Dental repair composite resin with bacteriostasis-remineralization dual functions as well as preparation and application thereof

A composite resin and dental restoration technology, applied in dental preparations, dentistry, dental prosthesis, etc., can solve the problem of slow dissolution rate of pure hydroxyapatite ions, pure hydroxyapatite does not have antibacterial biological activity, promotes biological Limited mineralization performance and other issues, to achieve the effect of promoting mineral deposition, improving long-term service performance, and controlling crystal form and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

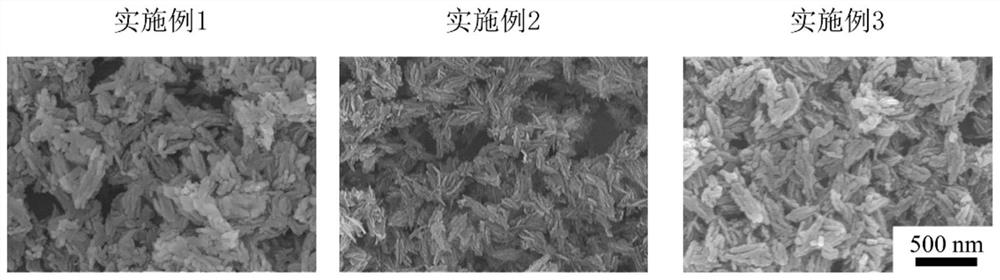

Embodiment 1

[0048] (1) Preparation of Sr-HAp nanoparticles

[0049] Weigh 4.25g of diammonium hydrogen phosphate, pour it into a three-necked flask filled with 100mL of deionized water, add magnets and stir in a 90°C oil bath until completely dissolved, adjust the pH to 10 with ammonia water, and weigh calcium nitrate tetrahydrate 10.03g and 1.59g of strontium nitrate were poured into a flask filled with 100mL of deionized water, added a magnet and stirred in an oil bath at 90°C until completely dissolved, then added dropwise to a three-necked flask, keeping the pH of the reaction system at 10, After the dropwise addition was completed, stirring was continued for 5 hours. After the reaction was completed, it was centrifuged and washed with deionized water, and dried to obtain Sr-HAp with a calcium substitution molar percentage of 15%.

[0050] (2) Silanization modification of Sr-HAp

[0051] Measure 90mL of ethanol, 10mL of deionized water, and 2.5mL of KH570 in a 250mL beaker, sonicate...

Embodiment 2

[0053] (1) Preparation of Zn-HAp nanoparticles

[0054] Weigh 4.25g of diammonium hydrogen phosphate, pour it into a three-necked flask filled with 100mL of deionized water, add magnets and stir in a 90°C oil bath until completely dissolved, adjust the pH to 10 with ammonia water, and weigh calcium nitrate tetrahydrate 10.03g, 2.23g of zinc nitrate hexahydrate, poured into a flask equipped with 100mL of deionized water, added a magnet, stirred in a 90°C oil bath until completely dissolved, then added dropwise to a three-necked flask, keeping the pH of the reaction system = 10. After the dropwise addition, continue to stir for 3 hours. After the reaction is completed, it is centrifuged and washed with deionized water, and dried to obtain a Zn-HAp with a calcium substitution molar percentage of 15%.

[0055] (2) Silanization modification of Zn-HAp

[0056] The Sr-HAp particles in step (2) of Example 1 were replaced with Zn-HAp particles to obtain silanized modified Zn-HAp part...

Embodiment 3

[0058] (1) Preparation of strontium / zinc co-doped hydroxyapatite Sr / Zn-HAp nanoparticles

[0059] Weigh 4.25g of diammonium hydrogen phosphate, pour it into a three-necked flask filled with 100mL of deionized water, add magnets and stir in a 90°C oil bath until completely dissolved, adjust the pH to 10 with ammonia water, and weigh calcium nitrate tetrahydrate 10.03g, 0.79g of strontium nitrate, and 1.12g of zinc nitrate hexahydrate were poured into a flask filled with 100mL of deionized water, added with a magnet, stirred in an oil bath at 90°C until completely dissolved, and then added dropwise into a three-necked flask. Keep the pH of the reaction system = 10, and continue stirring for 3 hours after the dropwise addition. After the reaction, it was centrifuged and washed with deionized water, and dried to obtain Sr / Zn-HAp particles with a strontium / zinc doping ratio of 1:1 and a calcium substitution molar percentage of 15%.

[0060] (2) Silanization modification of Sr / Zn-H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com