Fluoro-calcium silicate biological ceramic material and preparation method and application thereof

A bioceramic material, the technology of calcium fluoride-based silicate, which can be used in applications, other household appliances, dental preparations, etc., can solve the problems of inducing apatite, etc., and achieve the effect of simple production and good biological activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Take 236 grams (1 mole) of calcium nitrate tetrahydrate (Ca(NO 3 ) 2 4H 2 O) (analytically pure) was dissolved in 5000 ml of deionized water to make a solution, and stirred on a magnetic stirrer, and 284 grams (1 mole) of sodium silicate nonahydrate (Na 2 SiO 3 9H 2 O) (analytical grade) and 2.96 g (0.08 mol) of ammonium fluoride (NH 4 F) (analytical pure) made into a mixed solution,

[0029] (2) Slowly add the mixed solution to the calcium nitrate solution at 15 drops per minute, stir while dripping, continue stirring for 1 hour after dropping, and then age at room temperature for 24 hours.

[0030] (3) Filter out the supernatant, wash the precipitate with deionized water for 3 times, dehydrate with ethanol for 3 times, and then dry it in an oven at 70°C for 24 hours;

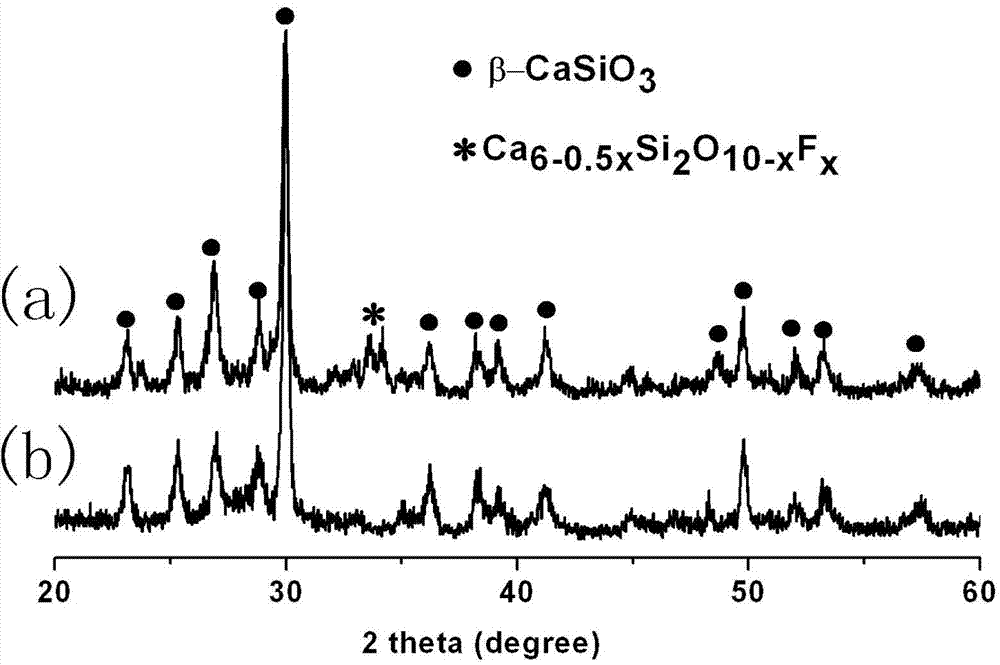

[0031] (4) Calcining the dried white powder at 700°C for 2 hours to obtain calcium fluoride silicate powder.

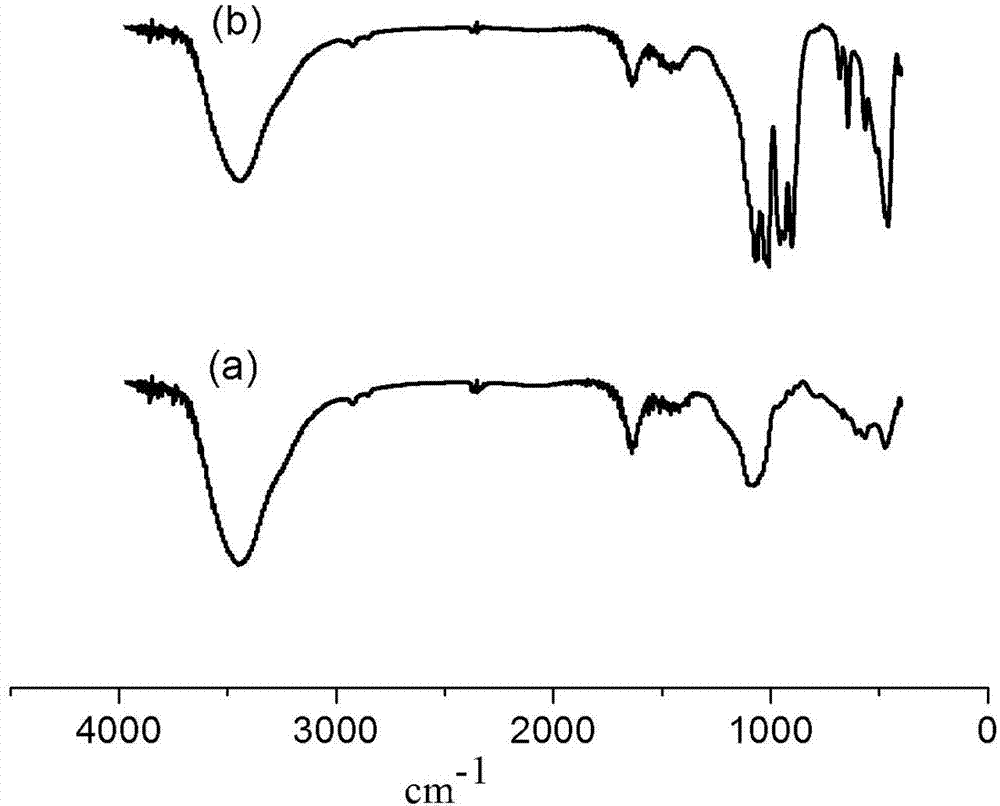

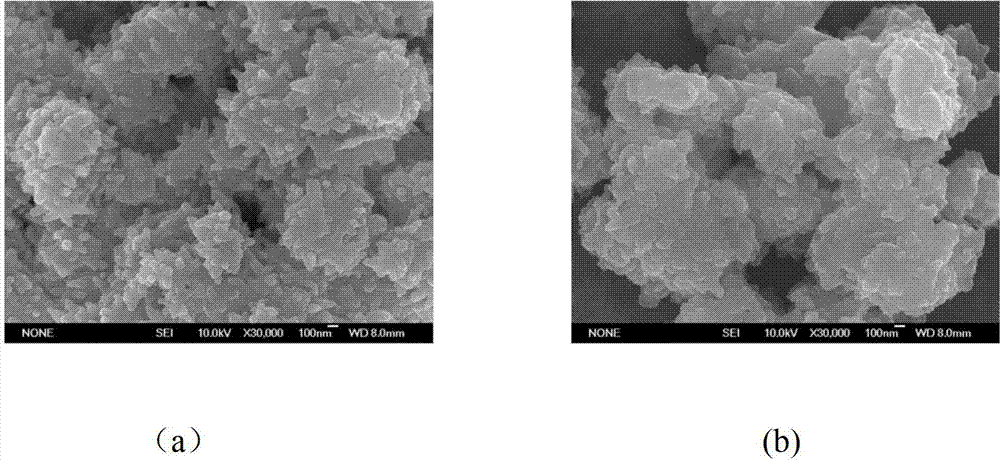

[0032] Take the fluorine-containing calcium silicate powder sample prepared abov...

Embodiment 2

[0041] (1) Take 111 grams (1 mole) of calcium chloride (CaCl 2 ) (analytically pure) was dissolved in 5000 ml of deionized water to make a solution, and stirred on a magnetic stirrer, and 117 grams (0.96 moles) of sodium silicate (Na 2 SiO 3 ) (analytical pure) and 0.84 g (0.02 mol) sodium fluoride (NaF) (analytical pure) to make a mixed solution,

[0042] (2) Slowly add the mixed solution to the calcium nitrate solution at 15 drops per minute, stir while dripping, continue stirring for 1.5 hours after the dripping, and then age at room temperature for 22 hours.

[0043] (3) Filter out the supernatant, wash the precipitate with deionized water for 3 times, dehydrate with ethanol for 3 times, and then dry it in an oven at 70°C for 24 hours;

[0044] (4) Calcining the dried white powder at 650°C for 2.2 hours to obtain fluorine-containing calcium silicate powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com