Preparation method for CaO-SiO2/PAA composite film material having biological activity

A bioactive, composite membrane technology, applied in the field of preparation of CaO-SiO2/PAA composite membrane material, can solve the problem of poor formation ability of bone-like apatite, and achieve the effect of good nanopore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Use nitric acid as a catalyst to prepare 1M TEOS aqueous solution; after TEOS is completely hydrolyzed, slowly drop 1M calcium hydroxide aqueous solution into TEOS, fully react for 1 hour under the action of a magnetic stirrer, and let stand until the solution forms a transparent Sol;

[0045] (2) Soak the 200nm PAA matrix in the sol; place the above solution containing the PAA matrix in a vacuum drying oven at room temperature for 3 hours; then take out the PAA matrix that has been vacuumed in the sol and put it in the muffle Heat treatment in the furnace at 550°C, the heating rate is 2°C / min, take it out after 8 hours of heat preservation. Washed three times with deionized water and dried for inspection.

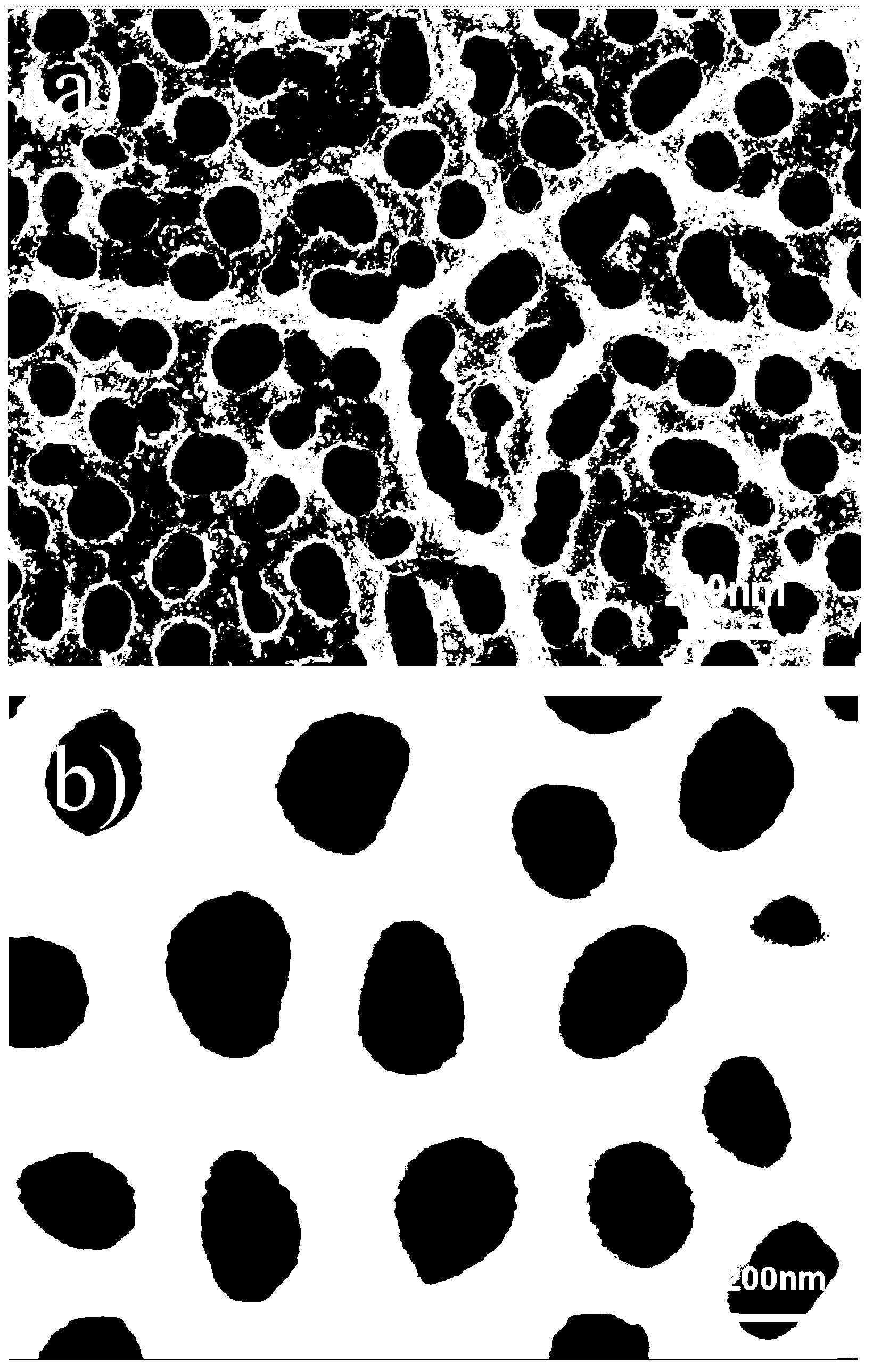

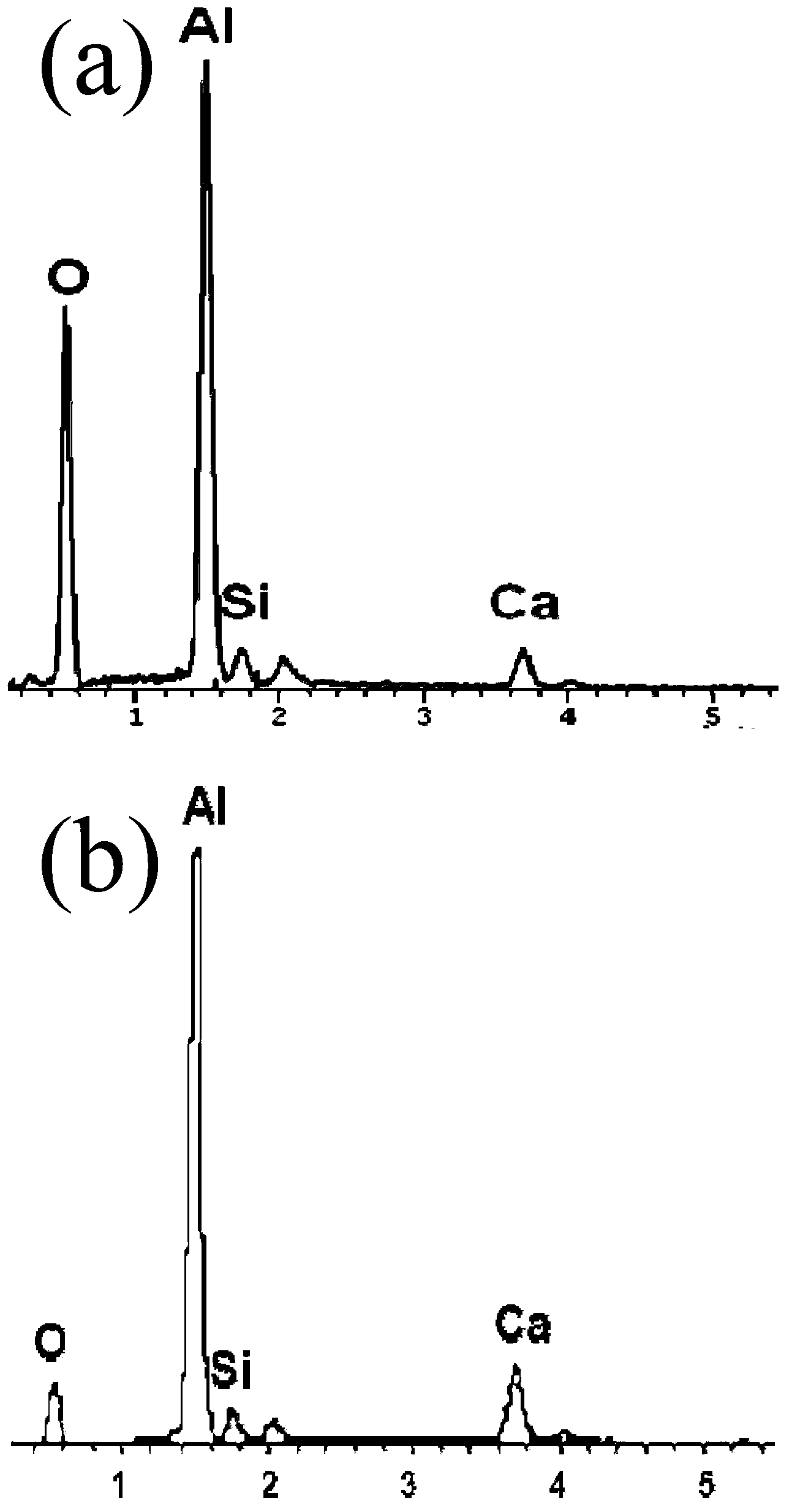

[0046] (3) CaO-SiO before soaking sol and after soaking sol 2 / PAA composite film was characterized by SEM and EDS respectively, as shown in Figure 1~Figure 3 shown.

Embodiment 2

[0048] (1) Use nitric acid as a catalyst to prepare 1M TEOS aqueous solution; after TEOS is completely hydrolyzed, slowly drop 1M calcium nitrate aqueous solution into TEOS, fully react for 2 hours under the action of a magnetic stirrer, and stand until the solution forms a transparent sol ;

[0049] (2) Soak the 100nm PAA matrix in the sol; put the solution containing the PAA matrix in a vacuum drying oven at room temperature for 2 hours; then take out the PAA matrix that has been vacuumed in the sol, and put it in the muffle Heat treatment in the furnace at 500°C with a heating rate of 3°C / min, keep it warm for 6 hours and take it out. Wash three times with deionized water and dry.

[0050] (3) CaO-SiO 2 The / PAA composite membrane was soaked in the prepared SBF solution for 1 day and 7 days, then it was taken out, washed twice with deionized water, and dried at room temperature for inspection.

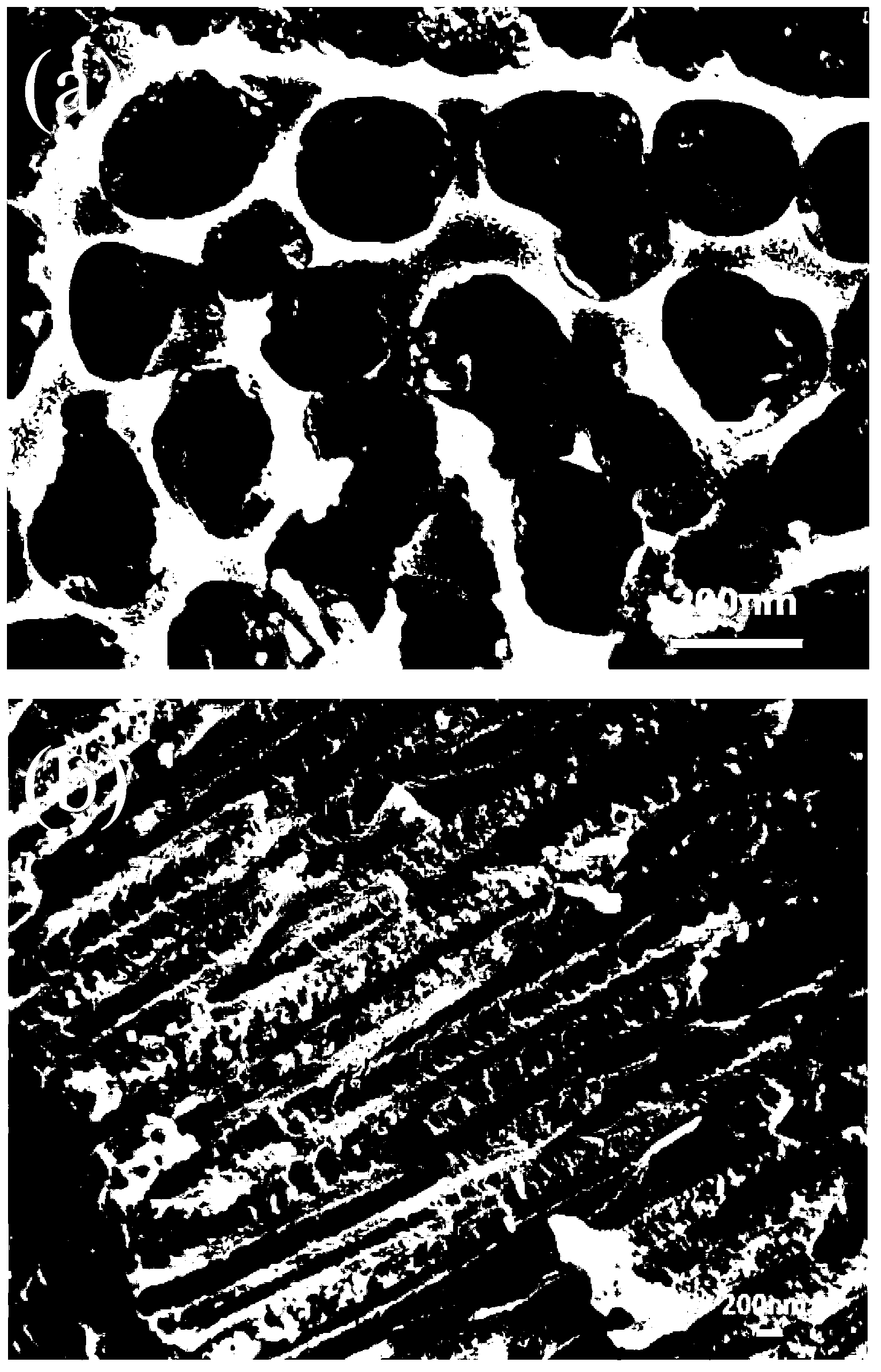

[0051] (4) CaO-SiO after soaking SBF solution for 1 day and 7 days 2 / PAA c...

Embodiment 3

[0053] (1) Use nitric acid as a catalyst to prepare 1M TEOS aqueous solution; after TEOS is completely hydrolyzed, slowly drop 1M calcium acetate aqueous solution into TEOS, fully react for 1 hour under the action of a magnetic stirrer, and let stand until the solution forms a transparent sol ;

[0054] (2) Soak the 75nm PAA matrix in the sol; put the solution containing the PAA matrix in a vacuum drying oven at room temperature for 1 hour; then take out the PAA matrix that has been vacuumed in the sol and put it in the muffle Heat treatment in the furnace at 450°C with a heating rate of 1°C / min, take it out after 4 hours of heat preservation. Wash three times with deionized water and dry.

[0055] (3) CaO-SiO 2 The / PAA composite membrane was soaked in the prepared SBF solution for 1 day, taken out, washed twice with deionized water, and dried at room temperature for inspection.

[0056] (4) CaO-SiO after soaking SBF solution for 1 day 2 / PAA composite films were characte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Channel diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com