Poly(phthalazinone ether) provided with composite coating on surface and preparation method of poly(phthalazinone ether)

A technology of naphthalene polyarylether and composite coating, which is applied in the field of polymer science, can solve the problem that the biocompatibility of polyarylene naphthalene cannot meet the needs of bone implant materials, and achieve improved biocompatibility , good biocompatibility, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

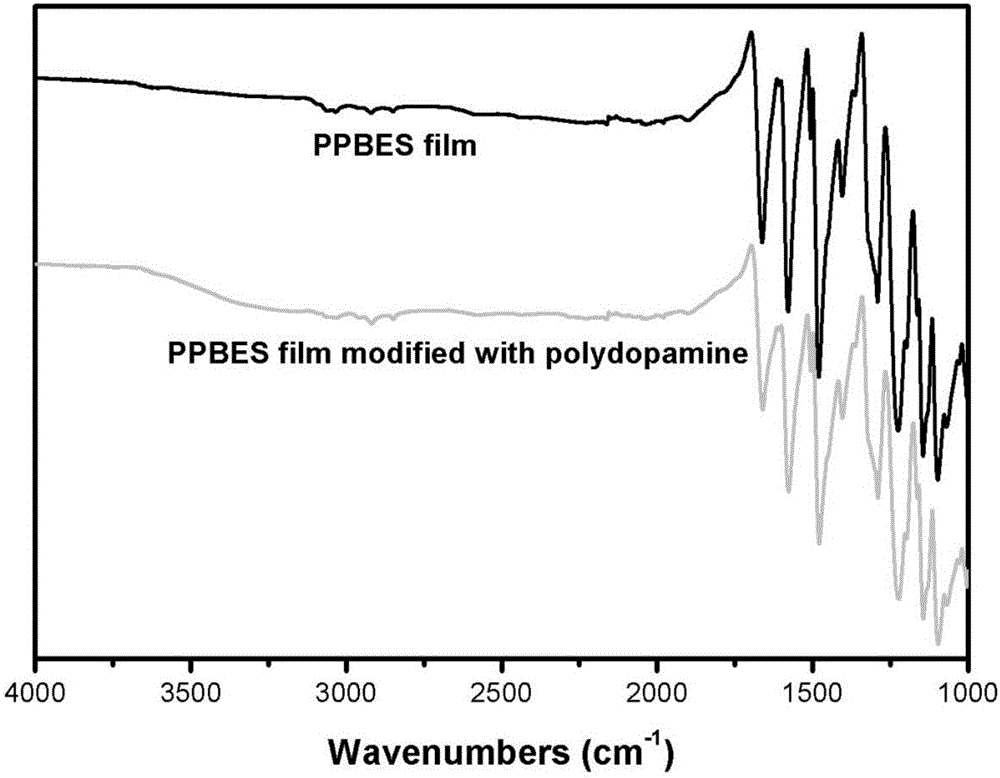

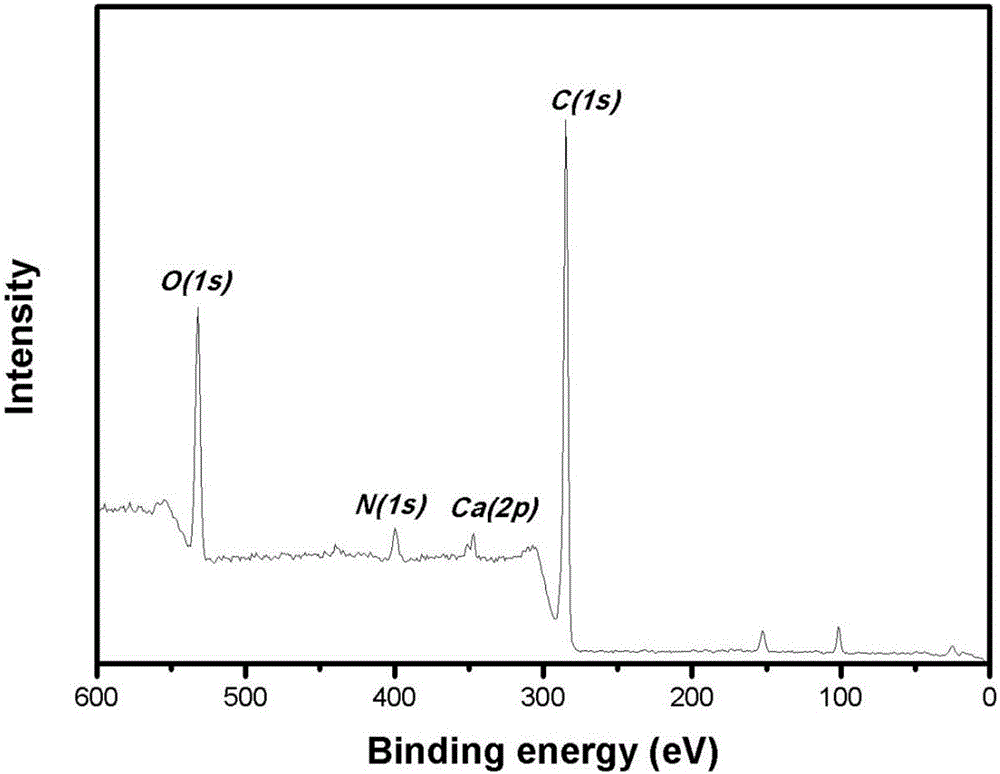

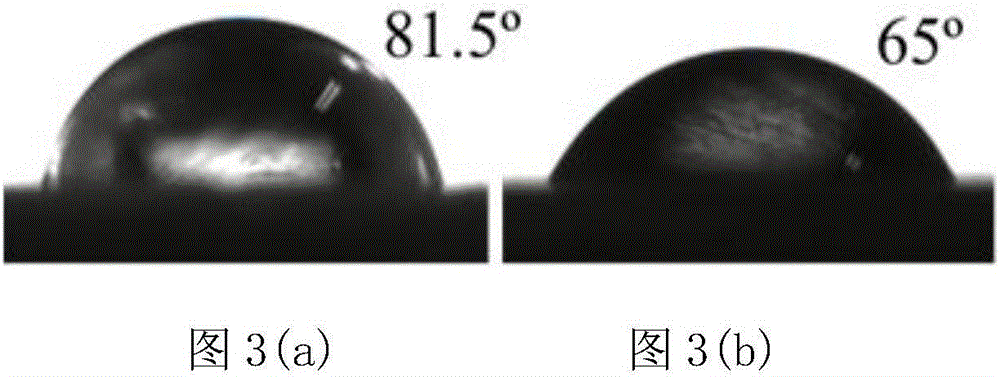

[0039] In the first step, a polydopamine layer is deposited on the surface of the PPBES sheet by self-polymerization of dopamine. Sonicate the PPBES sheet by immersing it in acetone for 10 to 20 minutes, immerse it in isopropanol for 10 to 20 minutes, and immerse it in ultrapure water for 10 to 20 minutes. Use Tris aqueous solution as a buffer solution, prepare 10 mL of dopamine aqueous solution with a concentration of 2 mg / mL, adjust the pH value to 8.5, add 0.5 g of washed PPBES tablets into the dopamine aqueous solution, and react at 45 °C for 2 days , take out the modified PPBES sheet, rinse it with ultrapure water 5 times, 30s each time. Dry in a vacuum oven at 60°C to obtain polydopamine-modified PPBES sheets.

[0040] In the second step, bone-like apatite is deposited on the surface of the polydopamine-modified PPBES sheet prepared in the first step. At room temperature, the polydopamine-modified PPBES sheet was soaked in Na + 、K + , Mg 2+ , Cl - 、HCO 3 - , SO ...

Embodiment 2

[0047] In the first step, a polydopamine layer is deposited on the surface of the polyaryl ether sulfone ketone (PPBESK) material through dopamine self-polymerization. As described in the first step of Example 1.

[0048] In the second step, the surface of the polydopamine-modified PPBESK sheet prepared in the first step is modified by phosphorylation. 1cm 2 The xaphthalene polyarylether tablets were immersed in 3.5 mL of different concentrations of POCl 3 In the acetonitrile solution, put it in an ice bath, react for 2 hours, suck out the solution, add 3.5mL of acetonitrile, let it stand for 5 minutes, then add 30mL of water, let it stand for 5 minutes, suck out the mixed solution, add 10mL of water, washed for 5 minutes, repeated washing 4 times, and the samples were dried for later use.

[0049] In the third step, bone-like apatite is deposited on the surface of the modified polydopamine layer prepared in the second step. As described in the second step of Example 1.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com