X-ray opaque glass

A glass and ray technology, applied in dental preparations, dental prostheses, filling teeth, etc., can solve the problems of low refractive index, low weather resistance, high X-ray opacity, etc., and achieve the effect of meeting aesthetic requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The glasses described in the examples were prepared as follows:

[0082] The raw materials for oxides were weighed without fining agent and then mixed thoroughly. The glass mixture is melted at about 1580° C. in a discontinuous melting apparatus, then clarified and homogenized. At a casting temperature of about 1600°C, the glass can be cast and processed into ribbons or other desired dimensions. In large volume, continuous installations, the temperature can drop by at least about 100K.

[0083] For further processing, the cooled glass ribbon is ground to a glass powder with an average particle size of not more than 10 μm by means of the method known from DE4100604C1. Glass properties were determined on glass gobs that were not pulverized. All glasses exhibit excellent chemical resistance to acids, bases, water and fluorine-containing species such as NaF and NaF / acetic acid.

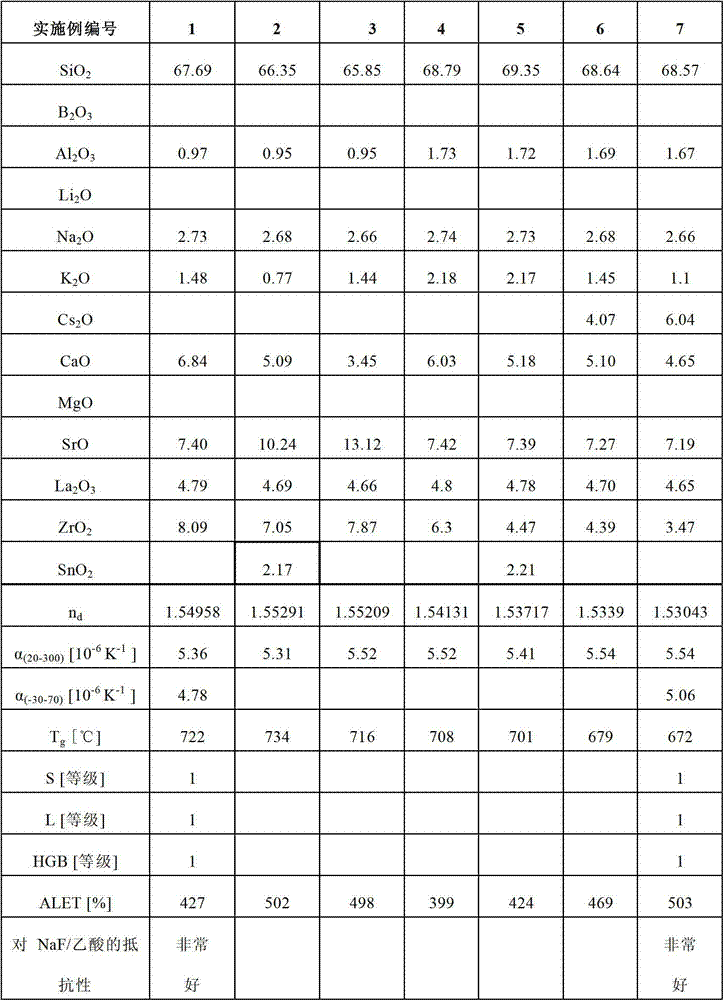

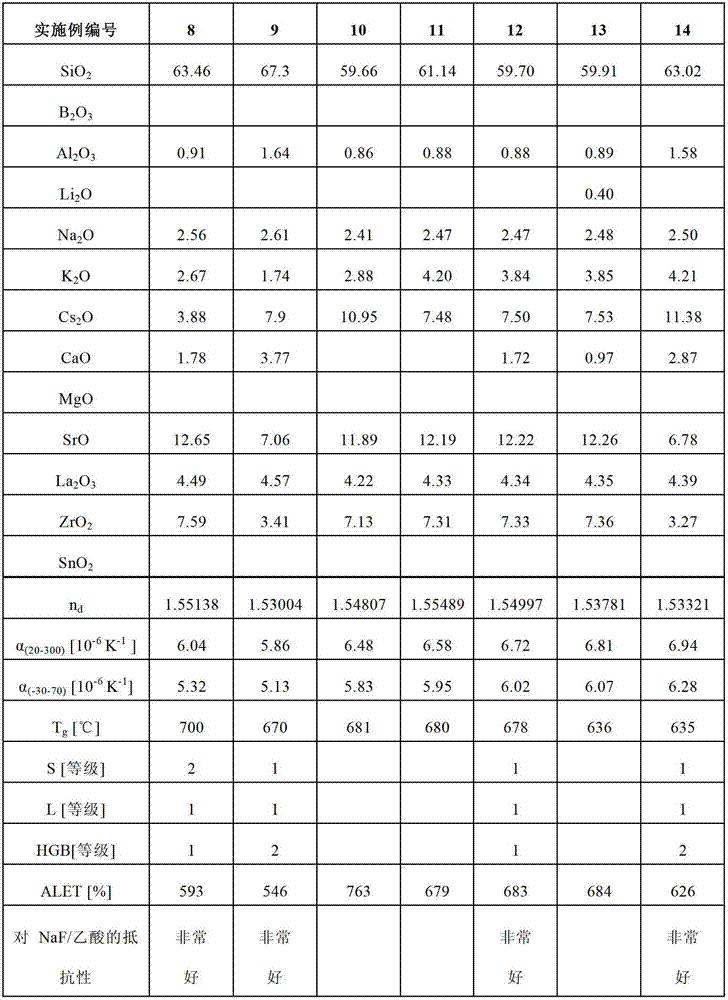

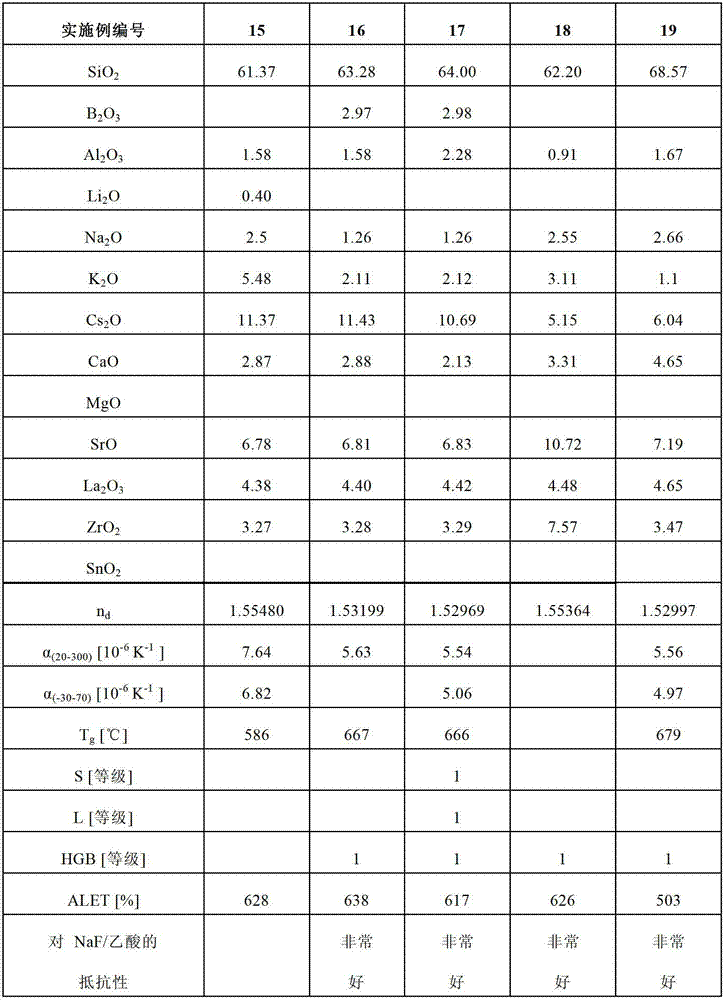

[0084] Table 1 also shows the refractive index n d , glass transition temperature T g and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com