Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47 results about "Barium glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass which differs from ordinary lime-soda glass in that barium oxide replaces part of the calcium oxide.

Method for preparing micro/nanocomposite photocurable resin

InactiveCN102161736AImprove interface effectGood dispersionImpression capsDentistry preparationsMethacrylateGlycidyl methacrylate

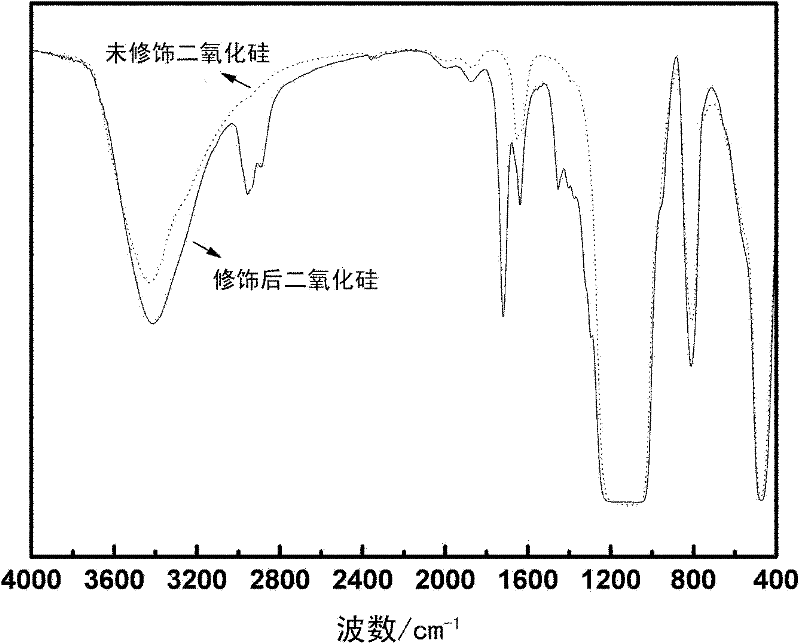

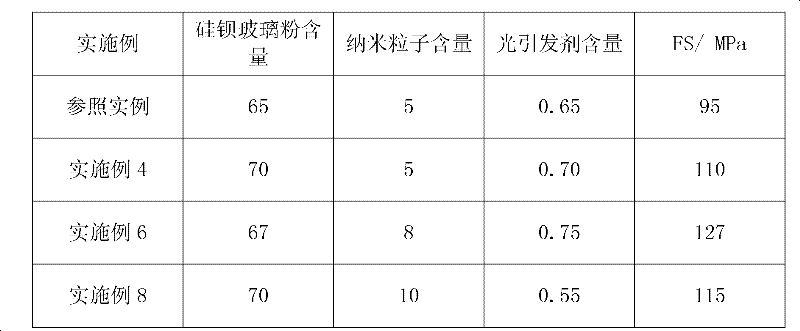

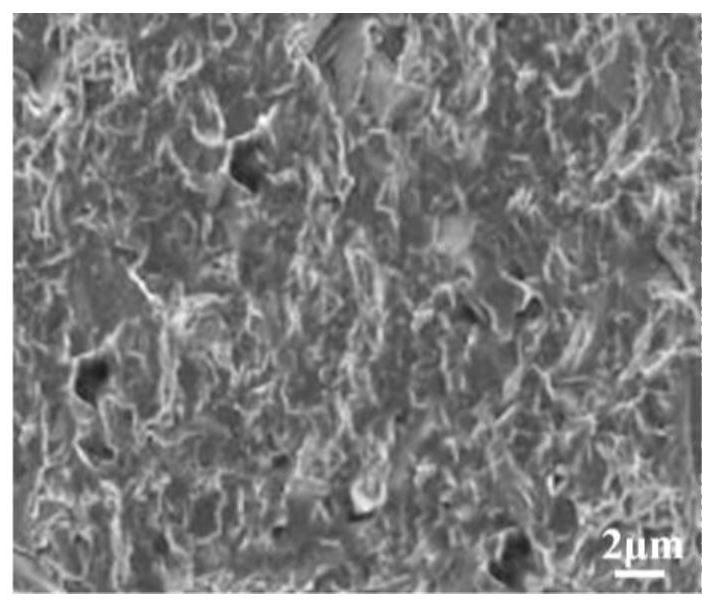

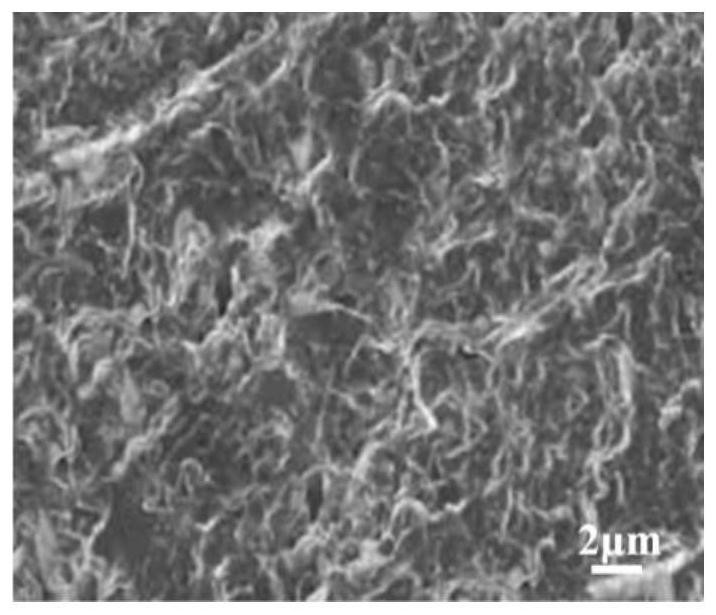

The invention relates to a method for preparing a micro / nanocomposite photocurable resin. The method for preparing the micro / nanocomposite photocurable resin is characterized by comprising the following steps of: 1) surface modification of nanoparticles, namely utilizing silicon dioxide nanoparticles as a nono-filler of a dental repair resin, and introducing a C=C double-bond functional group which can react with a resin monomer through two-step modification: (1) modifying by using gamma-aminopropyltriethoxysilane to introduce an amino group to the surfaces of the silicon dioxide nanoparticles, and (2) reacting the silicon dioxide nanoparticles with aminated surfaces and glycidyl methacrylate to introduce double bonds which can participate in a resin polymerization reaction to the surfaces of the nanoparticles; and 2) compounding of the modified nanoparticles, a resin and an initiator, namely adopting bisphenol A - glycidyl methacrylate and triethylene glycol dimethyl acrylate, introducing silicon barium glass powder serving as a microfiller and the modified nanoparticles, and adding a photoinitiator to obtain the micro / nanocomposite photocurable resin. The method has the characteristics of low cost and simple process.

Owner:WUHAN UNIV OF TECH

Low-boron glass for glass fiber, glass fiber and manufacturing method of glass fiber

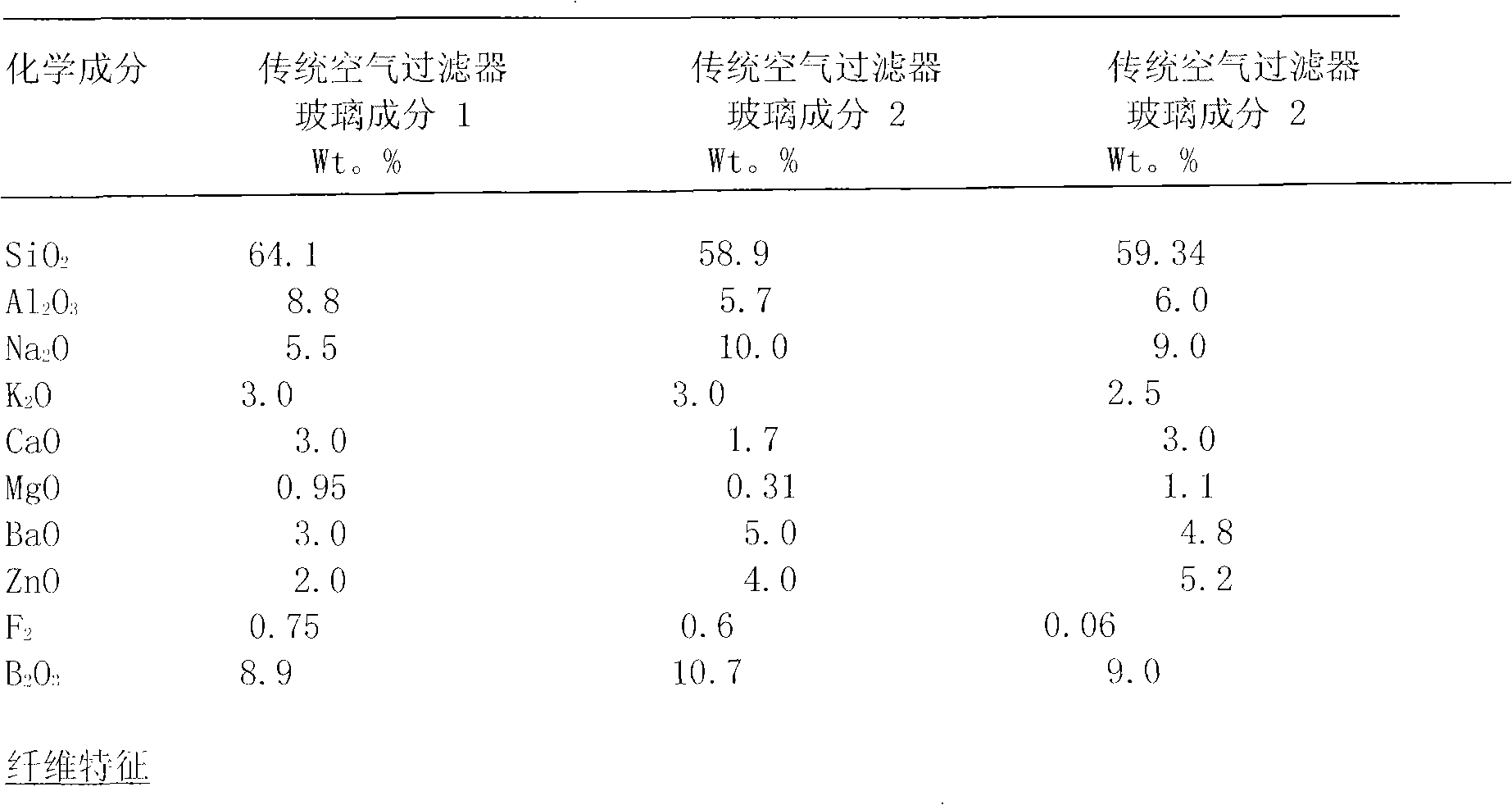

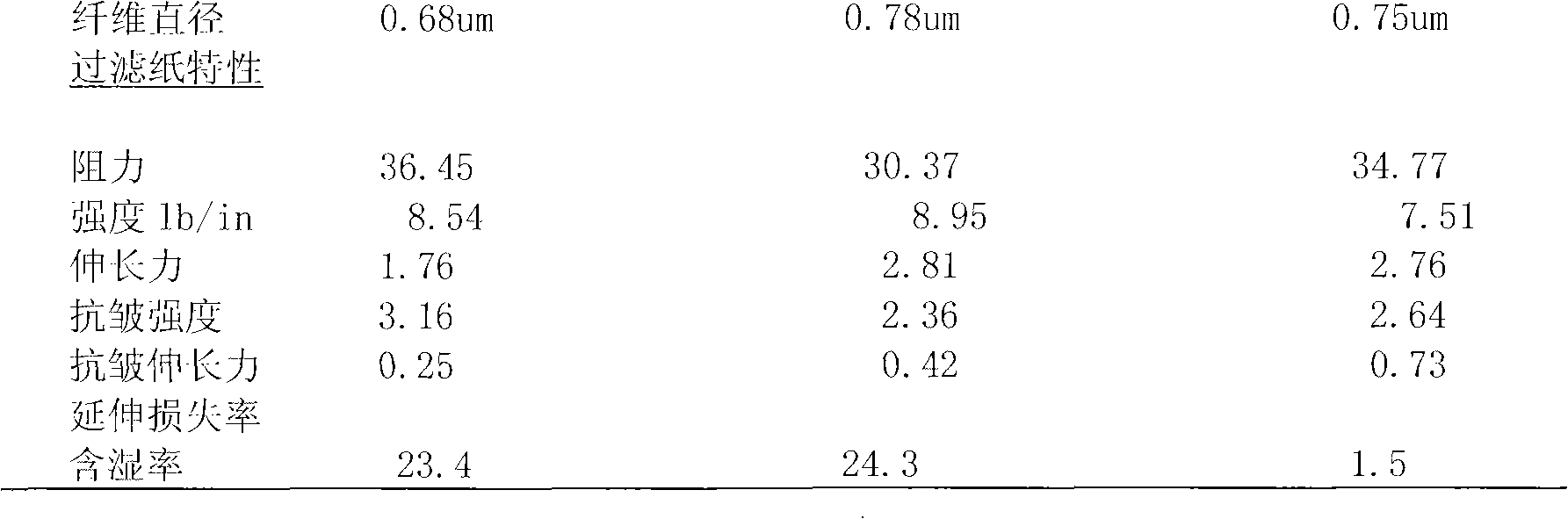

The invention discloses low-boron glass for glass fiber, glass fiber and a manufacturing method of the glass fiber. A glass composite comprises the following components by weight percent: 57-65 percent of SiO2, 5-9 percent of Al2O3, 4-10 percent of Na2O, 1-5 percent of K2O, 3-5 percent of CaO, 0.2-2 percent of MgO, 6.4-15 percent of BaO, 3-5 percent of ZnO, 0-0.1 percent of Fe2O3, 0-1 percent of B2O3 and 0.1-0.4 percent of F. Low-boron glass does not contain boron oxide or contains low-concentration boron oxide and relatively high-concentration barium, and the glass fiber can meet the requirement of no boron or low boron in some special industrials. A high-efficiency filter manufactured by using the glass fiber is very suitable for a cleaning environment and can avoid the problem of boron pollution. The glass fiber has higher humidity resisting ratio, and can resist degradation in an environment with high humidity, therefore, the glass composite of the invention with the concentration can be used for manufacturing thin glass fiber through a flame method and a centrifugal process in the prior art.

Owner:重庆再升净化设备有限公司

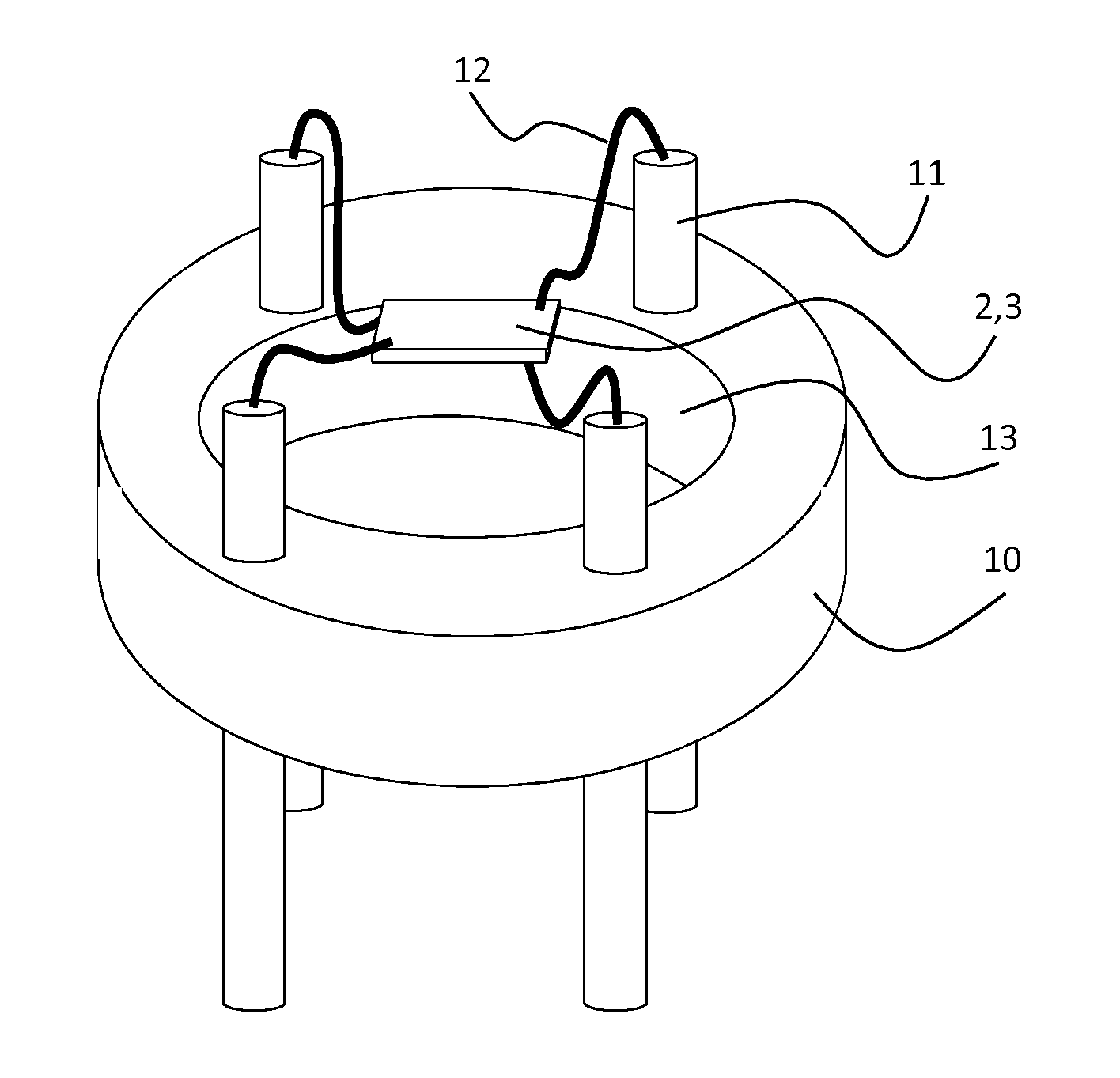

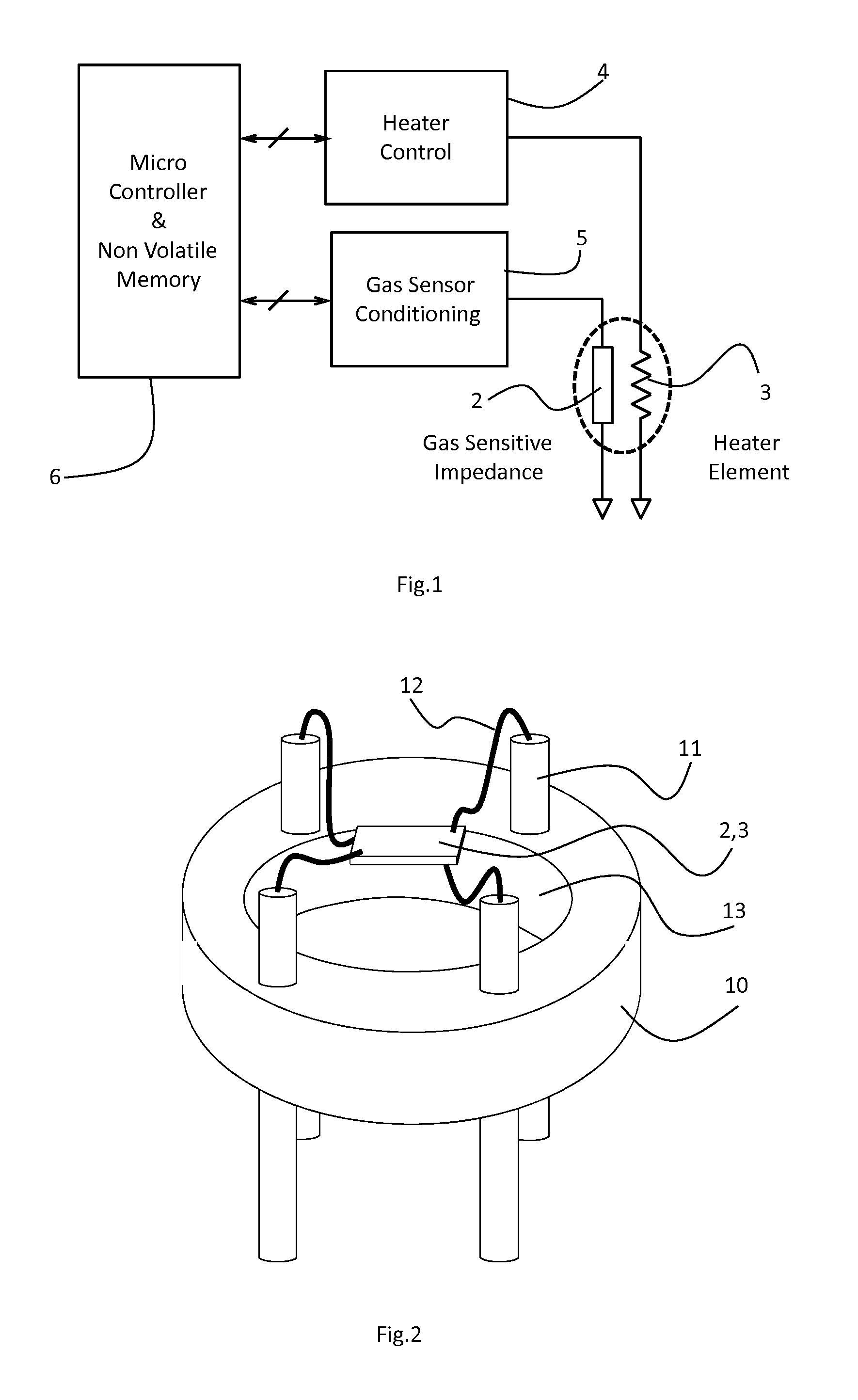

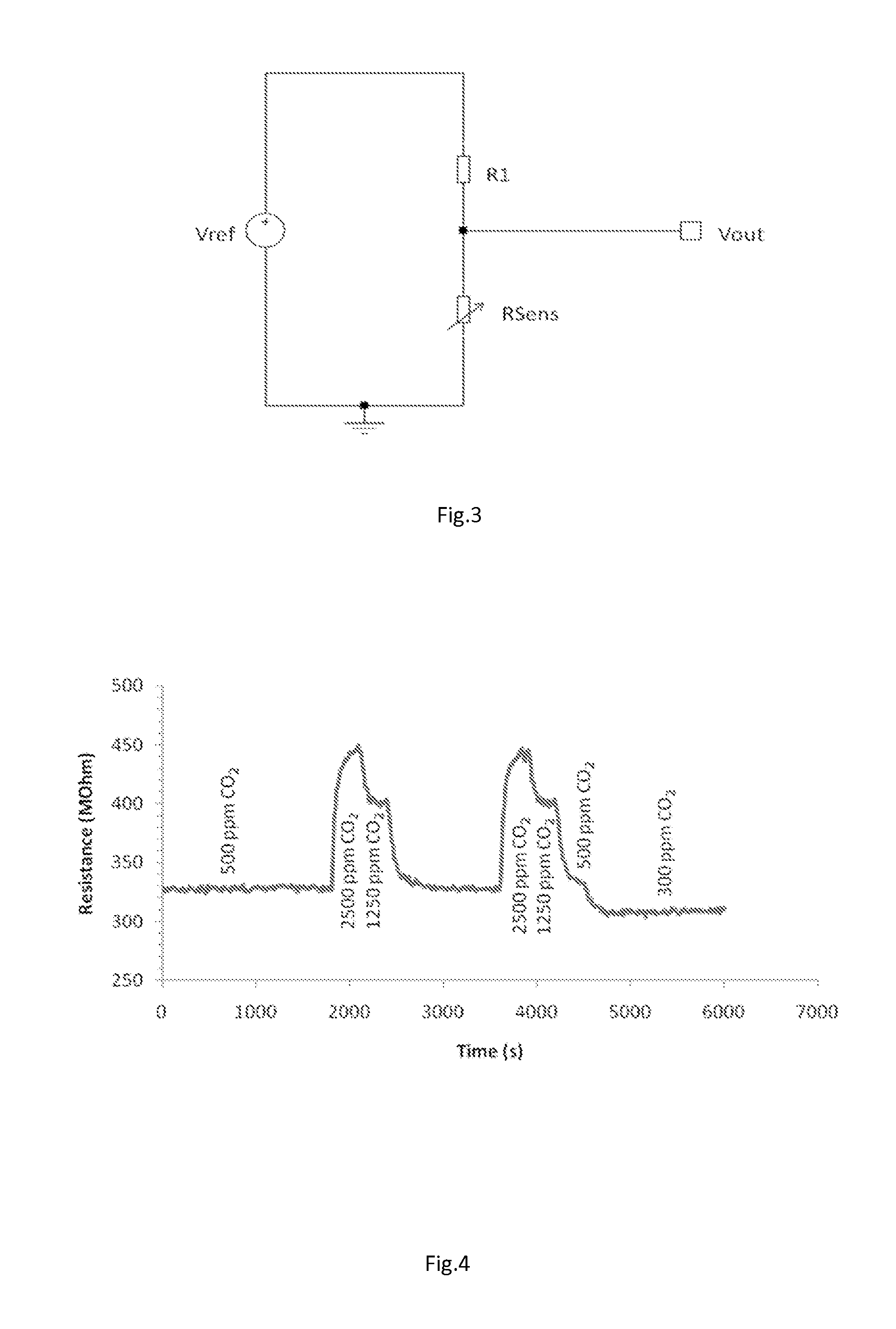

Co2 sensing materials and sensors incorporating said materials

InactiveUS20120161796A1Improve protectionImprove stabilityResistance/reactance/impedenceMaterial analysis by electric/magnetic meansDopantPhysical chemistry

A gas-sensitive material is disclosed for detecting CO2 for use in semiconductor-based gas sensors. The gas-sensitive material may comprise one or more Ba-containing phases and one or more W-containing phases, at least one of the Ba-containing phases being different than at least one of the W-containing phases; the one or more Ba-containing phases comprising at least one of BaCO3, BaO-rich glass, BaWO4, or any combination thereof; and the one or more W-containing phases comprising at least one of BaWO4, WO3, W(OH)6, or any combination thereof. The material may further comprise one or more oxides selected from the group CuO, Bi2O3, Sb2O3, Sb2O5, La2O3, Cr2O3, Fe2O3, NiO, and TiO2, and any combination thereof. The material may further comprise one or more dopants such as Pt, Pd, Ag, Au or their compounds, and any combination thereof. In one embodiment, the material comprises a mixture of BaO-rich glass, BaWO4, and WO3. In another embodiment, the material comprises a mixture of at least one of BaCO3 or BaO-rich glass in combination with at least one of WO3 or W(OH)6. Transducers and sensors incorporating such gas-sensitive materials are also disclosed.

Owner:SILICON LAB INC

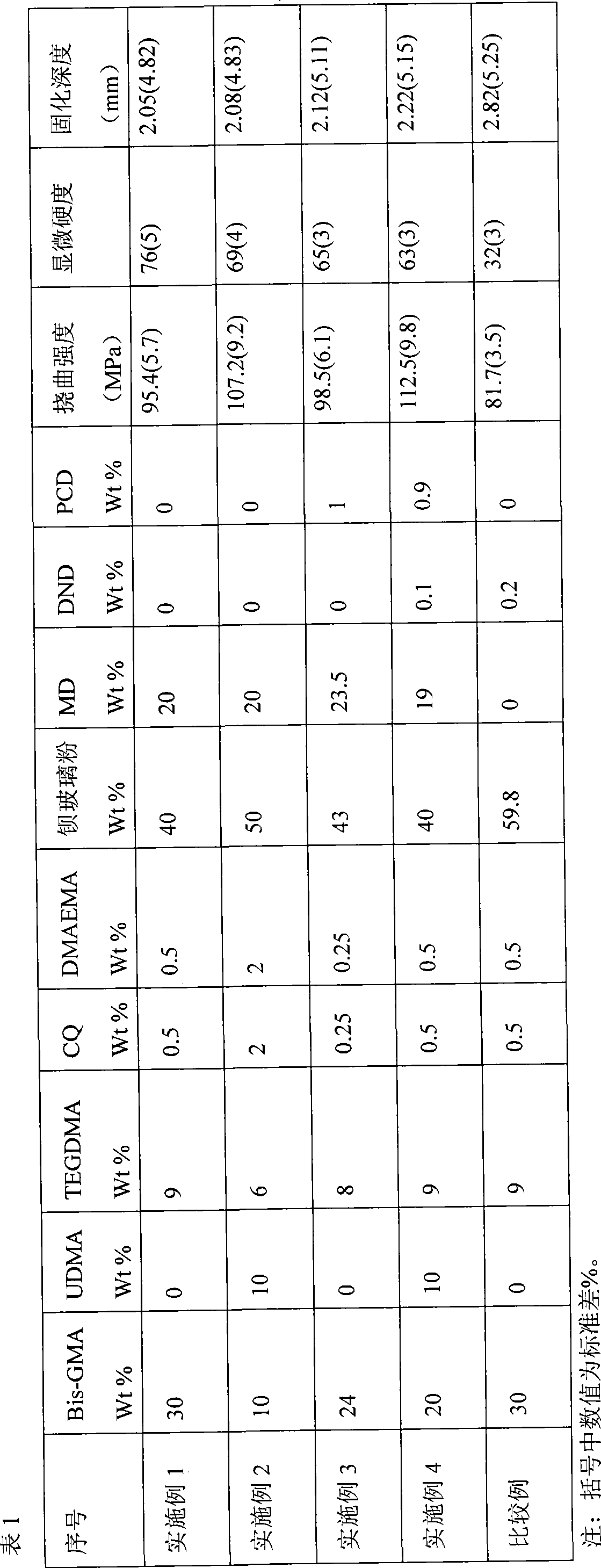

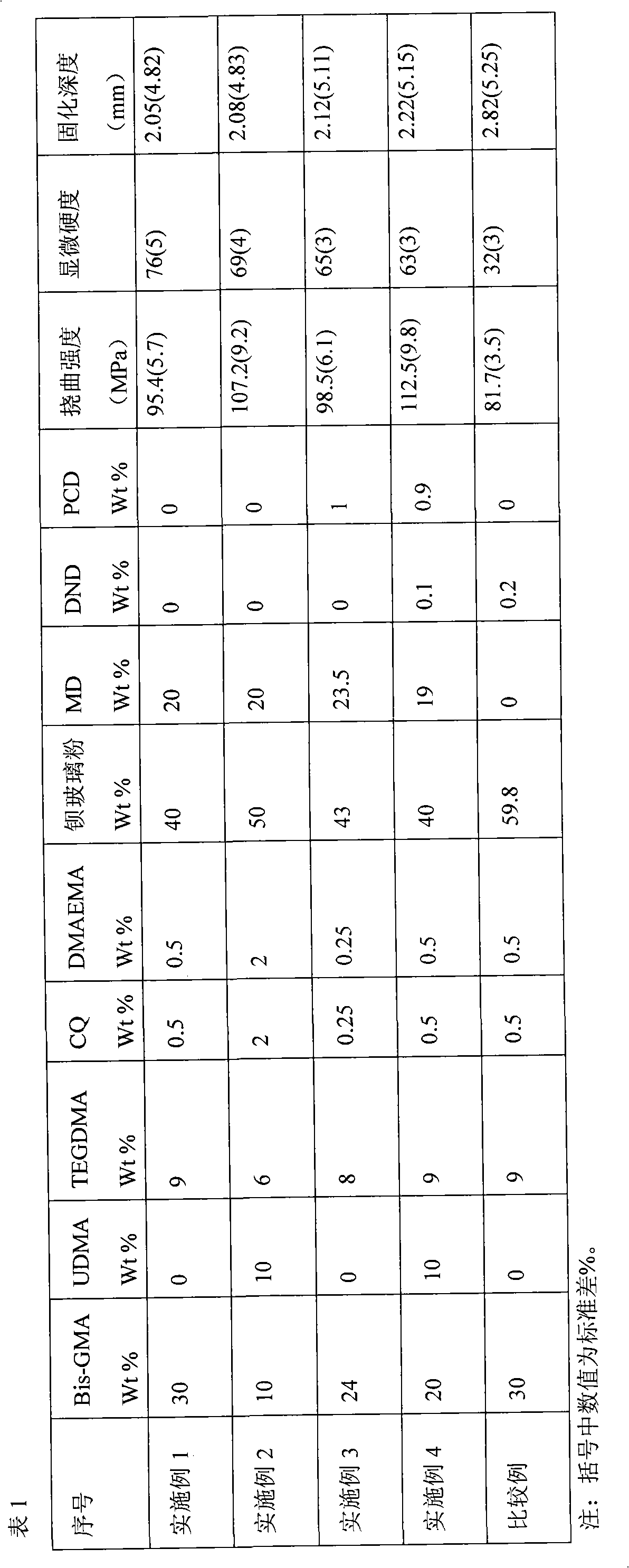

Light-cured composite resin for oral cavity by using single crystal diamond as filler and preparation method thereof

ActiveCN101518499AHigh strengthHigh hardnessImpression capsDigestive systemResin matrixFlexural strength

The invention relates to a light-cured composite resin for an oral cavity by using single crystal diamond as a filler, which belongs to the field of a medical oral cavity material. The resin comprises a resin matrix and the filler, wherein the filler comprises coupling barium glass powder and coupling diamond. The composite resin is characterized in that the coupling diamond comprises coupling single crystal diamond which accounts for 15-25 percent of the total weight of the composite resin, coupling glomerocryst diamond which accounts for 0-1 percent of the total weight of the composite resin and coupling nanometer diamond which accounts for 0-1 percent of the total weigh of the composite resin. The single crystal diamond is added as the functional filler, so that the flexural strength and the micro hardness of the prepared composite resin are observably increased, the maximum flexural strength value of the composite resin, which can reach 112.5MPa, can satisfy the requirement in a national medical standard that flexural strength value of the composite resin should be equal to or greater than 50 MPa, even can satisfy the requirement for the strength (greater than 80 MPa) of occlusal restoring materials.

Owner:BEIJING POLYSTAR HITECH CO LTD

Nano fluorine-containing resin dental material and preparation method thereof

ActiveCN101721316AHas the function of anti-dental cariesPerformance improvements and enhancementsImpression capsDentistry preparationsMethacrylateVolumetric Mass Density

The invention relates to a nano fluorine-containing resin dental material and a preparation method thereof and belongs to the technical field of light-cured resin dental materials and power dispersion methods. The resin dental material consists of a methacrylate monomer, an initiator and an inorganic filler, wherein the inorganic filter contains fluorine-containing glass powder, nano silicon powder, a pigment, strontium glass or / and barium glass and may contain nano YbF3 and Bi2O3. The preparation of the nano fluorine-containing resin dental material involves the silylanization of the fluorine-containing glass powder and the nano silicon powder and the technology for the ultrasonic dispersion of the nano silicon powder in an organic medium. The resin dental material of the invention has bioactivity, can resist dental caries and has ideal radiation resistance, transparency, tensile strength, wear resistance, density, rheological behavior and the like. Particularly, due to the combination of the fluorine-containing glass powder and the methacrylate monomer, excellent fluorine-releasing and excellent dynamic performance is achieved at the same time.

Owner:吉林省登泰克牙科材料有限公司

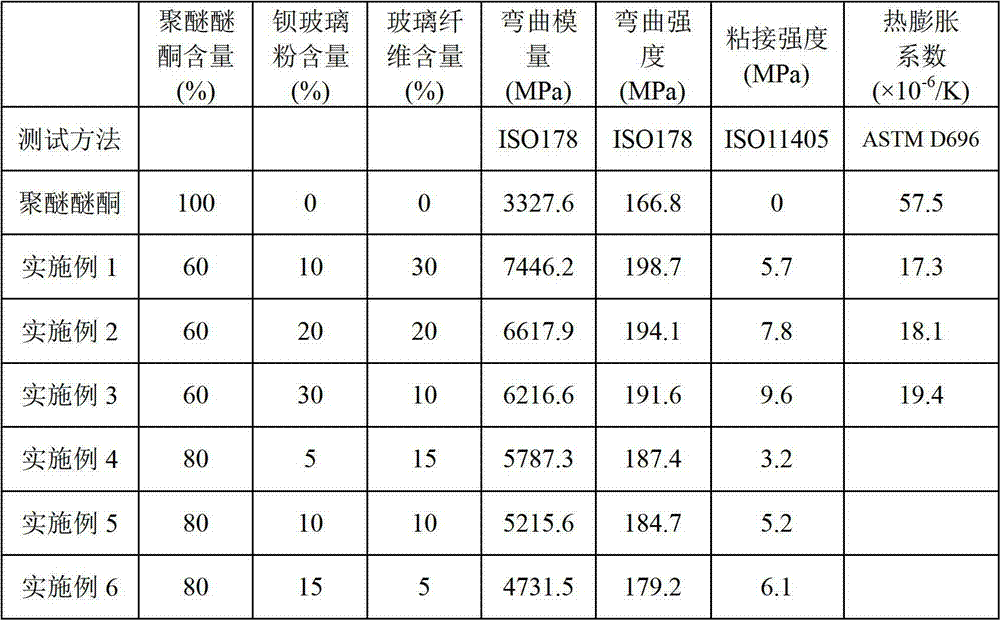

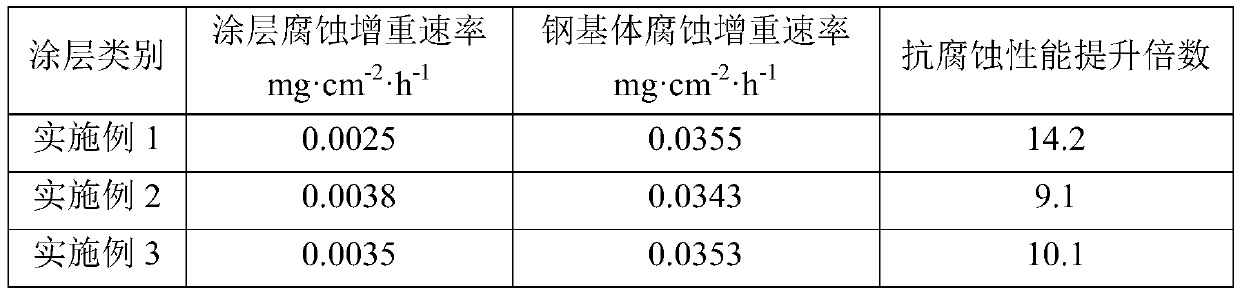

Poly(ether-ether-ketone)-based dental special material with high bonding strength and preparation method thereof

InactiveCN102827455AImprove mechanical propertiesHigh bonding strengthImpression capsDentistry preparationsKetoneThermal expansion

The invention provides a poly(ether-ether-ketone) (PEEK)-based dental special material with high bonding strength and a preparation method thereof, belonging to the technical field of dental material. The dental special material uses PEEK as matrix and glass fiber and barium glass powder as inorganic filler and comprises these components by weight: 60%-80% of PEEK, 5%-30% of barium glass powder and 5%-30% of glass fiber. The preparation method comprises the steps of mixing PEEK and barium glass powder, and extruding through a twin screw extruder to obtain a composite material A; extruding PEEK and glass fiber through a twin screw extruder to obtain a composite material B; and mixing the composite materials A and B, and extruding through a twin screw extruder to obtain the final product. According to the invention, through the filling of glass fiber and barium glass powder, mechanical property and bonding strength of the material are largely increased and coefficient of thermal expansion is reduced. Moreover, the material is prepared without plasma treatment, laser irradiation or concentrated sulfuric acid treatment, and is suitable to be used in oral clinic.

Owner:JILIN UNIV

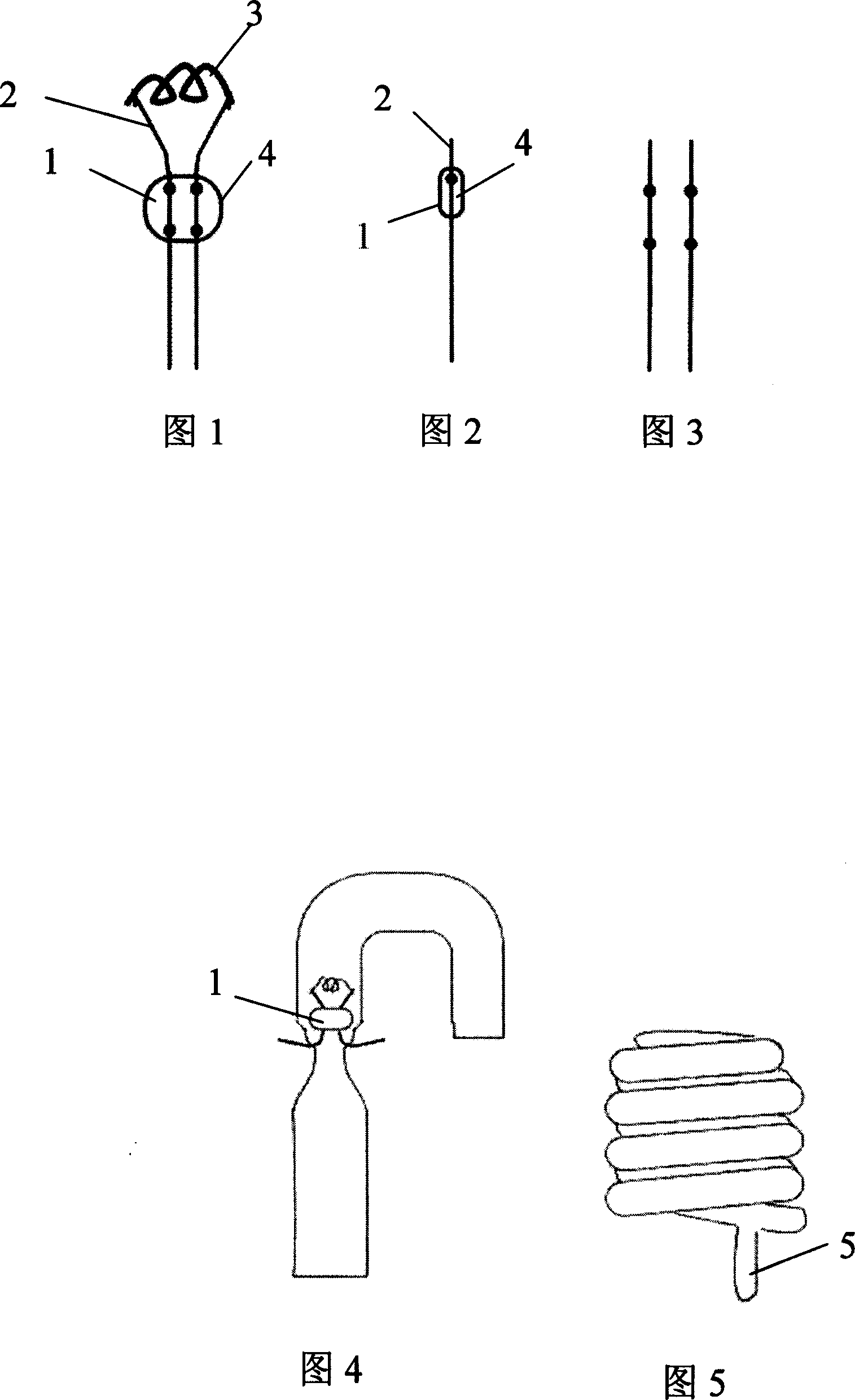

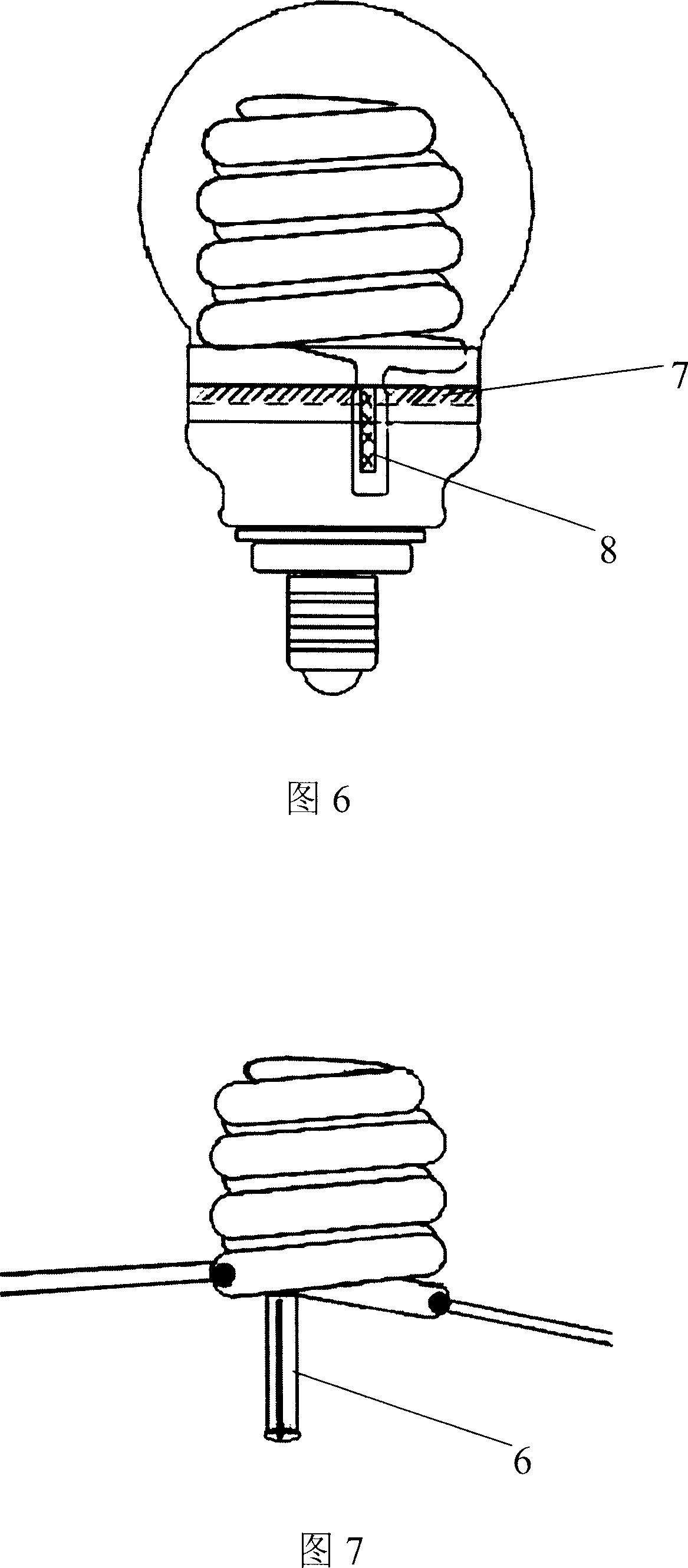

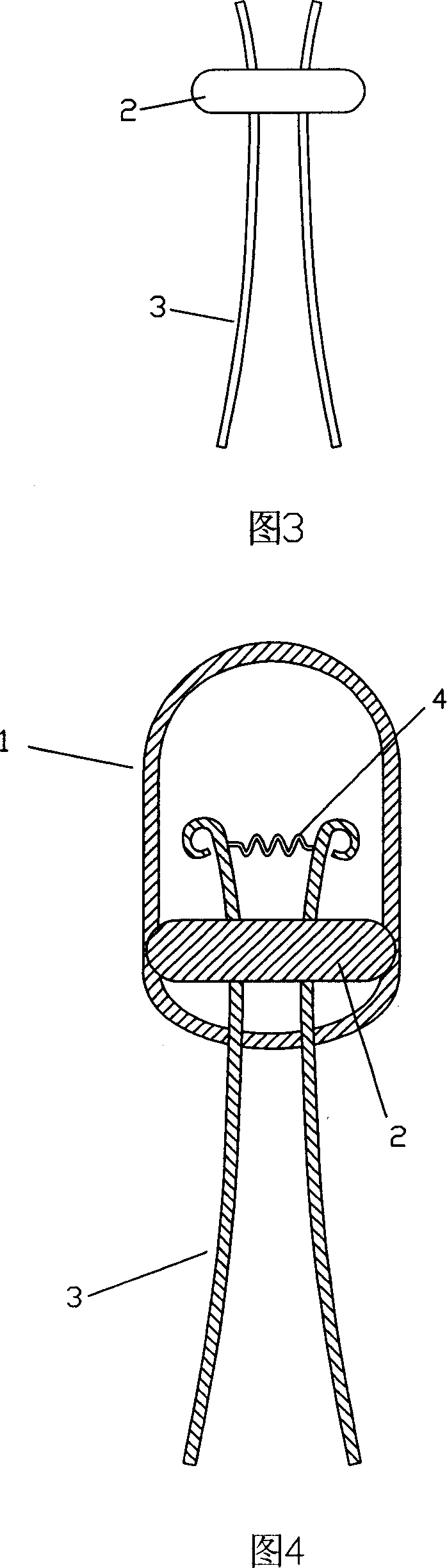

T2-T1 standard hot electrode fluorescence lamp production method

InactiveCN101145484AMagnetic deflection device manufactureCold cathode manufactureFluorescenceRare earth

A fabrication method of T2 and T1 hot-cathode fluorescent lamps is provided, which comprises processing potassium / barium glass, lead glass or borosilicate glass to a lamp tube, with the outside diameter of the lamp tube being controlled within a range of 1-9 mm; connecting two wires by glass bead fusion sealing to form a core column; winding a tungsten filament to form a spiral filament and then connecting with the wires; coating electronic powder; sealing the lamp tube and exhausting; placing mercury pills or amalgam in the entrance path at one end of the lamp tube, introducing high-purity argon gas (400-1600Pa pressure) into the lamp after exhaust operation, heating the wires by means of induction with a high frequency furnace to heat the mercury pills or amalgam to produce mercury vapors. The invention solves the technical problem of the prior fabrication process of hot-cathode fluorescent lamps rated up to T3 specification, such as large processing difficulty, difficulty in sealing lamp, failure to hermetically connect the core column with the lamp tube, difficulty in controlling processing flame, and complicated exhaust process. The invention provides an ideal technical proposal for the fabrication of hot-cathode tricolor rare earth fluorescent lamps with a tube diameter less than or equal to 7mm.

Owner:陈宗烈

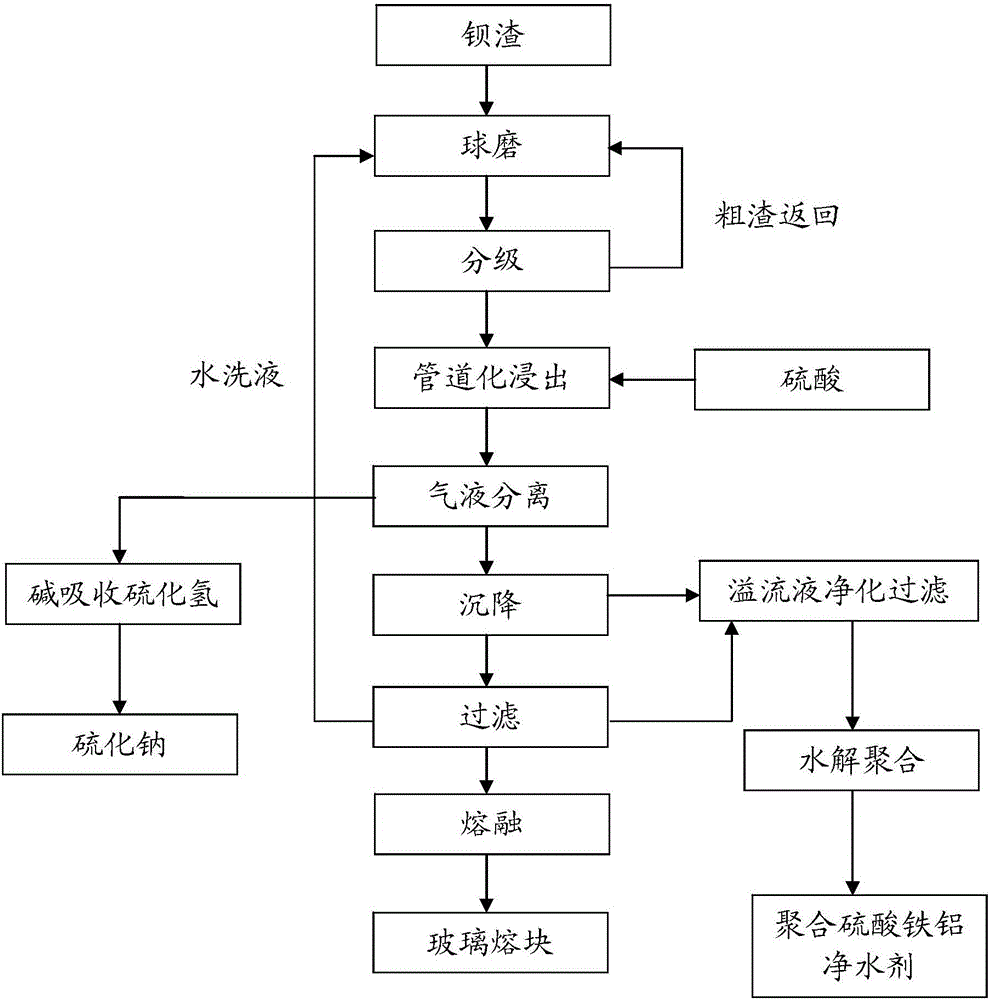

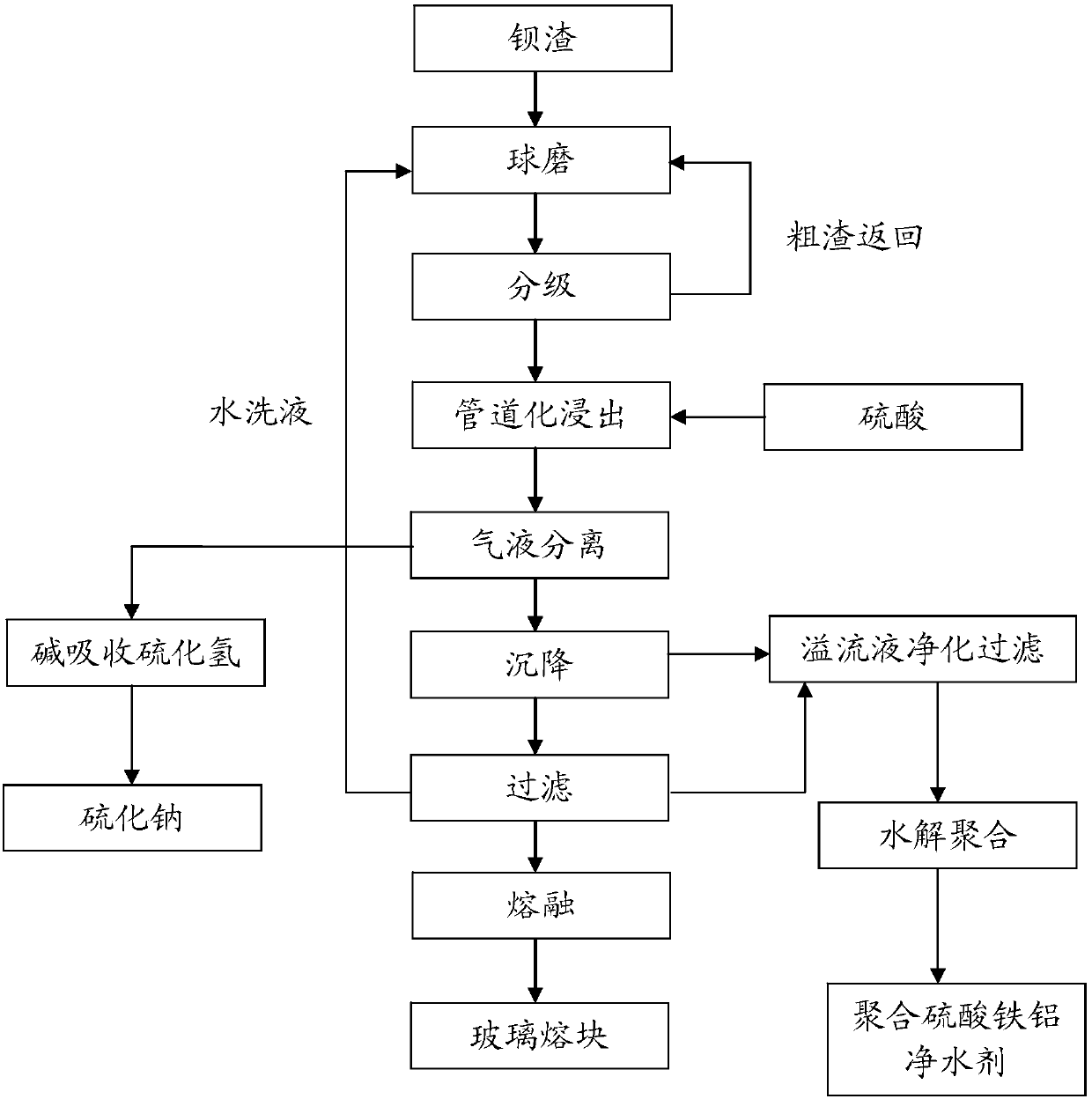

Method for preparing barium-based glass frit with barium slag

ActiveCN105948499AIncrease profitImprove the level ofAlkali metal sulfides/polysulfidesIron sulfatesSlagSlurry

The invention provided a method for preparing barium-based glass frit with barium slag. The method comprises the following steps: barium slag is ground, and a barium slag slurry is prepared; the barium slag slurry is subjected to pipeline sulfuric acid leaching; hydrogen sulfide gas produced in the product is absorbed with sodium alkali, such that sodium sulfide is obtained; solid-liquid separation is carried out, and an iron aluminum sulfate water purifying agent is obtained; the solid is washed and dried; the dried solid is added into a glass frit furnace, and is molten in an oxidation atmosphere; the molten glass is subjected to water extraction, such that the barium-based glass frit is obtained. With the method provided by the invention, barium slag utilization rate is improved, and a high-barium glass frit (ceramic glaze material) is obtained. A glass material prepared with the high-barium frit has the advantages of less bubbles, high transparency and bright color, and has functions that cannot be found in common glass.

Owner:贵州红星发展大龙锰业有限责任公司

Sodium lamp in low pressure

InactiveCN101093782AStop erosionGood pooling effectGas discharge lamp detailsWorking temperaturePhotochemistry

The low-pressure sodium vapor lamp includes discharging tube (DT) with inert gases and sodium metal being sealed inside. DT is setup inside high vacuum, columnar, transparent outer glass bulb. Through bracing frame, DT is fixed on the outer glass bulb. Electrodes are setup at two poles of the discharging tube respectively. DT includes sodium resisting jacking glass bulb in U type. The sodium resisting jacking glass bulb is composed of silicate glass layer in outer layer, and sodium resisting barium glass layer in inner layer. Compared with prior art, U type DT possesses features of compact structure, small size of outer glass bulb and cooling surface, fast temperature rise, good collection for light, and making DT reach 260 deg.C working temperature rapidly. Providing high light efficiency and high light penetrability, the invention is applicable to illuminant place including roads, tunnel, warehouses etc. in areas with different temperatures.

Owner:宋宝山

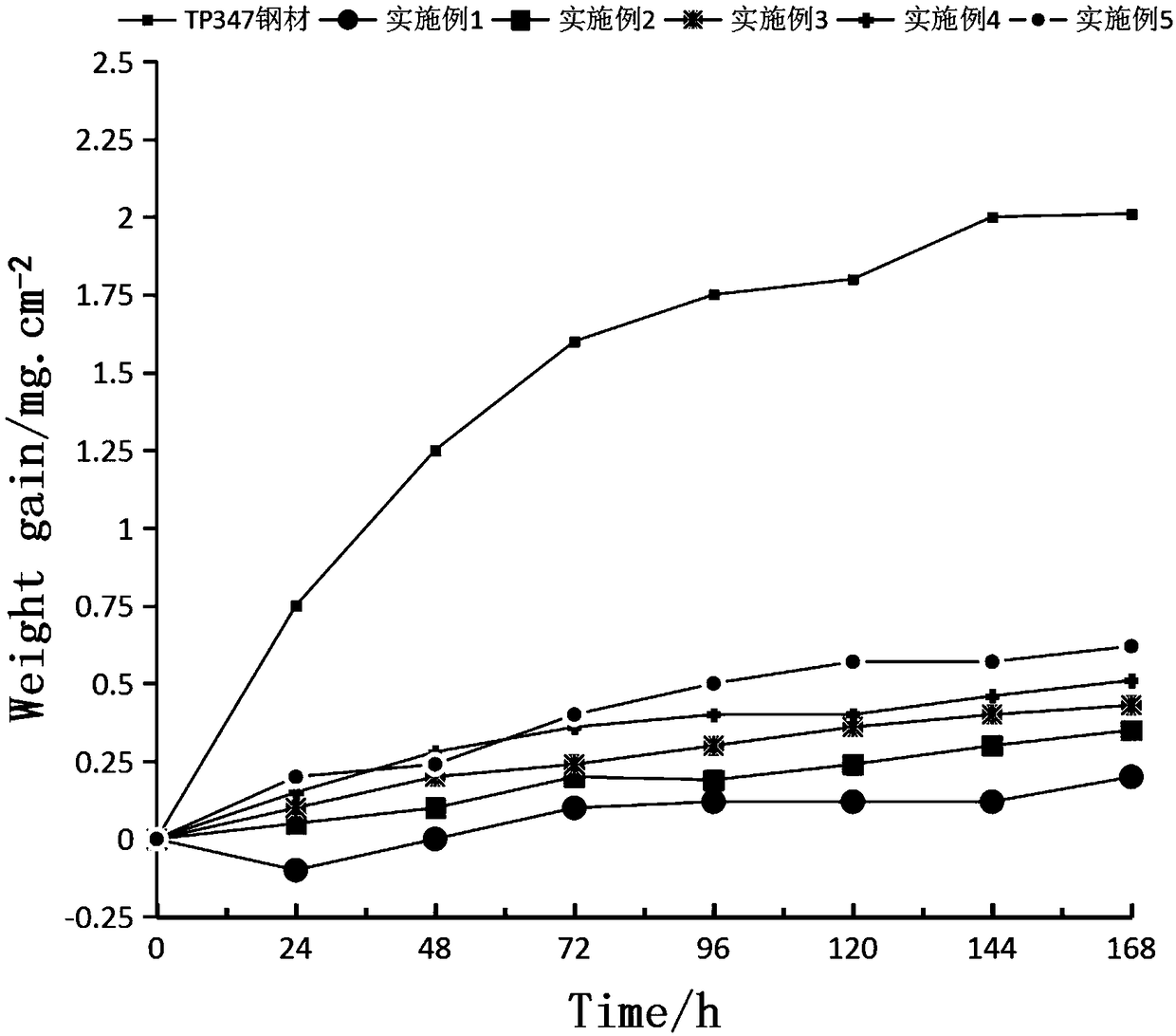

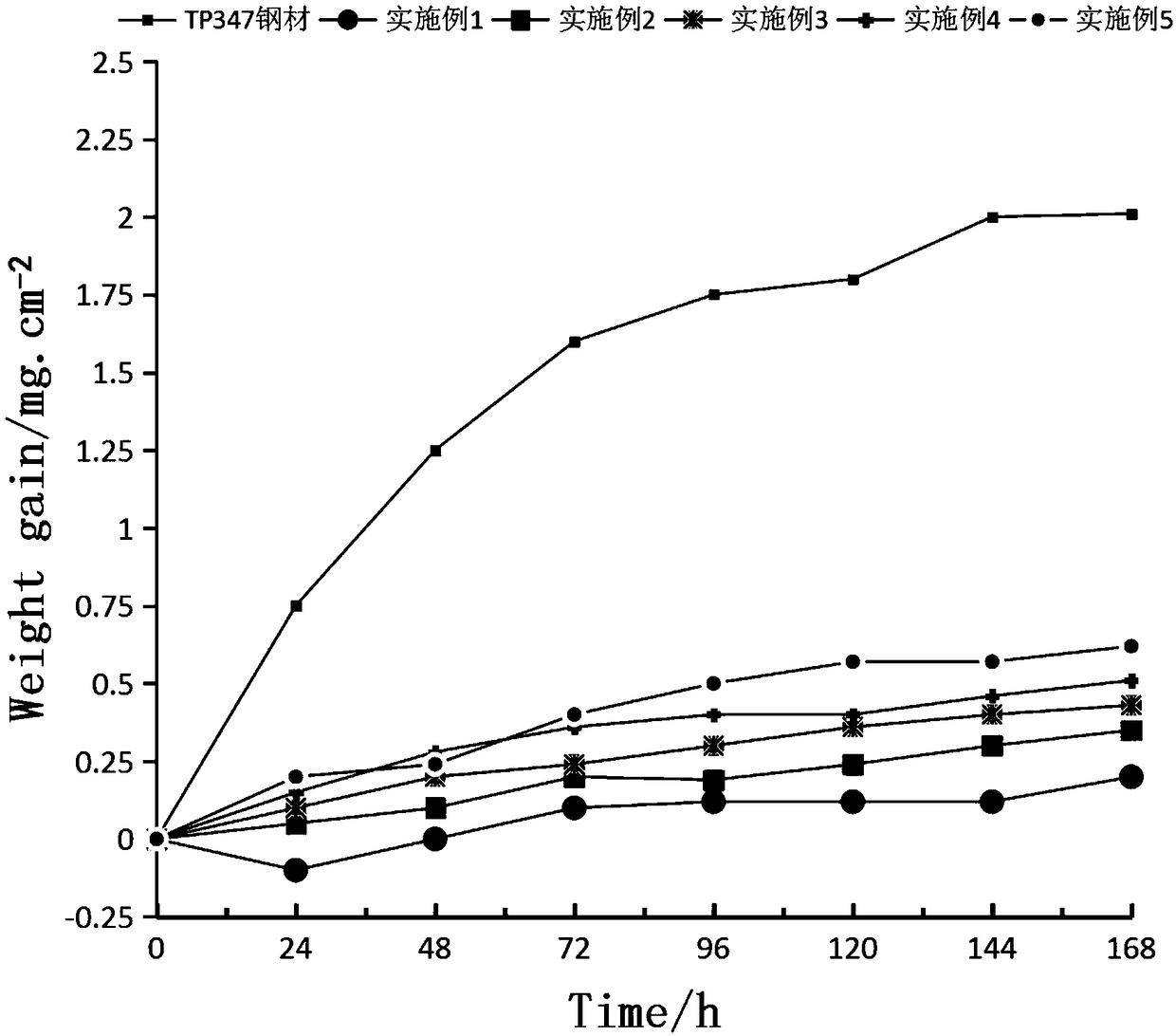

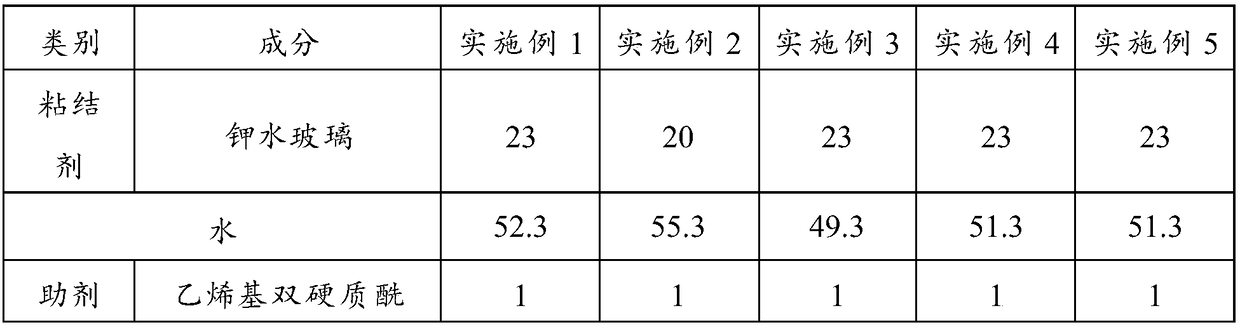

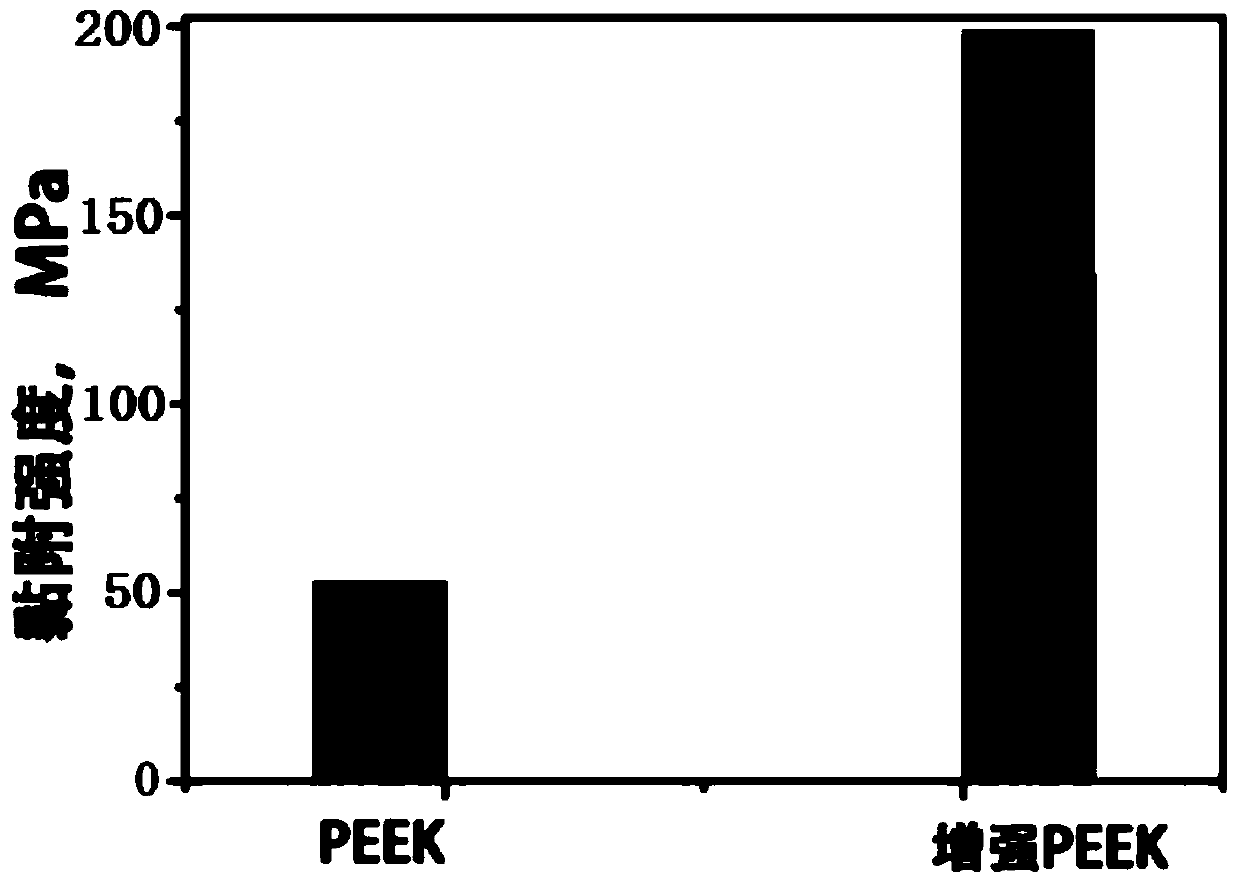

High-temperature chlorine corrosion resistant coating and preparation method thereof

ActiveCN108610680AHigh hardnessHigh surface energyFireproof paintsAlkali metal silicate coatingsAdhesiveCarbon nanotube

The invention provides a high-temperature chlorine corrosion resistant coating which comprises 20-30wt% of a filler, 20-35wt% of an adhesive and the balance of water, wherein the filler comprises 12-15wt% of barium glass, 2-5wt% of carbon nanotubes and 6-10wt% of aluminum oxide. The invention further provides a preparation method of the high-temperature chlorine corrosion resistant coating. The coating provided by the invention can be applied to heating-absorbing surfaces such as a boiler water cooling wall, can form a dense ceramic coated layer after high temperature curing, and is capable ofeffectively retarding high-temperature chlorine corrosion of the heating-absorbing surfaces.

Owner:ZHAOSHAN TECH BEIJING CO LTD

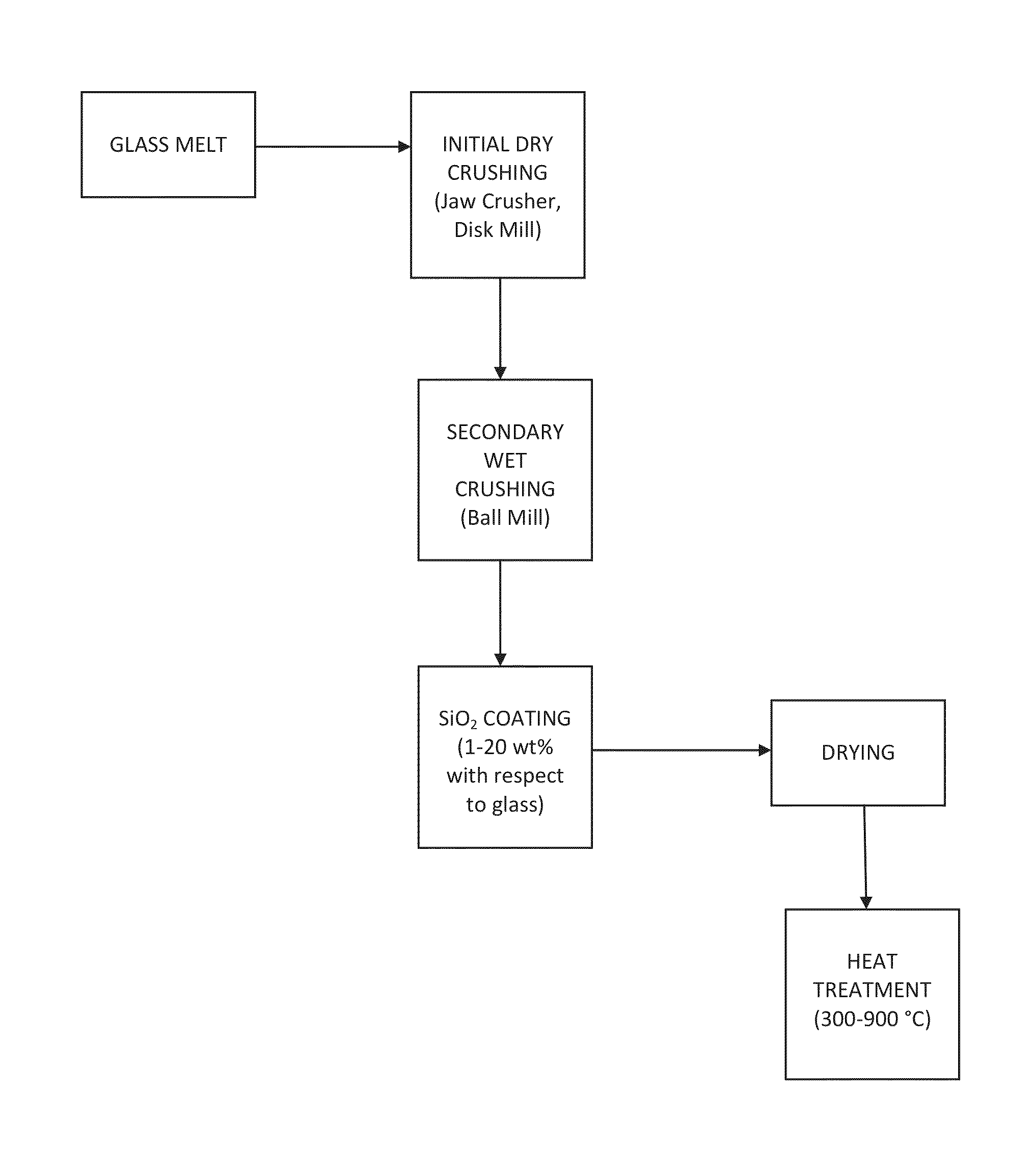

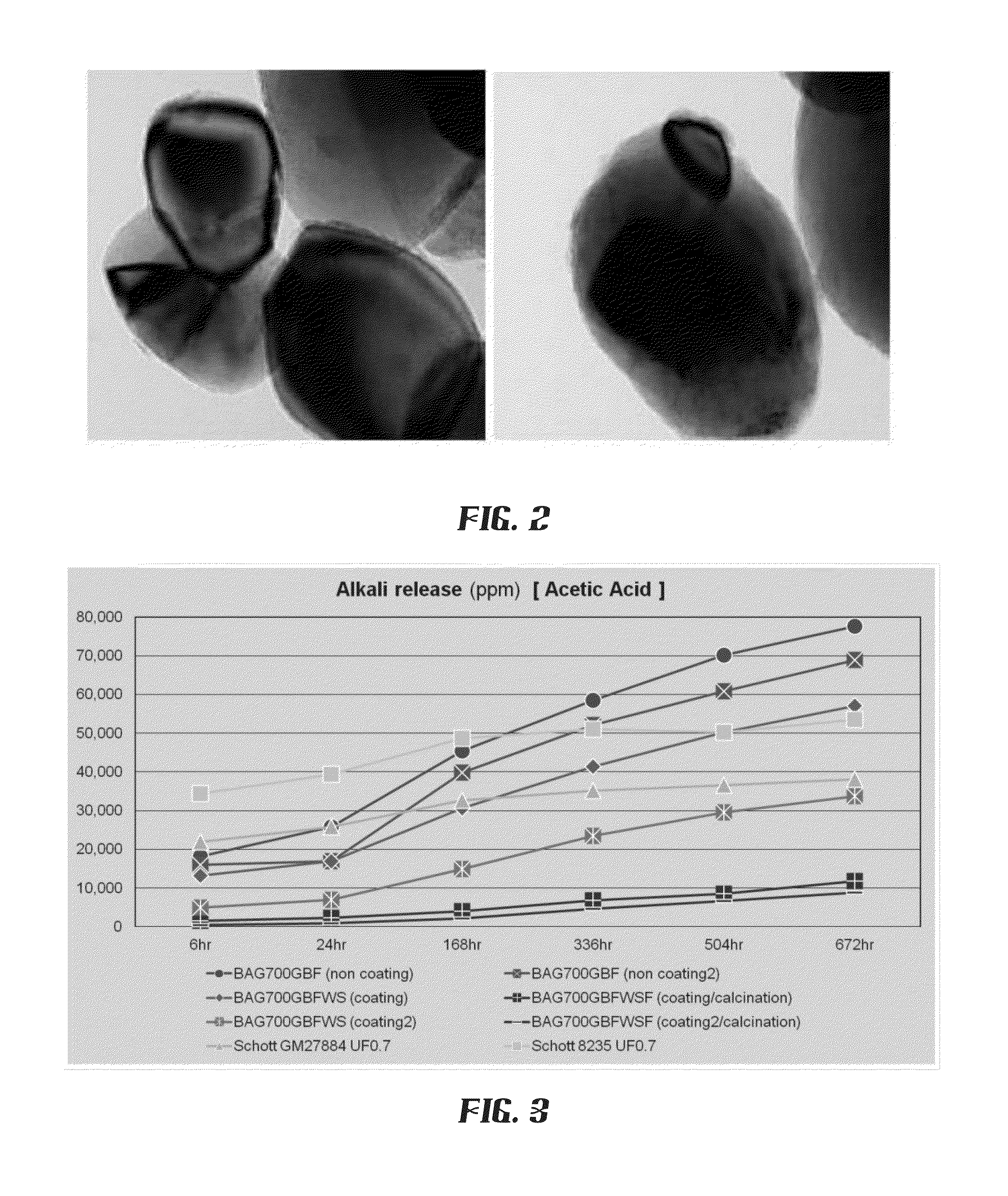

Glass Fillers Having Acid Resistance

InactiveUS20150013568A1Avoid disadvantagesAvoids shortcomingPigmenting treatmentImpression capsDental compositeStrontium

A glass filler manufacturing process and product which enable the manufacture of dental composite and dental cement products having superior product stability and also having superior physical properties. The process makes use of barium glass filler and strontium glass filler, which have high-radiopacity properties but could not previously be used for dental composites and dental cement. By simply coating the surface of the barium glass or strontium glass filler with an oxide having acid-resistance properties, and then following with a heat-treatment process, a suitable dental composite can be produced.

Owner:SUKGYUNG AT

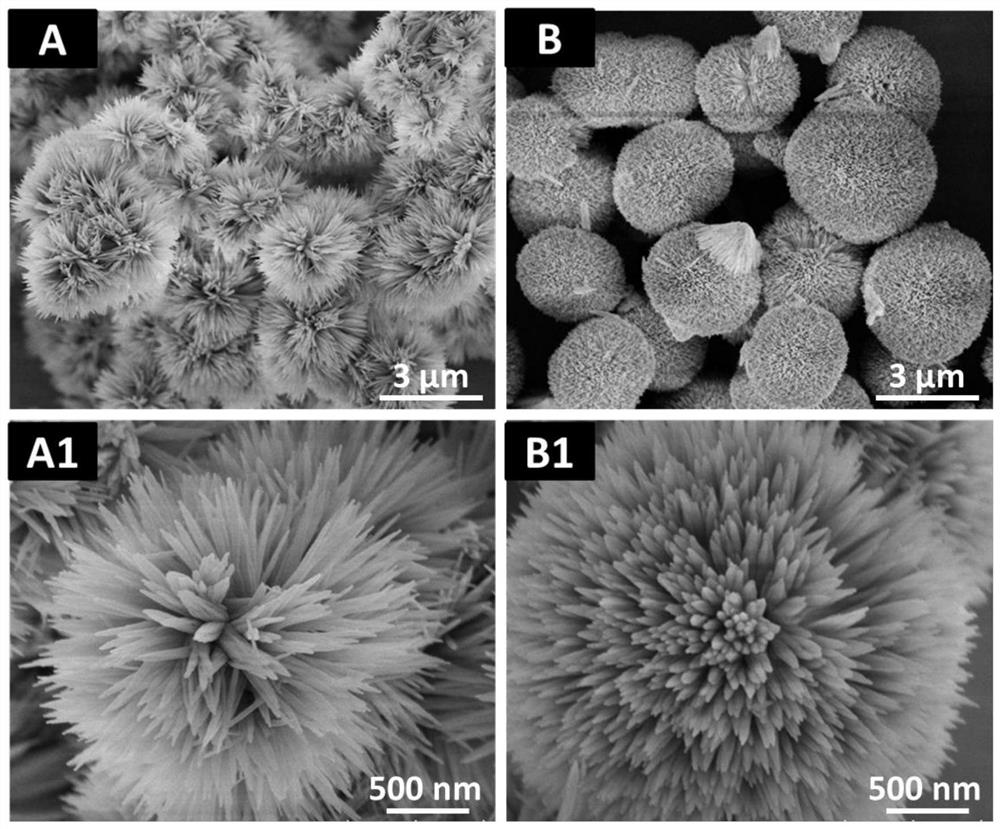

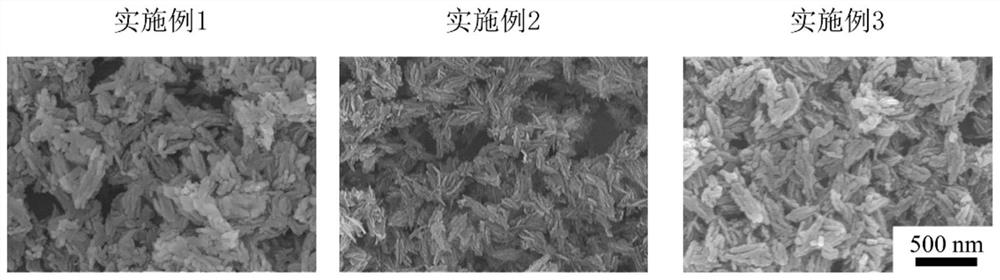

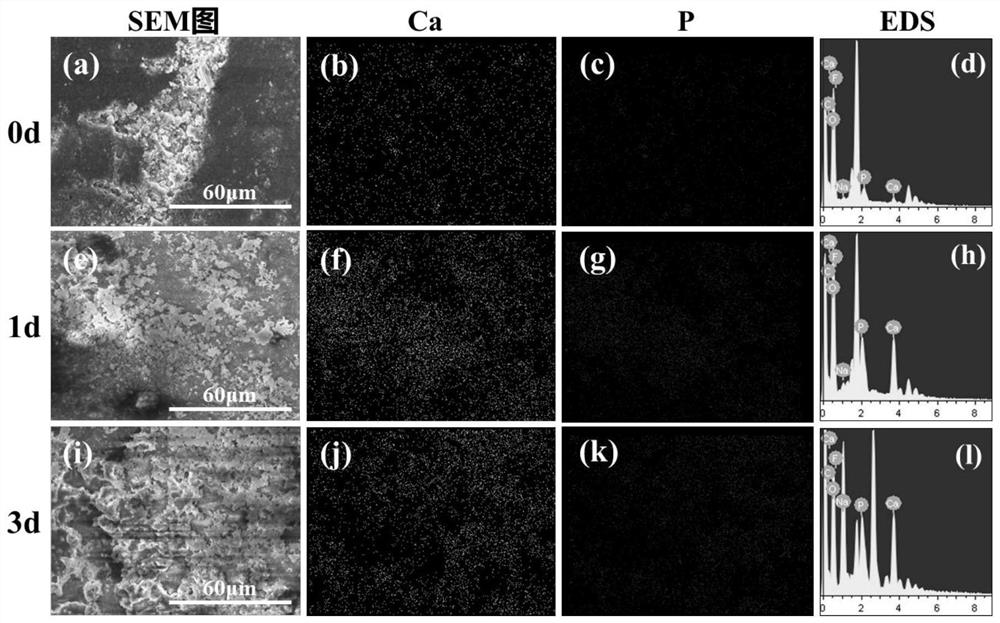

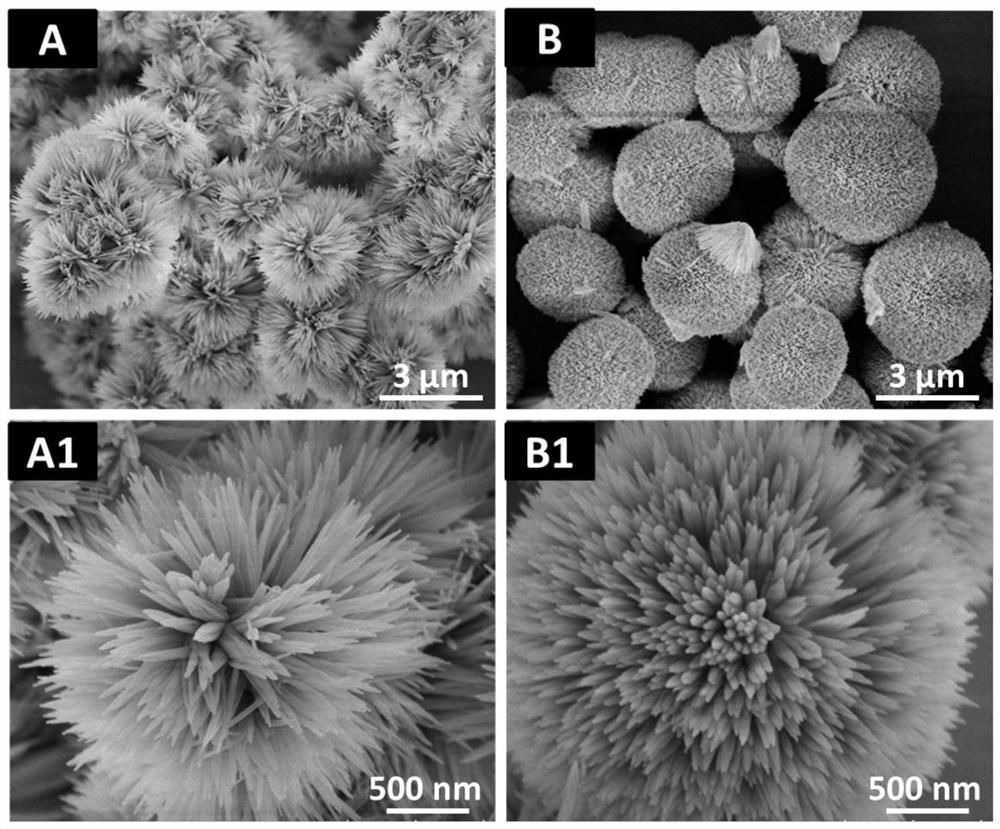

Similar "Echinops latifolius Tausch." ball-flower-shaped fluoridated hydroxyapatite base dentistry composite resin and preparation method thereof

ActiveCN111991241AHigh mechanical strengthImprove antibacterial propertiesImpression capsDentistry preparationsPolymer scienceEchinops latifolius

The invention relates to a similar "Echinops latifolius Tausch." ball-flower-shaped fluoridated hydroxyapatite base dentistry composite resin and a preparation method thereof. The composite resin comprises fillers, a resin base body and a photoinitiator, wherein the filler is a compound of silane modified fluoridated hydroxyapatite and barium glass powders. The method comprises the following stepsof preparing similar "Echinops latifolius Tausch." ball-flower-shaped fluoridated hydroxyapatite (E-FHAp), preparing the silane modified E-FHAp and preparing the E-FHAp base dentistry composite resin. The method constructs the high-quality dentistry composite resin which combines excellent mechanical strength and functionality, and therefore, the mechanical property and the service performance ofthe dentistry repairing resin can be effectively improved.

Owner:DONGHUA UNIV

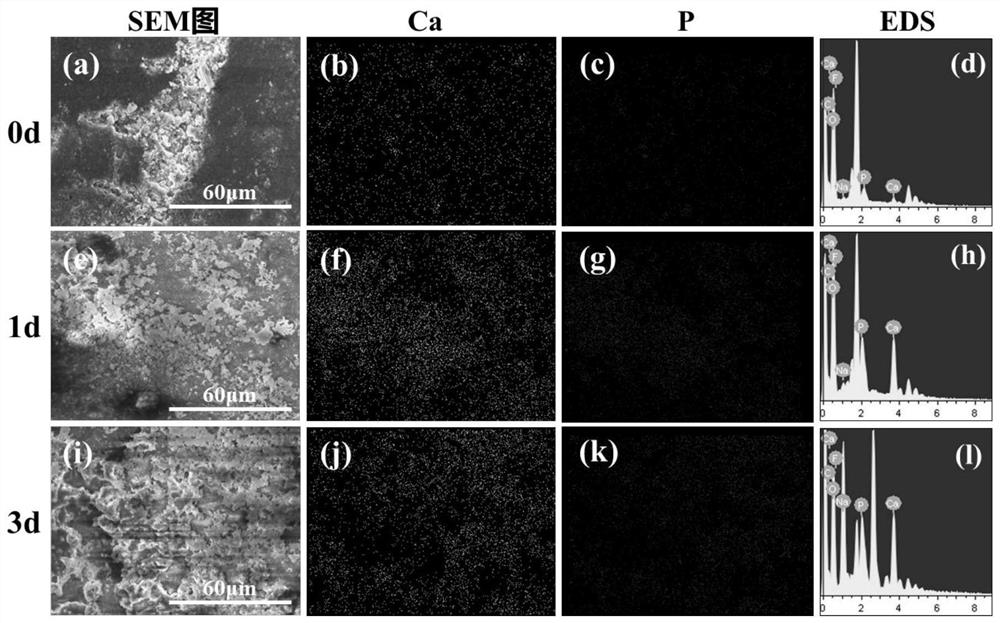

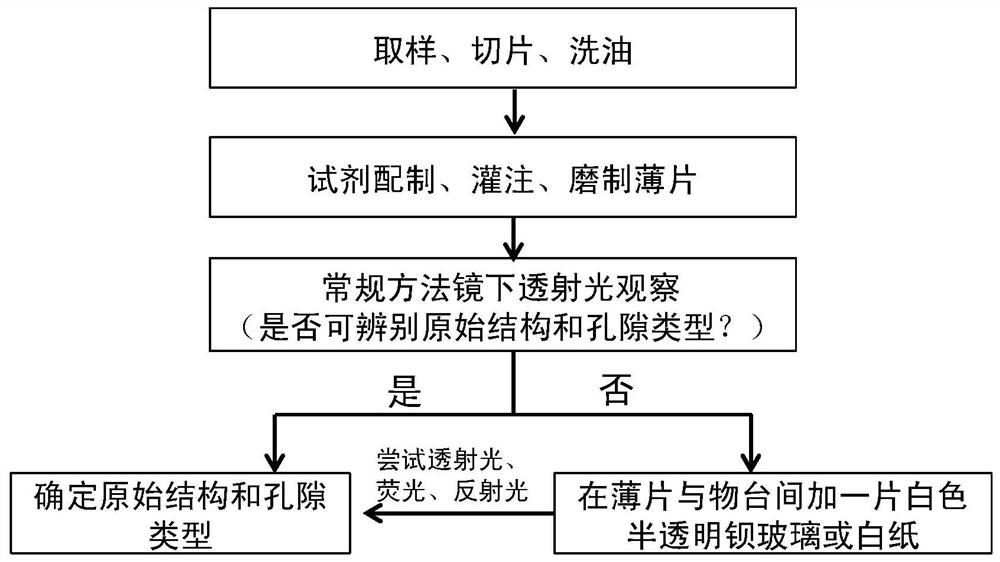

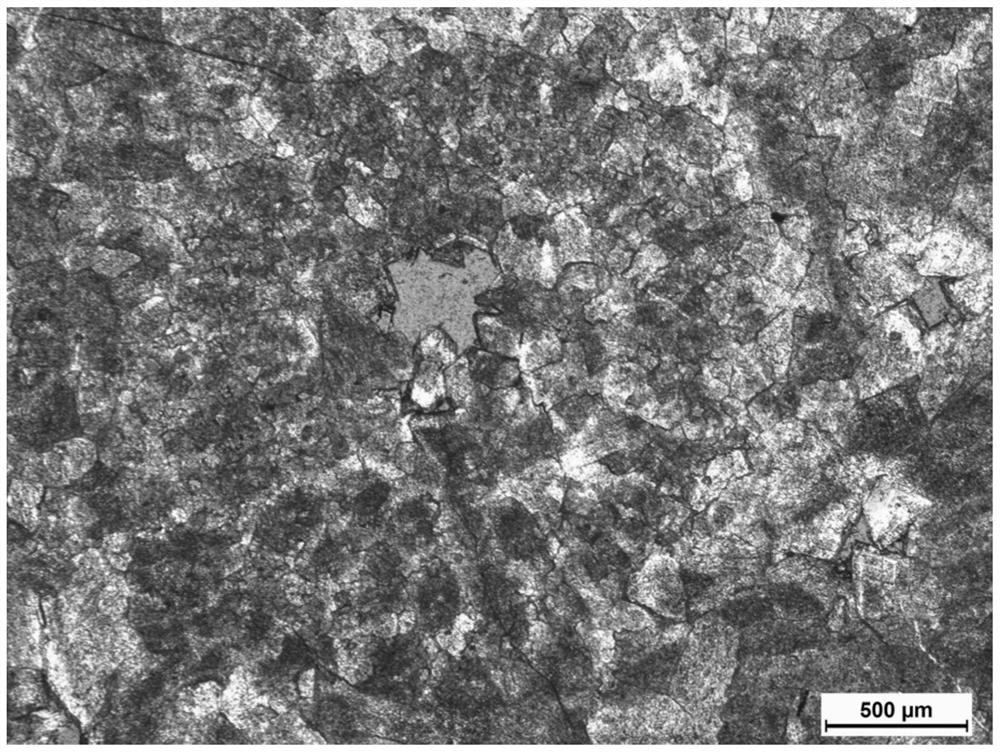

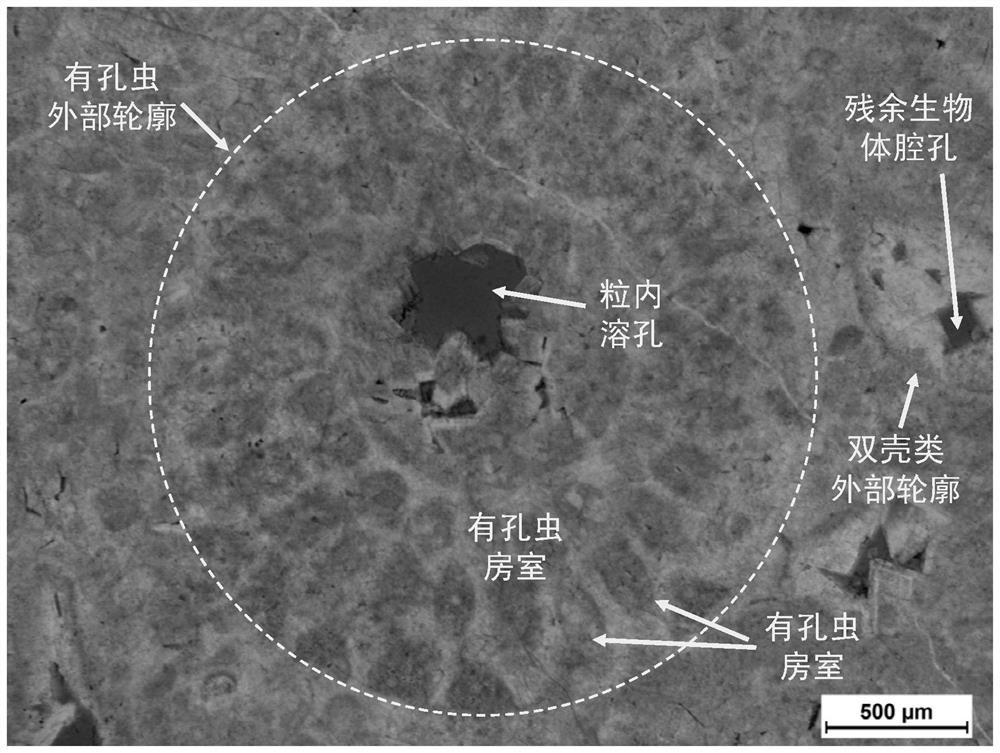

Carbonate rock original structure and pore type identification method

PendingCN112067609AEasy to describeImaging effect under the microscope is improvedPreparing sample for investigationFluorescence/phosphorescenceEngineeringPellets

The invention provides a carbonate rock original structure and pore type identification method. The method comprises the following steps: (1) cutting a circular slice from a carbonate rock sample; (2)pouring a blue reagent into pores of the circular slice in a high-pressure cavity; (3) grinding the slice filled with the blue reagent into sheets; and (4) placing a piece of white semitransparent barium glass or a piece of white paper between the sheet and a microscope stage, and observing the sheet by using a microscope so as to identify the original structure and the pore type of the carbonaterock. According to the carbonate rock original structure and pore type identification method provided by the invention, a carbonate rock sheet manufacturing method is improved, and an observation mode under the microscope is improved so that a microscopic imaging effect of residual particles and pores in the carbonate rock can be improved; and technical support is provided for correctly identifying the original structure and the pore type and enhancing reliability of sedimentary environment and reservoir formation cause interpretation.

Owner:PETROCHINA CO LTD

Light-cured composite resin for oral cavity by using single crystal diamond as filler and preparation method thereof

ActiveCN101518499BHigh strengthHigh hardnessImpression capsDigestive systemPolymer sciencePolycrystalline diamond

Owner:BEIJING POLYSTAR HITECH CO LTD

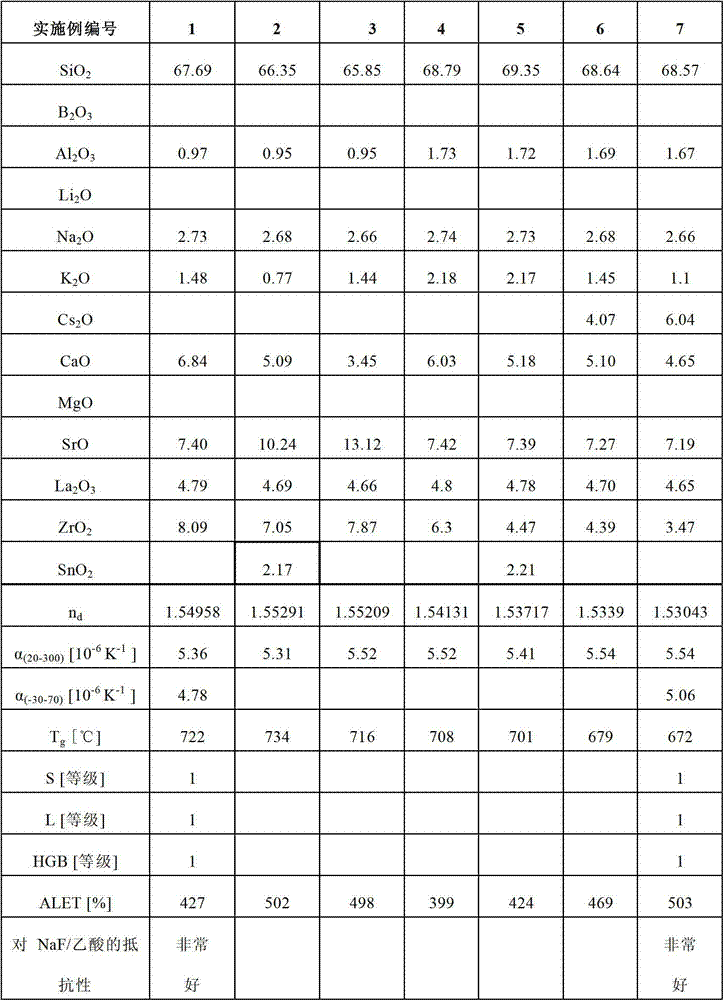

X-ray opaque glass

InactiveCN103043906AMeet aesthetic requirementsAvoid or at least suppress undesired interactionsImpression capsTooth crownsAluminiumRefractive index

An X-ray-opaque glass is disclosed which is free of BaO and PbO except for at most impurities and has a refractive index nd of from 1.50 to 1.58 and a high X-ray opacity with an aluminium equivalent thickness of at least 300%. The glass is based on the system Si02 - Al203 - SrO - R20 with additions of La203 and Zr02. The glass has very good chemical resistance and can be used, in particular, as dental glass or as optical glass.

Owner:SCHOTT AG

Solder additive for brazing of high nitrogen steel

ActiveCN109014661AImprove tissue performanceExtended service lifeWelding/cutting media/materialsSoldering mediaWater basedAdhesive

Disclosed is a solder additive for brazing of high nitrogen steel. The solder additive is composed of a reinforcing agent, a water-based adhesive and a BJQ mixture in a mass ratio of 1:7 to 8:3 to 5,the reinforcing agent being nickel-plated graphene or vanadium-plated graphene or a mixture of the nickel-plated graphene and the vanadium-plated graphene in any mass ratio, the BJQ mixture being a mixture of barium glass powder, fumed silica and tartaric acid in a mass ratio of 1:3.5:1. When the additive of the present invention is added to the solder for brazing, the high nitrogen steel base material hardly melts, so that the nitrogen element is not lost, overcoming the pore defects of the conventional welding method, so that the nitrogen element has almost no loss; and because the high nitrogen steel base material hardly melts, that is, no deformation is caused, and the connection strength and mechanical properties of the joint are improved to a certain extent, and the welded joint is formed very well.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

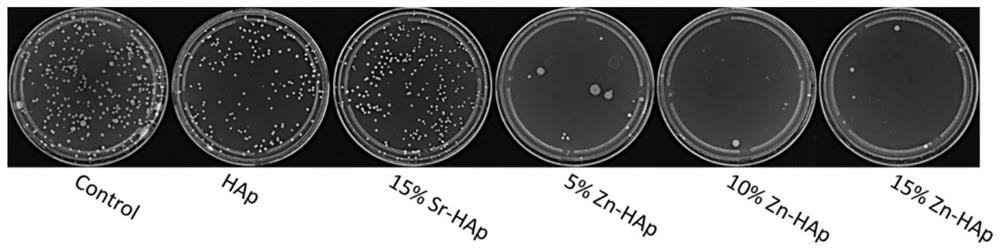

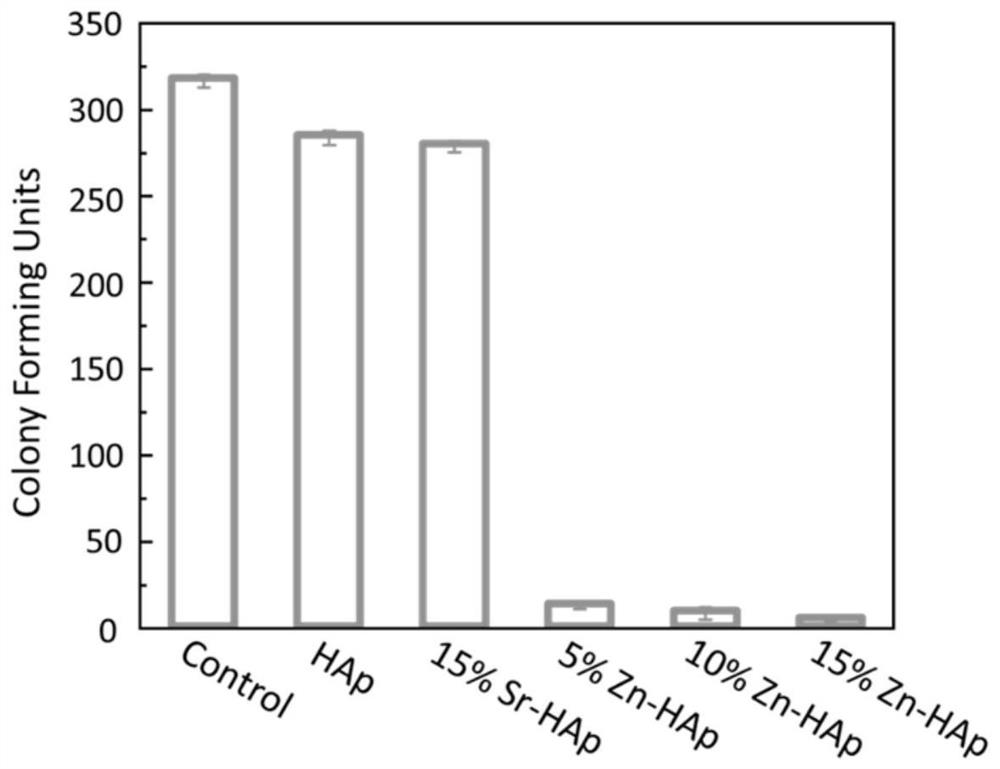

Dental repair composite resin with bacteriostasis-remineralization dual functions as well as preparation and application thereof

PendingCN113499269ASimple preparation processMild preparation conditionsImpression capsDentistry preparationsTooth fillingResin matrix

The invention relates to dental repair composite resin with bacteriostasis-remineralization dual functions and preparation and application thereof. The composite resin comprises an inorganic filler, a resin matrix and a photoinitiator, wherein the inorganic filler is a compound of silanization modified strontium / zinc mono-and co-doped hydroxyapatite nanoparticles and barium glass powder. According to the method, strontium / zinc doped hydroxyapatite is well dispersed and well combined with a resin matrix, and the method is simple, low in cost, low in equipment requirement and suitable for large-scale production; the obtained product has lasting bacteriostasis and remineralization capability, the color does not influence the beauty, the biocompatibility is excellent, and the long-term life and the curative effect of a prosthesis can be remarkably improved when the product is applied to the oral cavity as a decayed tooth filling and repairing material.

Owner:BEIJING UNIV OF CHEM TECH

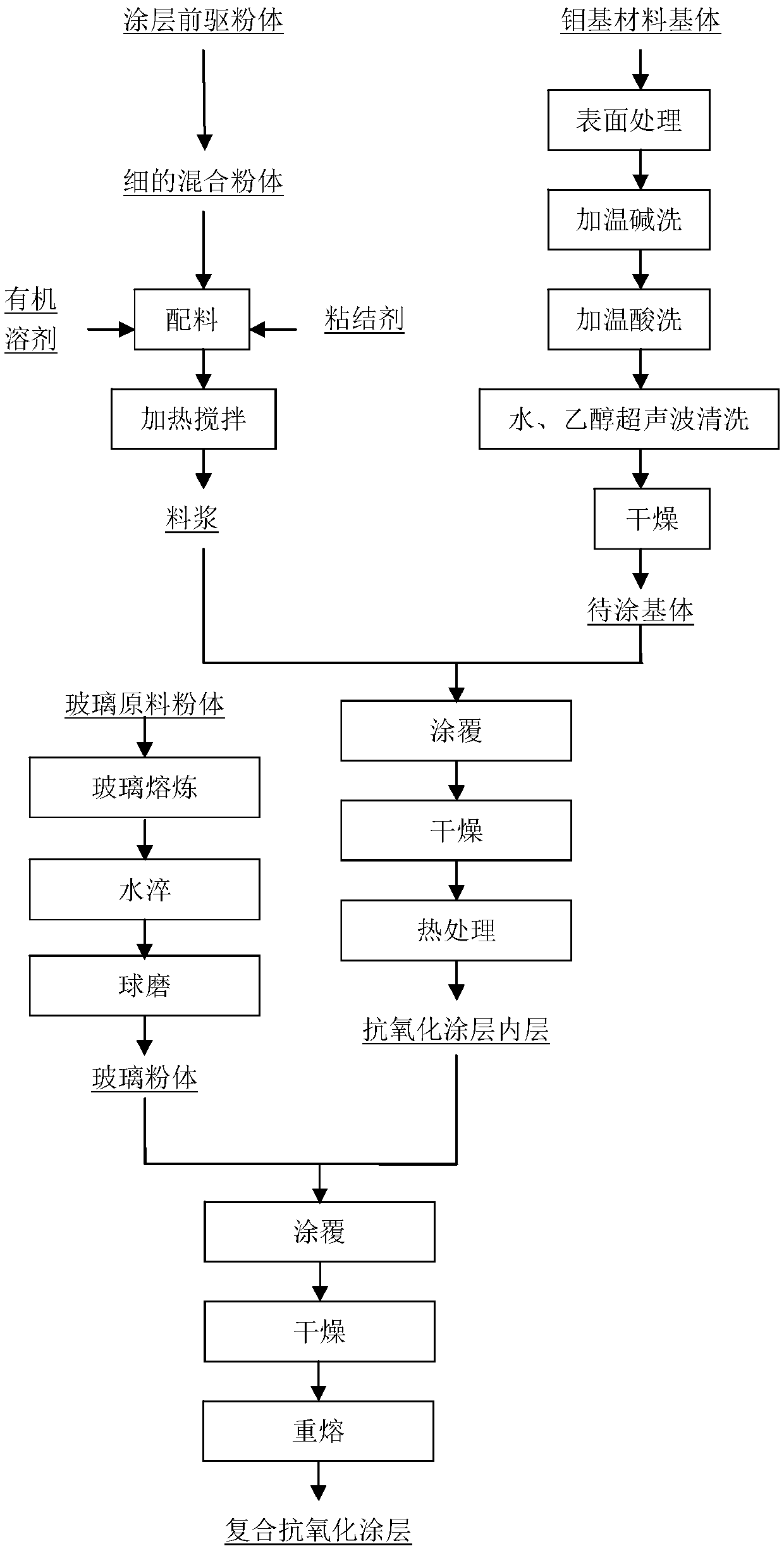

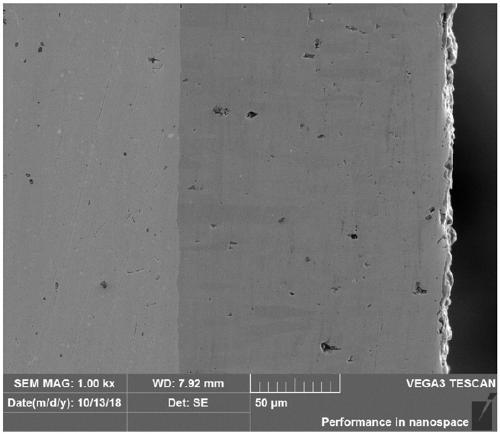

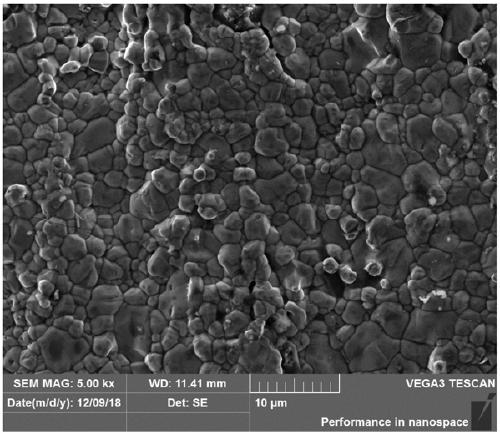

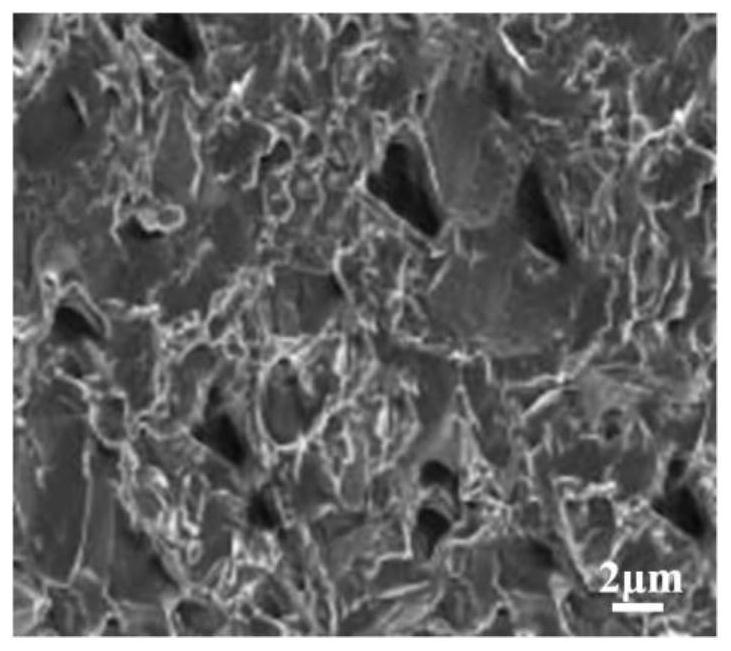

Molybdenum base composite material with composite oxidation resistant coating, and preparation method thereof

ActiveCN109536958ASolve the problem of poor high temperature oxidation resistanceMetallic material coating processesOxidation resistantMass content

The invention relates to a molybdenum base composite material with a composite oxidation resistant coating, and a preparation method thereof. The preparation method of the molybdenum base composite material comprises the steps of arranging a pretreated substrate with a molybdenum silicon compound coating on a molybdenum base composite material substrate; coating sizing agents containing barium glass powder on the surface of the molybdenum silicon compound coating, and performing heat treatment after drying at 500 DEG C-1200 DEG C; and cooling the coating, so that the molybdenum base compositematerial is obtained, wherein the mass content of BaO in the barium glass powder is 40%-45%. According to the method, the sizing agents containing the barium glass powder are coated on the surface ofthe molybdenum silicon compound coating, and a barium glass coating is formed on the surface of the molybdenum silicon compound coating through remelting heat treatment; the composite oxidation resistant coating is formed by the molybdenum silicon compound coating and the barium glass coating, and long-acting oxidation resistance protection of the molybdenum base composite material can be achieved; the composite oxidation resistant coating can be used for preventing gas invasion at high temperature effectively, so that the high temperature oxidation resistance of the molybdenum base compositematerial is improved effectively.

Owner:HENAN UNIV OF SCI & TECH

Photo-thermal curing resin composition as well as preparation method and application thereof

ActiveCN113717330AHigh hardnessHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyPolymer scienceSilicon oxide

The invention provides a photo-thermal curing resin composition and a preparation method and application thereof. The resin composition comprises a combination of a prepolymer, a monomer, a photoinitiator, a thermal initiator, fumed silica and glass powder in specific parts, the photoinitiator in specific parts is added to be matched with the thermal initiator, the completion rate of a curing reaction is increased, the resin composition is more sufficiently cured, and the monomer residual rate after curing is lower. Specific parts of fumed silica and barium-containing glass powder are also added as fillers, so that the hardness, strength and wear resistance of the resin composition are effectively enhanced, and a product obtained by performing 3D printing on the finally obtained resin composition completely meets the requirements of serving as a temporary crown bridge.

Owner:AIDITE (QINHUANGDAO) TECH CO LTD

Environment-friendly type lamp and method of manufacturing

InactiveCN101013651AWon't breakImprove air tightnessLamp incadescent bodiesLeading-in conductorsNickel alloyFlare

The invention provides one environment friendly bulb and its process method, wherein, the bulb and its roller comprises high barium glass with lead less than 0.0001 percent to form copper-coated iron and nickel alloy wire of lead wire and its expansion parameters less than 10 to 6; the process method comprises steps of copper-coated iron and nickel alloy wire processing, bulb roller processing, lamp tube processing and sealing process and backward processing with flare temperature as 1000 degrees.

Owner:HE SHAN YINYU LIGHT DECORATION LTD

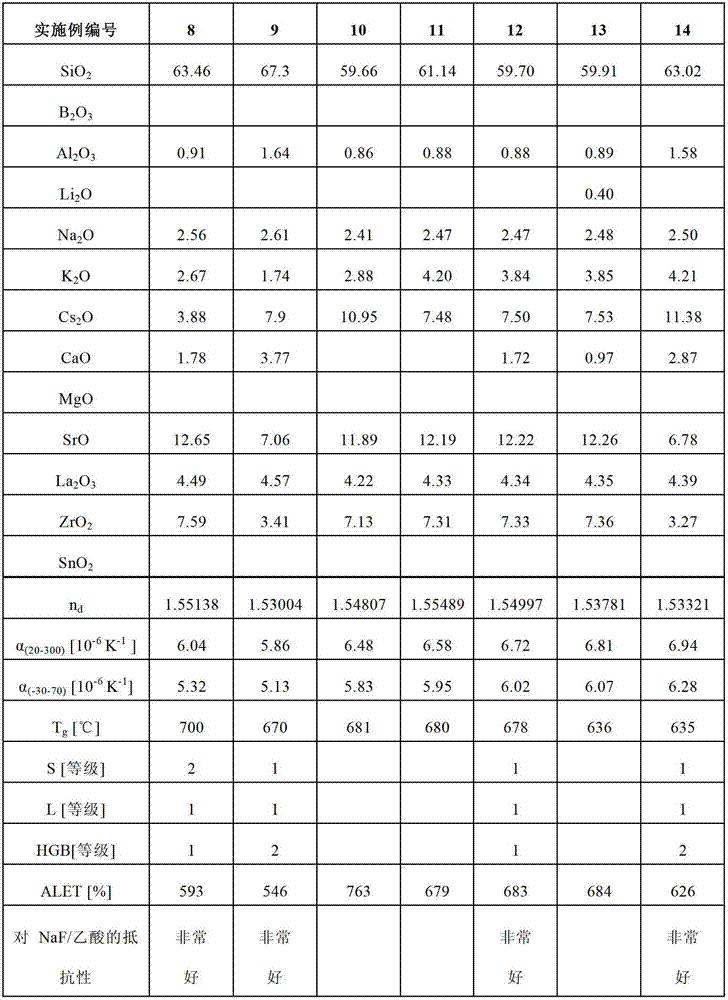

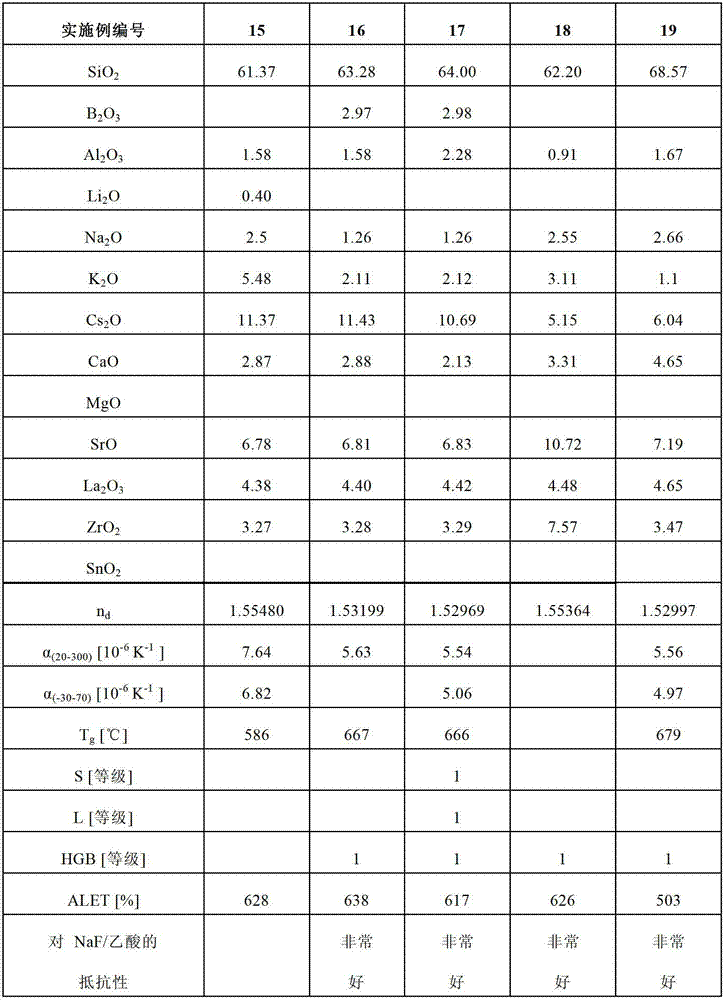

X-ray opaque barium-free glass and the use thereof

Zirconium-containing BaO- and PbO-free X-ray opaque glasses having a refractive index nd of about 1.480 to about 1.517 and a high X-ray opacity with an aluminum equivalent thickness of at least about 180% are provided. Such glasses are based on a SiO2-B2O3-Cs2O-K2O-La2O3 system with additions of Al2O3, Li2O, Na2O and / or ZrO2. Such glasses may be used, in particular, as dental glasses or as optical glasses.

Owner:SCHOTT AG

High-temperature-chlorine-corrosion-resistant coating for boiler heating surface, and preparation method thereof

ActiveCN111286224AHigh pottery yieldSmall volume shrinkageFireproof paintsAnti-corrosive paintsComposite ceramicThermal shock

The invention relates to a high-temperature-chlorine-corrosion-resistant coating for a boiler heating surface, and a preparation method thereof. The coating comprises an inner transition layer and anouter protective layer, wherein the transition layer is a perhydropolysilazane precursor composite ceramic coating, the protective layer is an organic polysilazane precursor composite ceramic coating,the transition layer is formed by spraying surface of a steel matrix with a coating material consisting of 60-70% by volume of perhydropolysilazane, 10-20% by volume of graphite powder and 10-20% byvolume of butyl acetate and then curing at a high temperature of 200 DEG C, and the protective layer is formed by spraying the transition layer with a coating material consisting of 20-25% by volume of organic polysilazane, 25-30% by volume of barium glass powder, 15-20% by volume of zirconium oxide, 5-10% by volume of aluminum powder and 20-30% by volume of butyl acetate and curing at a high temperature of 700 DEG C. The coating is simple in preparation process and low in cost, can be suitable for high-temperature chlorine corrosion protection of heating surfaces of various biomass boilers, waste incineration boilers and high-chlorine coal boilers, and has the advantages of high toughness, compact surface, high thermal shock resistance and the like.

Owner:CHINA JILIANG UNIV

Barium glass material and preparation method thereof

The invention relates to glass, in particular to barium glass. A barium glass material is prepared from the following raw materials in part by weight: 67 parts of SiO2, 1.70 parts of B2O3, 1.00 part of Al2O3, 3 parts of CaO, 1.80 parts of ZnO, 8 parts of BaO, 4 parts of K2O and 13 parts of Na2O. The barium glass material has a reasonable formula and is not prepared from the conventional barium methacrylate, so that the transmittance of the glass is greatly improved; the barium glass material has high low-energy X-ray shielding property; and the prepared barium glass has high surface hardness, high mechanical strength, solvent resistance, high light permeability and wide application.

Owner:DALIAN MINYUAN TECH

A kind of peek denture tooth composite material and preparation method thereof

The invention discloses a PEEK false tooth composite. The PEEK false tooth composite is prepared from, by weight, 110-150 parts of polyether-ether-ketone, 10-20 parts of nano calcium silicate, 8-12 parts of hydroxyl hydroxyapatites, 4-8 parts of barium glass short fibers, 15-22 parts of organic solvent, 8-18 parts of refined paraffin, 1-4 parts of co-binding agent, 8-12 parts of binder, 2-6 parts of antibacterial agent, 6-10 parts of carbide and / or 8-15 parts of oxide. The invention further discloses a preparation method of the PEEK false tooth composite. The preparation method includes the steps that firstly, the raw materials of nano calcium silicate, hydroxyl hydroxyapatites, carbide and / or oxide are mixed, the mixture is heated to 150-220 DEG C, the situation is kept for 10-30 min, cooling is carried out, the refined paraffin is added, mixing and stirring are carried out, and after the mixture is crushed ultrasonically, the organic solvent, polyether-ether-ketone, the co-binding agent, the binder and the antibacterial agent are added to be stirred till uniform paste is obtained; finally the barium glass short fibers are added, ball-milling and drying are carried out, and the finished composite powder is obtained.

Owner:广西深雅医疗科技股份有限公司

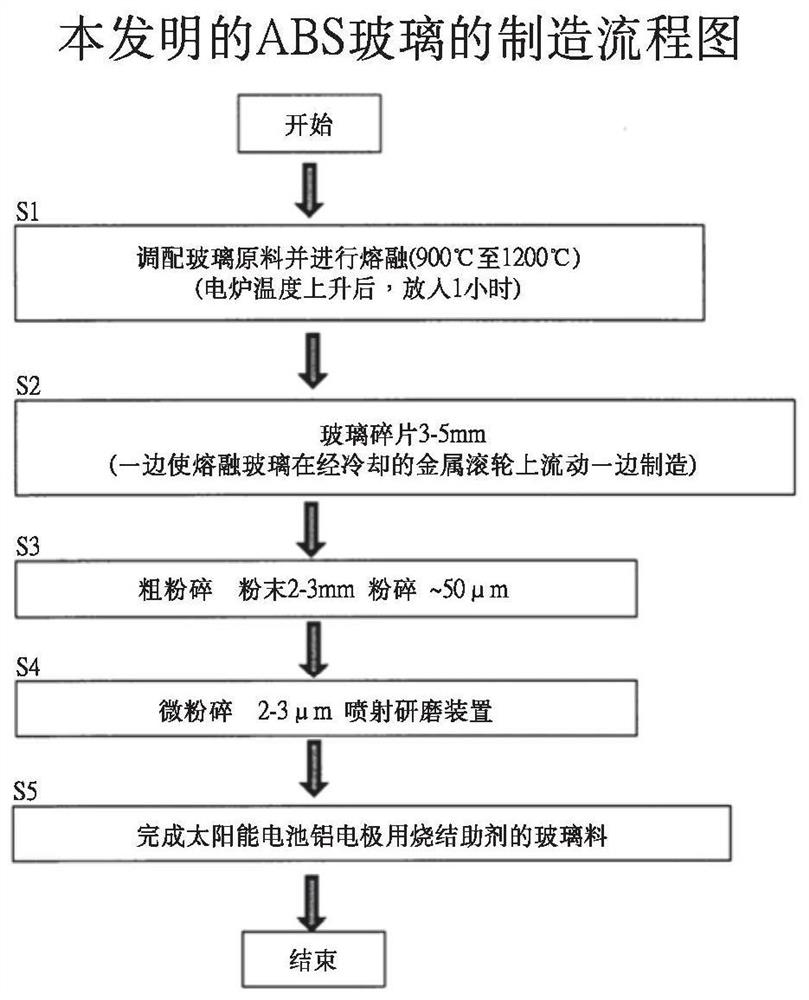

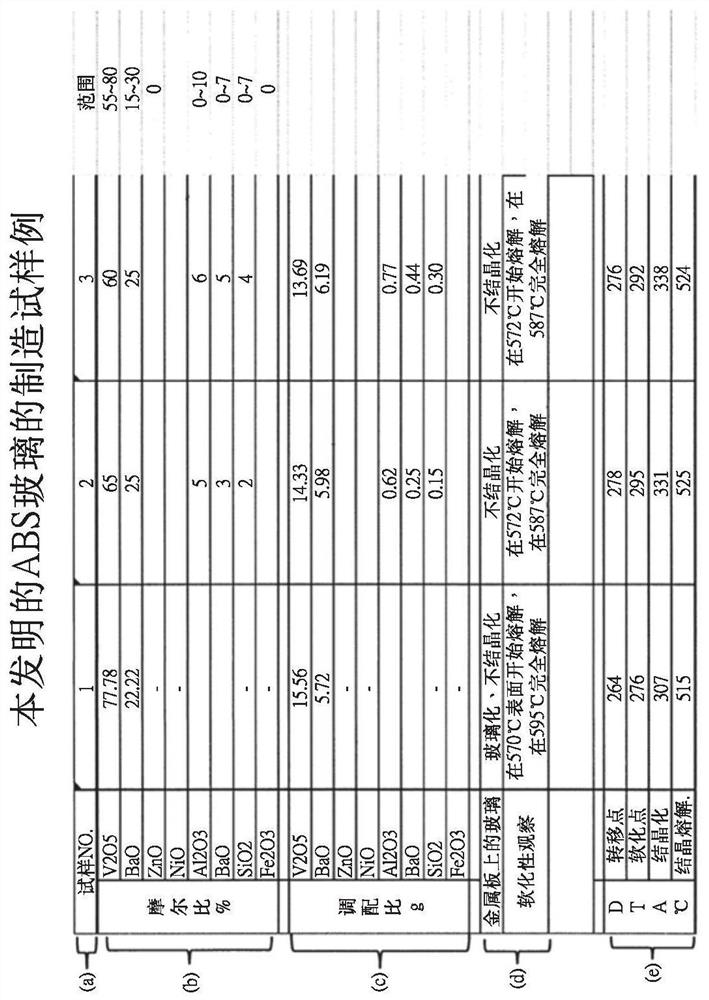

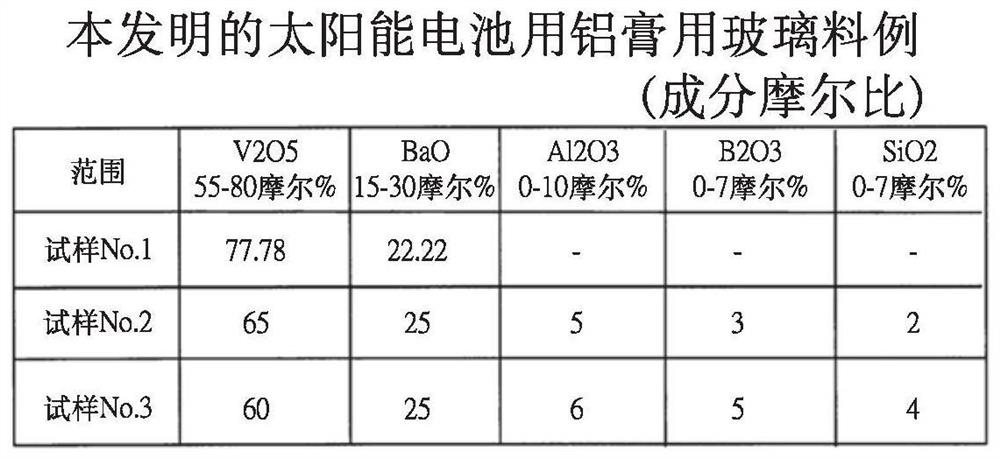

Glass frit, glass frit manufacturing method and aluminum paste

ActiveCN110461788BEliminate life expectancyEliminate warpingConductive layers on insulating-supportsQuartz/glass/vitreous enamelsElectrical batteryFrit

The present invention relates to a glass frit used in the aluminum paste used to form the aluminum electrode on the back surface of a solar cell, a glass frit manufacturing method, and an aluminum paste. , and will melt at the low temperature necessary for the manufacture of solar cells, etc., and the main components are only vanadium and barium glass frit. The invention provides a glass frit, which is: vanadium V with 55 to 80 mole % 2 o 5 And 15 to 30 mol% of barium BaO as the main material, or 10 to 55 mol% of vanadium V 2 o 5 and 10 to 40 mol% of barium BaO as a main material to produce glass frit by heating molten glass and rapidly cooling the molten glass to form pieces that are pulverized to produce a glass frit that melts below 650°C.

Owner:ARTBEAM CO LTD

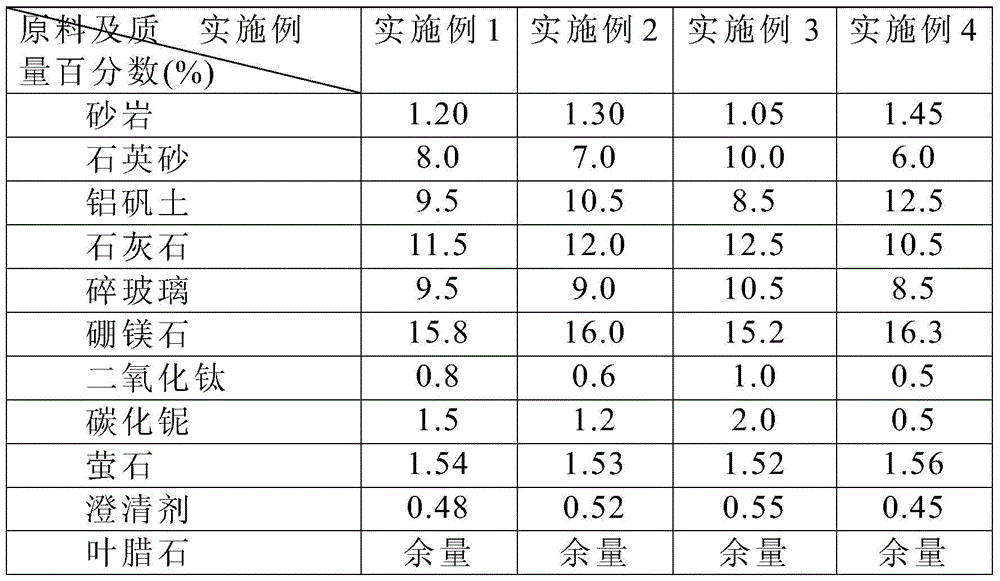

A kind of lead-free potassium-barium glass ball and its production process

The invention relates to a glass ball, particularly relates to a lead-free potassium barium glass ball and a production process thereof, and belongs to the technical field of glass material. The glass ball comprises the raw materials by the mass percentage: 1.05-1.45% of sandstone, 6.0-10.0% of quartz sand, 8.5-12.5% of bauxite, 10.5-12.50% of limestone, 8.5-10.5% of broken glass, 15.2-16.3% of ascharite, 0.5-1.0% of titanium dioxide, 0.5-2.0% of niobium carbide, 1.52-1.56% of fluorite, 0.45-0.55% of a clarifying agent, and the balance pyrophyllite. While the glass ball is guaranteed to have the advantages of being high in whiteness, glittering and translucent, high in gloss, rich in refractive index, toughness and the like, the chemical stability, the thermal stability and the mechanical strength of the lead-free potassium barium glass ball are improved, and the crystallization tendency of the lead-free potassium barium glass ball is reduced, and the cost of production is greatly reduced.

Owner:NINGBO CHANGLIFENG GLASS WARE

Dental restoration material for stomatology and preparation method thereof

ActiveCN113317995BGood dispersionImprove mechanical propertiesImpression capsDentistry preparationsPolymerisation shrinkageRestorative material

The invention discloses a dental restoration material for stomatology and a preparation method thereof, and relates to the field of medical materials. The dental restoration material for oral science comprises: base resin, the above-mentioned base resin includes at least one of Bis-GMA and UDMA; filler, the above-mentioned filler includes modified silane coupling agent modified barium glass powder, modified silane coupling At least one of agent-modified micro-silica powder; photoinitiator. The dental restoration material prepared by the present invention has excellent mechanical strength, strong wear resistance, and low polymerization shrinkage; and the water absorption and solubility are significantly reduced, thereby enhancing the service life of the restoration material, reducing its toxicity in use, and reducing the risk of periodontitis Incidence, expanding the scope of use of restorative materials.

Owner:云南中辉口腔医院有限公司

Method for preparing barium-based glass frit by using barium slag

ActiveCN105948499BIncrease profitImprove the level ofAlkali metal sulfides/polysulfidesIron sulfatesSlagSlurry

The invention provided a method for preparing barium-based glass frit with barium slag. The method comprises the following steps: barium slag is ground, and a barium slag slurry is prepared; the barium slag slurry is subjected to pipeline sulfuric acid leaching; hydrogen sulfide gas produced in the product is absorbed with sodium alkali, such that sodium sulfide is obtained; solid-liquid separation is carried out, and an iron aluminum sulfate water purifying agent is obtained; the solid is washed and dried; the dried solid is added into a glass frit furnace, and is molten in an oxidation atmosphere; the molten glass is subjected to water extraction, such that the barium-based glass frit is obtained. With the method provided by the invention, barium slag utilization rate is improved, and a high-barium glass frit (ceramic glaze material) is obtained. A glass material prepared with the high-barium frit has the advantages of less bubbles, high transparency and bright color, and has functions that cannot be found in common glass.

Owner:贵州红星发展大龙锰业有限责任公司

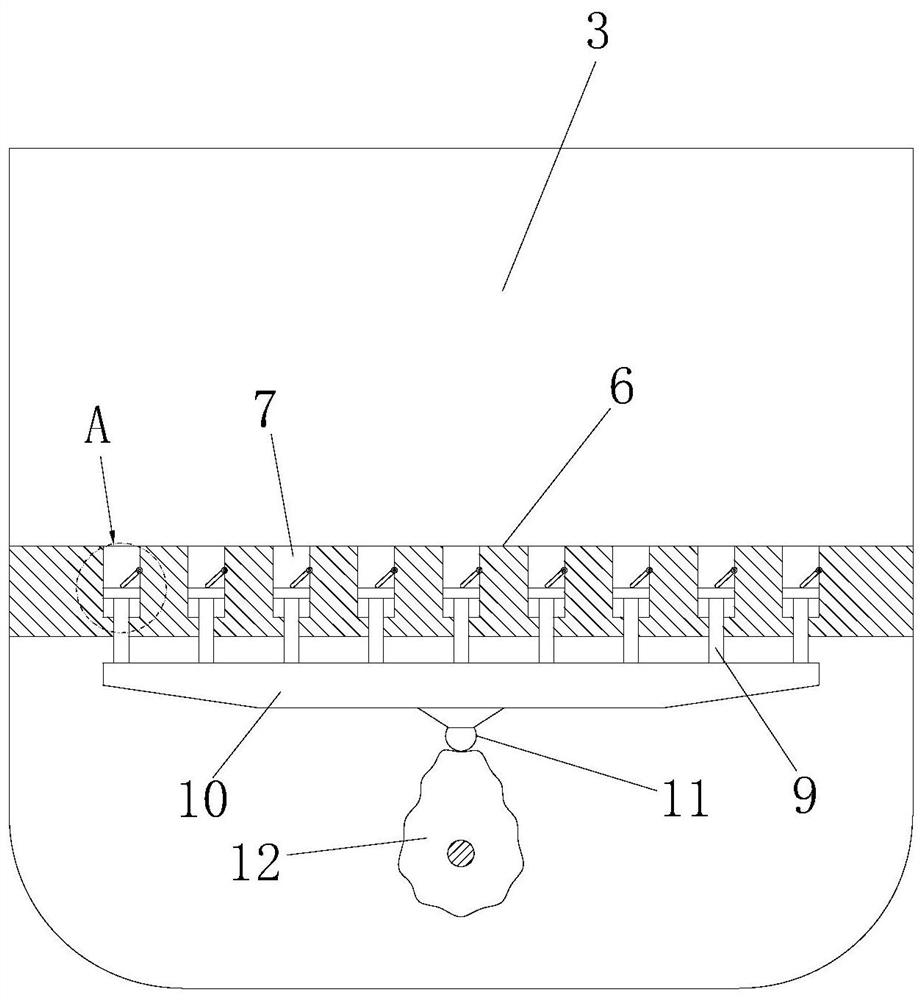

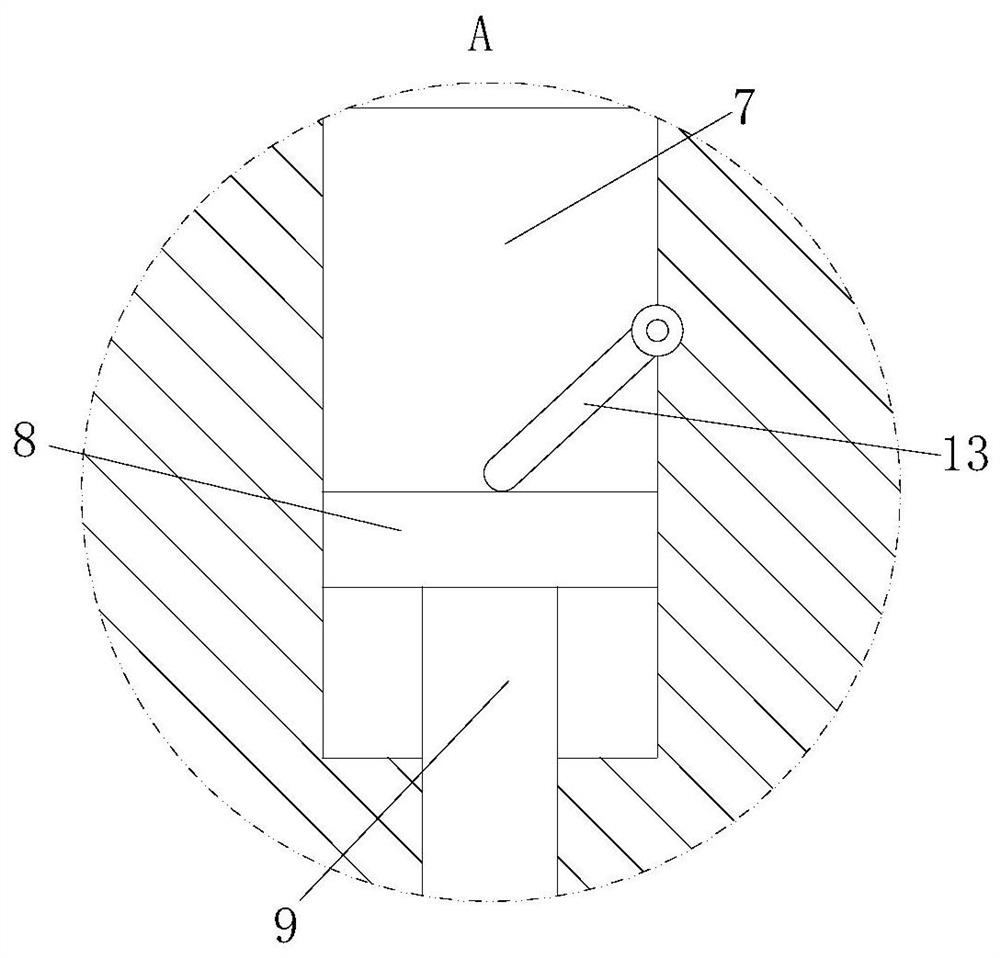

A technology and production equipment for making artificial teeth using peek resin composite material

ActiveCN112891635BWash thoroughlyAvoid accumulationTissue regenerationCleaning using liquidsFiberMolten state

The invention belongs to the technical field of artificial teeth, and specifically relates to a process and production equipment for making artificial teeth by using PEEK resin composite materials. Put silk and PEEK resin powder into a platinum crucible and heat it up to 350-400°C to a molten state, and inject or press film into a rod of φ3-φ7mm; S2: According to the fine structure of human teeth, use CAD / CAM CNC machine tools to process the rod Processed into artificial teeth; S3: Put the artificial teeth into the ultrasonic cleaning equipment, control the water temperature at 50°C-70°C, and clean for 10-15 minutes; the present invention puts the artificial teeth into the placement grooves on the supporting plate in turn, and the motor The cam is driven to rotate, and through the extrusion between the cam and the bump and the gravity of the guide plate, the guide plate drives the piston and the artificial teeth to vibrate continuously, and each artificial tooth is cleaned separately to prevent a large number of artificial teeth from accumulating together, causing The artificial teeth inside it cannot be cleaned, which improves the cleaning effect of the ultrasonic cleaning equipment.

Owner:深圳市杰威尔医疗科技有限公司

A kind of "donkey bully mouth" flower spherical fluorinated hydroxyapatite-based dental composite resin and its preparation method

ActiveCN111991241BHigh mechanical strengthImprove antibacterial propertiesImpression capsDentistry preparationsPolymer scienceResin matrix

The invention relates to a "donkey bully mouth" flower spherical fluorinated hydroxyapatite-based dental composite resin and a preparation method thereof. The composite resin comprises a filler, a resin matrix and a photoinitiator, and the filler is a compound of silane-modified fluorinated hydroxyapatite and barium glass powder. The method comprises: preparation of "donkey bully mouth" flower spherical fluorinated hydroxyapatite (E-FHAp), preparation of silane-modified E-FHAp, preparation of E-FHAp-based dental composite resin. The method constructs a high-quality dental restoration resin with excellent mechanical strength and functionality, thereby effectively improving the mechanical properties and service performance of the dental restoration resin.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com