High-temperature-chlorine-corrosion-resistant coating for boiler heating surface, and preparation method thereof

A heating surface and high temperature resistance technology, applied in coatings, anti-corrosion coatings, fire-proof coatings, etc., can solve the problems of high brittleness, easy cracking, poor thermal shock resistance, etc., and achieve improved density and hardness, low cost, and increased The effect of strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

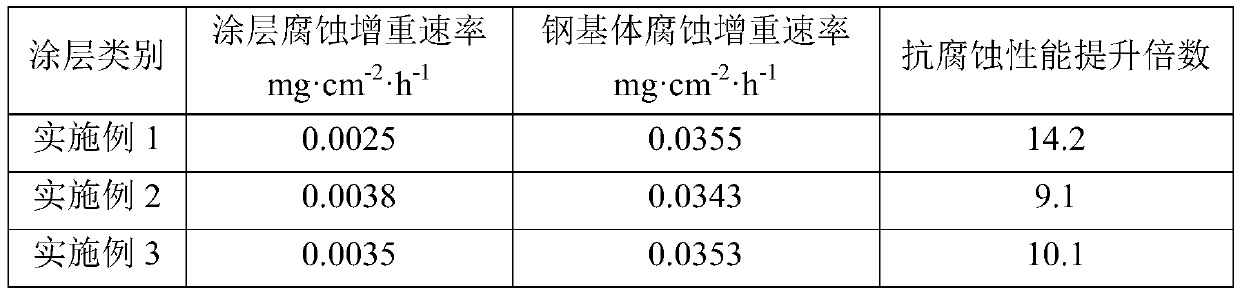

Embodiment 1

[0020] Weigh respectively 60% perhydropolysilazane and 20% graphite powder by volume, add them in turn to 20% butyl acetate, grind for 1 hour with a planetary ball mill, and then mechanically Stir with a mixer for 1 hour, then filter and encapsulate the paint sprayed as a transition layer. Then weigh the organopolysilazane, the barium glass powder of 30%, the zirconia powder of 15% and the aluminum powder of 5% respectively by volume percentage, add successively the butyl acetate of 30% by volume After being ground by a planetary ball mill for 1 hour, stirred by a mechanical stirrer for 1 hour, the coating sprayed as an organic polysilazane precursor composite ceramic coating was filtered and encapsulated.

[0021] The coating preparation process is as follows: first, the surface of the alloy steel substrate on the heating surface is pretreated by sandblasting; then the prepared transition layer coating is sprayed on the surface of the substrate, and placed in a heating furnac...

Embodiment 2

[0023] Weigh respectively 70% perhydropolysilazane and 15% graphite powder by volume, add them in turn to 15% butyl acetate, grind for 1 hour with a planetary ball mill, and then mechanically Stir with a mixer for 1 hour, then filter and encapsulate the paint sprayed as a transition layer. Then weigh the organopolysilazane, the barium glass powder of 25%, the zirconia powder of 20% and the aluminum powder of 10% respectively by volume percentage, add successively the butyl acetate of 20% by volume After being ground by a planetary ball mill for 1 hour, stirred by a mechanical stirrer for 1 hour, the coating sprayed as an organic polysilazane precursor composite ceramic coating was filtered and encapsulated.

[0024] The coating preparation process is consistent with Example 1.

Embodiment 3

[0026] Weigh respectively 60% perhydropolysilazane and 20% graphite powder by volume, add them in turn to 20% butyl acetate, grind for 1 hour with a planetary ball mill, and then mechanically Stir with a mixer for 1 hour, then filter and encapsulate the paint sprayed as a transition layer. Then weigh the organopolysilazane, the barium glass powder of 25%, the zirconia powder of 20% and the aluminum powder of 5% respectively by volume percentage, add successively the butyl acetate of 25% by volume After being ground by a planetary ball mill for 1 hour, stirred by a mechanical stirrer for 1 hour, the coating sprayed as an organic polysilazane precursor composite ceramic coating was filtered and encapsulated.

[0027] The coating preparation process is consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com