Stable pure monocline zirconium oxide coating in low-temperature, production method and application thereof

A low-temperature stable, zirconia technology, used in coatings, metal material coating processes, fusion spraying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The monoclinic ZrO used 2 The chemical composition of the raw material is as shown in Table 1. It is produced by Pan-Meiya (Jiujiang) High-Tech Materials Co., Ltd., and the preparation process of the coating is as follows:

[0030] 1) Calcination of zirconia powder

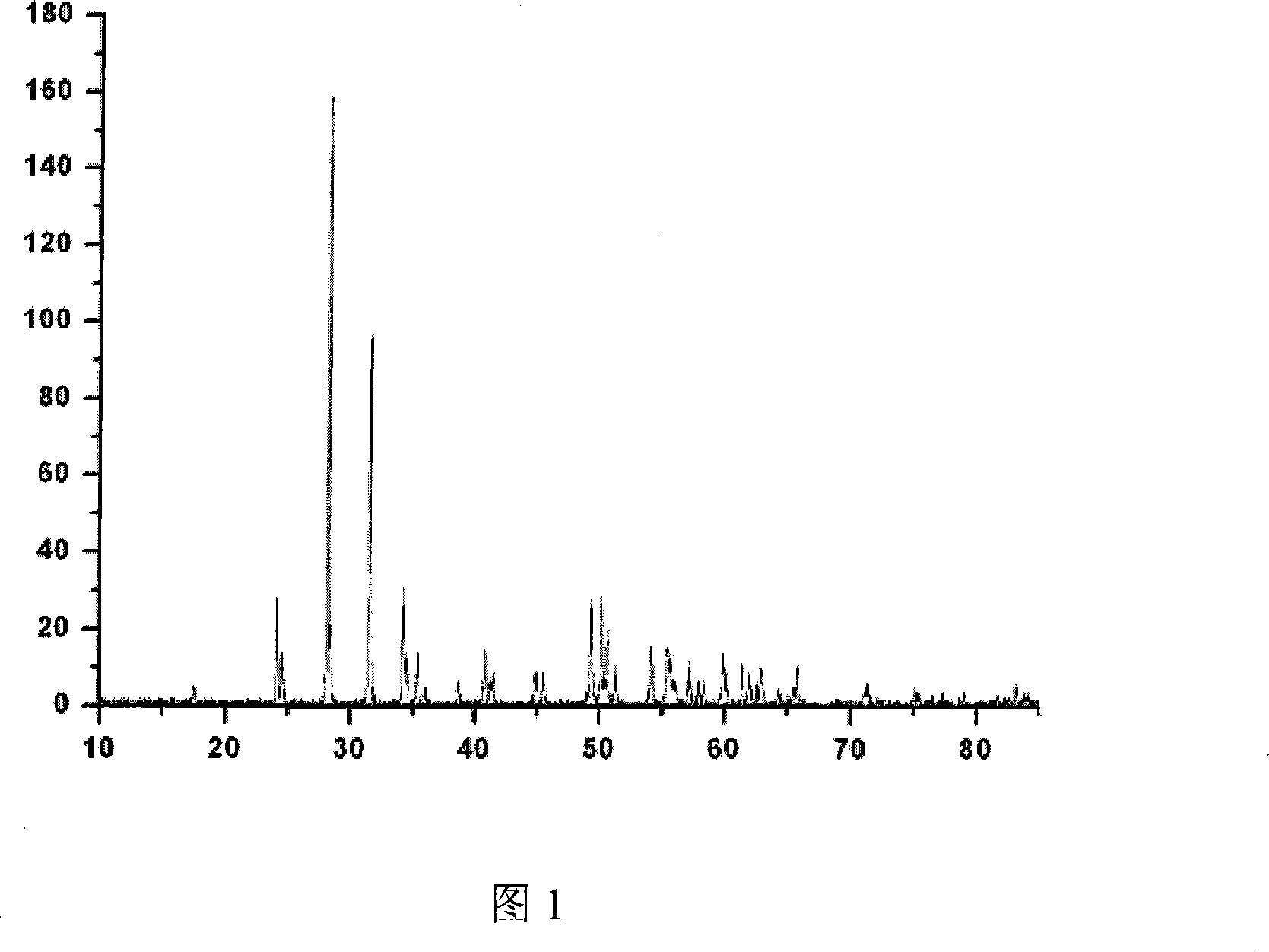

[0031] The zirconia powder is sintered in the atmosphere, the sintering parameters are as follows, heating rate: 5°C / min, sintering temperature: 1550°C, holding time: 12h. After the sintered powder is ball milled, the powder between 80 mesh and 180 mesh is sieved, the powder particle size ranges from 83 to 198 μm, and the sintered powder is composed of monoclinic phase. (figure 1)

[0032] 2) Coating preparation

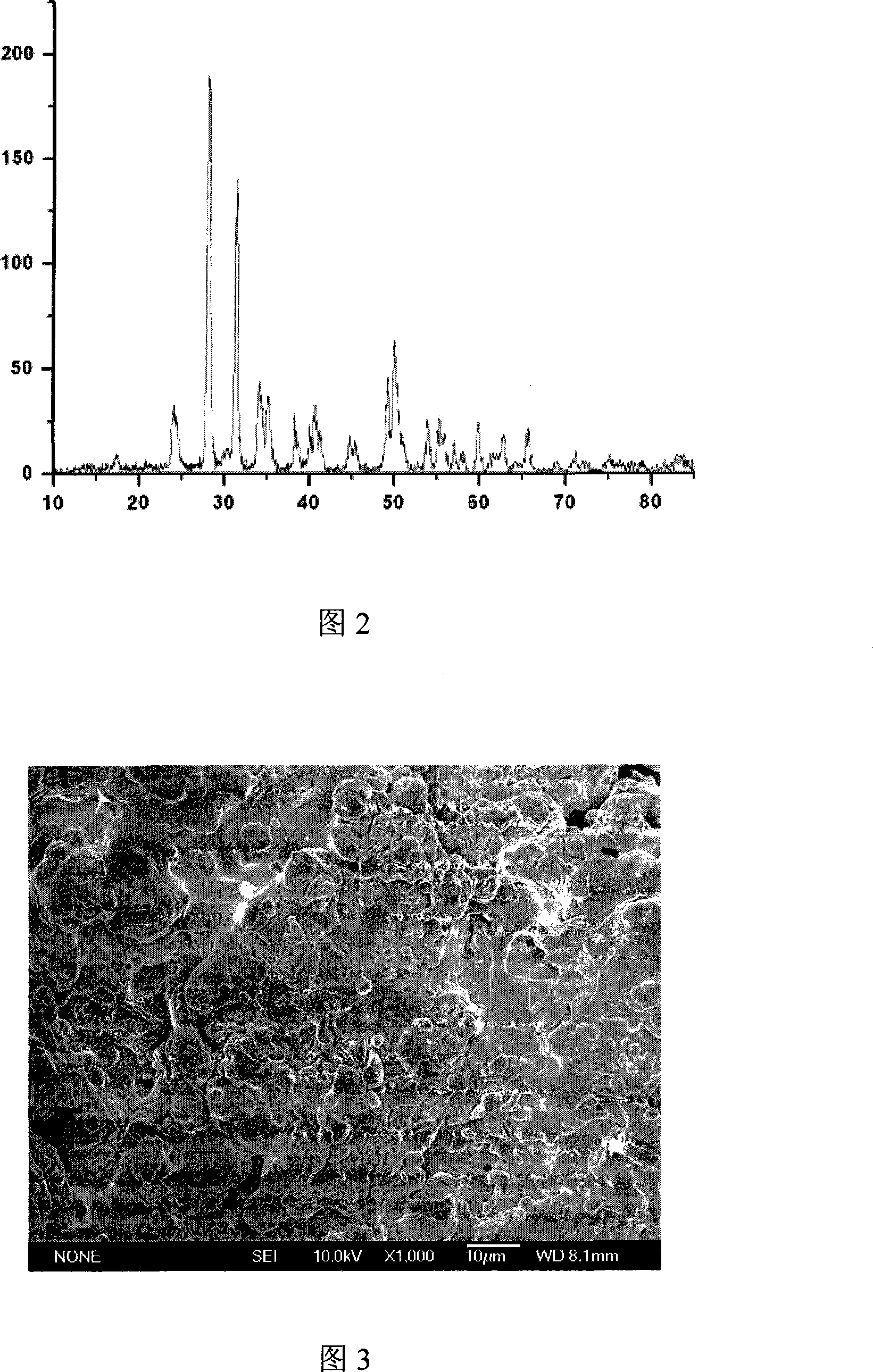

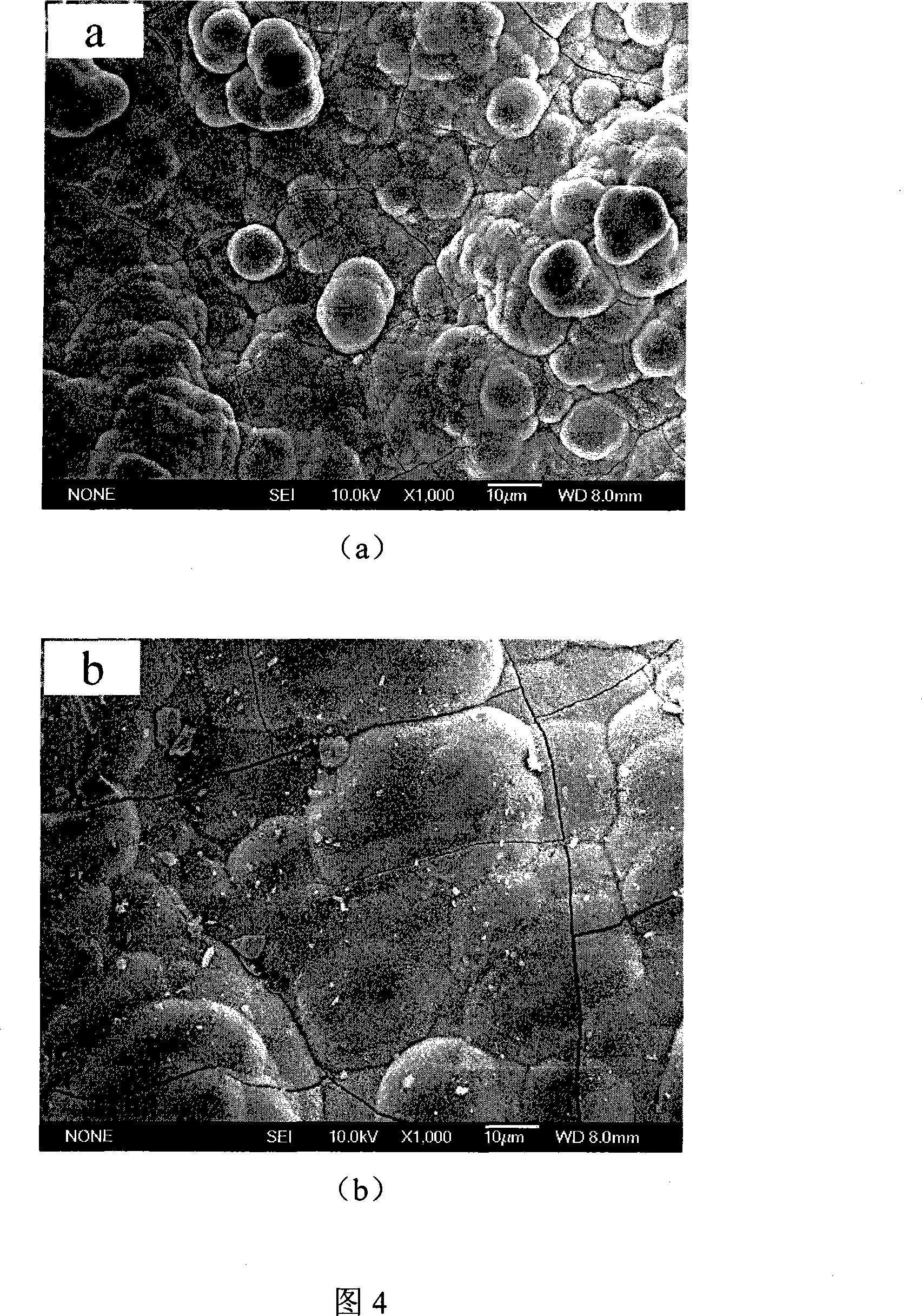

[0033] Zirconia coatings were prepared on cleaned and sandblasted titanium alloy substrates by atmospheric plasma spraying. Spraying parameters are listed in Table 4. The coating after spraying is still composed of monoclinic zirconia (Figure 2), and the surface of the coating is dense withou...

Embodiment 2

[0037] The pre-fired powder in Example 1 was ground and passed through an 80-mesh sieve, and the sieve residue was taken as the original powder for plasma spheroidization. The zirconia powder was sprayed into deionized water by plasma spraying technology to obtain zirconia powder with good spheroidization effect, and the spheroidization parameters are shown in Table 5. The coating preparation method and process are the same as in Example 1. The crystal phase of the coating is monoclinic zirconia. The bonding strength of the zirconia coating prepared with spheroidized powder and the titanium alloy substrate is about 40MPa measured by ASTM 633-79 method, which shows that the plasma spheroidization process can significantly improve the bonding strength of the coating and the substrate. In addition, the coating can well induce the deposition of hydroxyapatite in simulated body fluid, and has excellent biological activity.

[0038] Table 5 Plasma spheroidization parameters

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com