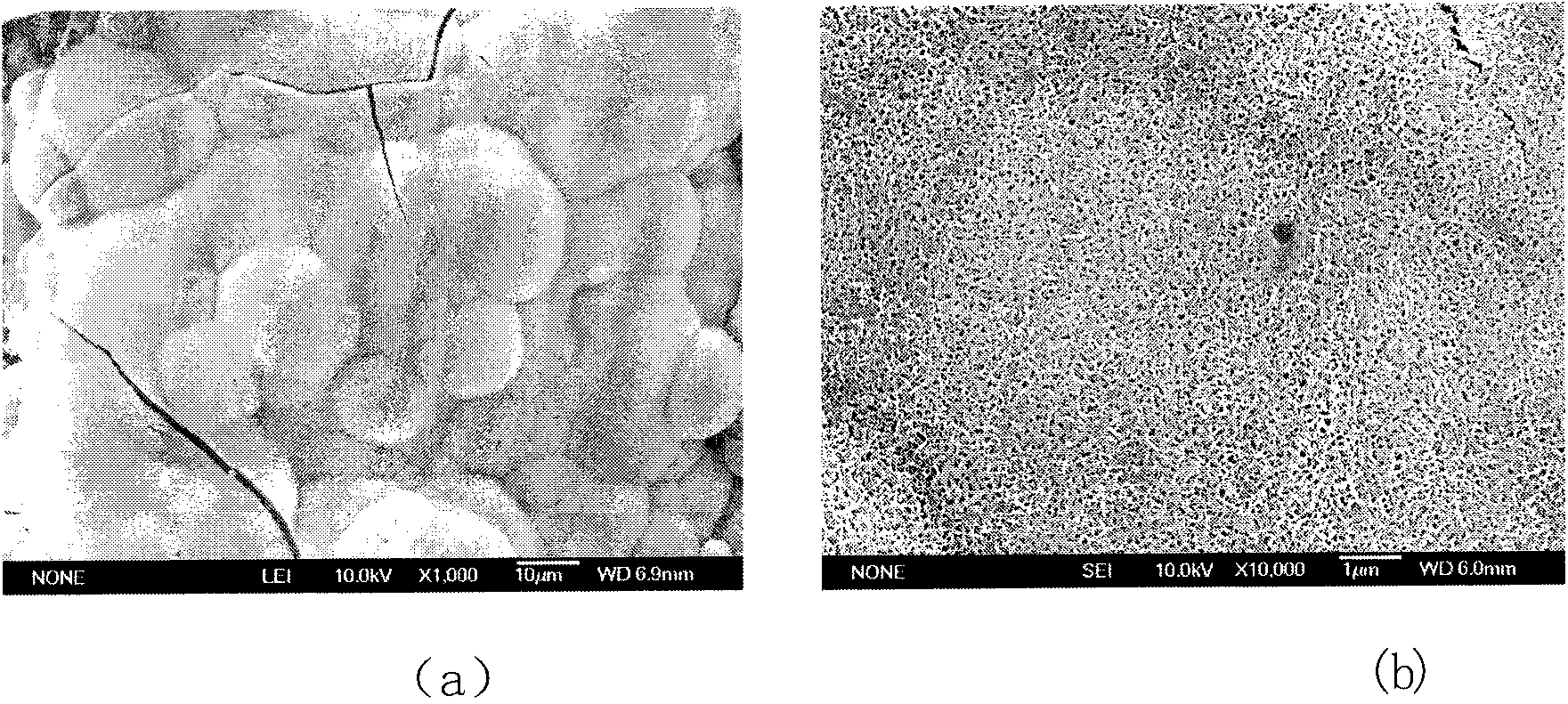

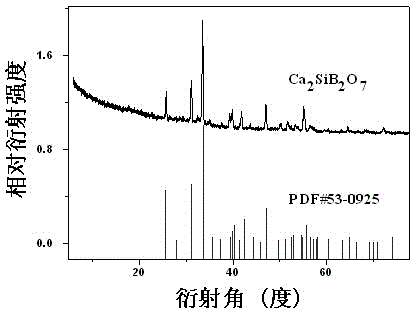

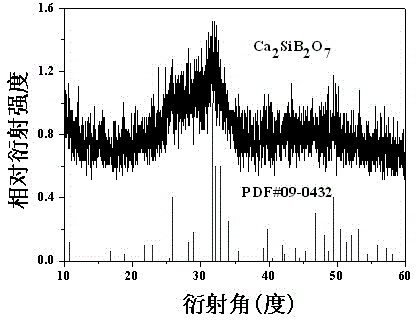

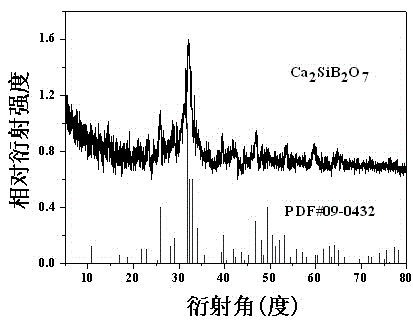

Calcium borate silicate biological material, preparation method and application of calcium borate silicate biological material

ActiveCN104058730AImprove biological activityNo side effectsImpression capsDentistry preparationsCalcium borateBone tissue

The invention discloses a calcium borate silicate biological material, a preparation method and application of the calcium borate silicate biological material. Pure-phase calcium borate silicate Ca2SiB2O7 powder is synthesized through a solid-phase synthesis method or a sol-gel method or a coprecipitation method, and the calcium borate silicate powder also can be pressed and formed so that calcium borate silicate ceramic blocks can be acquired. After the prepared calcium borate silicate material is placed in simulated body fluid (SBF) for soaking and mineralization, a bone-like apatite layer is deposited on the surface of the material, and the thickness of hydroxyapatite obtained after mineralization is increased along with soaking time. The prepared calcium borate silicate biological material has good biological performance, is suitable for being used as a material for bone tissue repair and filling and dentistry repair, and is a new biological and medical material.

Owner:青岛蓝皓生物技术有限公司

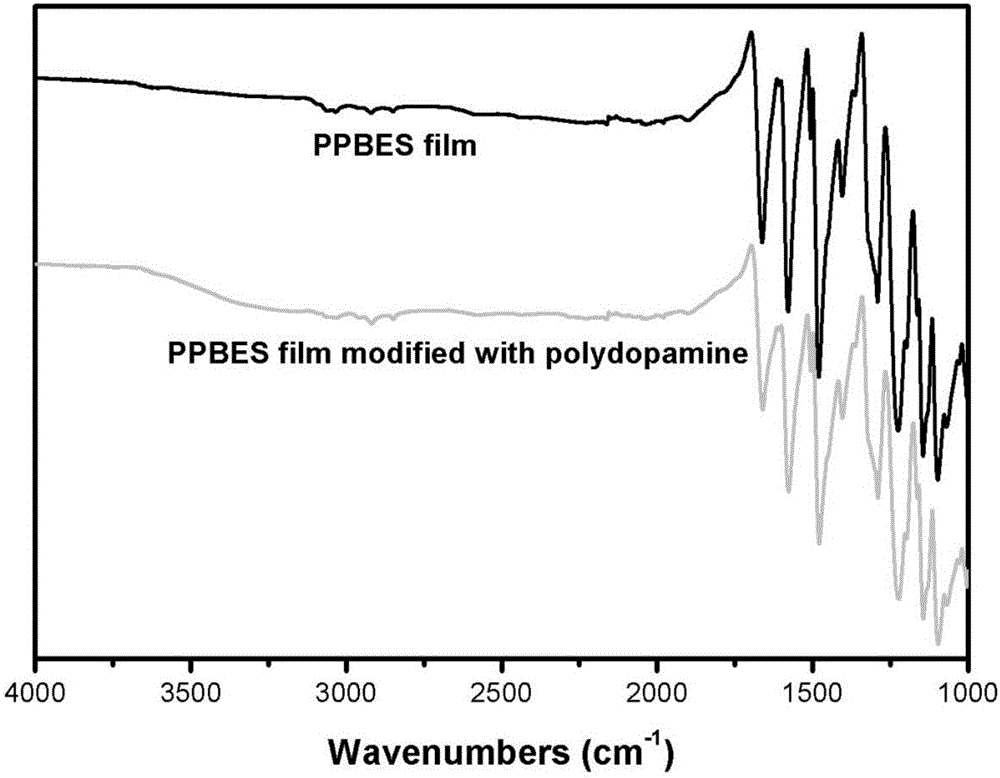

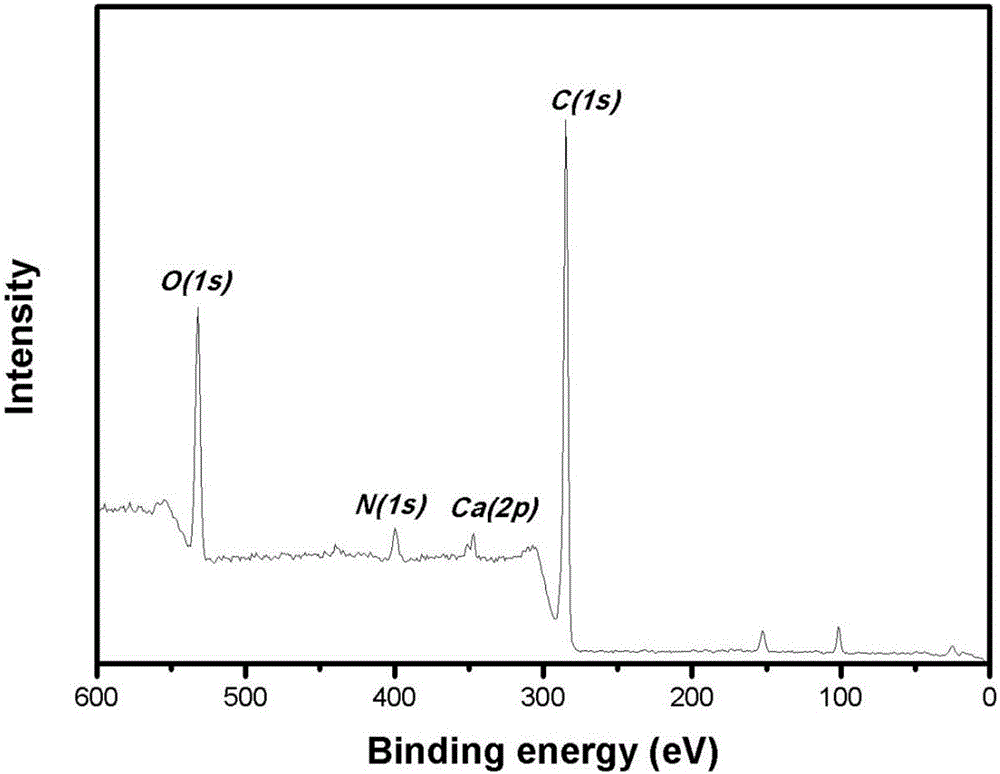

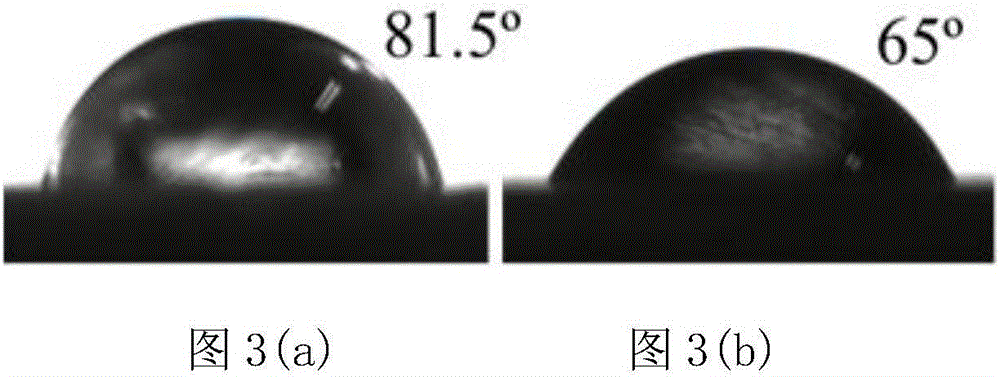

Poly(phthalazinone ether) provided with composite coating on surface and preparation method of poly(phthalazinone ether)

The invention provides poly(phthalazinone ether) provided with a composite coating on the surface and a preparation method of the poly(phthalazinone ether) and belongs to the technical field of polymer science. The composite coating of the poly(phthalazinone ether) provided with the composite coating on the surface comprises a polydopamine layer and a bone-like apatite layer, wherein the polydopamine layer comprises a polydopamine layer not modified with a phosphoric acid functional group and a polydopamine layer modified with the phosphoric acid functional group, and the thickness of the polydopamine layer is smaller than 1 mu m; the bone-like apatite layer contains Ca and P, and the thickness is smaller than 1 mu m. The preparation method of the poly(phthalazinone ether) comprises steps of surface deposition of polydopamine and biomimetic mineralization of bone-like apatite, adopts a simple process, and is low in cost. The bone-like apatite layer can improve properties including surface hydrophilicity and biocompatibility of polyarylether.

Owner:DALIAN UNIV OF TECH

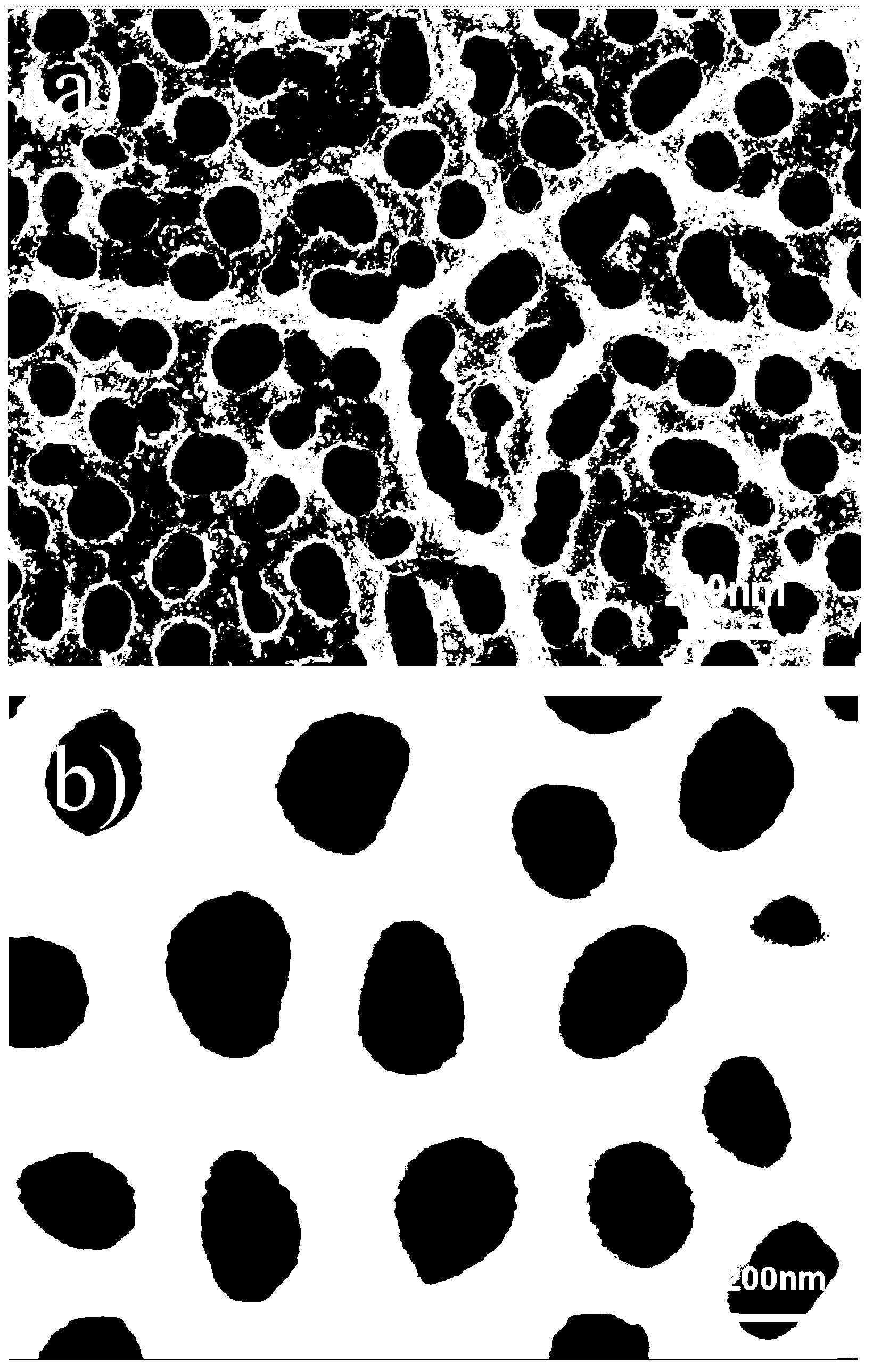

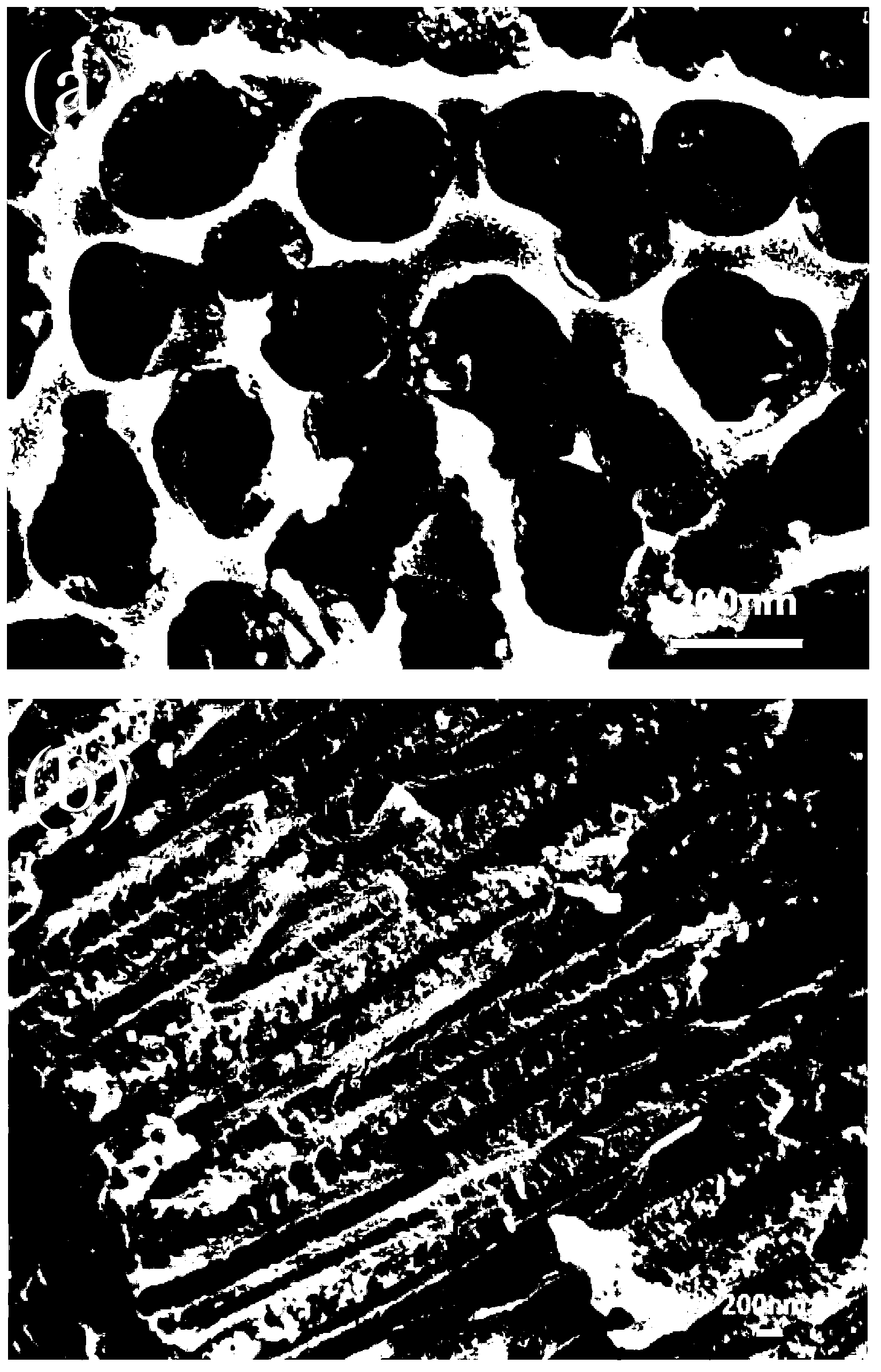

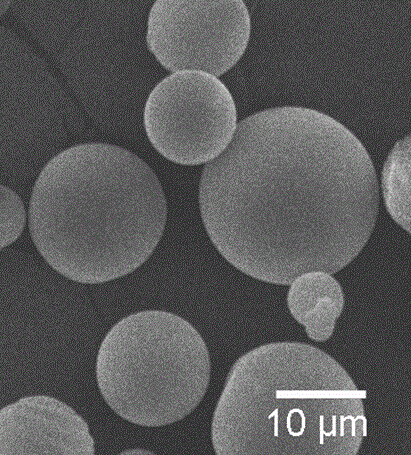

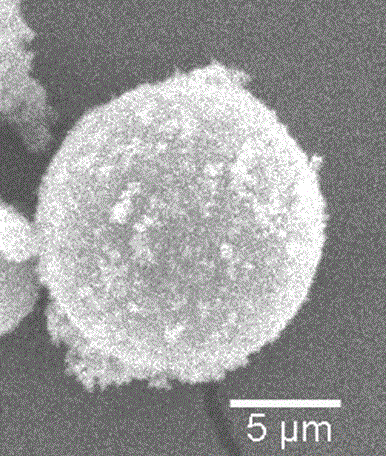

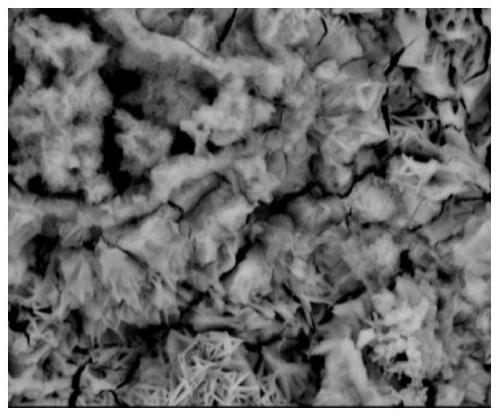

Preparation method of surface-mineralized chitosan microsphere

InactiveCN106046399AHigh specific surface areaPrecisely Regulated ComponentsTissue regenerationCoatingsEmulsionHydroxyapatite crystal

The invention relates to a preparation method of a surface-mineralized chitosan microsphere and belongs to the field of medical materials. The preparation method comprises the following steps: (1) preparing a chitosan microsphere by utilizing an emulsion-crosslinking method; (2) configuring a mineralized solution; (3) putting prepared chitosan microsphere powder into the configured mineralized solution to enable mineralization reaction for a certain time at a certain temperature, standing and precipitating, washing and drying to obtain a chitosan microsphere surface-mineralized composite material. A large number of uniformly-dispersed lamellar nano hydroxyapatite crystals are generated on the surface of the chitosan microsphere in situ through a mineralization method. According to the preparation method provided by the invention, under mild conditions, the accurate control of the components, the structure and the content of the nano hydroxyapatite crystals on the surface of the polymer microsphere are realized, so that a bone-like apatite surface with high surface activity and good osteogenetic activity is prepared; the preparation method is stable in process and low in cost and can realize large-scale production. The preparation method provided by the invention has a wide application value in clinical aspect of bone tissue engineering.

Owner:TAIYUAN UNIV OF TECH

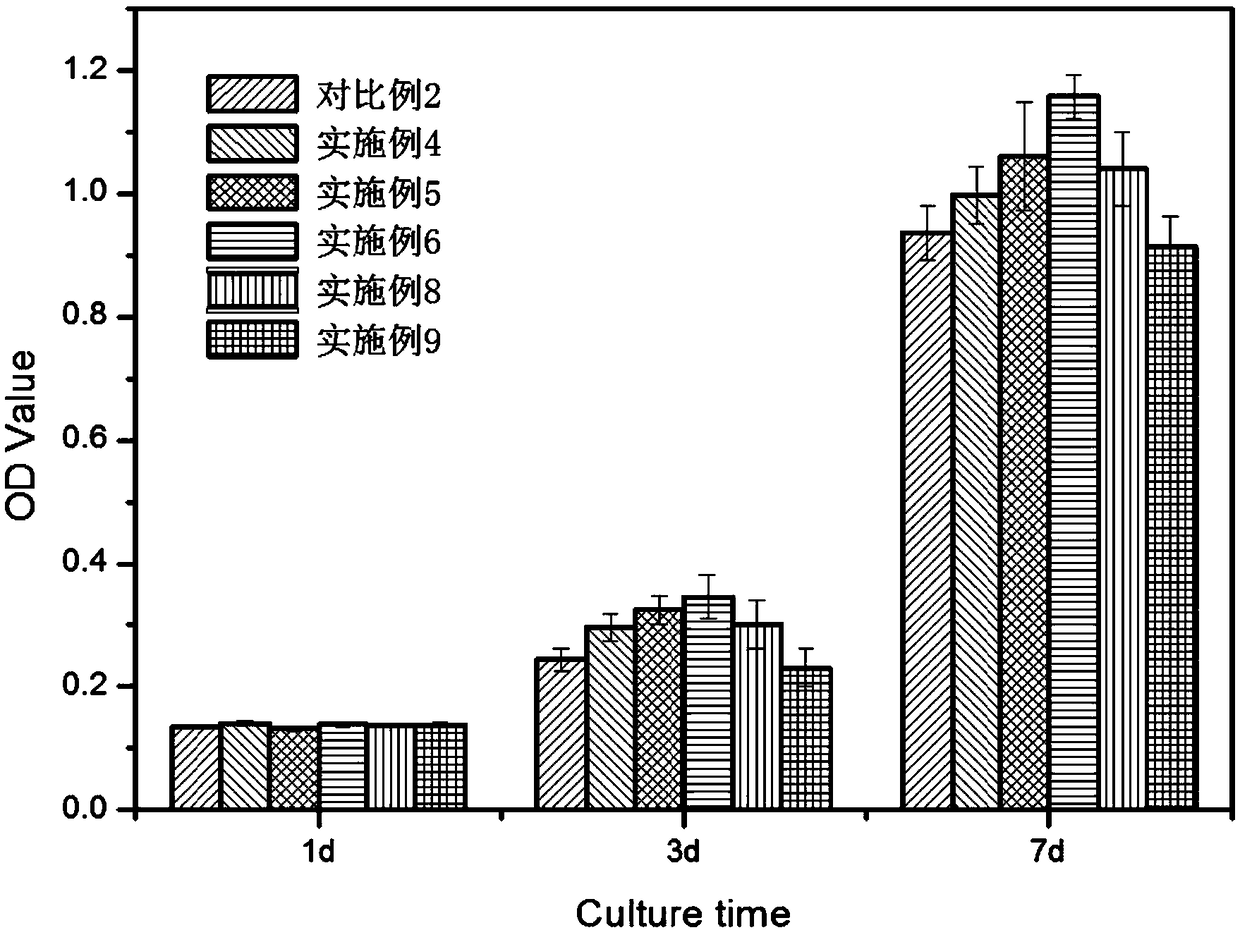

Drug loading biological activity glass complex calcium phosphate bone cement and application thereof

ActiveCN109331223AFast degradation rateLarge poresTissue regenerationProsthesisMicrospherePhosphoric acid

The invention discloses drug loading biological activity glass complex calcium phosphate bone cement and application thereof. According to the invention, drug loading biological activity glass microspheres are added into the calcium phosphate bone cement, the in vivo degradation rate of the biological activity glass microspheres is relatively high, a porous structure inside the calcium phosphate bone cement can be adjusted, a bone-like apatite layer can be formed on the surface of each biological activity glass microsphere, and the drug loading biological activity glass complex calcium phosphate bone cement has good biological activity; and simultaneously, loaded drugs are released while the biological activity glass microspheres are degraded, so that the bone cement has the effects of bone remodeling and drug therapy; and the cell proliferation is promoted by using strontium-doped octacalcium phosphate modified alpha-TCP bone cement. The calcium phosphate bone cement has moderate timeof coagulation, is good in syringeability, mechanical strength and biocompatibility, and meets clinic requirements of bone repair.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

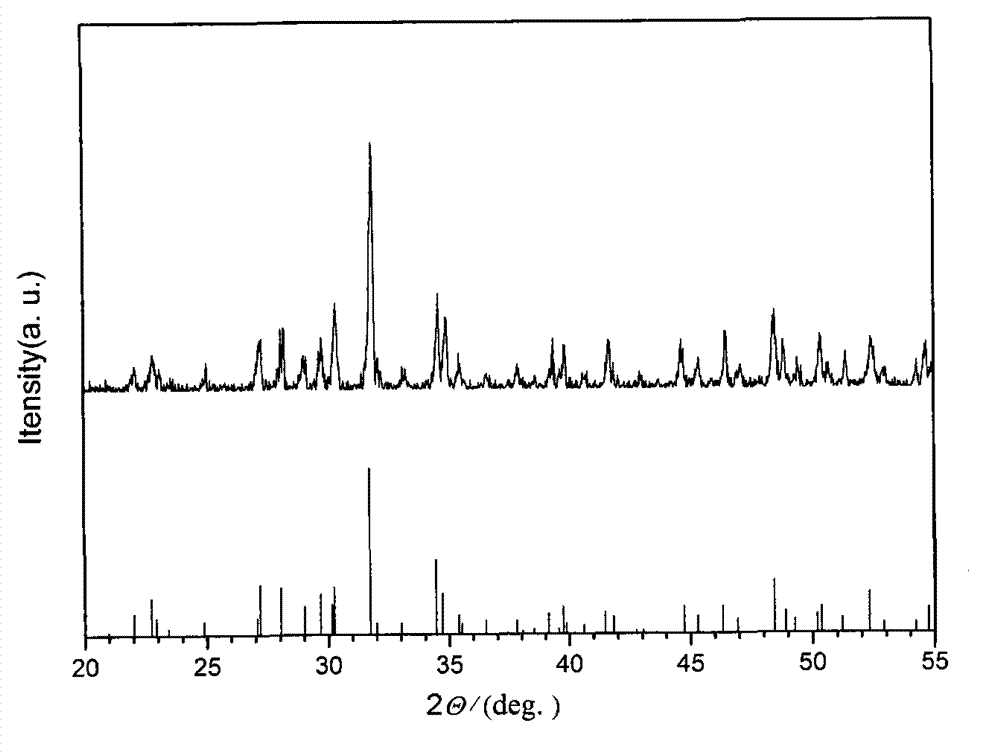

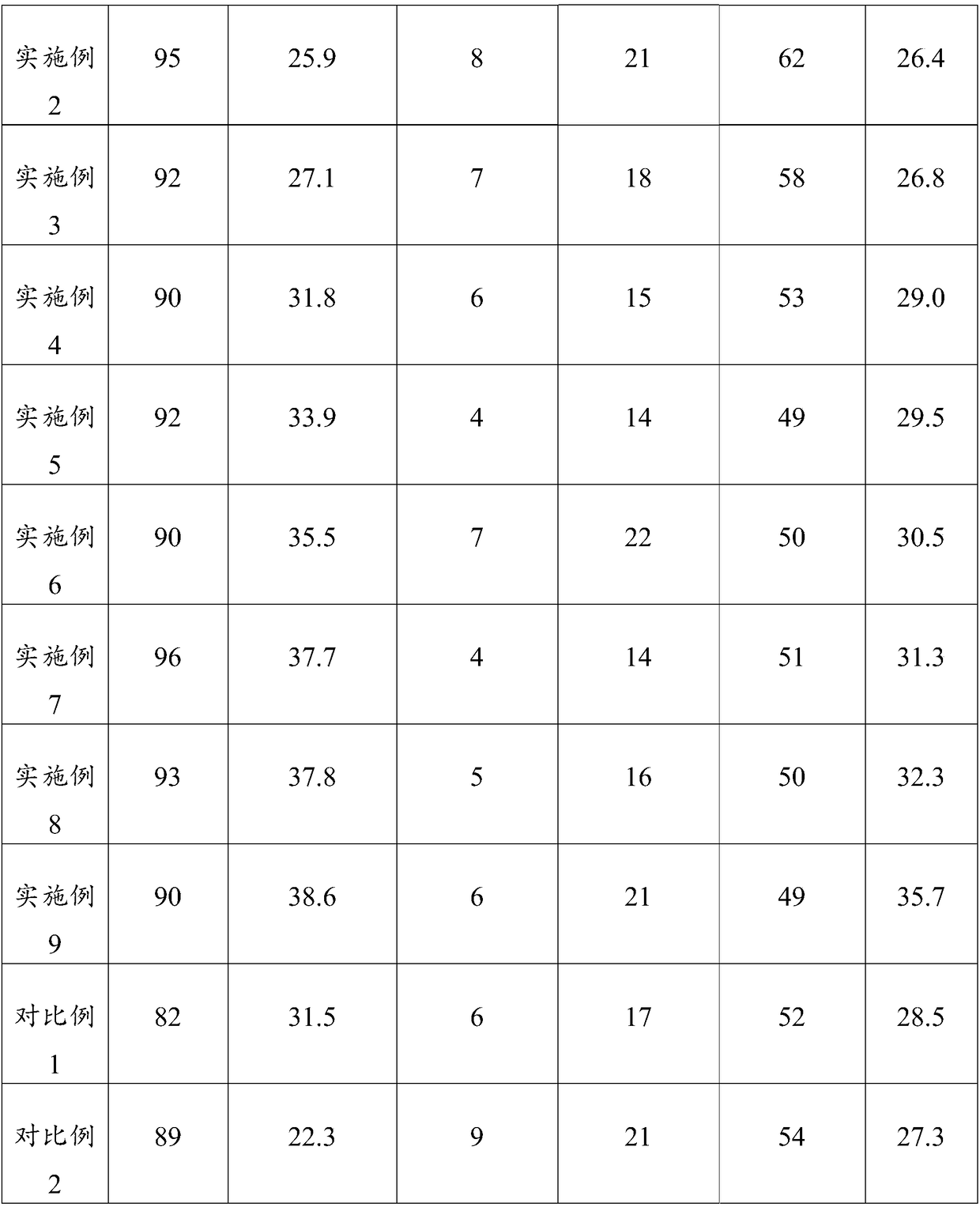

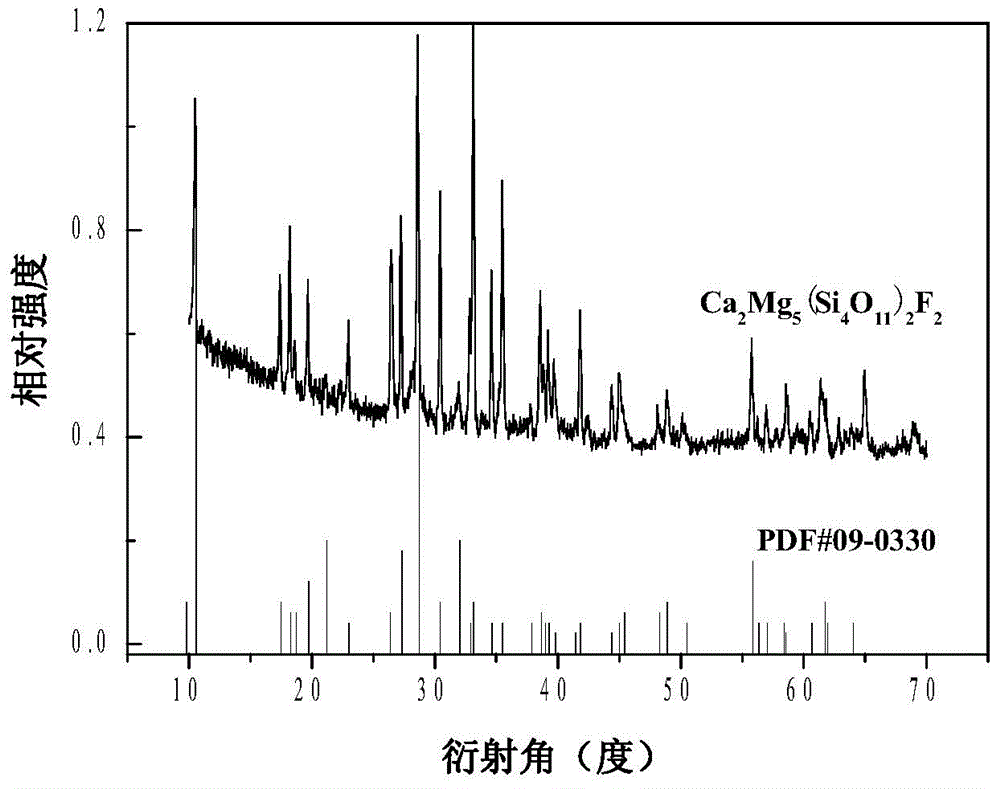

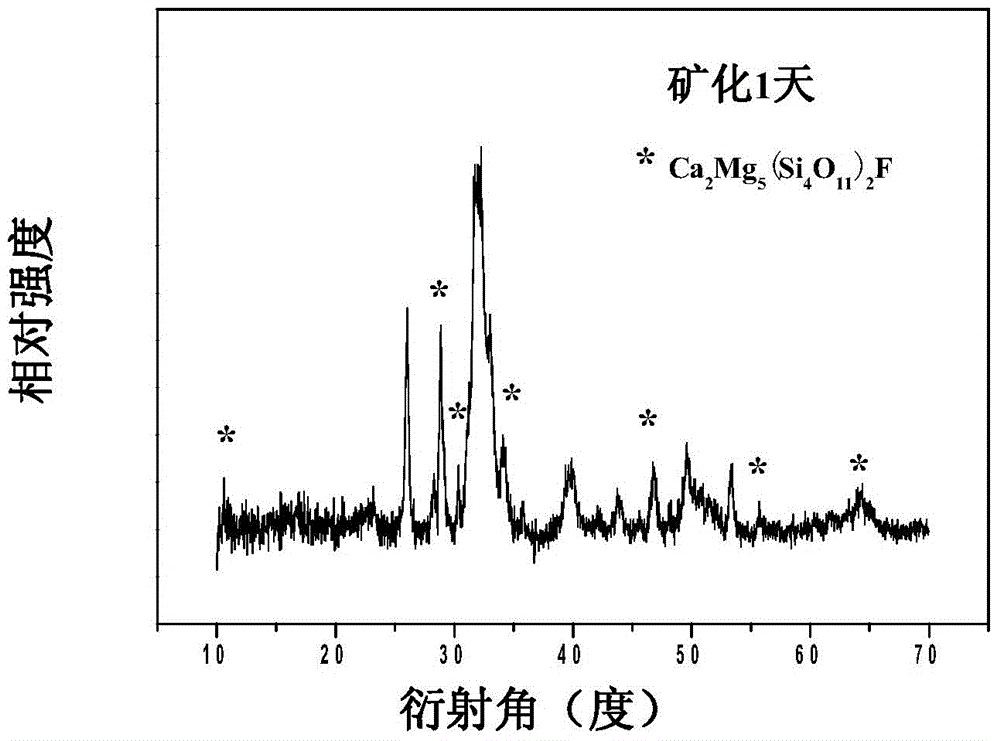

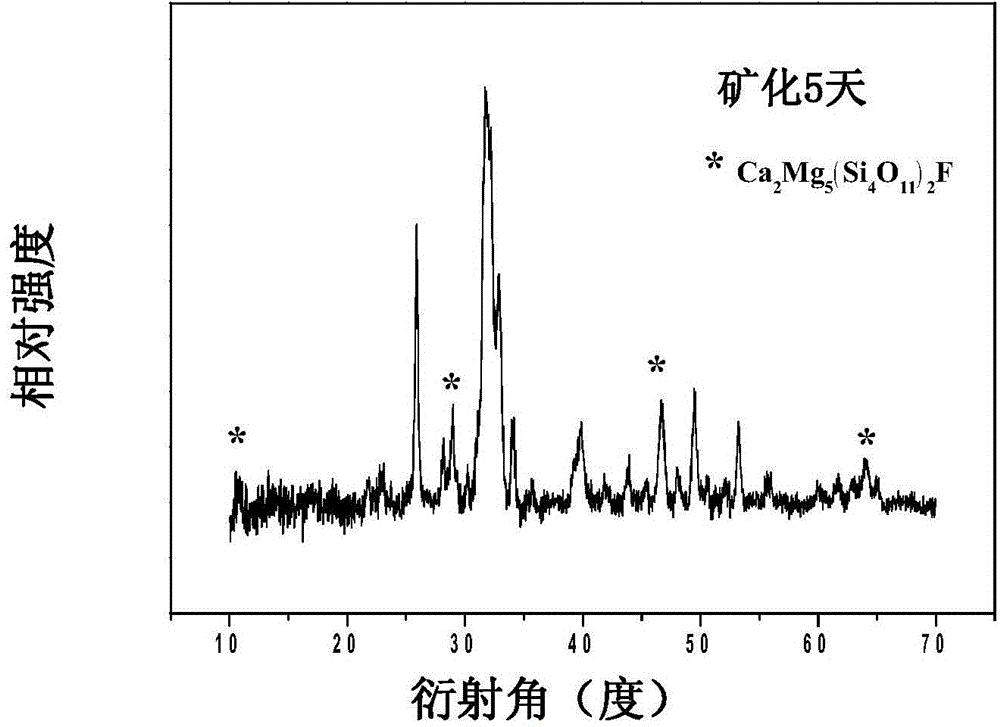

Biomaterial for repairing osseous tissues and preparation method of biomaterial

ActiveCN104623727AImprove biological activityImprove mechanical propertiesProsthesisChemical solutionBone Cortex

The invention discloses a biomaterial for repairing osseous tissues and a preparation method of the biomaterial. A chemical formula of the biomaterial is Ca2Mg5(Si4O11)2F2. The method comprises the following steps: selecting compounds containing elements required for synthesis of the biomaterial according to the ratio; calcining for many times, or dissolving with a chemical solution, mixing and then calcining to prepare the material; mineralizing the prepared Ca2Mg5(Si4O11)2F2 powder or Ca2Mg5(Si4O11)2F2 ceramic blocks in a simulated body fluid for a period of time, then depositing a large amount of bone-like apatite layer on the surface. The biomaterial has relatively good biological activity and can be applied to repairing of osseous tissues. The prepared biomaterial has good biological activity and mechanical property; the mechanical property is close to that of a cortical bone of a human body; the biomaterial is an ideal biological and medical material, can be used as a repairing material for a non-bearing bone part; the required raw materials are abundant; the preparation method is simple, flexible, and easy to operate; the product is easy to collect; energy consumption and product cost are low.

Owner:徐州博创建设发展集团有限公司

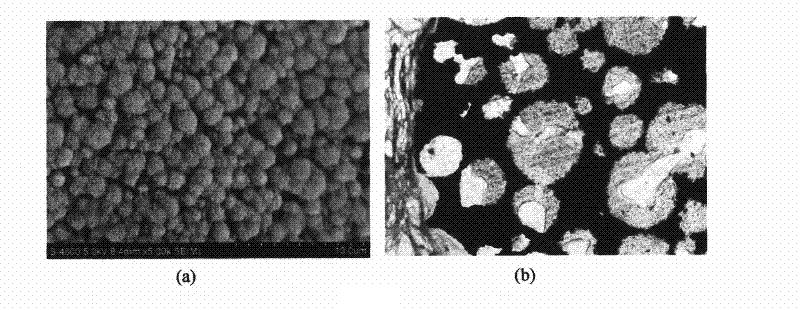

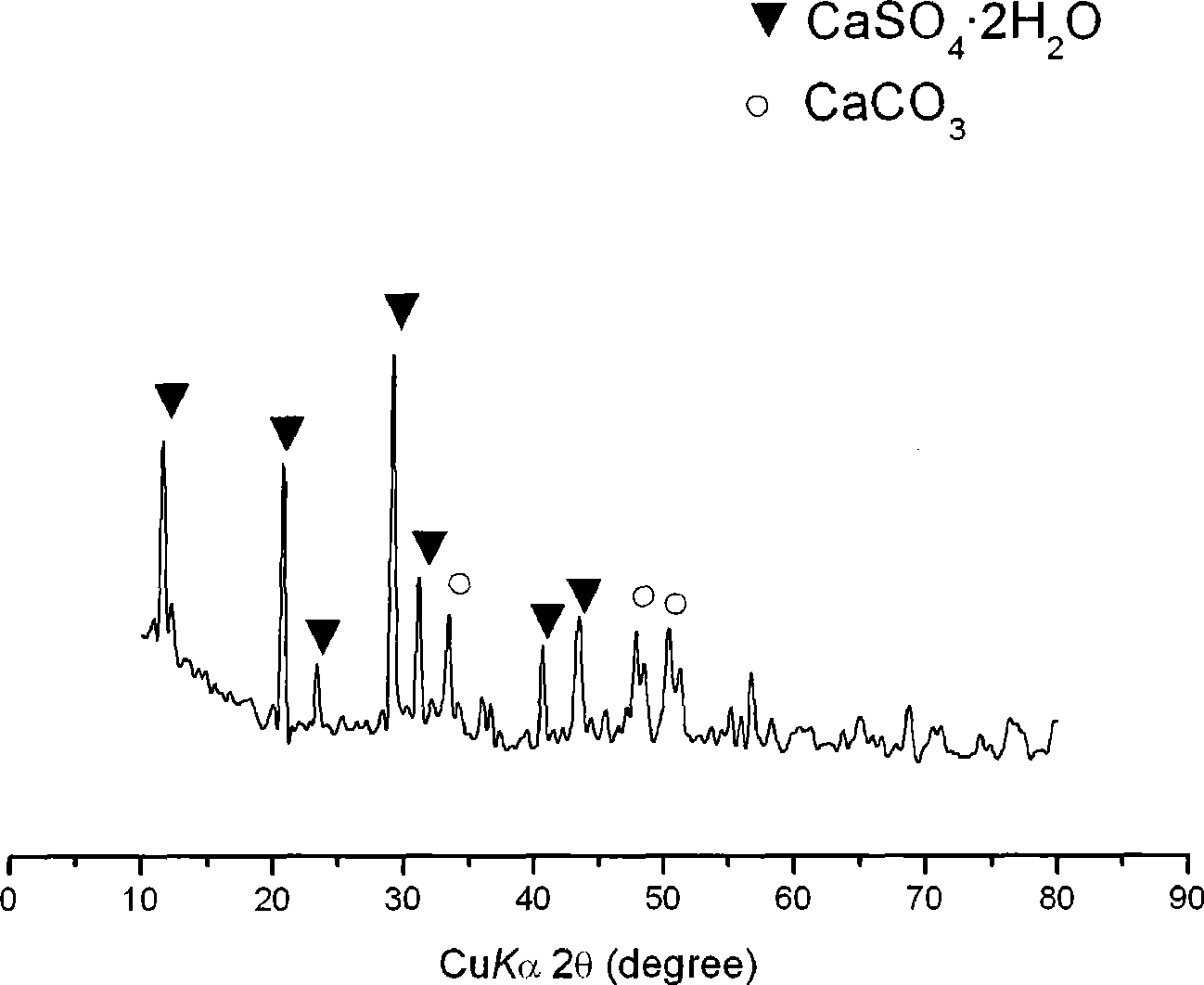

Method for simultaneously improving degradation rate and biological activity of iron-based implants

InactiveCN109925534APromote degradationGood biocompatibilityMetallic material coating processesProsthesisManufacturing technologyDrug biological activity

The invention relates to a method for simultaneously improving the degradation rate and biological activity of iron-based implants, which belongs to the technical field of biomedical implant design and manufacturing. A scheme is characterized in that iron powder and calcium sulfate are used as raw materials, through an alternative laser melting process, an iron-based implant is obtained, and the iron-based implant comprises the following components in mass percentage: 0.5-12% of calcium sulfate; and 88-99.5% of iron. The method solves the problem that the conventional iron-based implant degrades too slowly, and controls the degradation rate within a reasonable range; in addition, the calcium sulfate can form a bone-like apatite layer by degradation, forms good bone bonding with the tissue,and increases the biological activity of the iron-based implant. At the same time, the method can realize the uniform dispersion of calcium sulfate in an iron matrix and maintain the structural integrity by optimizing the preparation process, and fully exerts the effect of improving the degradation behavior and biological activity of the iron-based implant.

Owner:CENT SOUTH UNIV

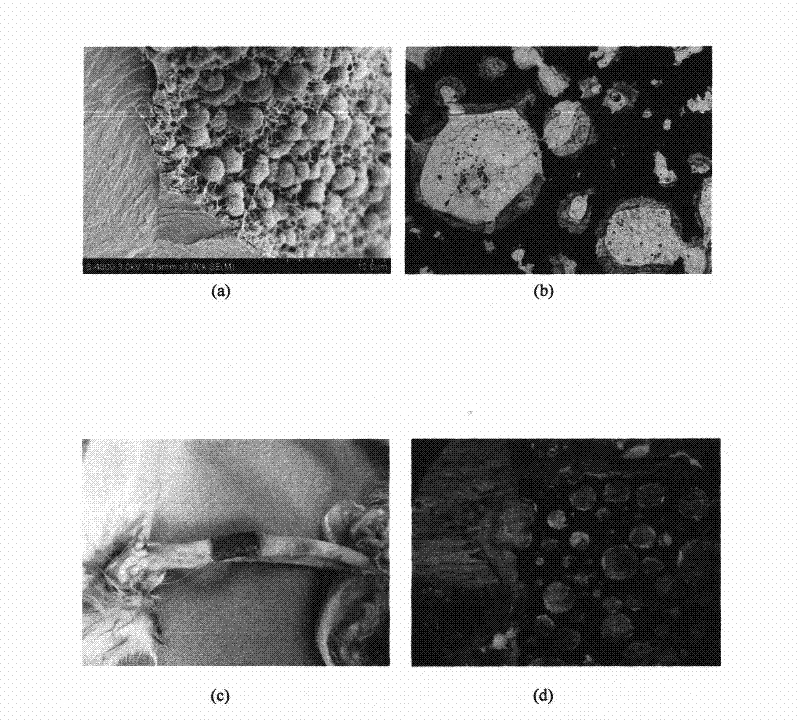

Method for enhancing disintegration resistance of calcium sulfate bone scaffold by utilization of bioglass

InactiveCN106693049AOvercoming the disadvantage of being easily disintegratedImprove mechanical propertiesProsthesisNatural boneSelective laser sintering

According to the invention, in the selective laser sintering process for preparation of the calcium sulfate bone scaffold, 45S5 bioglass is used as a binder so as to overcome the disadvantage that calcium sulfate is easy to disintegrate and further enhance mechanical property; by the utilization of 45S5 bioglass for coating crystal grain, degradation velocity of calcium sulfate is inhibited so as to achieve the purpose of delaying degradation; and by the characteristic that 45S5 bioglass is easy to bond natural bones, formation of a bone-like apatite layer on the surface of calcium sulfate is induced so as to promote extracellular responses. The method of the invention comprises the following steps: 1, dispersion of particles; 2, mixing of materials; and 3, selective laser sintering. The method of the invention has characteristics of simple preparation process, convenience in operation, low cost, good product performance and easy control of technical parameters.

Owner:CENT SOUTH UNIV

Preparation method of CaO-SiO2-CuO/PAA (porous anode alumina) composite biological membrane material

InactiveCN104274425APromote growthFast wayAntibacterial agentsInorganic active ingredientsApatiteHard tissue

The invention relates to a preparation method of a CaO-SiO2-CuO / PAA (positive anode alumina) composite biological membrane material. The preparation method of the CaO-SiO2-CuO / PAA composite biological membrane material comprises the following steps: firstly preparing CaO-SiO2-CuO sol by adopting an ultrasonic assisted sol-gel method, then loading the CaO-SiO2-CuO sol into nano pore passages of PAA under the ultrasonic and pressure induced conditions, drying, and roasting, so that the CaO-SiO2-CuO / PAA composite biological membrane material is obtained. The preparation method of the CaO-SiO2-CuO / PAA composite biological membrane material has the advantages that CaO-SiO2-CuO bioactive particles are successfully loaded in the nano pore passages of PAA, a bioactive surface which has bone-like apatite deposition inducing capability and also has effective antibacterial property and excellent cytocompatibility is constructed, and the bioactive surface is expected to be applied to the field of hard tissue repairing materials as a novel artificial implant material surface coating.

Owner:DONGHUA UNIV

Method for preparing bone-like apatite/polyamide composite material

The invention provides a preparing method of the bone-like apatite / polyamide composite material, which is characterized in that the mixture sizing agent of the bone-like apatite and water is mixed with the benzyl alcohol, which is heated and dehydrated under protection of the inert gas; after that, continuously in the conditions of the inert gas protection, the temperature of 160 DEG C to 180 DEG C and the stirring, the polyamide is added to completely dissolve the mixture and remove the benzyl alcohol; finally, the remains is completely washed by use of water and ethanol and dried in vacuum and under 120 DEG C. Without any additives, the preparing method of the present invention is simple and convenient and is good for ensuring that the calcium-phosphor proportion of the obtained bone-like apatite / polyamide composite material does not change; moreover, compared with the charge calculation, the apatite content of the composite material has good exactness, repeatability and stability, and the compositions have perfect uniformity and high purity, which contains no impurity, promising the yield over 98 percent.

Owner:SICHUAN GUONA TECH

Stable pure monocline zirconium oxide coating in low-temperature, production method and application thereof

InactiveCN101219239AImprove biological activityImprove performanceMolten spray coatingTitanium alloyDrug biological activity

The invention relates to a pure monoclinic zirconia coating which is stable at low temperature, a preparation method thereof and application thereof. The invention is characterized in that titanium alloy is used as a matrix; the zirconia coating is composed of monoclinic zirconia which is stable at low temperature, specifically, lower than 100 DEG C and equal to or high than the temperature province of human body environment. The zirconia coating which is stable at the low temperature is characterized in that: the binding strength of the zirconia coating and the titanium alloy is between 20 and 40MPa; the zirconia coating has a dense surface without crackles; market monoclinic zirconia powder is adopted as raw material, pretreated with ball mill, and spheroidized or not spheroidized, and then the monoclinic zirconia coating being stable at low temperature is prepared by directly adopting a plasma spraying process. The provided coating has excellent biological activity, can stably exist in body environment, and is used as a surface coating of artificial implants. The surface of the coating can induce the formation of bone-like apatite in simulated body fluid.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com