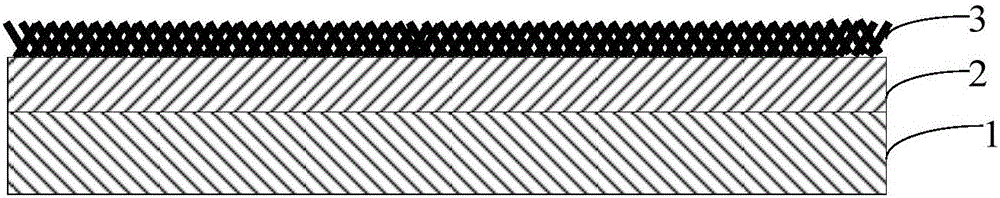

Preparation method of tin dioxide electroactive biological ceramic coating composited on surface of micro-arc oxidation titanium

A technology of tin dioxide and surface compounding, applied in the direction of surface reaction electrolytic coating, coating, electrolytic coating, etc., can solve the problem of weak biological activity of titanium and its alloy surface coating, achieve good biological activity, simple process, The effect of enhancing biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

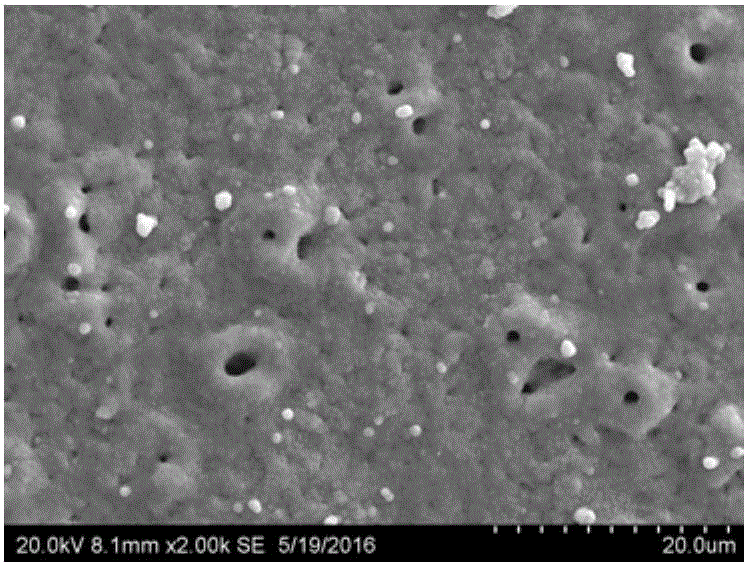

[0030] 1) Micro-arc oxidation treatment: NaOH and β-C 3 h 7 Na 2 o 6 P is added to water to form an electrolyte; the concentration of NaOH in the electrolyte is 1g / L, β-C 3 h 7 Na 2 o 6 The concentration of P is 25g / L; the titanium sample is used as the anode, the electrolyte is added to the stainless steel tank, and the stainless steel tank is used as the cathode, and the titanium sample is placed in the electrolyte at 30°C for micro-arc oxidation. The arc oxidation parameters are as follows: the micro-arc oxidation adopts pulse voltage, the positive voltage is 250V, the negative voltage is 80V, the micro-arc oxidation pulse frequency is 500Hz, the duty cycle of the micro-arc oxidation is 15%, and the micro-arc oxidation time is 10min. Arc oxidation titanium sample; wherein, the titanium sample is TA2 industrial pure titanium.

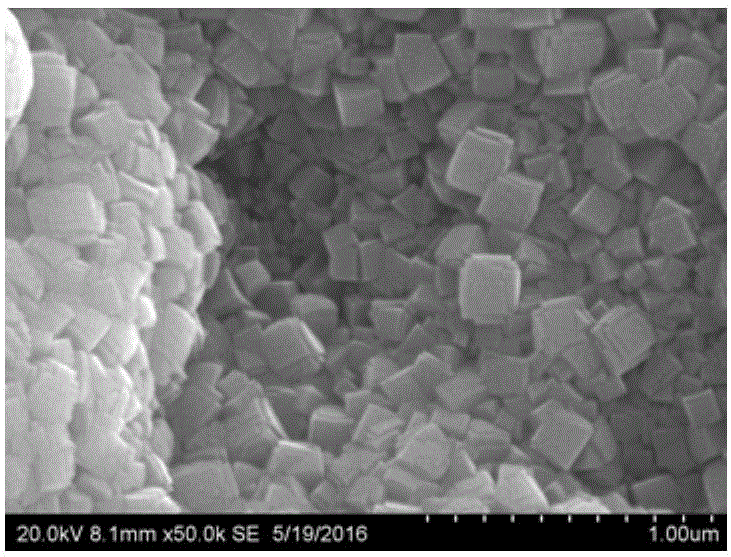

[0031] 2) hydrothermal treatment: adding tin salt, sodium hydroxide, water and alcohol into water to form a mixed solution, the concentration ...

Embodiment 2

[0035] 1) Micro-arc oxidation treatment: NaOH and β-C 3 h 7 Na 2 o 6P is added to water to form an electrolyte; the concentration of NaOH in the electrolyte is 10g / L, β-C 3 h 7 Na 2 o 6 The concentration of P is 30g / L; the titanium sample is used as the anode, the electrolyte is added to the stainless steel tank, and the stainless steel tank is used as the cathode, and the titanium sample is placed in the electrolyte at 20°C for micro-arc oxidation. Arc oxidation parameters are as follows: micro-arc oxidation adopts pulse voltage, positive voltage is 500V, negative voltage is 100V, micro-arc oxidation pulse frequency is 200Hz, duty cycle of micro-arc oxidation is 6%, micro-arc oxidation time is 8min, and micro-arc oxidation is obtained. Arc oxidation titanium sample; wherein, the titanium sample is TA3 industrial pure titanium.

[0036] 2) hydrothermal treatment: adding tin salt, sodium hydroxide, water and alcohol into water to form a mixed solution, the concentration ...

Embodiment 3

[0039] 1) Micro-arc oxidation treatment: NaOH and β-C 3 h 7 Na 2 o 6 P is added to water to form an electrolyte; the concentration of NaOH in the electrolyte is 15g / L, β-C 3 h 7 Na 2 o 6 The concentration of P is 15g / L; the titanium sample is used as the anode, the electrolyte is added to the stainless steel tank, and the stainless steel tank is used as the cathode, and the titanium sample is placed in the electrolyte at 10°C for micro-arc oxidation. Arc oxidation parameters are as follows: micro-arc oxidation adopts pulse voltage, positive voltage is 550V, negative voltage is 30V, micro-arc oxidation pulse frequency is 800Hz, duty cycle of micro-arc oxidation is 30%, micro-arc oxidation time is 5min, and micro-arc oxidation is obtained. Arc oxidation titanium sample; wherein, the titanium sample is TA4 industrial pure titanium.

[0040] 2) Hydrothermal treatment: adding tin salt, sodium hydroxide, water and alcohol into water to form a mixed solution, the concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Surface thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com