Poly(ether-ether-ketone)-based dental special material with high bonding strength and preparation method thereof

A technology based on polyetheretherketone and polyetheretherketone, which is applied in the field of barium glass powder, glass fiber, polyetheretherketone ternary composite materials and their preparation, can solve material erosion, affect material biocompatibility, concentration Sulfuric acid can not be used and other problems, to achieve the effect of improving mechanical properties and bonding strength, reducing the coefficient of thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

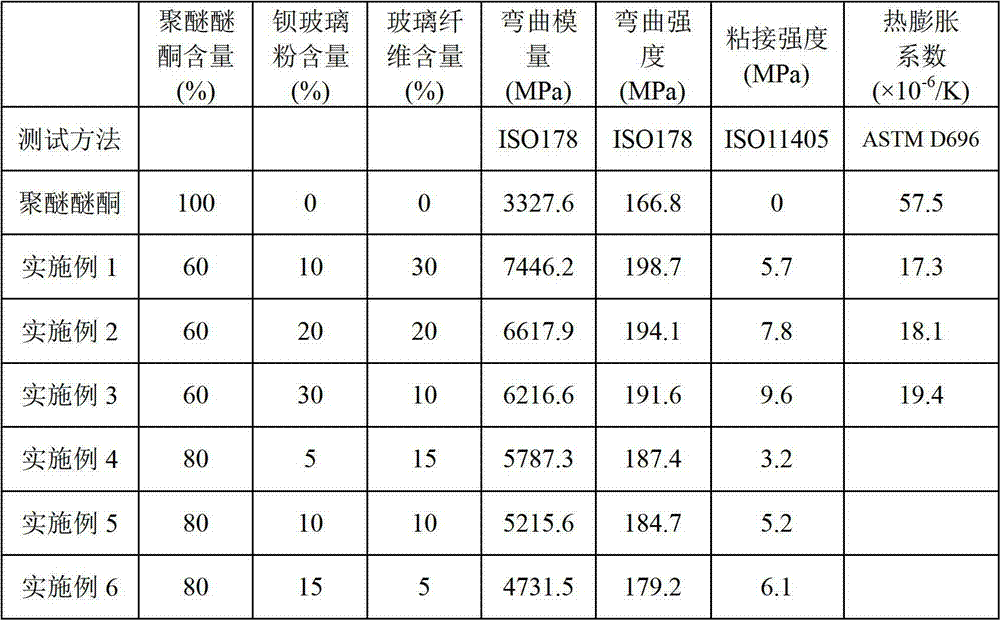

Examples

Embodiment 1

[0030] Select barium glass powder and glass fiber as the reinforcing phase, and polyether ether ketone as the matrix. The specific steps are as follows:

[0031] 1. Mixing polyether ether ketone and barium glass powder: Add 2400g polyether ether ketone and 1600g barium glass powder into a high-speed mixer, stir mechanically for 2 minutes, then dry at 120°C for 3 hours for later use; put the processed powder in Haake Processing by twin-screw extruder, processing temperature is 280°C-360°C, speed is 80r / min-160r / min, extruded and cut as composite material A;

[0032] 2. Mixing of polyether ether ketone and glass fiber: Dry 2400g polyether ether ketone and 1600g glass fiber at 120°C for 3 hours respectively, add polyether ether ketone into the twin-screw extruder from the feeding port, and glass fiber from the twin-screw extruder Imported at the first exhaust port of the screw extruder, the processing temperature is 280°C-360°C, the speed is 80r / min-160r / min, and the material is ...

Embodiment 2

[0036] In step 3, 2000g of composite material A and 2000g of composite material B are extruded twice, and other steps are the same as in embodiment 1.

Embodiment 3

[0038] In step 3, 3000g of composite material A and 1000g of composite material B are extruded twice, and other steps are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com