Method for simultaneously improving degradation rate and biological activity of iron-based implants

A technology of degradation rate and biological activity, which is applied in the field of biomedical implant design and manufacturing, can solve the problems of poor biological activity and slow degradation of iron-based implants, and achieve reduced mechanical properties, good biocompatibility and, The effect of accelerating bone healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

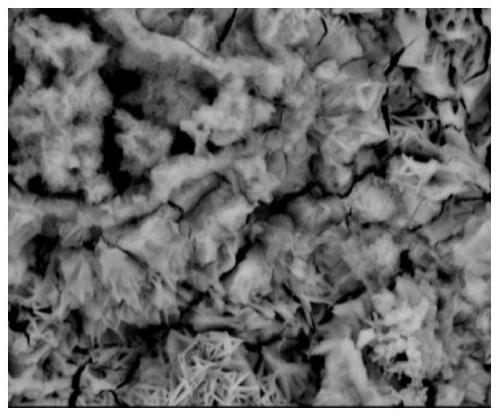

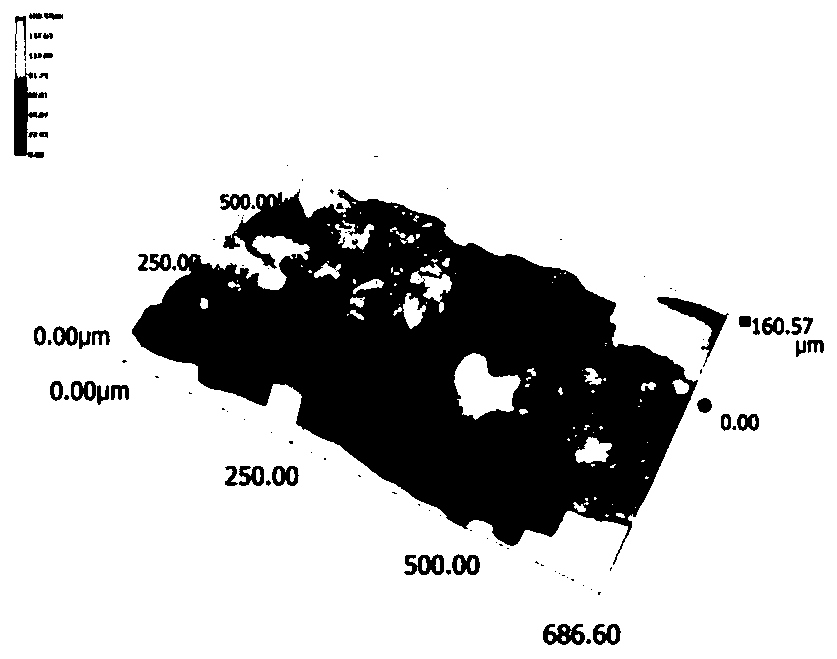

[0045] Using calcium sulfate powder (3-10 μm in particle size) and iron powder (30-40 μm in particle size) as raw materials, weigh 8 g of calcium sulfate powder and 92 g of iron powder at a mass ratio of 8:92; The powder and calcium sulfate powder were mechanically stirred and mixed for 30 minutes, and then stirred and ball-milled for 100 minutes to obtain a uniformly dispersed iron-calcium sulfate mixed powder; the above-mentioned uniformly dispersed iron-calcium sulfate mixed powder was used as raw material, and selective laser melting was used as the process , the laser power is 100W, the laser spot diameter is 0.1mm, the scanning speed is 50mm / s, and the iron-based implant is obtained after being melted and solidified under the protection of argon.

[0046] Implementation effect: The prepared iron-based implant was tested, and it was found that calcium sulfate was evenly dispersed in the iron matrix. After soaking in human simulated body fluid for 20 days, the calculated de...

Embodiment 2

[0048] Using calcium sulfate powder (3-10 μm in particle size) and iron powder (30-40 μm in particle size) as raw materials, weigh 3 g of calcium sulfate powder and 97 g of iron powder at a mass ratio of 3:97; The powder and calcium sulfate powder were mechanically stirred and mixed for 30 minutes, and then stirred and ball-milled for 100 minutes to obtain a uniformly dispersed iron-calcium sulfate mixed powder; the above-mentioned uniformly dispersed iron-calcium sulfate mixed powder was used as raw material, and selective laser melting was used as the process , the laser power is 100W, the laser spot diameter is 0.1mm, the scanning speed is 50mm / s, and the iron-based implant is obtained after being melted and solidified under the protection of argon.

[0049] Implementation effect: The prepared iron-based implant was tested, and it was found that calcium sulfate was uniformly dispersed in the iron matrix. After soaking in human simulated body fluid for 20 days, the calculated...

Embodiment 3

[0051] Using calcium sulfate powder (3-10 μm in particle size) and iron powder (30-40 μm in particle size) as raw materials, weigh 8 g of calcium sulfate powder and 92 g of iron powder at a mass ratio of 8:92; The powder and calcium sulfate powder were mechanically stirred and mixed for 30 minutes, and then stirred and ball-milled for 100 minutes to obtain a uniformly dispersed iron-calcium sulfate mixed powder; the above-mentioned uniformly dispersed iron-calcium sulfate mixed powder was used as raw material, and selective laser melting was used as the process , the laser power is 120W, the laser spot diameter is 0.1mm, the scanning speed is 50mm / s, and the iron-based implant is obtained after being melted and solidified under the protection of argon.

[0052] Implementation effect: The prepared iron-based implant was tested and found that calcium sulfate was uniformly dispersed in the iron matrix. After the iron-based implant prepared by this method was soaked in human simula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com