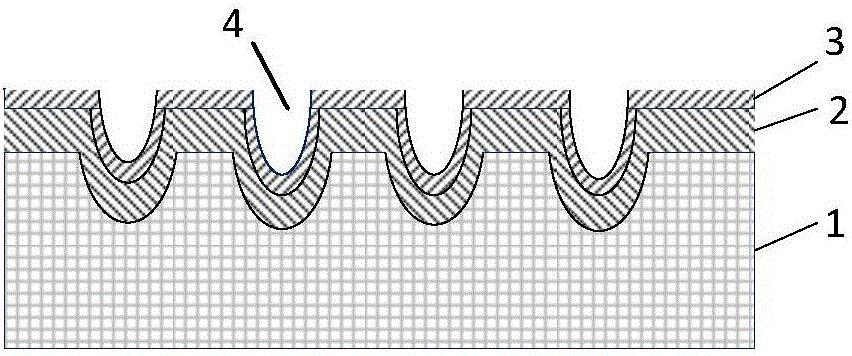

Preparation method of bioelectricity activity implant with multistage composite structure

A composite structure and bioelectric technology, applied in the direction of prosthesis, electrolytic coating, superimposed layer plating, etc., can solve the problem of poor biological activity of the coating, and achieve the effect of strong interface binding force, improved biological activity, and tight combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

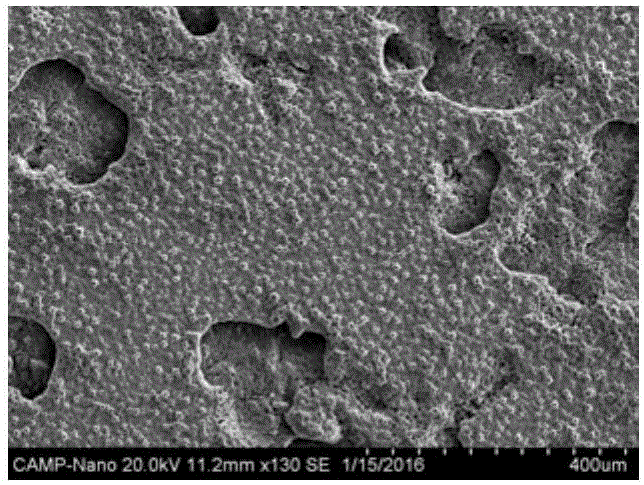

[0037] 1) One-time micro-arc corrosion oxidation: Add the electrolyte solution containing chloride ions into the stainless steel tank, put the titanium sample into the electrolyte solution containing chloride ions at 20°C, use the titanium sample as the positive electrode, and use the stainless steel tank body As the negative electrode, perform micro-arc oxidation. The parameters of micro-arc oxidation are as follows: under the conditions of current 4A, working frequency 900 Hz and duty cycle 15%, micro-arc oxidation is performed for 15 minutes to obtain a titanium sample with grooves on the surface; Wherein, the electrolyte solution containing chloride ions is prepared by adding sodium chloride and sodium hydroxide to water, the concentration of sodium hydroxide in the electrolyte solution is 0.01mol / L, and the concentration of sodium chloride is 0.5mol / L. The titanium sample is TA2 industrial pure titanium;

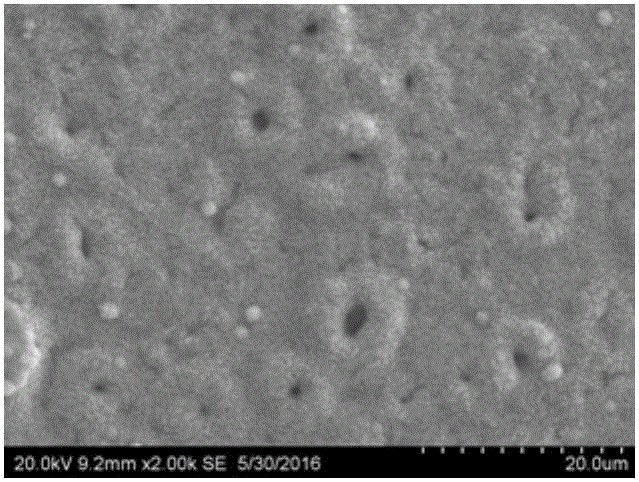

[0038] 2) Secondary micro-arc oxidation treatment: NaOH and β-C 3...

Embodiment 2

[0043] 1) One-time micro-arc corrosion oxidation: Add the electrolyte solution containing chloride ions into the stainless steel tank, put the titanium sample into the electrolyte solution containing chloride ions at 30°C, use the titanium sample as the positive electrode, and use the stainless steel tank body As the negative electrode, perform micro-arc oxidation. The parameters of micro-arc oxidation are as follows: under the conditions of current being 5A, operating frequency being 700Hz and duty ratio being 4%, micro-arc oxidation is carried out for 5min to obtain a titanium sample with grooves on the surface; Wherein, the electrolytic solution containing chloride ions is prepared by adding potassium chloride and sodium hydroxide to water, the concentration of sodium hydroxide in the electrolytic solution is 0.1 mol / L, and the concentration of potassium chloride is 0.08 mol / L. The titanium sample is TA3 industrial pure titanium;

[0044] 2) Secondary micro-arc oxidation tr...

Embodiment 3

[0048] 1) One-time micro-arc corrosion oxidation: Add the electrolyte solution containing chloride ions into the stainless steel tank, put the titanium sample into the electrolyte solution containing chloride ions at 40°C, use the titanium sample as the positive electrode, and use the stainless steel tank body As the negative electrode, perform micro-arc oxidation. The parameters of micro-arc oxidation are as follows: under the conditions of current of 7A, operating frequency of 400Hz and duty cycle of 10%, micro-arc oxidation is performed for 10 minutes to obtain a titanium sample with grooves on the surface; Wherein, the electrolytic solution containing chloride ions is prepared by adding potassium chloride and sodium hydroxide to water, the concentration of sodium hydroxide in the electrolytic solution is 0.5 mol / L, and the concentration of potassium chloride is 0.01 mol / L. The titanium sample is TA4 industrial pure titanium;

[0049] 2) Secondary micro-arc oxidation treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com