Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

110 results about "Aminophenylboronic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

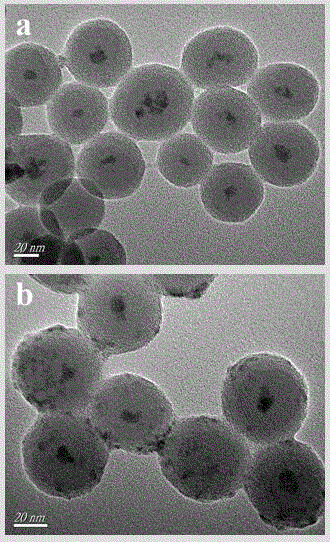

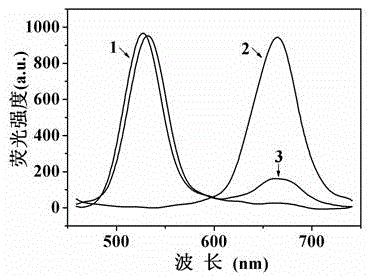

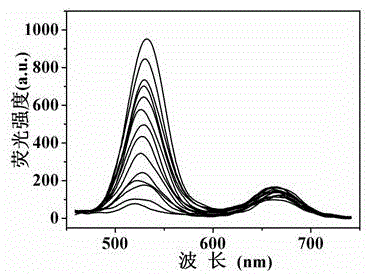

Method for preparing ratio fluorescence dopamine probe based on carbon spot/copper nanocluster compound

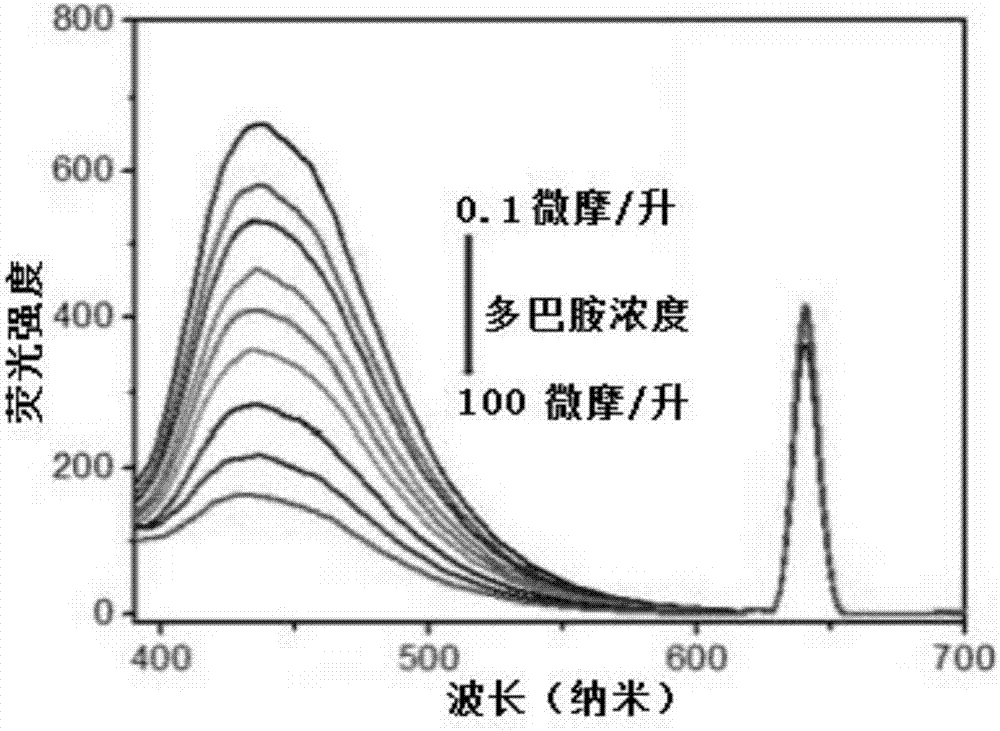

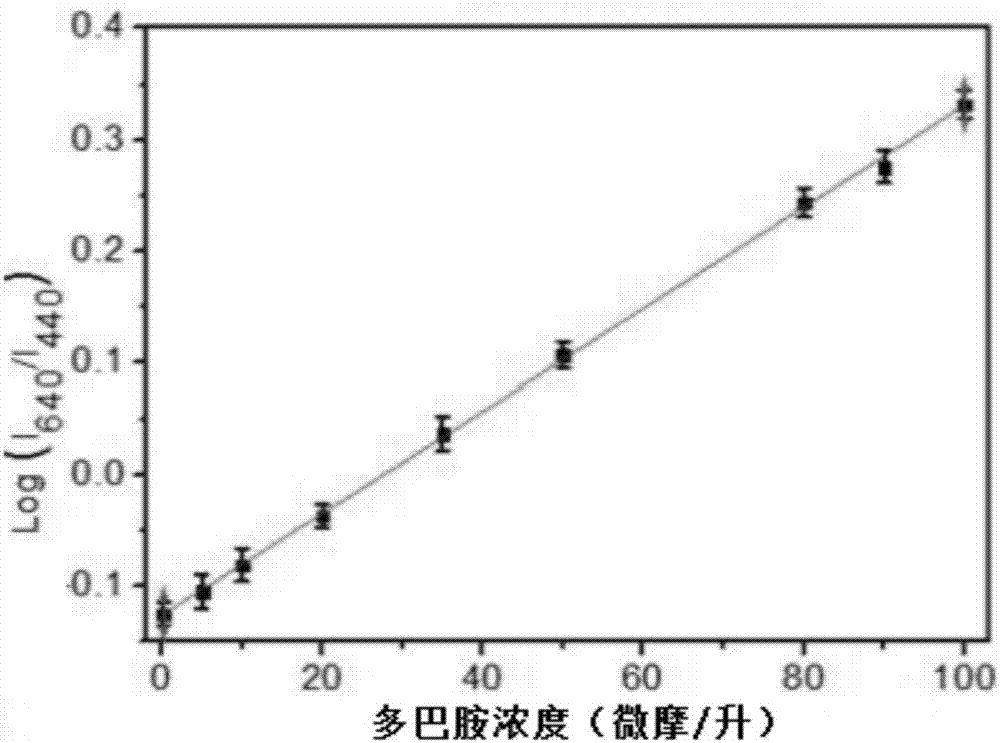

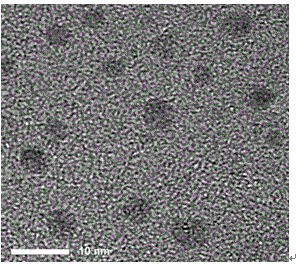

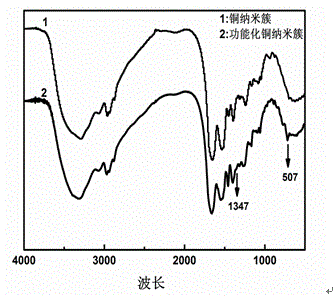

ActiveCN106970061AHigh selectivityIncreased sensitivityFluorescence/phosphorescenceLinear relationshipBovine serum albumin

The invention belongs to technical field of crossing of nano-materials and biochemical sensing, and relates to a method for preparing a ratio fluorescence dopamine probe based on a carbon spot / copper nanocluster compound. The method comprises the following steps: firstly, preparing carbon spots emitted by blue fluorescence to perform aminophenylboronic acid modification on the surface; then preparing bovine serum albumin-stabilized copper nanoclusters emitted by red fluorescence; mixing and reacting the carbon spots with the copper nanoclusters to prepare the carbon spot / copper nanocluster compound emitted by double fluorescence; then, adding dopamine to aqueous dispersion of the carbon spot / copper nanocluster compound; using a fluorescence spectrometer for measuring a fluorescence emission spectrum; fitting a linear relationship between ratio fluorescence peak intensity and dopamine coexistence concentration; and further, constructing the ratio fluorescence dopamine probe based on the carbon spot / copper nanocluster compound. The probe is simple in preparation process, low in preparation cost, high in sensitivity and selectivity, and capable of being developed into a novel ratio fluorescence probe applied to efficient detection of dopamine.

Owner:QINGDAO UNIV

Synthesis method for near-infrared fluorescent probe copper nano-cluster and application of synthesis method

InactiveCN104972135AGood water solubilityNo toxicityNanotechnologyBiological testingFluoProbesCell membrane

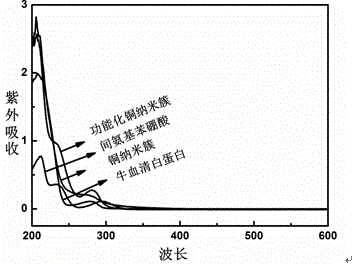

The invention discloses a synthesis method for a near-infrared fluorescent probe copper nano-cluster and a detection method for glycoprotein. The near-infrared fluorescent probe copper nano-cluster is synthesized through a one-pot method, aminophenylboronic acid is used for functionally transforming the synthesized copper nano-cluster, and the functionalized copper nano-cluster is obtained. Due to the specific action of boric acid groups on aminophenylboronic acid and cis diol in glycoprotein, the fluorescence intensity of the copper nano-cluster is quenched. A fluorescent probe can detect glycoprotein at high specificity and sensitivity. Glycoprotein widely exists in mucus, plasma, cytoplasm and cell membranes, is tightly related to living organisms, is an important physiological active material, and is tightly related to certain genetic diseases, and therefore important practical significance is provided for detecting glycoprotein.

Owner:TIANJIN NORMAL UNIVERSITY

Aminophenylboronic acid surface-modified nano-carbon material, as well as preparation method and application thereof

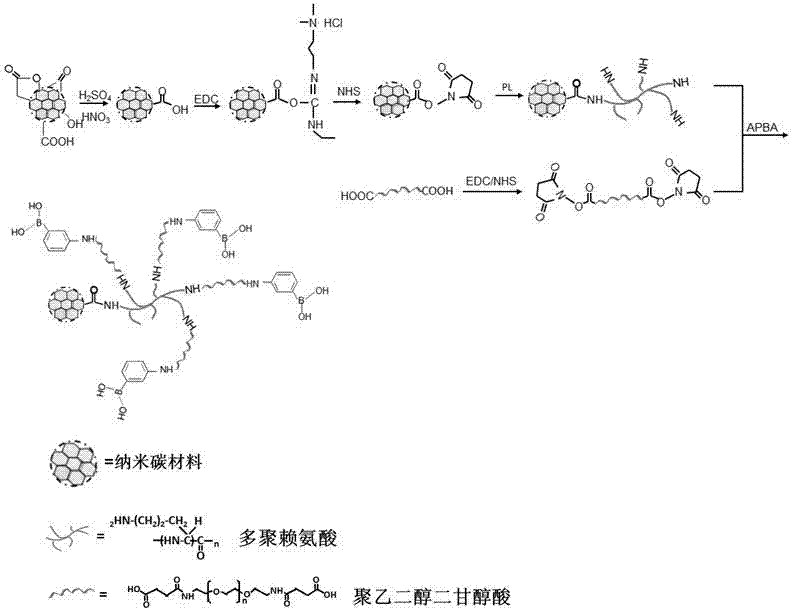

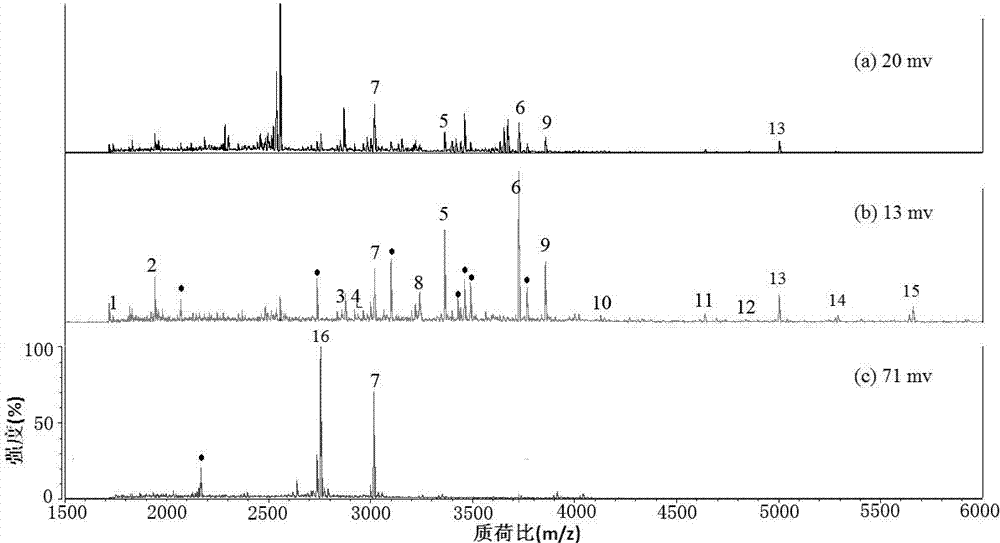

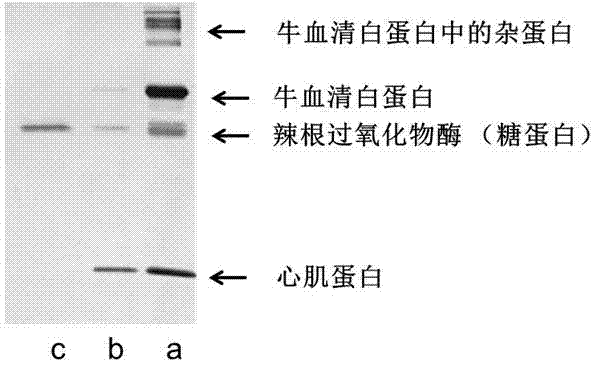

InactiveCN103043647AThe synthesis method is simpleGood dispersionMaterial nanotechnologyPeptide preparation methodsPolyethylene glycolFunctional modification

The invention belongs to the technical field of inorganic materials and bioanalysis and in particular relates to an aminophenylboronic acid surface-modified nano-carbon material, as well as a preparation method and application thereof. According to the invention, an available nano-carbon material is subjected to carbodiimide reaction on the basis of acid treatment. Firstly, the surface of the nano-carbon material is modified by polylysine and polyethylene glycol / diglycolic acid, then the nano-carbon material reacts with aminophenylboronic acid for surface functional modification of the nano-carbon material. The synthesis method provided by the invention is simple and efficient. The prepared aminophenylboronic acid-functionalized nano-carbon material, as a nano-adsorbent, has a large specific surface area and strong selective specificity, exhibits better dispersibility and stability in aqueous solutions, and can rapidly achieve the effect of specifically separating and concentrating glycopeptide / glycoprotein. The material is significant in use value and application prospects in the glycoprotein proteomics field and the like.

Owner:FUDAN UNIV

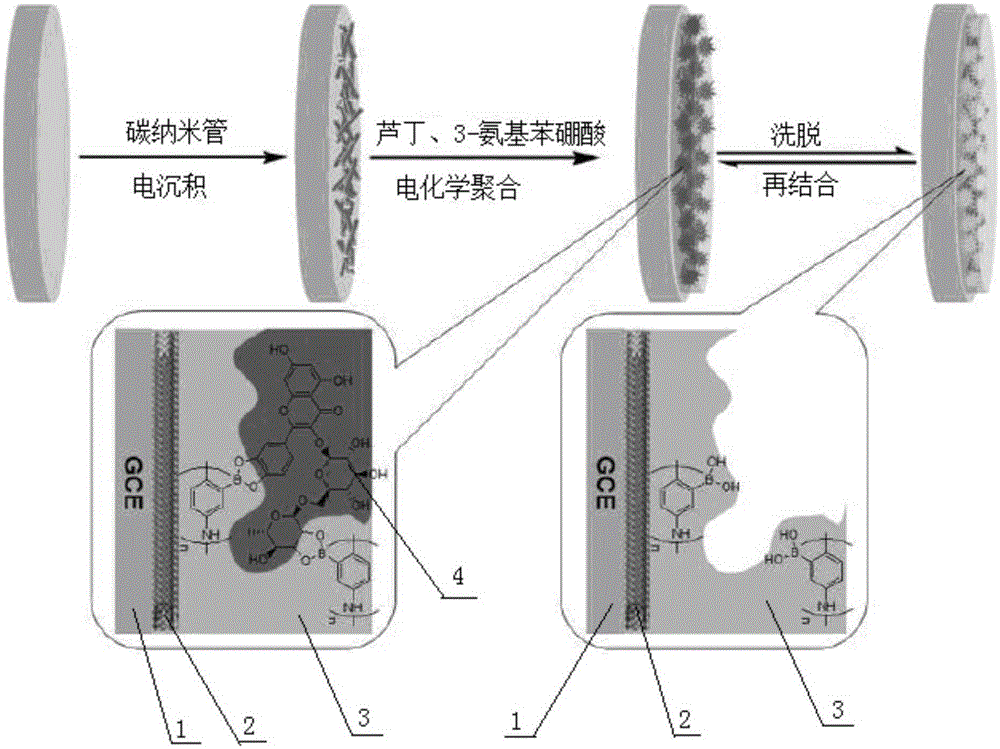

Modified electrode based on phenylboronic acid imprinted polymer/carbon nanotube, preparation method thereof and application

ActiveCN105223248AIncrease transfer rateSensitive Quantitative DetectionMaterial electrochemical variablesPhenylboronic acidQuantitative determination

The invention discloses a modified electrode based on phenylboronic acid imprinted polymer / carbon nanotube, a preparation method thereof and application. The preparation method comprises: 1) depositing carbon nanotube on the surface of the glassy carbon electrode to get a carbon nanotube modified electrode; 2) adding the carbon nanotube modified electrode prepared by step 1) into a buffer solution containing 3-aminophenylboronic acid and rutin to get a 3-aminophenylboronic modified electrode by using a cyclic voltammetry method; 3) and washing out the 3-aminophenylboronic modified electrode to get the modified electrode based on phenylboronic acid imprinted polymer / carbon nanotube. According to the invention, the effects on specific recognition of rutin, sensitive quantitative determination of rutin, high anti-interference capability, simple preparation and low cost can be realized.

Owner:ANHUI NORMAL UNIV

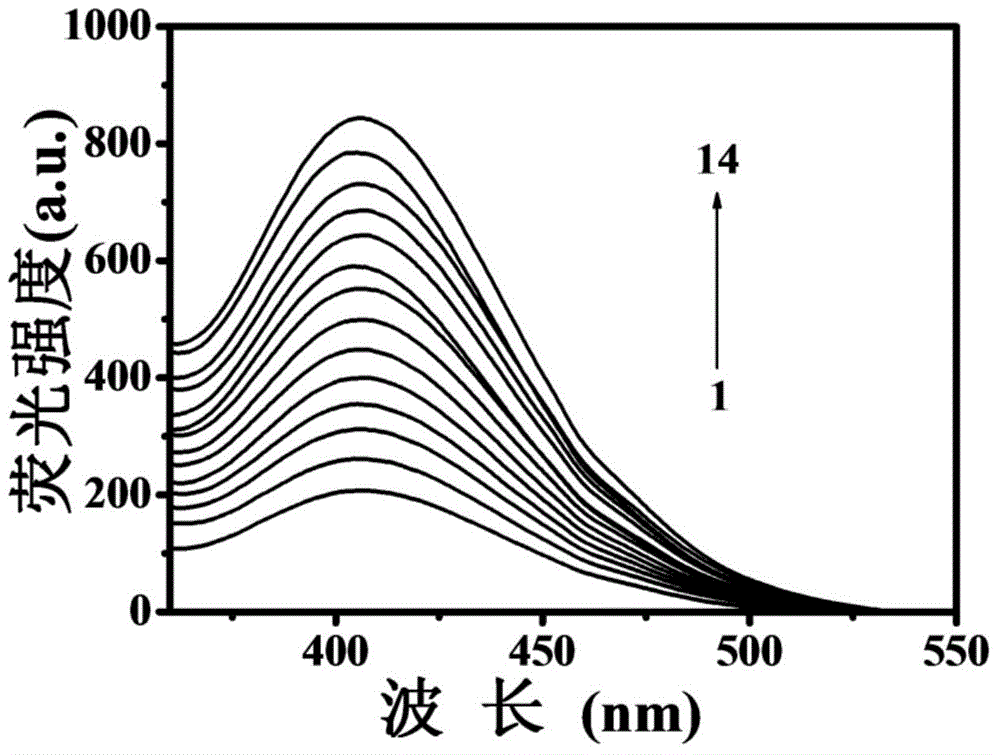

Boric acid quantum dot ratio fluorescent probe and preparation method and application thereof

InactiveCN105462590ARealize visual detectionReduce the impactFluorescence/phosphorescenceLuminescent compositionsFluoProbesAminophenylboronic acid

The invention relates to a boric acid quantum dot ratio fluorescent probe and a preparation method and application thereof and belongs to the field of fluorescent probes and preparation thereof. The preparation method comprises the following steps: utilizing routine techniques to obtain required green fluorescent quantum dots and red fluorescent quantum dots; coating silicon balls with the red fluorescent quantum dots by the reverse microemulsion method, wherein under the action of poly dimethyl diallyl ammonium chloride, the green fluorescent quantum dots are adsorbed onto the surfaces of the silicon balls; finally, adding EDC / NHS and aminophenylboronic acid (APBA) into a Tris-HCl buffer solution; conducting reaction under the photophobic condition at the room temperature to finally obtain the boric acid quantum dot ratio fluorescent probe; detecting the content of glucose by fluorescent quantitation and visual analysis. The prepared boric acid quantum dot ratio fluorescent probe has favorable optical property and stability and has the visualized glucose detection capability.

Owner:JIANGSU UNIV

Medical hydrogel with pH sensitivity, self-healing nature and cell adhesion and preparation method thereof

The invention discloses a medical hydrogel with pH sensitivity, self-healing nature and cell adhesion and a preparation method thereof. 3-aminophenylboronic acid modified sodium alginate and I type collagen grafted carboxylic polyvinyl alcohol are cross-linked according to a certain proportion so as to prepare the hydrogel, wherein the modified sodium alginate has phenylboronic acid groups, the phenylboronic acid groups and diol of the polyvinyl alcohol form supermolecule dynamic bonds, the supermolecule bonds with pH sensitivity break at acidic pH and regrow at alkaline pH, so that the hydrogel has pH response and self-healing performance; the phenylboronic acid groups can combine with carbohydrates on biological cell membranes, such as glycolipids or glycoproteins, thereby enabling the hydrogel to attach to cells and improving the cell adhesion; the introduced polyvinyl alcohol improves the mechanical performance of the hydrogel, and the polyvinyl alcohol molecular chains form hydrogen bonds through a physical method of repeated freezing and thawing, thereby improving the mechanical strength of the hydrogel. The main raw materials of the hydrogel, sodium alginate and polyvinyl alcohol, have high biocompatibility, pH response and self-healing performance. The hydrogel can be widely used in fields of medicine slow release, wound repair and tissue engineering and the like.

Owner:SICHUAN UNIV

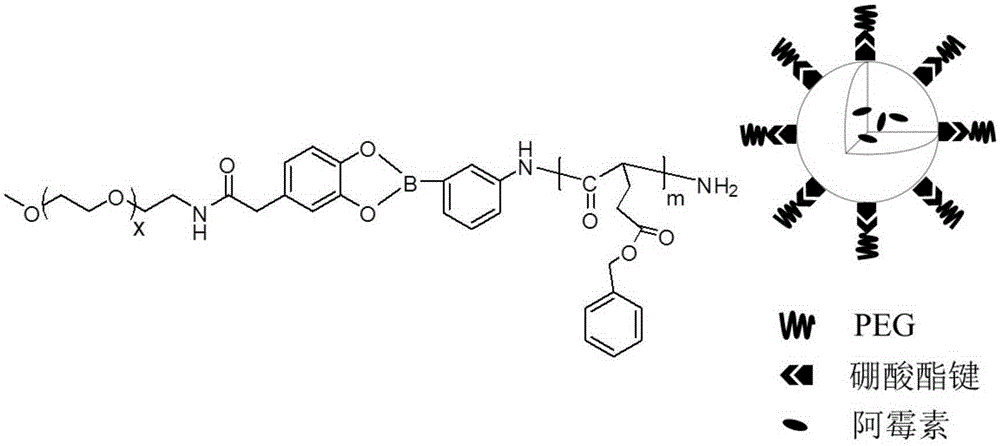

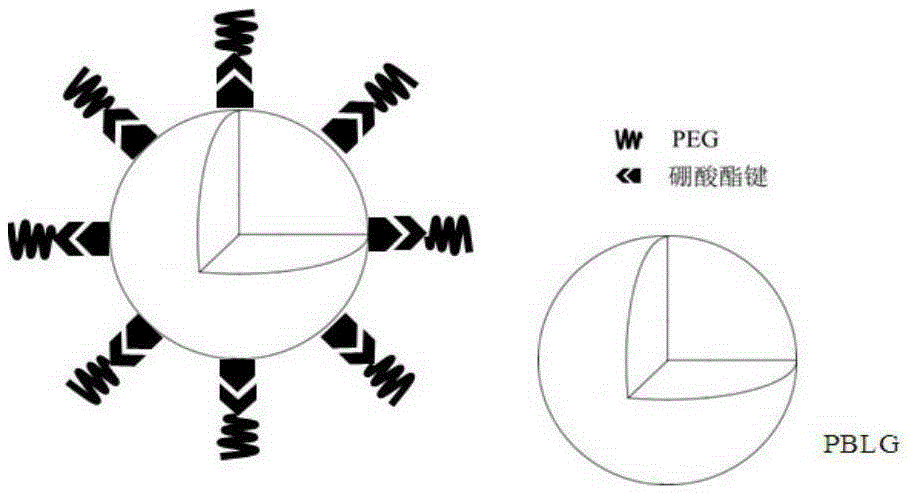

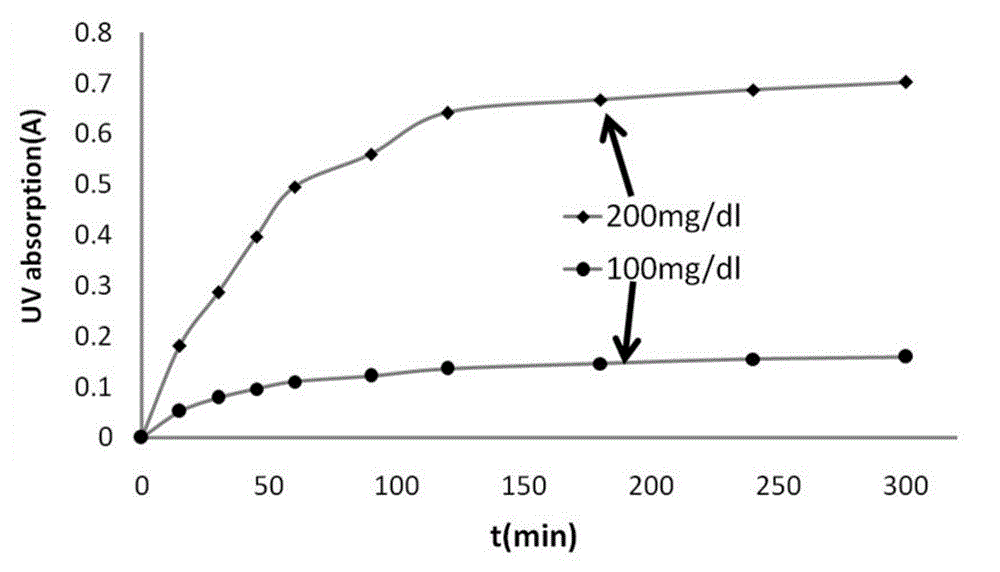

Block polymer with benzeneboronic acid ester as connecting unit, synthesis method and application thereof

InactiveCN105273205AGood drug releasePromote phagocytosisOrganic active ingredientsPharmaceutical non-active ingredientsPolymer scienceSynthesis methods

The invention discloses a diblock polymer with benzeneboronic acid ester as the connecting unit. Benzeneboronic acid catechol ester (BC) is adopted as the connecting unit to synthesize PEG-BC-PBLG diblock polymer so as to construct doxorubicin loaded micelle (PEG-BC@PBLG.Dox). The invention also discloses a preparation method of the diblock polymer, and the method includes: (1) preparing the dopa derivative PEG-3, 4-DA of PEG-NH2; (2) subjecting PEG-3, 4-DA and 3-aminophenylboronic acid to dehydration condensation so as to synthesize the benzeneboronic acid ester derivative PEG-BC of PEG; and (3) using PEG-BC to perform ring opening on 5-benzyl ester-L-glutamic acid-N-carboxyanhydride (BLG-NCA), thus obtaining the diblock polymer PEG-BC-PBLG with benzeneboronic acid ester as the connecting unit. The diblock polymer prepared by the method provided by the invention can be used for construction of a nano-micelle, and has the advantages of good drug release, low cytotoxicity and good cell phagocytosis.

Owner:EAST CHINA NORMAL UNIV

Glucose-sensitive self-regulated insulin release micro-gel carrier and preparation method thereof

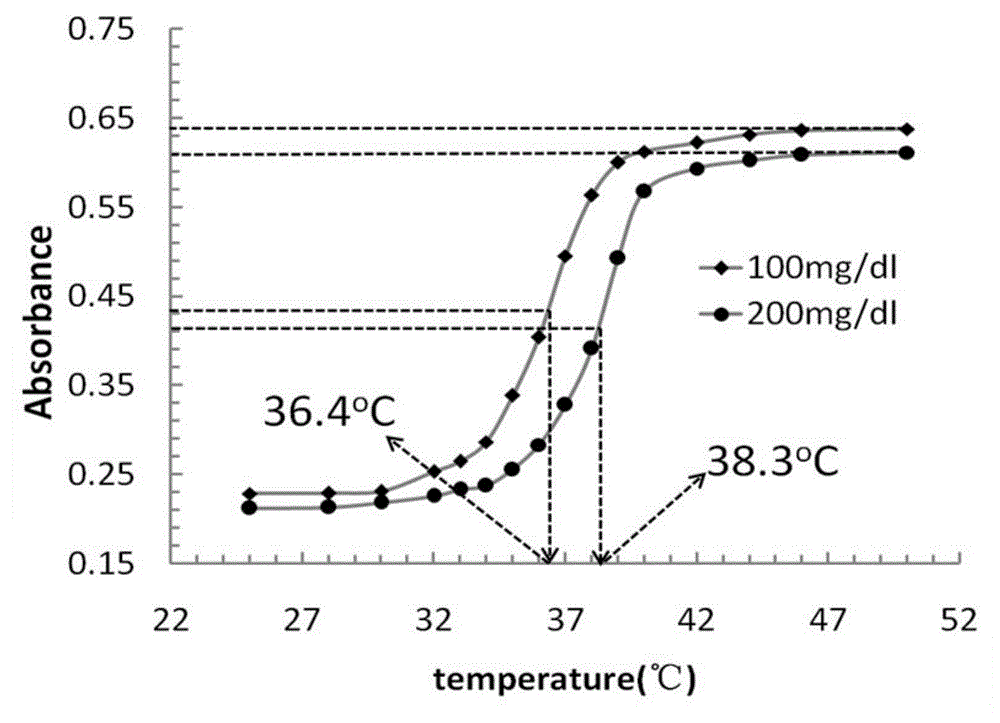

InactiveCN104586752AImprove hydrophilic abilityGood biocompatibilityPeptide/protein ingredientsMetabolism disorderConcentrations glucoseAminophenylboronic acid

The invention provides a glucose-sensitive self-regulated insulin release micro-gel carrier and a preparation method thereof. The preparation method of the glucose-sensitive self-regulated insulin release carrier comprises the following steps: performing free radical polymerization on three monomers namely 3-acryloyl aminophenylboronic acid, hydrophilic RGD polypeptide containing ethenyl functional groups and N-isopropylacrylamide to obtain a glucose-sensitive nano gel, and then combining the glucose-sensitive nano gel with insulin to obtain a medicine-loaded micro-gel. According to the glucose-sensitive self-regulated insulin release micro-gel carrier provided by the invention, the release of insulin can be automatically 'opened and closed' according to the changes of glucose concentrations at human body temperature.

Owner:HUBEI UNIV

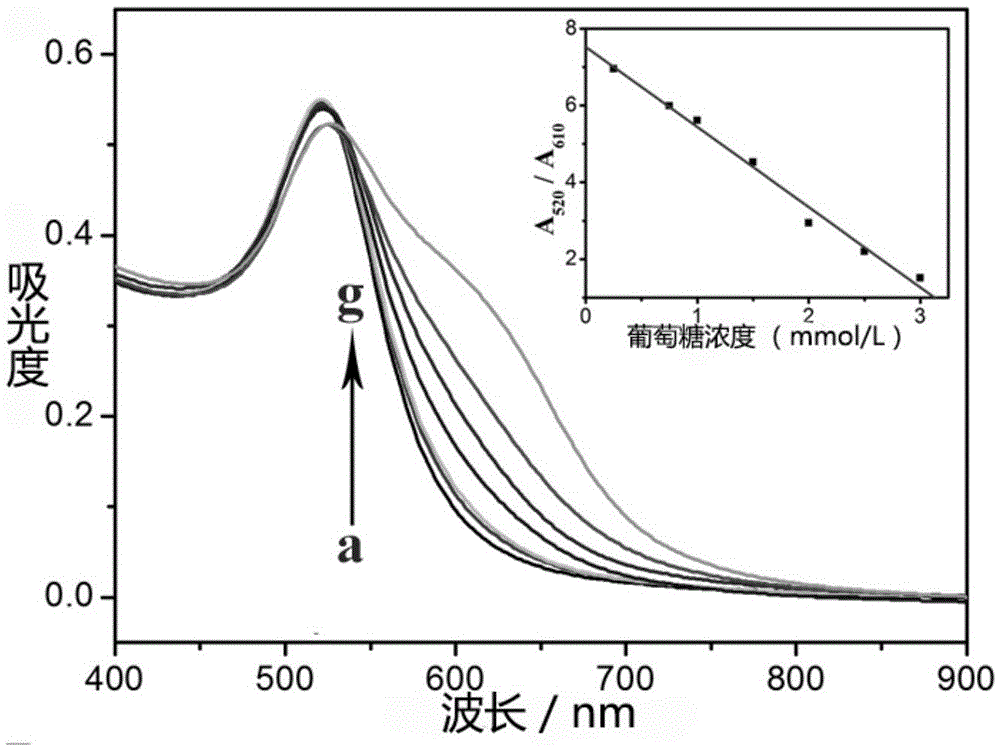

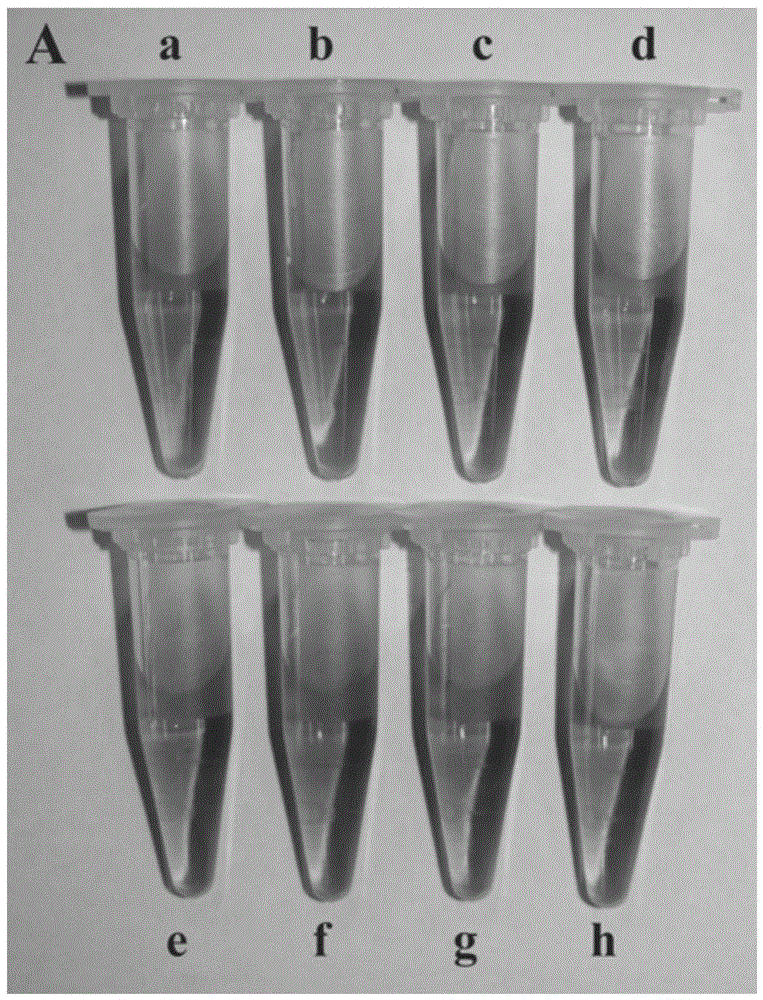

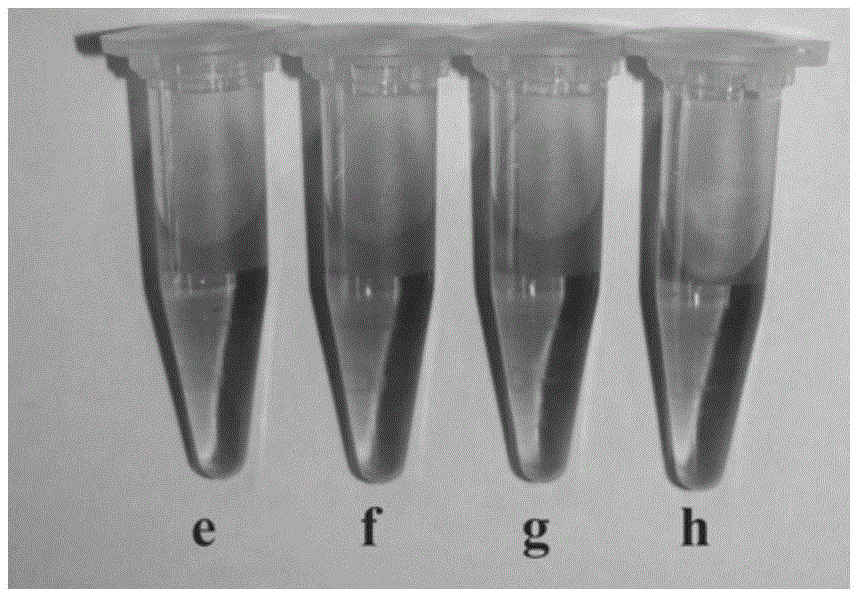

Gold nanoparticle-containing glucose visual detection sensor and its preparation method and use

ActiveCN105548153AHigh sensitivityGood choiceMaterial analysis by observing effect on chemical indicatorGlucose sensorsRead through

The invention discloses a gold nanoparticle-containing glucose visual detection sensor and its preparation method and use. The preparation method comprises that 1, chloroauric acid and trisodium citrate undergo a contact reaction in a solvent to produce a colloidal gold solution, and 2, pH of the colloidal gold solution is adjusted to 6.0-7.5 and 3-aminophenylboronic acid (APBA) and amino-terminated poly(N-isopropylacrylamide) (PNIPAM-NH2) are added into the colloidal gold solution for electrostatic interaction so that the gold nanoparticle-containing glucose visual detection sensor is obtained. The sensor has good sensitivity, selectivity and ion interference resistance in the glucose detection. The preparation method can be operated simply and easily and the detection result can be read through naked eyes.

Owner:ANHUI NORMAL UNIV

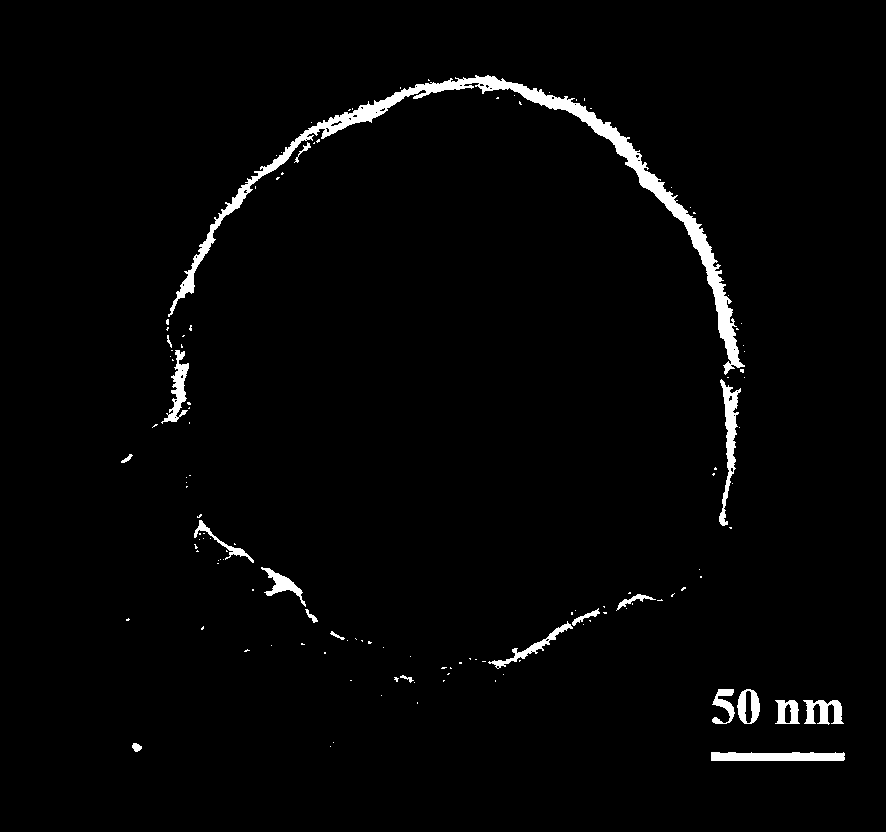

Preparation method of molecularly imprinted sensor based on carbon quantum dot/hollow nickel base material composite film modified glassy carbon electrode and application thereof

InactiveCN110208344AEasy to operateLow costMaterial electrochemical variablesComposite filmFunctional monomer

The invention belongs to the technical field of preparation of electrochemical sensors, and relates to a preparation method of a molecularly imprinted sensor based on a carbon quantum dot / a hollow nickel base material composite film modified glassy carbon electrode. The preparation method comprises the following steps of firstly depositing a Ni-Cu alloy layer in a three-electrode system, and thendealloying and removing copper to obtain a nano hollow nickel sphere layer; preparing an environment-friendly carbon quantum dot solution by adopting a biomass material, and modifying a glassy carbonelectrode coated with a nano hollow nickel sphere by using a composite solution of the carbon quantum dot and chitosan; and taking 3-aminophenylboronic acid as a functional monomer, and preparing themolecular imprinted sensor which has specific recognition response to the template molecular glucose on the surface of the glassy carbon electrode modified by a composite film through an electrochemical polymerization method. The preparation method of the molecularly imprinted sensor based on the carbon quantum dot / the hollow nickel base material composite film modified glassy carbon electrode provided by the invention effectively improves the active area and the electron transport performance. Combined with the molecular imprinting technology, the molecularly imprinted sensor with specific recognition response to glucose is prepared, and the molecularly imprinted sensor has the advantages of being simple in operation, low in cost, high in selectivity and sensitivity, and is expected to bepractical.

Owner:JIANGSU UNIV

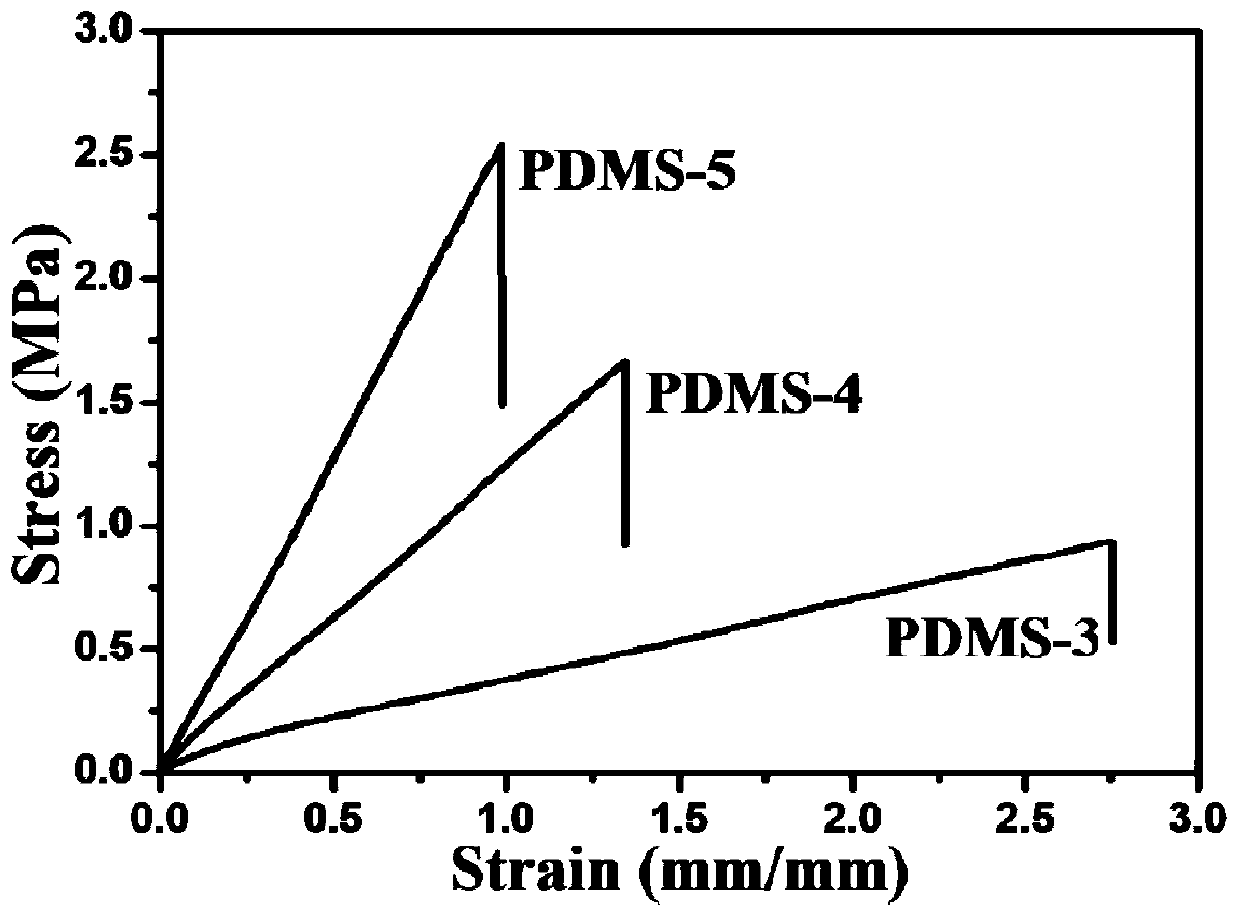

Boron-oxygen bond-containing repairable easily-soluble organosilicone elastomer and preparation method thereof

The invention relates to a boron-oxygen bond-containing repairable easily-soluble organosilicone elastomer and a preparation method thereof. According to the invention, an amino-containing polysiloxane derivative A, a chain extender aldehyde-containing monomer derivative B and 3-aminophenylboronic acid C are used, organopolysiloxane with a main chain containing a boron-oxygen bond and a dynamic imine bond is formed through a boron hydroxyl condensation reaction and a Schiff base reaction, multiple hydrogen bonds are formed between amino and hydroxyl and hydroxyl and hydroxyl, and therefore therepairable easily-soluble organosilicone elastomer is prepared. The organosilicone elastomer prepared by the method has the advantages of good mechanical properties, dissolving properties, self-repairing properties in heat and water, and high self-repairing efficiency, and can be applied to the fields of flexible display, flexible sensing, wearable electronic products, electronic skin and the like.

Owner:QINGDAO UNIV OF SCI & TECH

Preparation method of phenylboronic acid modified magnetic chitosan and application of phenylboronic acid modified magnetic chitosan in selective separation of shikimic acid

ActiveCN110394163AEasy to manufactureGood biocompatibilityIon-exchange process apparatusOther chemical processesWater bathsResource utilization

The invention belongs to the field of resource utilization and chemical separation, and relates to a preparation method of phenylboronic acid modified magnetic chitosan, which comprises the followingsteps: preparing a nano Fe3O4 solid by using a solvothermal method, dispersing the nano Fe3O4 solid in water, mixing a formed mixture with an acetic acid solution of chitosan, and conducting reactingto obtain a Fe3O4@chitosan solid; mixing the Fe3O4 / chitosan solid with epoxy chloropropane in an alkaline solution, and conducting washing with water to neutrality for later use; dispersing the Fe3O4@chitosan in a NaOH solution for alkalization for 12-48 hours, adding a succinic anhydride-containing DMF solution, and carrying out a water bath reaction to obtain a carboxylated Fe3O4@chitosan solid;and finally, fully mixing the carboxylated Fe3O4@chitosan solid with EDC and NHS, and adding 3-aminophenylboronic acid to react for 6-18 hours, thereby obtaining the product. According to the method,boric acid is replaced by surface modification, so that the shikimic acid with a cis-dihydroxy structure is enriched on the surface of the material, the shikimic acid is separated and recycled by magnetic separation, and the purity and yield of the shikimic acid are effectively improved. The method has a good application prospect in the field of enrichment, separation and purification of naturalproducts with cis-dihydroxy structures, and has the advantages of energy conservation, environmental protection, convenience in recovery and the like.

Owner:JIANGSU UNIV

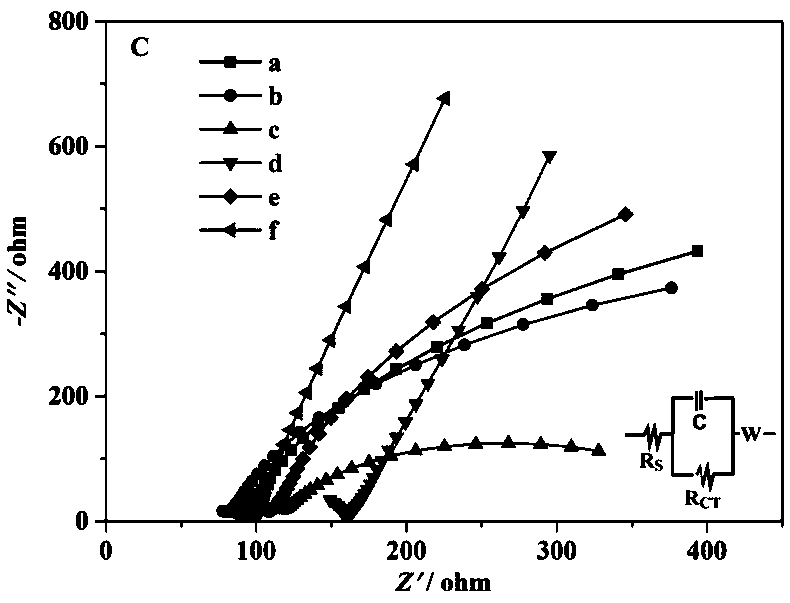

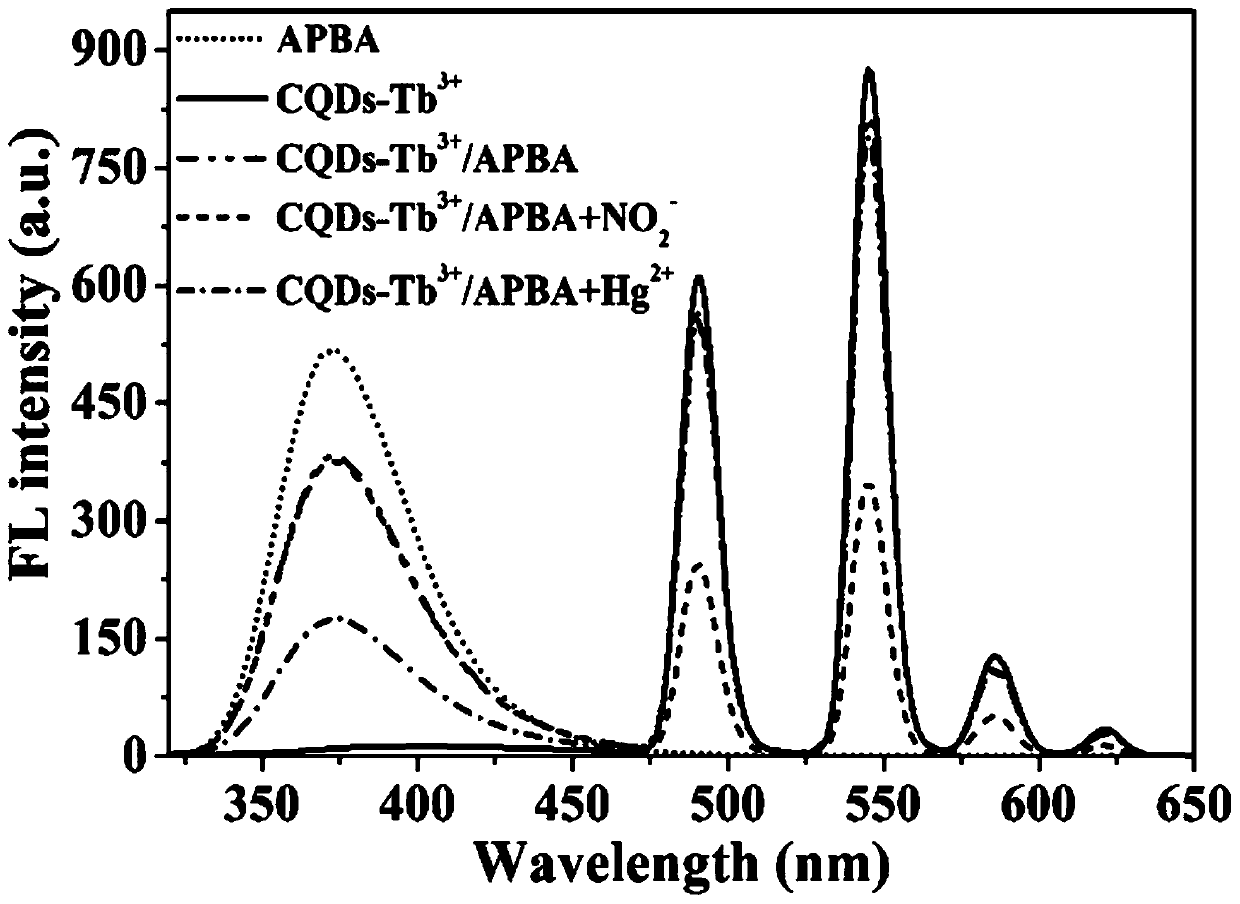

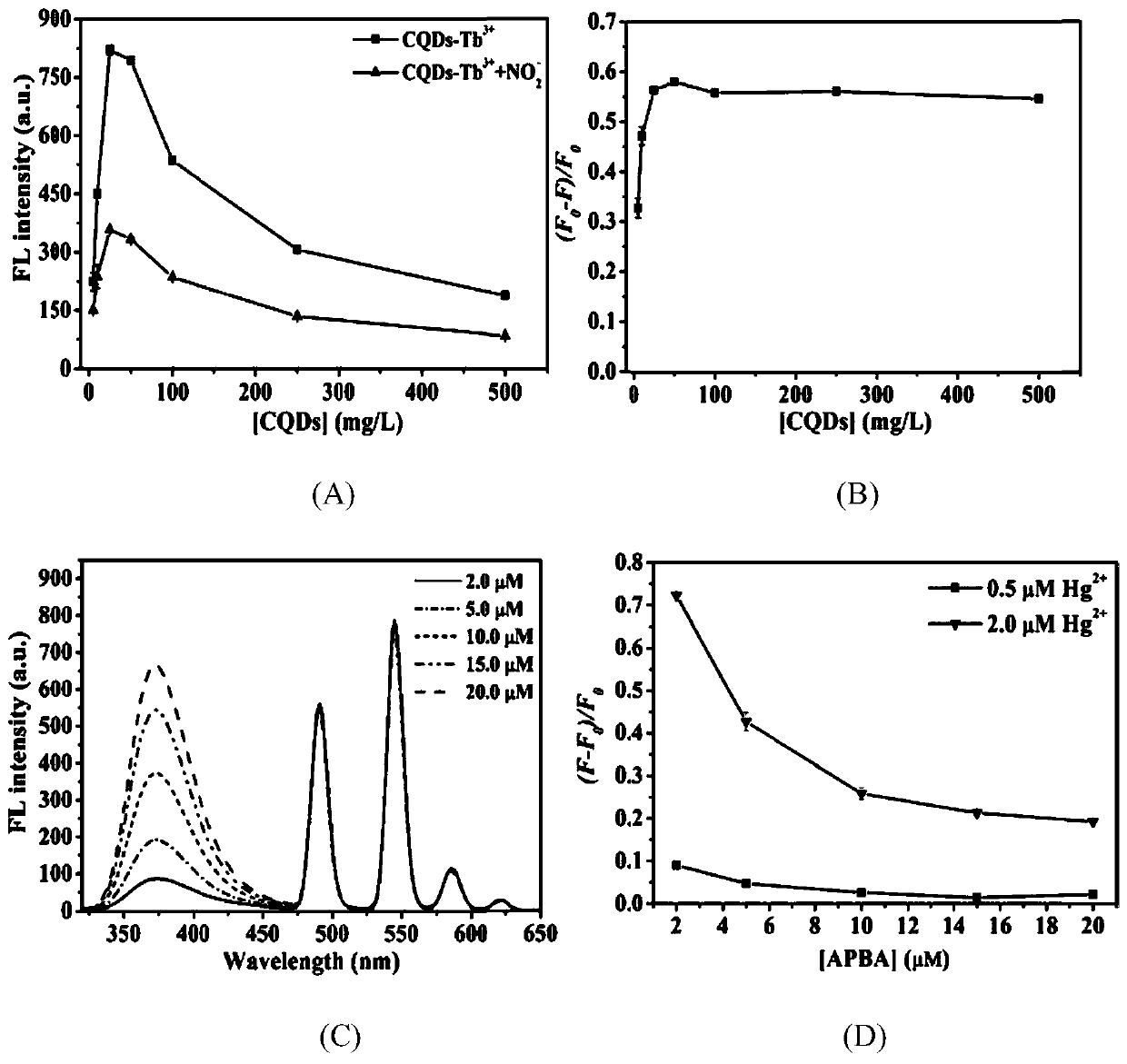

Dual-emission fluorescent probe for simultaneously detecting nitrite ions and Hg<2+> and method thereof

ActiveCN110865061AEnables trace detectionImprove consistencyPreparing sample for investigationFluorescence/phosphorescenceNitrite ionFluoProbes

The invention discloses a dual-emission fluorescent probe and a method for simultaneously detecting nitrite ions and Hg<2+>, which belong to the technical field of environmental detection. The fluorescent probe is a compound formed by carbon quantum dots CQDs, Tb<3+> and 3-aminophenylboronic acid in a buffer solution system with the pH value of 7.0 to 8.0. The carbon quantum dots CQDs are preparedfrom a mixed aqueous solution of nicotinic acid and barbituric acid through a hydrothermal reaction. The detection method comprises the steps of quantitatively adding a to-be-detected solution into the buffer solution system for constant volume, and then scanning an emission spectrum of a fluorescence system in a wavelength range of 320 to 650nm by taking 260 to 280nm as an excitation wavelengthof the buffer solution after constant volume; and calculating the concentrations of Hg<2+> and NO2<-> in the to-be-detected solution according to the linear relationship between the fluorescence quenching efficiency at 373 nm and 545 nm and the concentration of a to-be-detected substance. The fluorescent probe provided by the invention not only can realize trace detection of NO2<-> and Hg<2+> in awater sample, but also has better consistency and selectivity in detection results compared with a spectrophotometric method.

Owner:ZHEJIANG UNIV

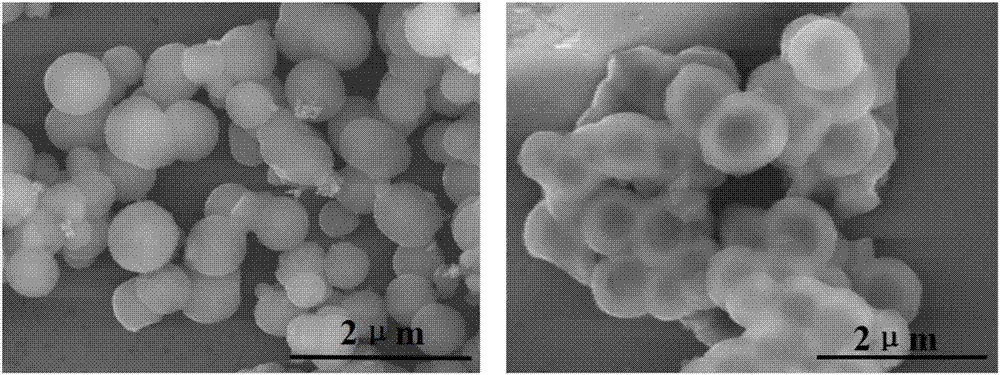

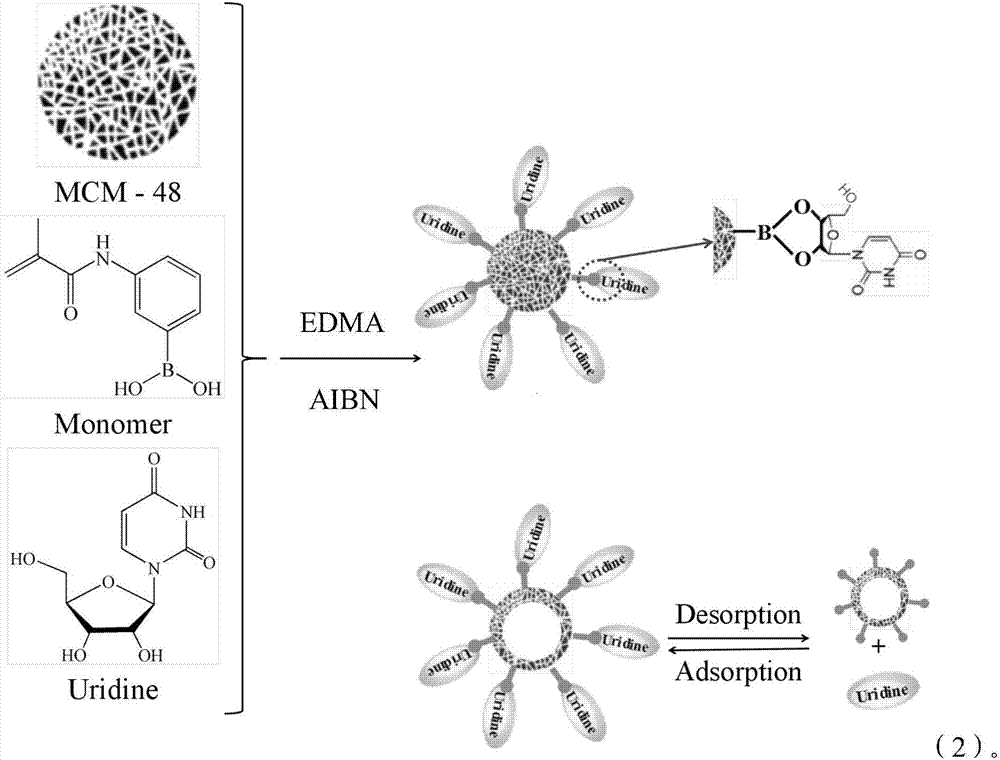

Hollow molecularly imprinted polymers and solid phase extraction column and preparation method and application thereof

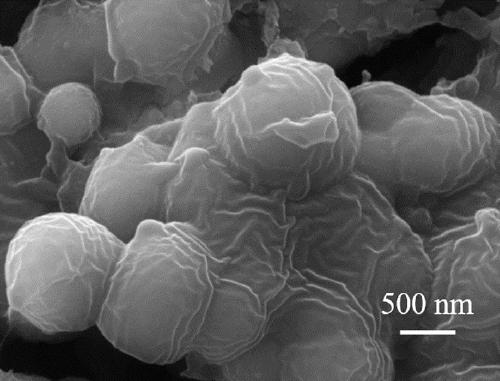

InactiveCN107189011AGood enrichment effectReversible adsorptionComponent separationSolid sorbent liquid separationFunctional monomerSynthesis methods

The invention provides hollow molecularly imprinted polymers which are modified by phenylboronic acid and an extraction column which is made by adopting the polymers. According to the synthetic method of the polymers, 3-aminophenylboronic acid is used as a modifying agent to conduct chemical modification on methacrylic acid monomers, uridine is used as a template, the modified methacrylic acid is used as functional monomers, matrixes, crosslinking agents and initiating agents are added to prepare molecularly imprinted materials, the prepared molecularly imprinted materials are subjected to template elution, the matrixes are corroded by adopting hydrofluoric acid, and the hollow molecularly imprinted polymers are obtained. The provided boron affinity hollow molecularly imprinted solid phase column has obvious enrichment effects on nucleoside type materials mainly due to the fact that molecular imprints conduct preferential adsorption on template molecules and structural analogues, and most binding sites of the hollow molecular imprints are distributed on surfaces of carrier matrix materials and in the hollow cavities and thus the adsorption efficiency is improved; furthermore, boric acid groups can carry out reversible adsorption and dissociation on the nucleoside type materials of a cis-diol structure, and therefore the boron affinity hollow molecularly imprinted solid phase column has obvious enrichment effects on the nucleoside type materials.

Owner:HARBIN NORMAL UNIVERSITY

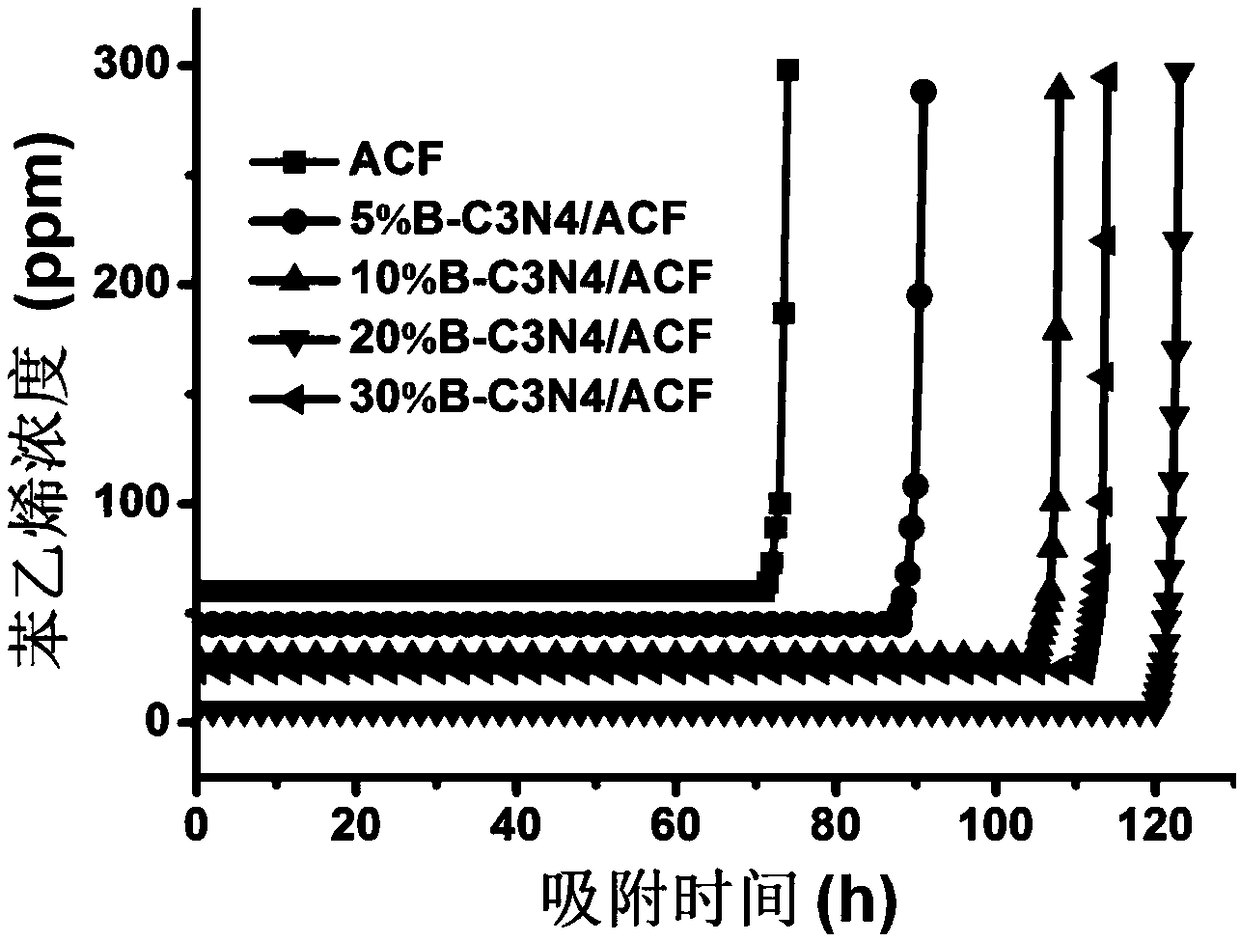

Active carbon fiber adsorbent and preparation method and application of active carbon fiber adsorbent in benzene series adsorption

ActiveCN108262015AIncreased boron contentImprove adsorption efficiencyGas treatmentOther chemical processesFiberCarbide coating

The invention provides an active carbon fiber adsorbent preparation method, which belongs to the field of processing of a volatile organic compound. The method comprises the following steps: mixing aboron precursor, a water-soluble nitrogenous organic substance, an active auxiliary agent, a surfactant and water to obtain a mixed solution, wherein the active auxiliary agent is glucose, citric acidor ascorbic acid, and the boron precursor is m-aminophenylboronic acid, p-aminophenylboronic acid, m-cyanophenylboronic acid or p-cyanophenylboronic acid; and mixing the mixed solution and the activecarbon fiber and performing a hydro-thermal reaction to obtain the active carbon fiber adsorbent. The active carbon fiber adsorbent can generate a fluffy boron doped nitrogen carbide coating layer with a nano size, uniform distribution, high boron element content and taking an active B-N bond as a main form on the active carbon surface, content of boron and nitrogen elements of the surface of a carbon material can be greatly increased, the benzene series adsorption and desorption performance by the active carbon fiber adsorbent is increased, and the cycle adsorption performance of the activecarbon fiber adsorbent can be greatly improved.

Owner:上海申丰地质新技术应用研究所有限公司

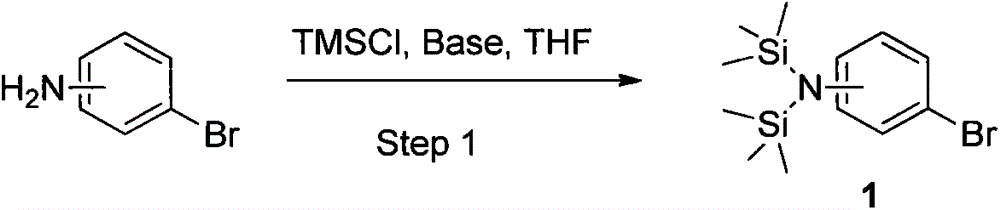

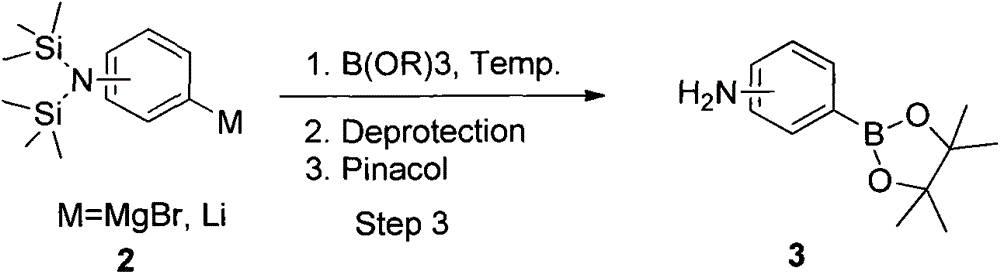

A method of synthesizing aminophenylboronic acid pinacol ester

The invention relates to a method of synthesizing aminophenylboronic acid pinacol ester. The method includes subjecting bromoaniline having different substitute positions to silanization protection, reacting with magnesium metal or butyl lithium, and performing boronization / deprotection / esterification to obtain a product. Raw materials and agents, which are adopted in the method, are cheap and easily available. Reaction conditions are mild. Only simple treatment is needed after a reaction in each step is finished. The method is capable of continuous operation. The total yield is 40-55%. The purity of the product is high. The method is suitable for large-scale amplification production.

Owner:CANGZHOU PURUI DONGFANG SCI & TECH

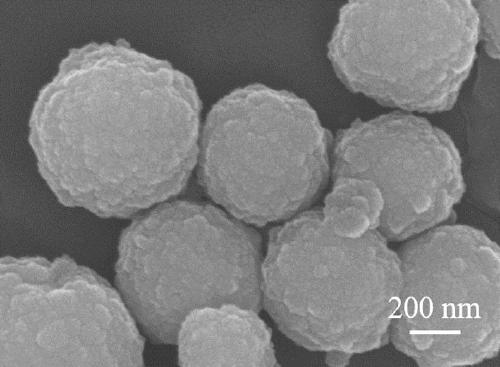

Nano mimic enzyme material, preparation method and application thereof, and method for detecting ovomucoid

ActiveCN114289066AAvoid the impact of detection accuracyWide detection rangeMaterial nanotechnologyMaterial analysis by observing effect on chemical indicatorCopper oxideAminophenylboronic acid

The invention relates to the technical field of biosensing detection, in particular to a nano mimic enzyme material, a preparation method and application thereof and a method for detecting ovomucoid. The invention provides a nano mimic enzyme material. The nano mimic enzyme material comprises copper peroxide and 3-aminophenylboronic acid which is chemically combined with the copper peroxide. The copper peroxide in the nano mimic enzyme material disclosed by the invention has ultrahigh enzyme activity so as to improve the generation of photochemical signals; the 3-aminophenylboronic acid can be specifically combined with vicinal diol on an ovoid mucoprotein sugar chain; the 3-aminophenylboronic acid enables copper peroxide to have better dispersibility and increased catalytic active sites, not only plays a role in specific binding of target molecules (ovomucoid), but also amplifies ultraviolet visible light signals, and fully exerts the excellent performance of the 3-aminophenylboronic acid as a probe material.

Owner:YUNNAN UNIV

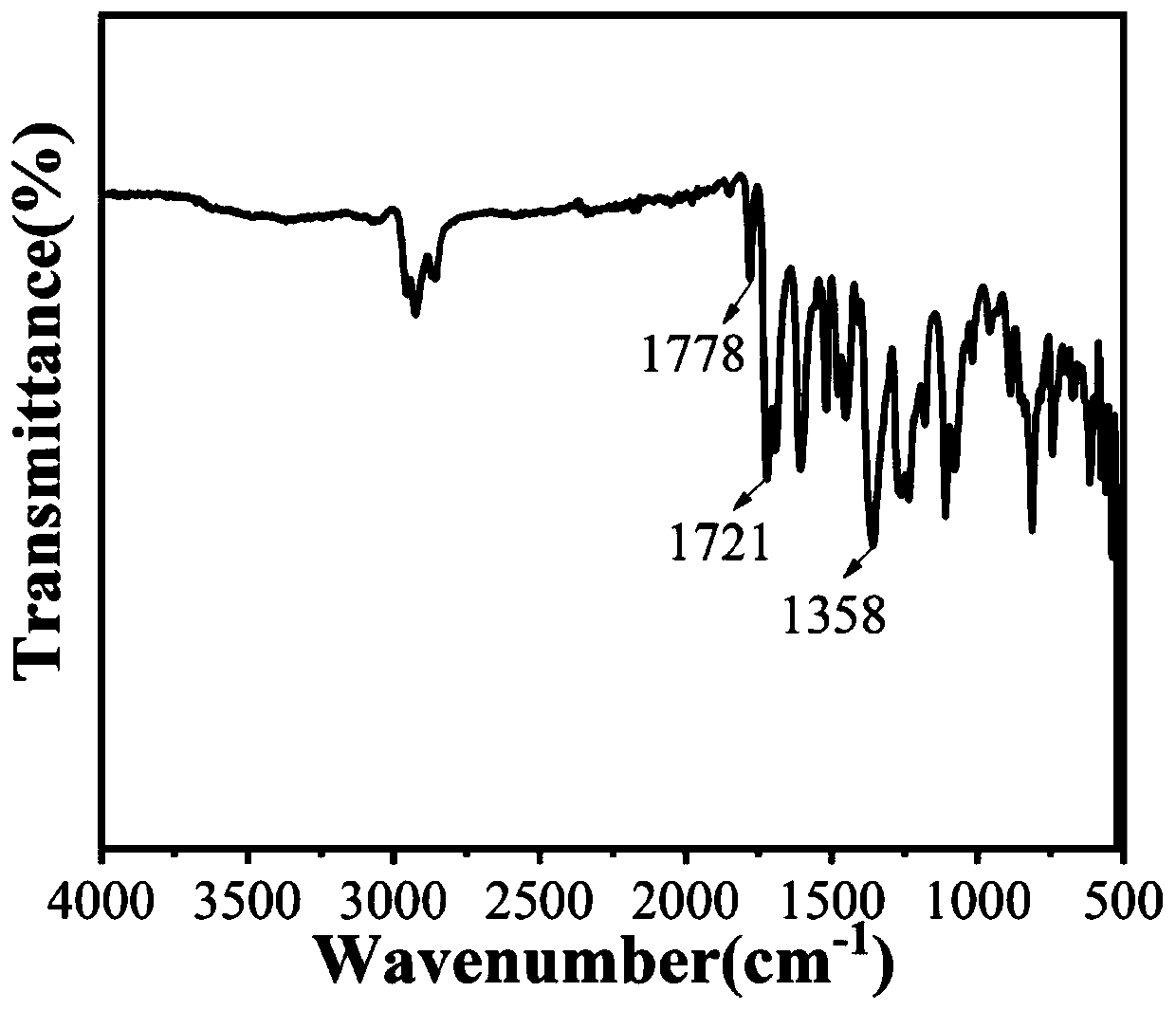

Diamine monomer containing isoindigo structure and black polyimide synthesized by diamine monomer

ActiveCN111574426AImprove solubilityEasy to synthesizeOrganic chemistryPhotovoltaic energy generationImidePolymer science

The invention belongs to the technical field of organic polymer materials, and discloses a diamine monomer containing an isoindigo structure and black polyimide synthesized by the diamine monomer. According to the invention, halogenated indolone, halogenated isatin, alkyl halide (or acylating agent) and aminophenylboronic acid pinacol ester (or nitrophenylboronic acid pinacol ester) are used as raw materials to synthesize the dark red or black diamine monomer containing the isoindigo structure. Condensation polymerization is conducted on the synthesized diamine monomer (other diamines can be added) and aromatic dianhydride to obtain a polyamide acid solution, and thermal or chemical imidization is performed to prepare black polyimide. According to the invention, the intrinsic black polyimide is prepared from the diamine monomer containing the large-plane conjugated strong electron-withdrawing isoindigo structure, a method is simple to operate and efficient in reaction, and the black polyimide can be prepared without adding or coating any shading substance. The black polyimide prepared by the method is excellent in shading performance and has wide application value in the fields ofelectronic industry, aerospace, instrument communication and the like.

Owner:XIANGTAN UNIV

Method for preparing conductive polyaniline hydrogel based on composite oxidant

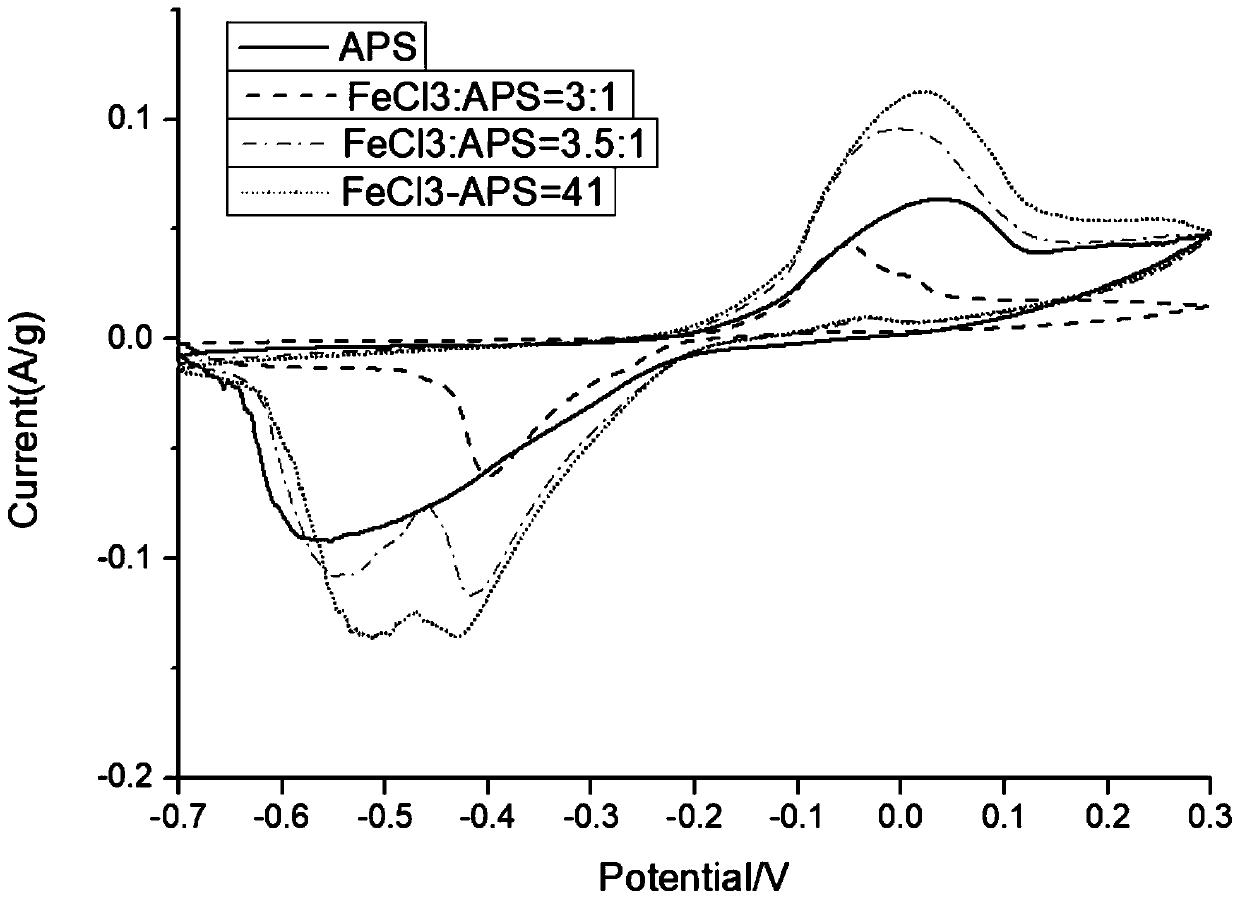

PendingCN111499884ABreak the cumbersomenessBreaking the Insufficiency of FlexibilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitancePhenylboronic acid

The invention provides a method for preparing conductive polyaniline hydrogel based on a composite oxidant. The method comprises the following steps: heating an aqueous solution containing PVA to obtain a PVA aqueous solution; mixing 3-aminophenylboronic acid hydrochloride with a PVA aqueous solution to obtain an initial solution; mixing aniline with the initial solution, and then mixing with twooxidant aqueous solutions for reaction to obtain the conductive hydrogel. The material provided by the invention has good mechanical properties and high electrochemical activity, can be assembled intoan all-solid-state supercapacitor, and has good stretchability, energy storage performance and cycling stability. Meanwhile, based on the technology provided by the invention, other materials with good electrical activity, such as carbon materials, nano metal particles and the like, can also be added into the PANI-based hydrogel, so that the properties such as specific capacitance and the like ofthe flexible electrode are improved, and the application range of the flexible electrode is expanded.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

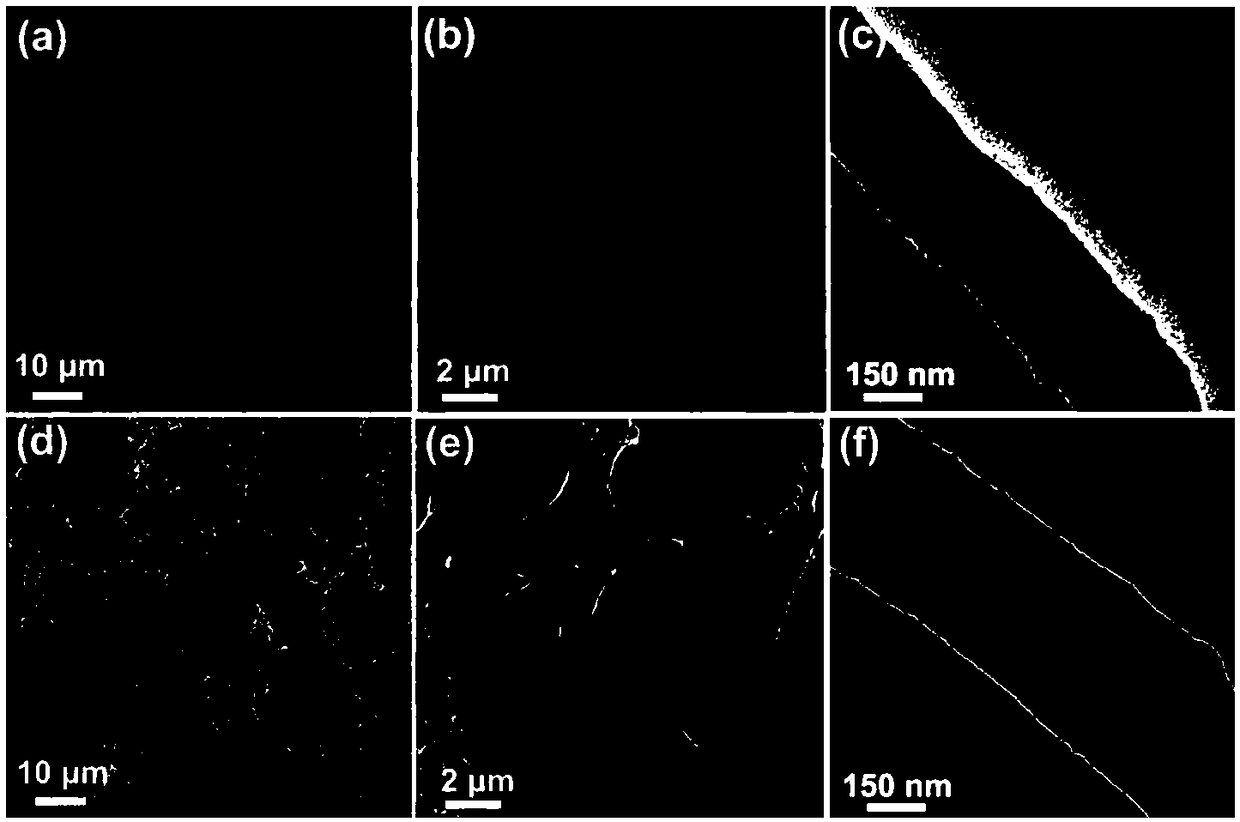

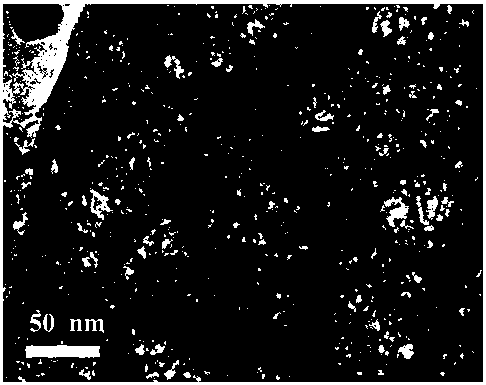

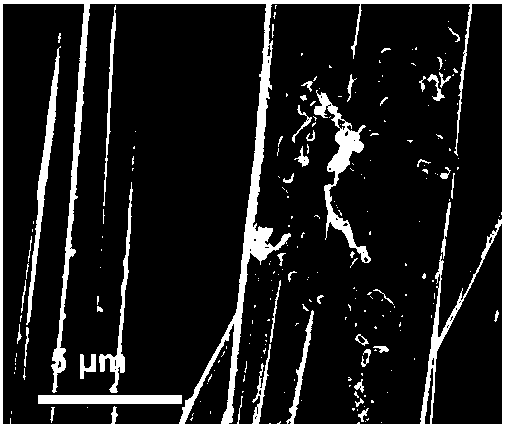

Poly-3-aminophenylboronic acid carbon-based microbial fuel cell anode and preparation method thereof

ActiveCN109962249AGood biocompatibilityImprove power generation performanceFinal product manufactureCell electrodesAcid etchingBiocompatibility Testing

The invention discloses a poly-3-aminophenylboronic acid carbon-based microbial fuel cell anode and a preparation method thereof. The anode is formed by loading a porous poly-3-aminophenylboronic acidfilm on a carbon base at a speed of 0.05-0.15 mg / cm<2>. The preparation method comprises the following steps: (1) coating the carbon base with a hard template agent sol or solution, and performing natural drying to obtain a carbon-based hard template; (2) putting the template into PBS buffer solution containing 3-aminophenylboronic acid and sodium fluoride, carrying out electropolymerization by cyclic voltammetry, and performing natural drying to obtain a carbon-based hard template bearing the poly 3-aminophenylboronic acid; (3) soaking the hard template in acid etching solution, and performing etching, water washing and drying at room temperature to obtain the anode. The anode provided by the invention has good biocompatibility and high bacterial loading capacity, and the assembled MFC electrode / electrogenic bacteria have the advantages of high extracellular electron transfer rate, high power density, high output power and good electrogenic performance. The method is simple in process, low in cost and suitable for industrial production.

Owner:HUNAN NORMAL UNIVERSITY

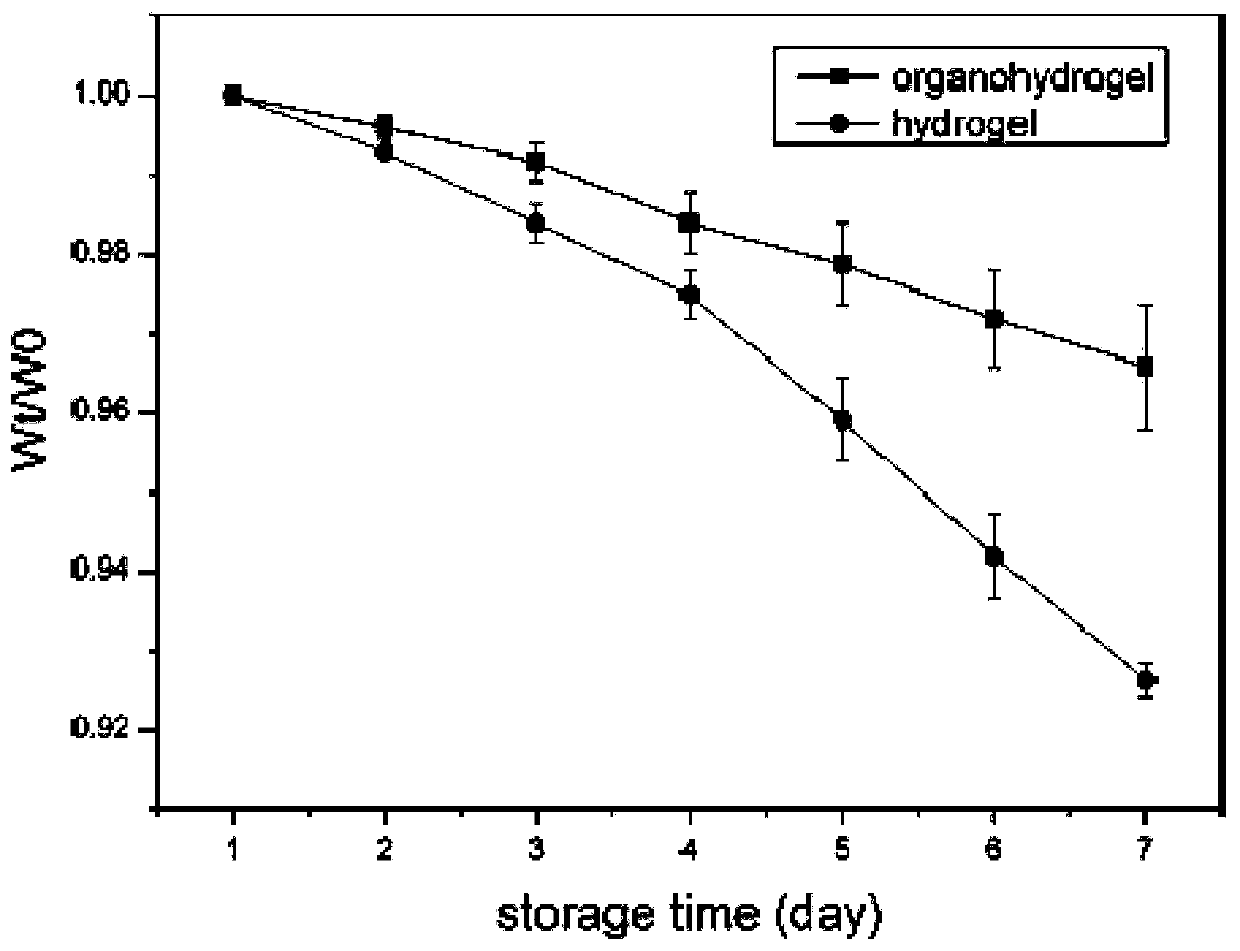

PVA (Polyvinyl Alcohol) sodium alginate dual-network cold-resistant conductive hydrogel and preparation method thereof

ActiveCN110144051AExtended temperature application rangeImprove conductivitySelf-healingFreeze-drying

The invention provides PVA (Polyvinyl Alcohol) sodium alginate dual-network cold-resistant conductive hydrogel and a preparation method thereof and belongs to the technical field of hydrogel preparation. The method comprises the following steps: dissolving sodium alginate into deionized water, adding EDC*HCl to react with aminophenylboronic acid, dialyzing and freeze-drying the product, and dissolving the freeze-dried product into the deionized water, and stirring to obtain a first solution; dissolving PVA and polyaniline into a mixed solution of deionized water and glycerin so as to obtain asecond solution; and mixing the first solution and the second solution, thereby obtaining the PVA sodium alginate dual-network cold-resistant conductive hydrogel. The hydrogel disclosed by the invention can still maintain excellent conductivity and self-healing property at a low temperature, and can be applied to the fields of electronic skin, biological or chemical sensors and the like.

Owner:CHANGCHUN UNIV OF TECH

Conductive oil gel and preparation method thereof

The invention discloses a preparation method of a conductive oil gel. The preparation method comprises the following steps: dissolving purified aniline and 3-aminophenylboronic acid monohydrate in a mixed solution to make the molar amount of 3-aminophenylboronic acid be 0.06 mmol and the molar amount of aniline be 1 mmol; adding 3 mL of an aqueous polyvinyl alcohol solution with a concentration of10 wt%, and performing stirring until uniformity is achieved in order to obtain a mixed solution; and mixing an oxidizing agent solution with the mixed solution at -4 DEG C, and standing the obtainedsolution for 12 h. The conductive oil gel of the present invention has the best compression performance in oil gels ontaining an antifreeze agent. The conductive oil gel also has self-healing ability, and keeps stable properties such water content and flexibility for a long term in the room temperature environment.

Owner:成都爱睿康美医疗科技有限责任公司

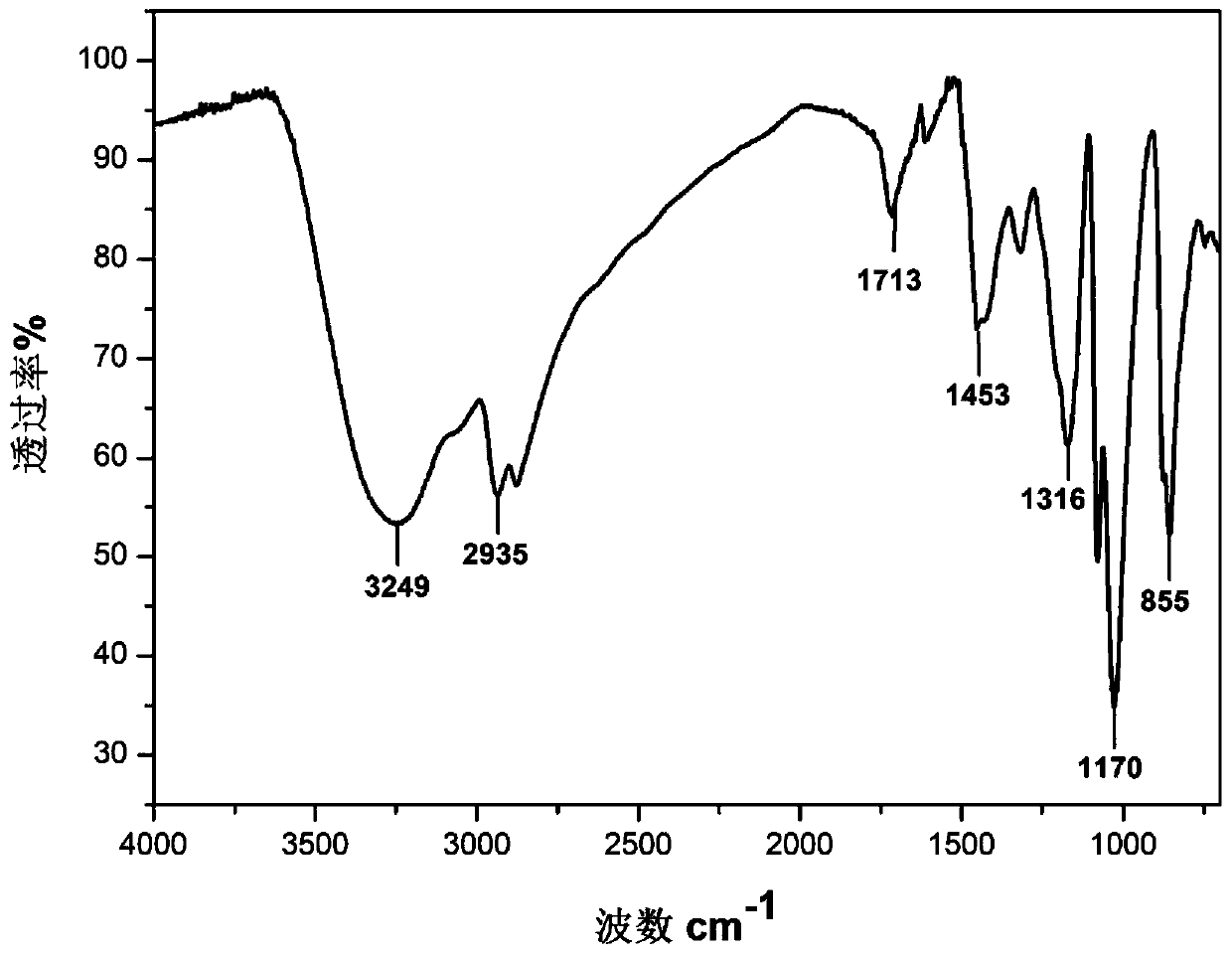

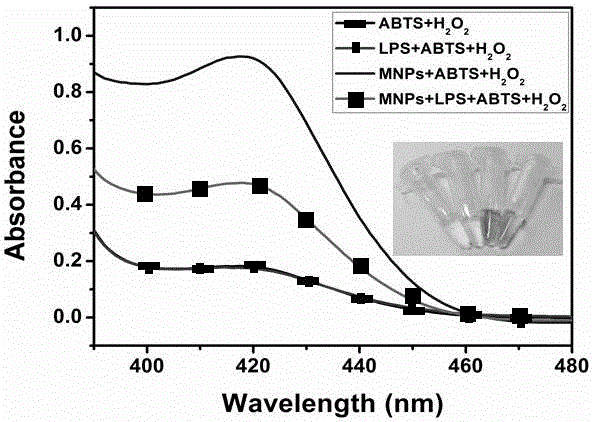

Colorimetric sensor for detecting lipopolysaccharide and preparation method and application thereof

InactiveCN106290326AGood choiceHigh sensitivityMaterial nanotechnologyMaterial analysis by observing effect on chemical indicatorPhenylboronic acidPeroxidase

The invention discloses a colorimetric sensor for detecting lipopolysaccharide and a preparation method and application thereof. The sensor carries out detection through the ultraviolet-visible light spectrum technology. The sensor is characterized in that recognition of aminophenylboronic acid modified magnetic nano-particles to lipopolysaccharide, the catalytic oxidation activity, similar to that of peroxidase, of the magnetic nano-particles and the hindering effect of lipopolysaccharide lipid bilayerson on ion transport are utilized. High specific binding of 3-amino phenylboronic acid and lipopolysaccharide and the hindering effect of the lipopolysaccharide lipid bilayerson on ion transport are utilized, high specificity of detection is guaranteed, and detection sensitivity is improved through the catalytic oxidation activity, similar to that of peroxidase, of the magnetic nano-particles. Color changes generated in the magnetic nanocatalyzed oxidationof ABTS with H2O2 are captured through the ultraviolet-visible light spectrum technology, and analysis and detection of lipopolysaccharide are achieved. The method is simple, rapid and free of signal marking. Sensitivity is high and can linearly detect lipopolysaccharide within the range of 0.00001 microgram / mL to 180 microgram / mL, high specificity is achieved, and lipopolysaccharide and other contrast matter can be effectively distinguished.

Owner:SHANGHAI UNIV

Finish paint for building aluminum veneer curtain wall and preparation method thereof

The invention belongs to the technical field of finish paint for buildings, and particularly discloses finish paint for a building aluminum veneer curtain wall and a preparation method thereof. The finish paint for the building aluminum veneer curtain wall comprises a component A and a component B. The component A is prepared from the following raw materials: fluorocarbon resin, filler, modified carbon nanotubes, methyl methacrylate resin, silica sol, a dispersing agent, 3-(trihydroxysilyl) propyl methyl phosphate, 4-aminophenylboronic acid, diethylenetriamine, ethylene glycol butyl ether, a defoaming agent, a thickening agent, dioctyl phthalate, a pH regulator and a solvent; and the component B is prepared from hexamethylene diisocyanate resin and sodium hexametaphosphate. On the basis of good corrosion resistance, the finish paint also has good heat insulation and wear resistance.

Owner:佛山市南海宇诚装饰材料有限公司

Preparation method of phenylboronic acid modified magnetic beta-cyclodextrin polymer and application of phenylboronic acid modified magnetic beta-cyclodextrin polymer in selective separation of shikimic acid

ActiveCN110396146AGood biocompatibilityEasy to manufactureOther chemical processesAlkali metal oxides/hydroxidesEpoxyResource utilization

The invention belongs to the technical fields of resource utilization and chemical separation, and relates to a preparation method of a phenylboronic acid modified magnetic beta-cyclodextrin polymer and an application of the phenylboronic acid modified magnetic beta-cyclodextrin polymer in selective separation of shikimic acid. The preparation method comprises the following steps: firstly, preparing a nano Fe3O4 solid, and dissolving 0.1-0.5 g of dopamine hydrochloride and 0.12-0.2 g of Fe3O4 into an aqueous solution of Tris with a concentration of 0.1211 g / 100mL to prepare a Fe3O4@PDA solid;mixing the a Fe3O4@PDA solid with beta-cyclodextrin and epoxy chloropropane to obtain a Fe3O4@PDA@beta-cyclodextrin solid; and finally, fully mixing the Fe3O4@PDA@beta-cyclodextrin solid with EDC andNHS, adding 3-aminophenylboronic acid, and performing a reaction for 6-18 hours to obtain the product. According to the preparation method provided by the invention, boric acid is replaced by surfacemodification, so that the shikimic acid with a cis-dihydroxy structure is enriched on the surface of the phenylboronic acid modified magnetic beta-cyclodextrin polymer, the shikimic acid can be separated out through magnetic separation and recycled, and the purity and yield of the shikimic acid are effectively improved; and the method has better application prospects in the field of enrichment, separation and purification of natural products with cis-dihydroxy structures, and has the advantages of energy conservation, environmental protection, convenient recovery and the like.

Owner:JIANGSU UNIV

Responding type gold nano-cluster particles for blood glucose regulation and preparation method of responding type gold nano-cluster particles

ActiveCN108635570AReduce concentrationConcentration real-time responsePeptide/protein ingredientsMetabolism disorderGlycineConcentration Response

The invention discloses responding type gold nano-cluster particles for blood glucose regulation and a preparation method of the responding type gold nano-cluster particles, and belongs to the field of biomedicine. The responding type gold nano-cluster particles comprise a carrier material, a glucose responding sensitive switch factor and pharmaceutical molecules. The preparation method comprisesfollowing steps: firstly, preparing BSA-coated gold nano-cluster particles BSA-GNCs to serve as the carrier material of the pharmaceutical molecules; removing amino on BSA molecules by glutaraldehyde,converting tail ends of the molecules into carboxyl by glycine, activating carboxyl, and grafting and modifying carboxyl with 4-aminophenylboronic acid to serve as the glucose responding sensitive switch factor; grafting the glucose responding sensitive switch factor with glycosylated insulin to obtain the responding type gold nano-cluster particles for blood glucose regulation. The gold nano-cluster particles can release insulin according to glucose concentration response; functions of responding to glucose concentration in real time, rapidly and intelligently transmitting and releasing insulin and regulating blood glucose of a human body are achieved.

Owner:WUHAN UNIV

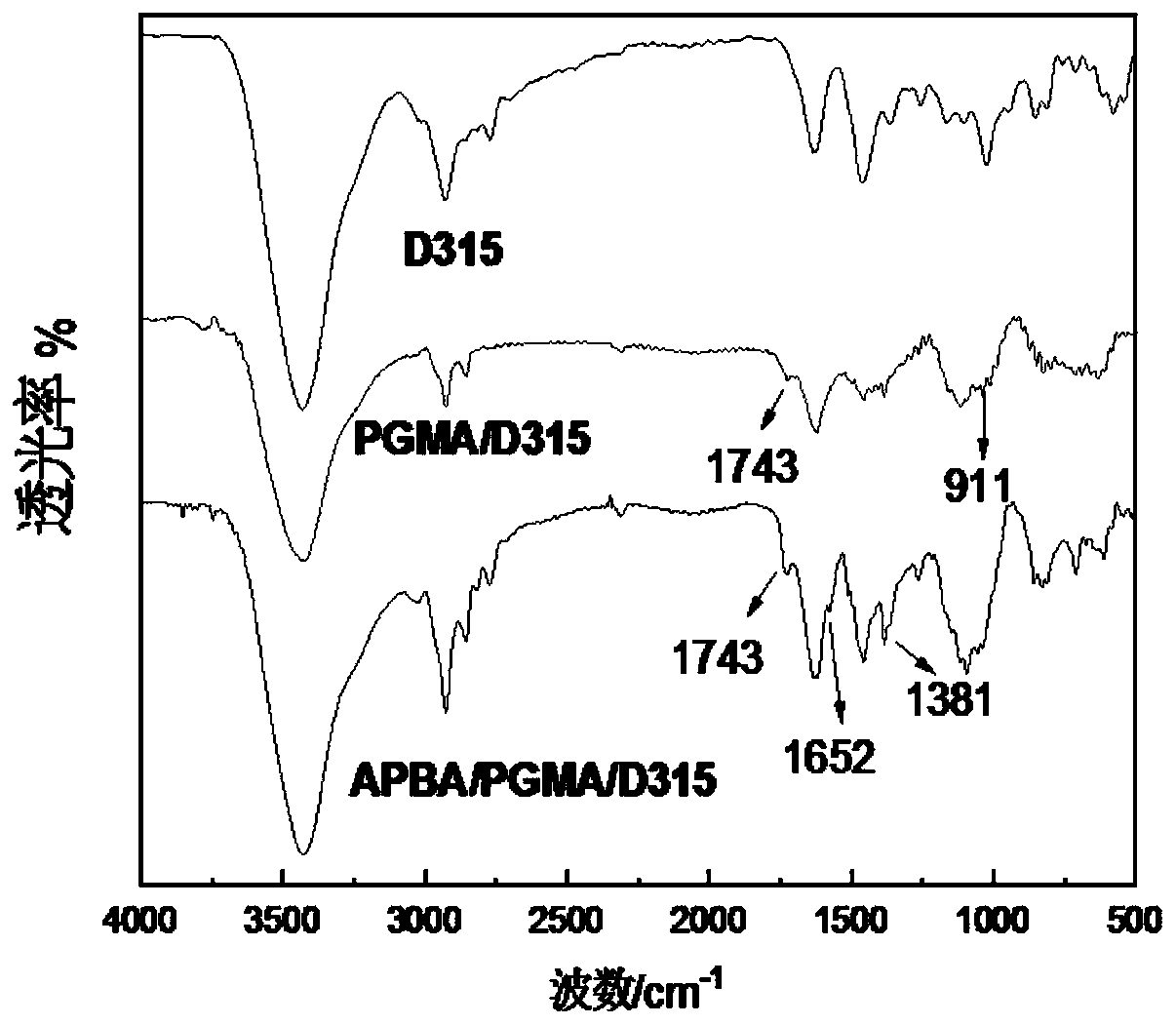

Flavonoid glycoside adsorption resin and preparation method thereof

ActiveCN110835421AEfficient separationStrong specificityOther chemical processesAlkali metal oxides/hydroxidesEpoxyPolymer science

The invention discloses a flavonoid glycoside adsorption resin and a preparation method thereof. The flavonoid glycoside adsorption resin is prepared through using macro-porous resin as a matrix and adopting a technology firstly adopting graft polymerization and then epoxy ring opening. The method is specifically characterized in that glycidyl methacrylate is used as a functional monomer, the surface of the macro-porous resin is grafted with an organic long-chain polymer through a free radical chain reaction, 3-aminophenylboronic acid is used as a ring-opening reaction substance, and a boric acid group is introduced into the chain segment of the organic long-chain polymer through an epoxy ring-opening reaction. The flavonoid adsorption resin has the following advantages: (1) the flavonoidadsorption resin has high specificity, can be used to effectively separate flavonoid glycosides from natural plants, the separation efficiency is high, and the adsorption capacity is large; and (2) the elution is very easy and convenient, the eluted resin does can be directly used for the next flavonoid glycoside adsorption without being regenerated and preprocessed, and the operation process is very simple and convenient.

Owner:ZHONGBEI UNIV

Fluorescence sensor for detecting fluorine ions, and preparation method of fluorescence sensor

ActiveCN104655604ALow toxicityHigh quantum yieldFluorescence/phosphorescenceQuantum yieldBiocompatibility Testing

The invention discloses a fluorescence sensor for detecting fluorine ions, and a preparation method of the fluorescence sensor. The preparation method comprises the steps of dissolving 3-aminophenylboronic acid into water, and adjusting the pH value of the system to be alkaline; then, carrying out a hydrothermal reaction to obtain carbon dots; feeding a sodium citrate solution into a boiling HAuCl4 solution, and carrying out agitation backflow until the system is red; then, cooling, centrifuging and washing to obtain nanogold; mixing 3-sulfydryl-1,2-propylene glycol and the nanogold, and carrying out a reaction to obtain modified nanogold; mixing the carbon dots and the modified nanogold, and carrying out a reaction to obtain the fluorescence sensor for detecting the fluorine ions. According to the preparation method of the fluorescence sensor for detecting the fluorine ions, the process is simple and easy, an environment-friendly effect is achieved, and the preparation method can be generalized into preparation of other luminous nanometer materials; the obtained fluorescence sensor for detecting the fluorine ions can be used for detecting the fluorine ions in a water solution, and is low in toxicity, high in quantum yield as well as good in light stability, biocompatibility and sensitivity.

Owner:ANHUI UNIV OF SCI & TECH

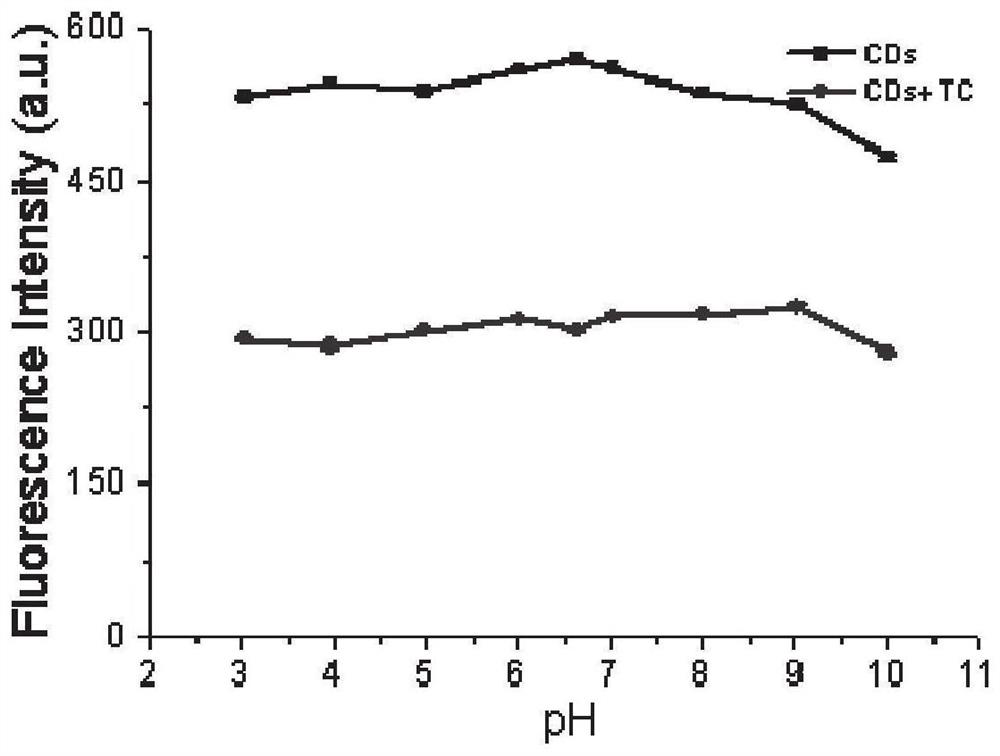

Doped carbon quantum dot/PVA-based composite membrane, preparation method thereof and application in tetracycline detection

InactiveCN113046071AGood choiceImprove anti-interference abilityNanoopticsFluorescence/phosphorescencePolyvinyl alcoholCross linker

The invention discloses a doped carbon quantum dot / PVA-based composite membrane, a preparation method thereof and application in tetracycline detection. The doped carbon quantum dot / PVA-based composite membrane comprises carbon quantum dots and a polyethylene hydrogel membrane, wherein the polyethylene hydrogel membrane loads the carbon quantum dots, and the carbon quantum dots are synthesized by using 3-aminophenylboronic acid and citric acid as precursors. The preparation method comprises the steps of preparing carbon quantum dots from 3-aminophenylboronic acid and citric acid by adopting a hydrothermal method, adding polyvinyl alcohol into an aqueous solution of the carbon quantum dots, adding a cross-linking agent for cross-linking, and removing water from a cross-linked material to prepare a membrane material, namely, the doped carbon quantum dot / PVA-based composite membrane. The composite membrane prepared by the invention can be used as a fluorescent sensor for detecting TC, is convenient to carry, has higher sensitivity and better selectivity for TC detection, and can be used for monitoring TC in real time.

Owner:LIAOCHENG UNIV

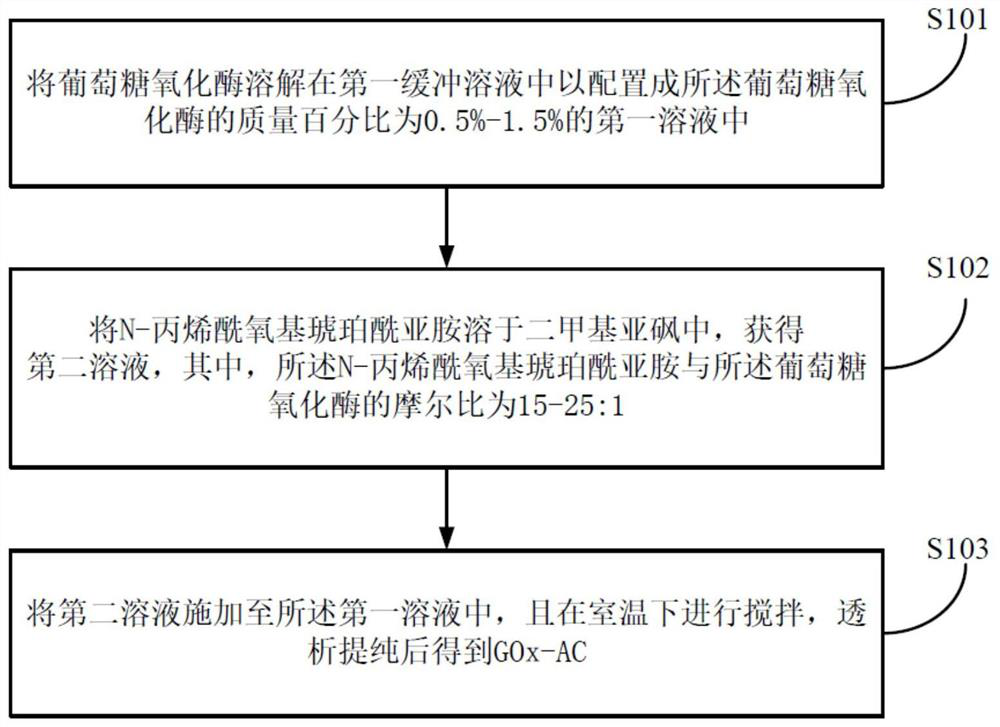

Preparation method of glucose-triggered active oxygen response injection type composite hydrogel

PendingCN113599507ANo side effectsGood biocompatibilityPeptide/protein ingredientsMetabolism disorderPolymer sciencePolyvinyl alcohol

The invention provides a preparation method of glucose-triggered active oxygen response injection type composite hydrogel. The preparation method comprises the following steps of preparing a hyaluronic acid-aminophenylboronic acid derivative HA-g-PBA of which the main chain has phenylboronic acid and an acrylic group modified glucose oxidase derivative GOx-AC; carrying out Michael addition reaction on sulfydryl of sulfydryl phenylboronic acid and an acrylate group of GOx-AC to prepare a derivative GOx-g-PBA with phenylboronic acid glucose oxidase; forming a borate dynamic covalent bond through a hydroxyl group of GOx-g-PBA and a hydroxyl group of polyvinyl alcohol, so as to prepare a polyvinyl alcohol derivative PVA-g-GOx modified with glucose oxidase; and mixing HA-g-PBA and PVA-g-GOx according to a preset proportion, and then forming boric acid ester dynamic covalent bonds to prepare the glucose-triggered active oxygen response injection type composite hydrogel. The preparation method is simple and has a good application prospect, and the degradation period can be regulated and controlled through dual response of glucose and active oxygen.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com