Bone substitute material for Ca3ZrSi2O9 coating-titanium alloy and preparation method of bone substitute material

A technology for replacing materials and titanium alloys, applied in the fields of coating, metal material coating technology, medical science, etc., can solve problems such as affecting bone tissue reconstruction, affecting long-term stability, and increasing pH value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

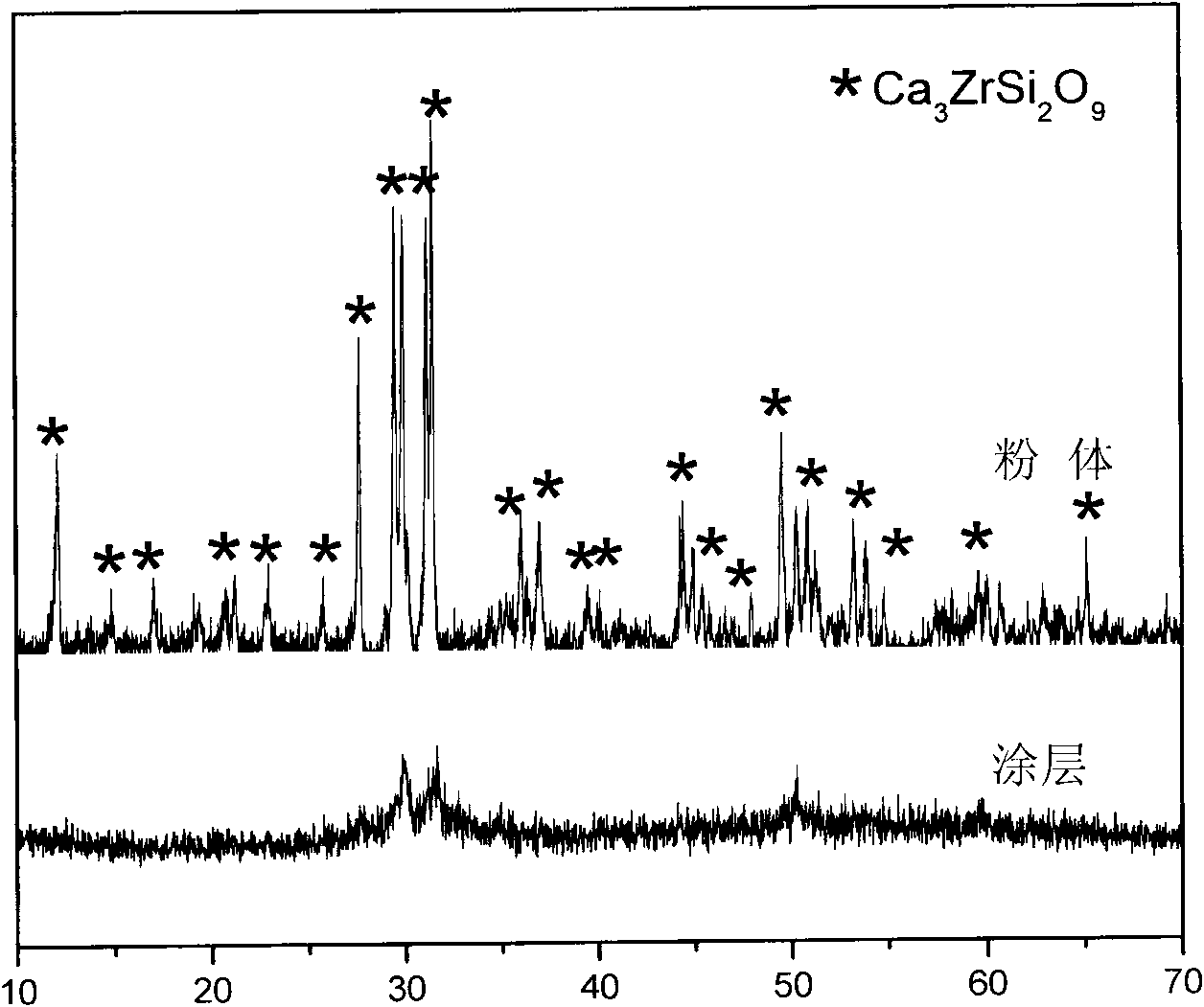

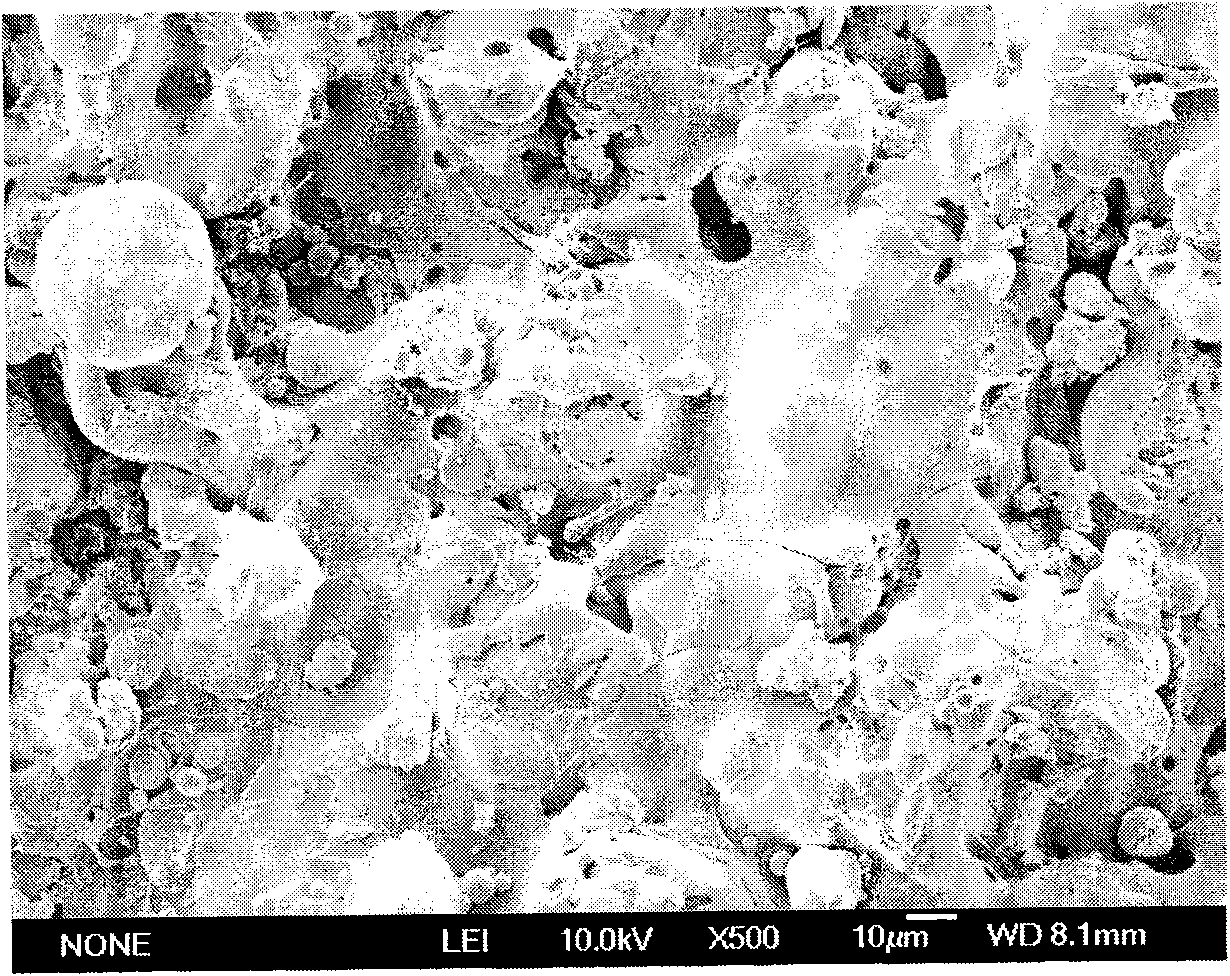

[0021] will analyze pure CaCO 3 , SiO 2 And commercially available high-purity ZrO 2 (produced by Hangzhou Wanjing New Material Co., Ltd., content 99.99%) according to the molar ratio of 3: 2: 1 ingredients, ball milling and mixing in water medium for 8 hours, after drying at 110 ° C, put it in a corundum crucible, and use 5 ° C / min The heating rate was raised from room temperature to 1400 °C, kept for 6 hours, and the furnace was cooled to room temperature to obtain Ca 3 ZrSi 2 o 9 For powder, after grinding, sieve the powder between 80 mesh and 200 mesh, and the particle size range of the powder is 5-60 μm. The above-mentioned sieved powder and 5wt% PVA aqueous solution are uniformly mixed at a ratio of 9:1 (mass ratio), dried and ground through an 80-mesh sieve to obtain Ca with good fluidity. 3 ZrSi 2 o 9 Powder, particle size between 10-150μm.

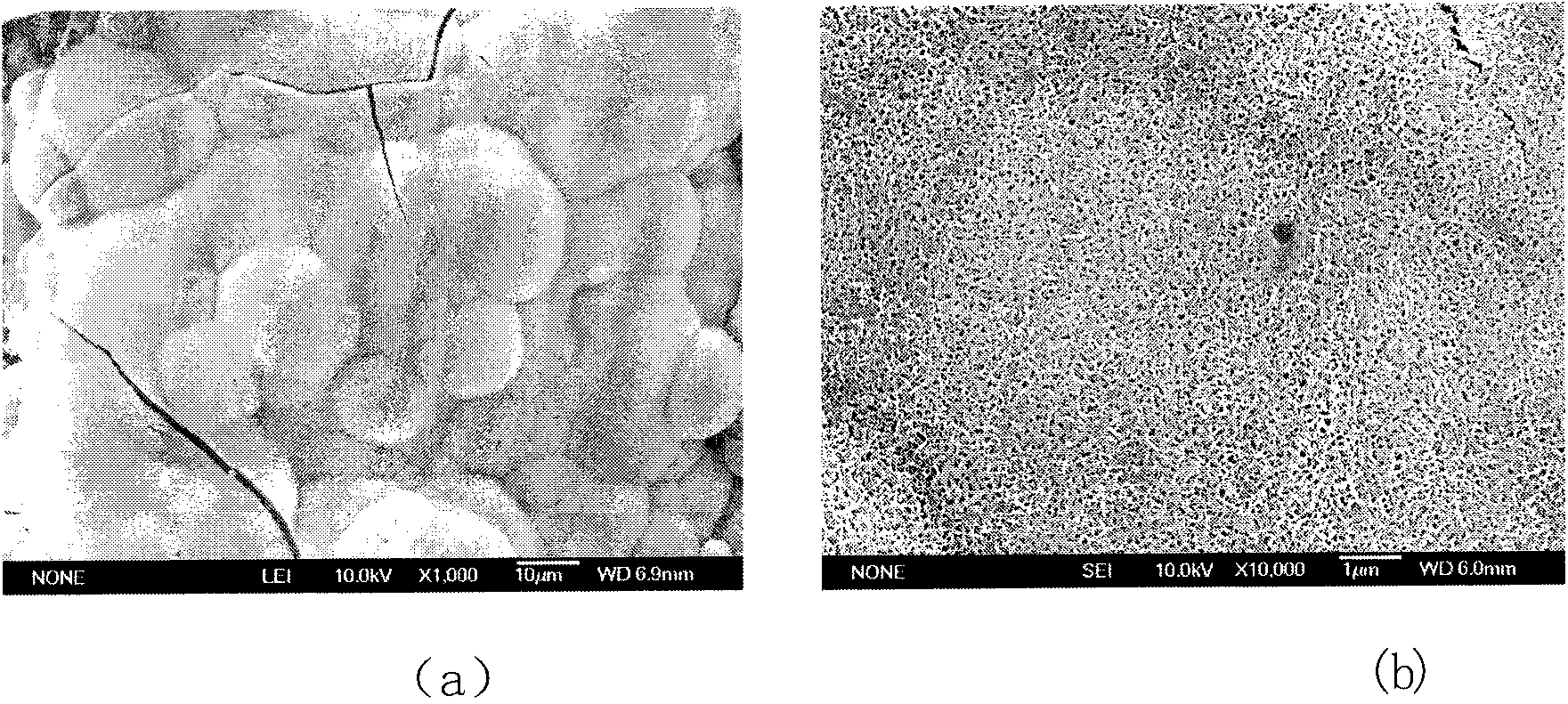

[0022] Preparation of Ca on cleaned and blasted Ti-6Al-4V substrates by atmospheric plasma spraying 3 ZrSi 2 o 9 Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com