Method of preparing titanium implant having bioelectricity activity by carrying out water-vapor treatment on tin-bearing microarc oxidation coating

A technology of micro-arc oxidation and titanium implants, which is applied in the direction of coating, surface reaction electrolytic coating, metal material coating technology, etc., can solve the problem of weak biological activity of titanium micro-arc oxidation coating, achieve good biological activity, Simple process and improved biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

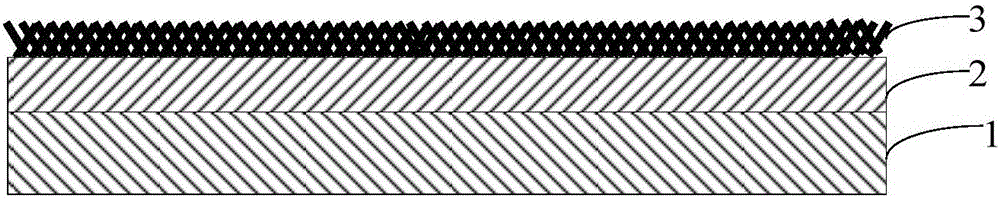

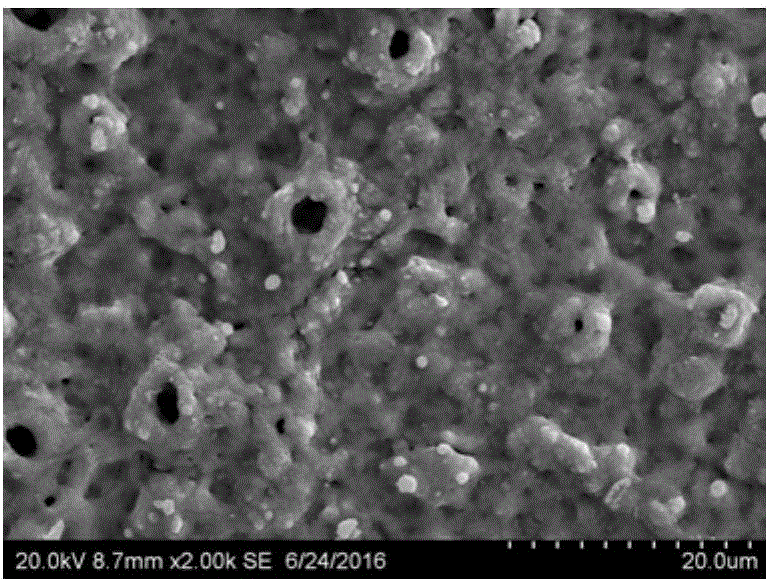

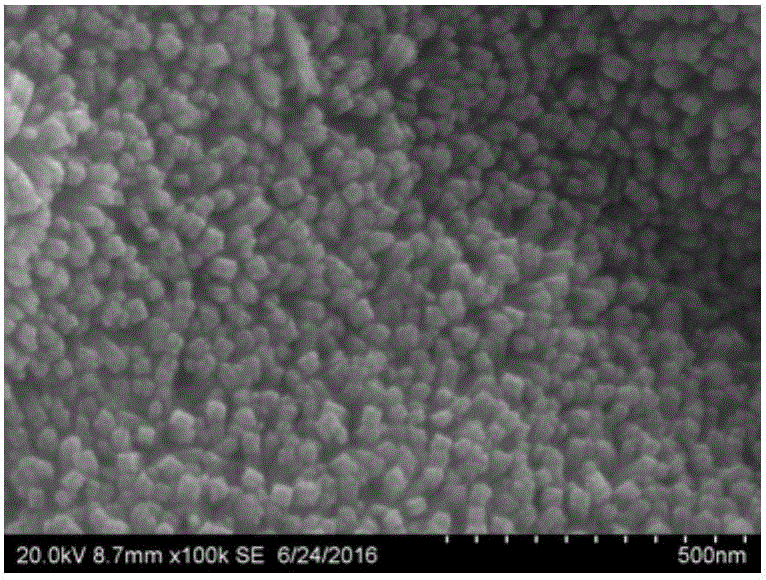

[0033] 1) Micro-arc oxidation treatment: Add sodium stannate, sodium hydroxide and sodium β-glycerophosphate into water to obtain a mixed solution, use the mixed solution as the electrolyte, use the titanium sample as the anode, and use the stainless steel tank as the cathode; The electrolyte is added to the stainless steel tank, and the titanium sample is placed in the electrolyte at 0°C for micro-arc oxidation. The micro-arc oxidation uses pulse voltage, the positive voltage is 250V, the negative voltage is 70V, and the pulse frequency of the micro-arc oxidation is 700Hz, the duty ratio of the micro-arc oxidation is 30%, the micro-arc oxidation time is 5min, a micro-porous micro-arc oxidation coating is formed on the surface of the titanium sample, and a tin-containing micro-arc oxidation titanium sample is obtained; wherein, the mixed The concentration of sodium stannate in the solution is 0.01mol / L, the concentration of sodium hydroxide is 0.1mol / L, the concentration of β-s...

Embodiment 2

[0038]1) Micro-arc oxidation treatment: Add sodium stannate, sodium hydroxide and sodium β-glycerophosphate into water to obtain a mixed solution, use the mixed solution as the electrolyte, use the titanium sample as the anode, and use the stainless steel tank as the cathode; The electrolyte is added to the stainless steel tank, and the titanium sample is placed in the electrolyte at 10°C for micro-arc oxidation. The pulse voltage is used for the micro-arc oxidation, the positive voltage is 550V, the negative voltage is 40V, and the pulse frequency of the micro-arc oxidation is 800Hz, the duty ratio of the micro-arc oxidation is 6%, the micro-arc oxidation time is 10min, a micro-porous micro-arc oxidation coating is formed on the surface of the titanium sample, and a tin-containing micro-arc oxidation titanium sample is obtained; wherein, the mixed The concentration of sodium stannate in the solution is 1mol / L, the concentration of sodium hydroxide is 0.6mol / L, the concentratio...

Embodiment 3

[0042] 1) Micro-arc oxidation treatment: Add sodium stannate, sodium hydroxide and sodium β-glycerophosphate into water to obtain a mixed solution, use the mixed solution as the electrolyte, use the titanium sample as the anode, and use the stainless steel tank as the cathode; The electrolyte is added to the stainless steel tank, and the titanium sample is placed in the electrolyte at 40°C for micro-arc oxidation. The micro-arc oxidation uses pulse voltage, the positive voltage is 300V, the negative voltage is 0V, and the pulse frequency of the micro-arc oxidation is 200Hz, the duty cycle of the micro-arc oxidation is 15%, the micro-arc oxidation time is 15min, a micro-porous micro-arc oxidation coating is formed on the surface of the titanium sample, and a tin-containing micro-arc oxidation titanium sample is obtained; wherein, the mixed The concentration of sodium stannate in the solution is 0.08mol / L, the concentration of sodium hydroxide is 0.01mol / L, the concentration of β...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com