Preparation method of molecularly imprinted sensor based on carbon quantum dot/hollow nickel base material composite film modified glassy carbon electrode and application thereof

A glassy carbon electrode and carbon quantum dot technology, which is applied in the field of electrochemical sensor preparation, can solve problems such as defects, electrode electrocatalytic activity and active area need to be further improved, etc., and achieves simple operation, improved electron transfer performance, and improved active area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

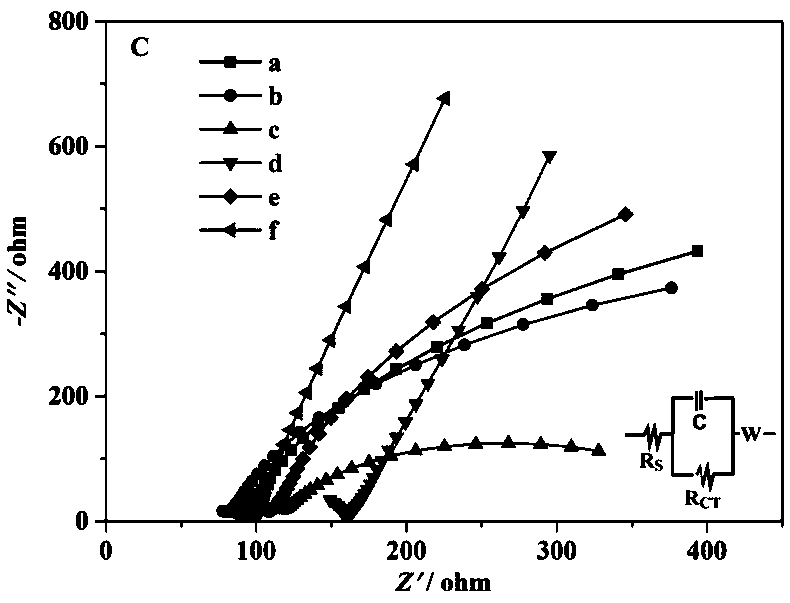

Image

Examples

Embodiment 1

[0031] a) Preparation of modified electrode: The Ni-Cu alloy layer was prepared by a three-electrode system containing 1.0 M NiSO 4 , 0.01 M CuSO 4 and 0.5 M H 3 BO 3 Electrodeposited on the treated glassy carbon electrode in the mixed solution, and then dealloyed in the same solution to remove copper to prepare nanometer hollow nickel sphere layer. Put pure cotton material with a mass ratio of 1:40 and distilled water in a reaction vessel, heat at 180° C. for 12 hours, and cool to room temperature to obtain a solution of carbon quantum dots. The solution containing the carbon quantum dots is filtered, centrifuged, and freeze-dried to obtain the solid-state fluorescent carbon quantum dots. Mix it with 1% chitosan acetic acid solution at a ratio of 1:1, drop-spray 5 μL on the surface of a glassy carbon electrode coated with a hollow nickel ball, dry it in an oven at 60°C for 30 minutes, and cool it to room temperature to obtain the modification. electrode.

[0032] b) Prep...

Embodiment 2

[0034] a) Preparation of modified electrode: The Ni-Cu alloy layer was prepared by a three-electrode system containing 1.0 M NiSO 4 , 0.01 M CuSO 4and 0.5 M H 3 BO 3 Electrodeposited on the treated glassy carbon electrode in the mixed solution, and then dealloyed in the same solution to remove copper to prepare nanometer hollow nickel sphere layer. Put pure cotton material with a mass ratio of 1:50 and distilled water in a reaction vessel, heat at 190° C. for 14 hours, and cool to room temperature to obtain a solution of carbon quantum dots. The solution containing the carbon quantum dots is filtered, centrifuged, and freeze-dried to obtain the solid-state fluorescent carbon quantum dots. Mix it with 1% chitosan acetic acid solution at a ratio of 2:1, drop-spray 10 μL on the surface of the glassy carbon electrode coated with hollow nickel balls, dry in an oven at 60°C for 30 minutes, and cool to room temperature to obtain the modification. electrode.

[0035] b) Preparati...

Embodiment 3

[0037] a) Preparation of modified electrode: The Ni-Cu alloy layer was prepared by a three-electrode system containing 1.0 M NiSO 4 , 0.01 M CuSO 4 and 0.5 M H 3 BO 3 Electrodeposited on the treated glassy carbon electrode in the mixed solution, and then dealloyed in the same solution to remove copper to prepare nanometer hollow nickel sphere layer. Put pure cotton material with a mass ratio of 1:60 and distilled water in a reaction vessel, heat at 200°C for 15 hours, and cool to room temperature to obtain a solution of carbon quantum dots. The solution containing the carbon quantum dots is filtered, centrifuged, and freeze-dried to obtain the solid-state fluorescent carbon quantum dots. Mix it with 1% chitosan acetic acid solution at a ratio of 3:1, drop-spray 9 μL on the surface of the glassy carbon electrode coated with hollow nickel balls, dry in an oven at 60°C for 30 minutes, and cool to room temperature to obtain the modification. electrode.

[0038] b) Preparation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com