Preparation method of CaO-SiO2-CuO/PAA (porous anode alumina) composite biological membrane material

A cao-sio2-cuo, biofilm technology, applied in the direction of medical preparations containing active ingredients, drug combinations, pharmaceutical formulations, etc., can solve the problems of bacterial death, microbial loss of division and proliferation, interference with DNA synthesis, etc., to achieve the method Fast, promotes osteoblast growth, good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] (1) SiO 2 Preparation of sol: Mix 10.65ml of deionized water with 0.1ml of 2mol / L nitric acid, stir to make it uniform, then add dropwise the aqueous solution acidified by nitric acid to 21.32ml of tetraethyl orthosilicate while stirring, Continued to form SiO 2 Sol; (the volume ratio of ethyl orthosilicate, deionized water and nitric acid is 1:0.5:0.005)

[0066] (2) Mix 31.9ml of 0mol / L copper nitrate solution with 60ml of 2mol / L calcium nitrate solution, and stir to make it evenly mixed;

[0067](3) Slowly add the mixed solution of copper and calcium nitrate to the SiO in (1) 2 In the sol, keep magnetic stirring to make it fully react for 65 minutes, and the reaction temperature is controlled at 20°C; (CaO-SiO 2 -The mass percent of CuO three components is 55:46:0)

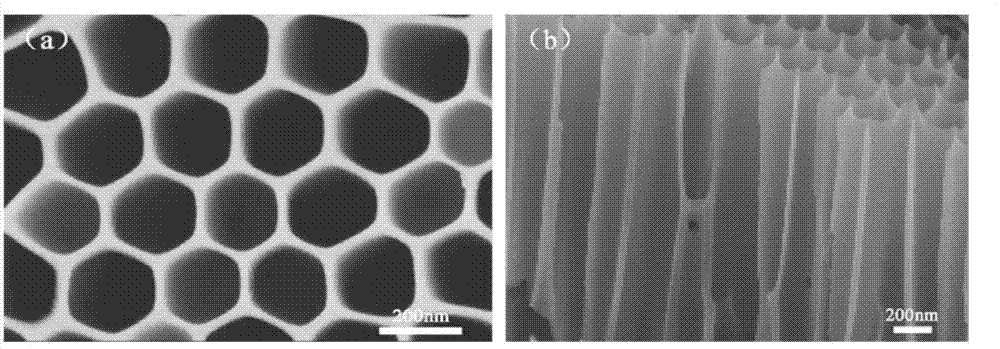

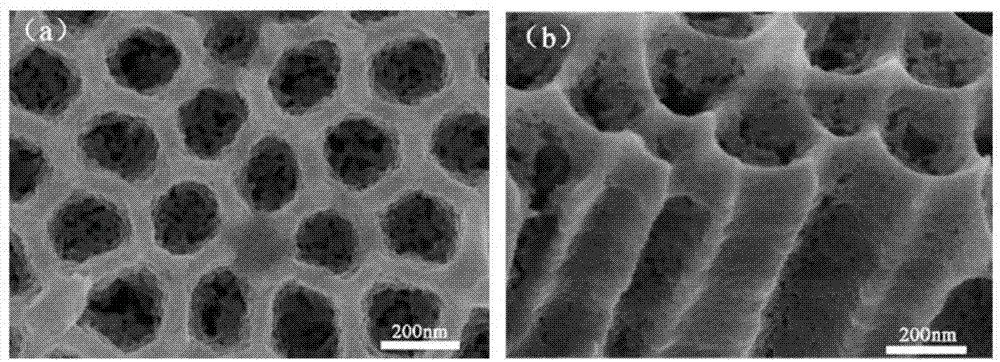

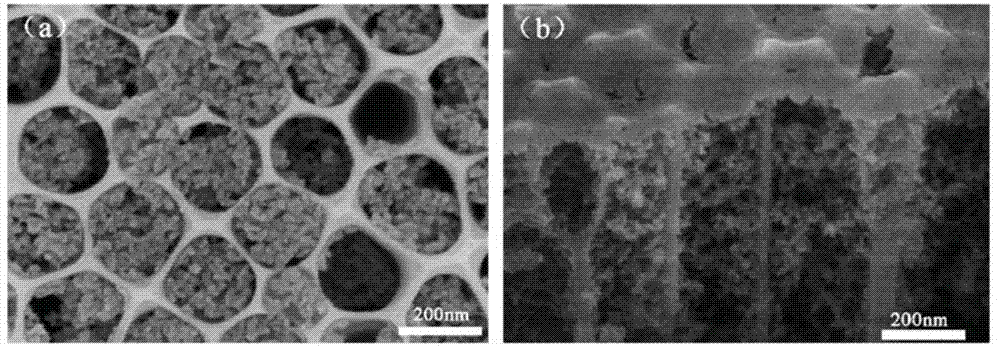

[0068] (4) Place the PAA film with a pore size of 200nm in the above-prepared sol and perform ultrasonic treatment for 15 minutes, then transfer it to a vacuum drying oven, and maintain it for 30 min...

Embodiment 2

[0078] (1) SiO 2 Preparation of sol: Mix 13.7ml of deionized water with 0.15ml of 2mol / L nitric acid, stir to make it uniform, then add dropwise the aqueous solution of nitric acid acidification to 15.8ml of orthosilicate methyl ester while stirring. continuation, eventually forming SiO 2 Sol; (the volume ratio of methyl orthosilicate, deionized water and nitric acid is 1:0.87:0.009)

[0079] (2) Mix 32.2ml of 0.1mol / L copper nitrate solution with 40ml of 3mol / L calcium nitrate solution, and stir to make it evenly mixed;

[0080] (3) Slowly add the mixed solution of copper and calcium nitrate to the SiO in (1) 2 In the sol, keep magnetic stirring to make it fully react for 40 minutes, and the reaction temperature is controlled at 30 °C; (CaO-SiO 2 -The mass percent of CuO three components is 50:40:2)

[0081] (4) Place the PAA film with a pore size of 200nm in the above-prepared sol and transfer it to a vacuum drying oven for ultrasonic treatment for 15 minutes, then trans...

Embodiment 3

[0090] (1) SiO 2 Preparation of sol: mix 26.6ml of deionized water with 0.29ml of 2mol / L nitric acid, stir to make it uniform, then add dropwise the aqueous solution acidified by nitric acid to 26.6ml of tetraethyl orthosilicate while stirring, Continued to form SiO 2 Sol; (the volume ratio of ethyl orthosilicate, deionized water and nitric acid is 1:1:0.01)

[0091] (2) Mix 8.81ml of 0.2mol / L copper nitrate solution with 30ml of 4mol / L calcium nitrate solution, and stir to make it evenly mixed;

[0092] (3) Slowly add the mixed solution of copper and calcium nitrate to the SiO in (1) 2 In the sol, keep magnetic stirring to make it fully react for 50 minutes, and the reaction temperature is controlled at 40°C; (CaO-SiO 2 -The mass percent of CuO three components is 45:55:3)

[0093] (4) Place the PAA film with a pore size of 250nm in the above-prepared sol and transfer it to a vacuum oven for 4 hours at a relative vacuum of 0.1MPa;

[0094] (5) Take out the obtained sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com