Biomaterial for repairing osseous tissues and preparation method of biomaterial

A biomaterial and bone tissue technology, applied in medical science, prostheses, etc., can solve the problems of poor performance of hydroxyapatite biomaterials, unfavorable popularization and application, and complicated preparation methods, so as to promote biological compatibility, The effect of easy collection and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

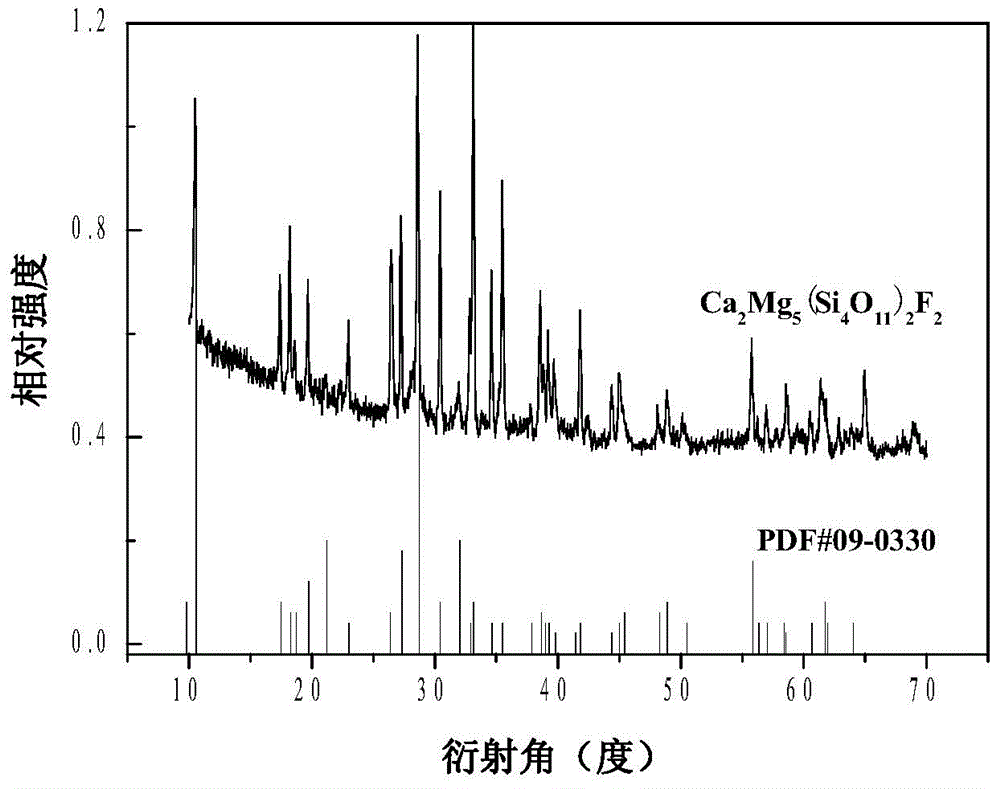

[0040] According to the chemical formula Ca 2 Mg 5 (Si 4 o 11 ) 2 f 2 The molar ratio of each element in, respectively weigh calcium carbonate CaCO 3 : 0.333 g, magnesium basic carbonate 4MgCO 3 ·Mg(OH) 2 ·5H 2 O: 1.619 g, silicon dioxide SiO 2 : 1.603 g, calcium fluoride CaF 2 : 0.338g, ground in an agate mortar and mixed evenly, pre-calcined in air atmosphere, pre-calcined at 250°C, pre-calcined for 14 hours, then cooled to room temperature, and the sample was taken out; the pre-calcined raw materials were fully mixed and ground again Uniform, calcined again in air atmosphere, calcined temperature 950 ° C, calcined time 8 hours, cooled and ground to get Ca 2 Mg 5 (Si 4 o 11 ) 2 f 2 Powder.

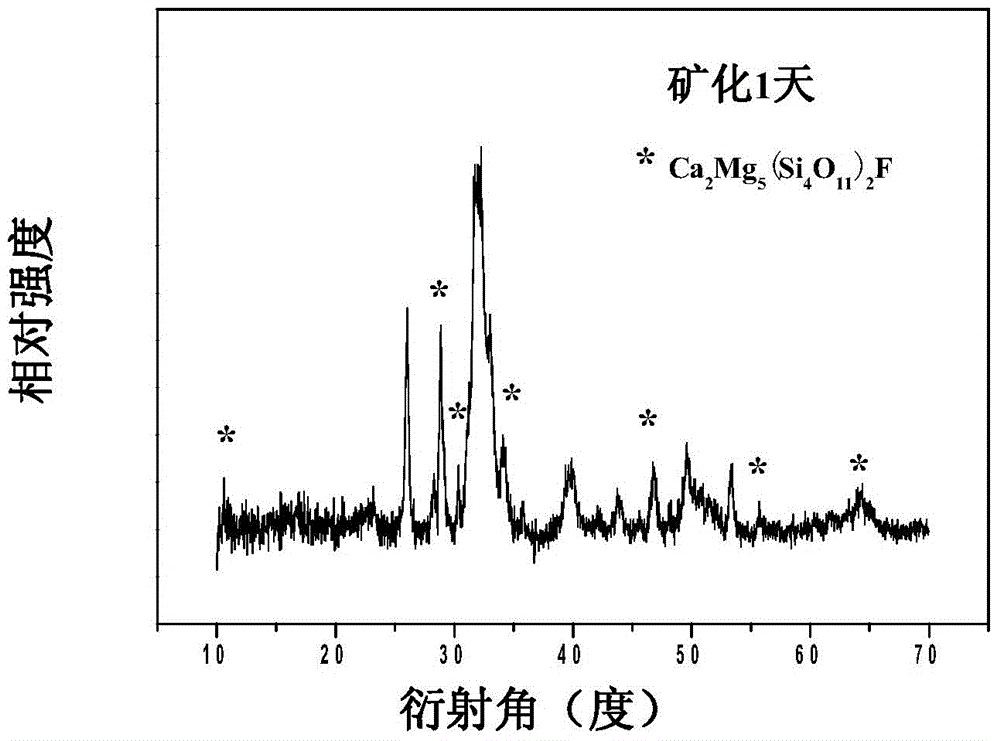

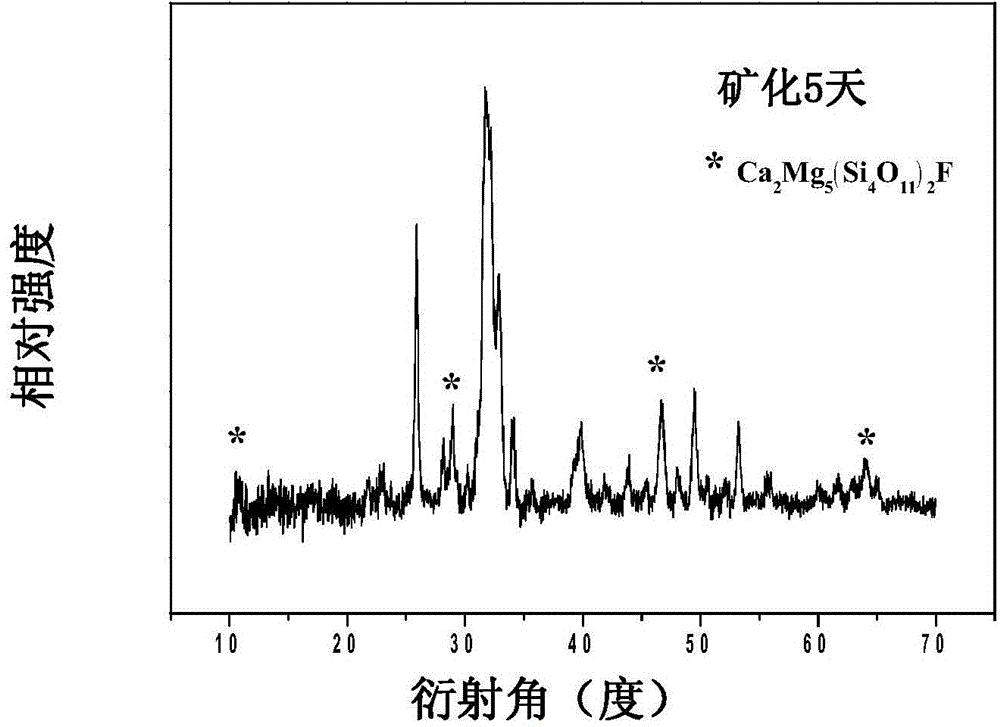

[0041] Prepared Ca 2 Mg 5 (Si 4 o 11 ) 2 f 2 The powder was soaked in simulated body fluid for 1 day, 5 days and 10 days, and the changes of surface morphology at different mineralization times were observed to judge the Ca 2 Mg 5 (Si 4 o 11 ) 2 f 2 Whether th...

Embodiment 2

[0052] According to the chemical formula Ca 2 Mg 5 (Si 4 o 11 ) 2 f 2 The molar ratio of each element in the formula is weighed respectively calcium oxide CaO: 0.1869 grams, magnesium oxide MgO: 0.6717 grams, calcium fluoride CaF 2 : 0.338 grams, respectively dissolved in nitric acid, and diluted with deionized water, constantly stirred, then respectively weighed 0.5wt% oxalic acid of each raw material quality and added to the solution respectively, and stirred, weighed ethyl orthosilicate Ester Si(OC 2 h 5 ) 4 : 5.556 grams, and add an equal volume of ethanol and 5 times the volume of nitric acid solution in tetraethyl orthosilicate, dilute with deionized water, and carry out stirring treatment. After completely dissolving, the above-mentioned various solutions are mixed, and Heating and stirring at 40°C for 3 hours, standing and drying to obtain a fluffy precursor; placing the precursor in a muffle furnace for calcination at a calcination temperature of 600°C for 10 ...

Embodiment 3

[0057] According to the chemical formula Ca 2 Mg 5 (Si 4 o 11 ) 2 f 2 The molar ratio of each element in , respectively weigh calcium sulfate CaSO 4 2H 2 O: 0.4538 g, magnesium chloride MgCl 2 : 1.587 g, silicon dioxide SiO 2 : 1.603 grams, magnesium fluoride: 0.5205 grams, ground in an agate mortar and mixed evenly, select the air atmosphere for pre-calcination, pre-calcination temperature 700 ℃, pre-calcination time 2 hours, then cool to room temperature, take out the sample; The calcined raw materials are fully mixed and ground again, and calcined again in the air atmosphere, the calcining temperature is 900°C, the calcining time is 10 hours, cooling and grinding to obtain Ca 2 Mg 5 (Si 4 o 11 ) 2 f 2 Powder.

[0058] Weigh 2 grams of powder, dry press molding under 10MPa to make a ceramic green body with a diameter of 20 mm and a thickness of 2 mm; the ceramic green body is sintered at 950 ° C for 2 hours to prepare a ceramic disc.

[0059] Soak the prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com