Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "With hydrophobic function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

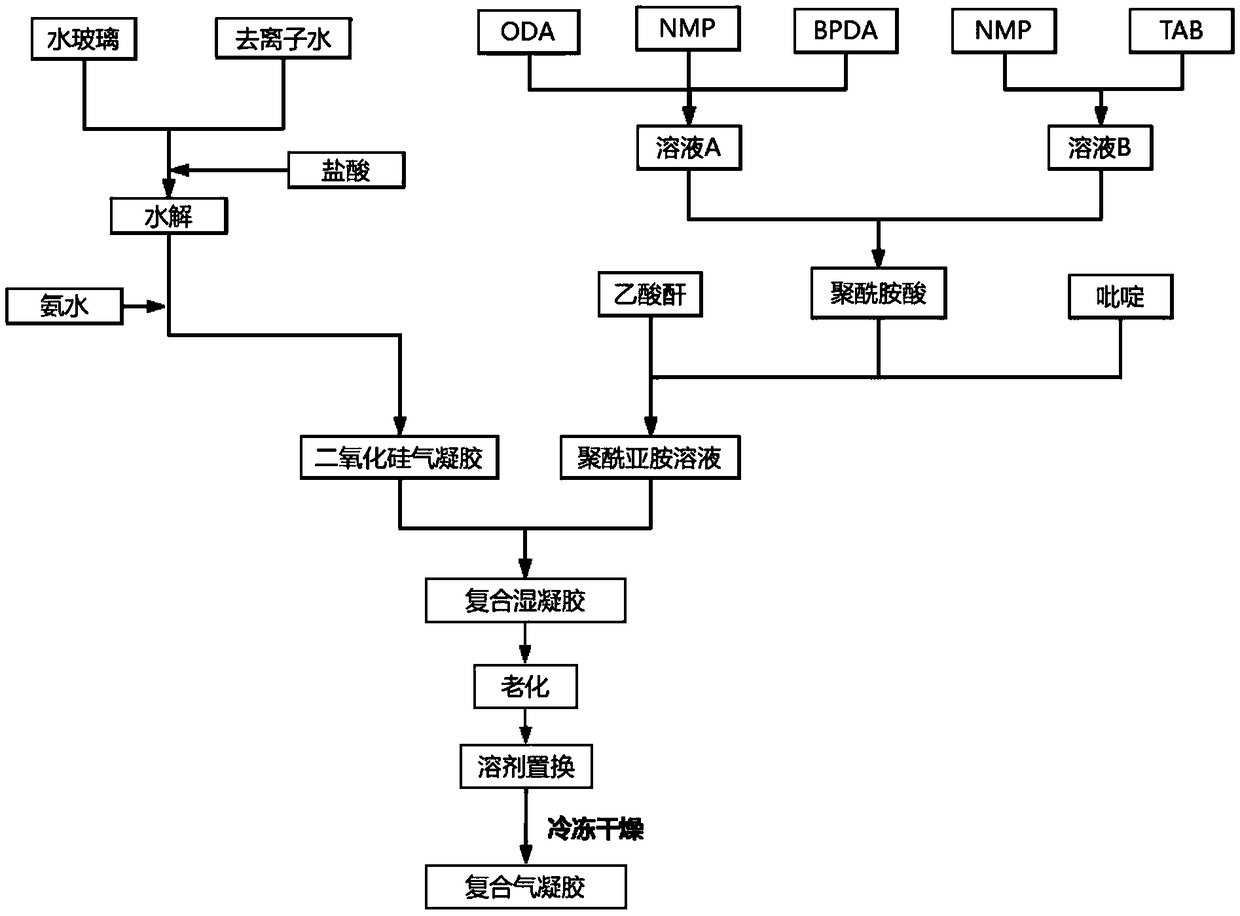

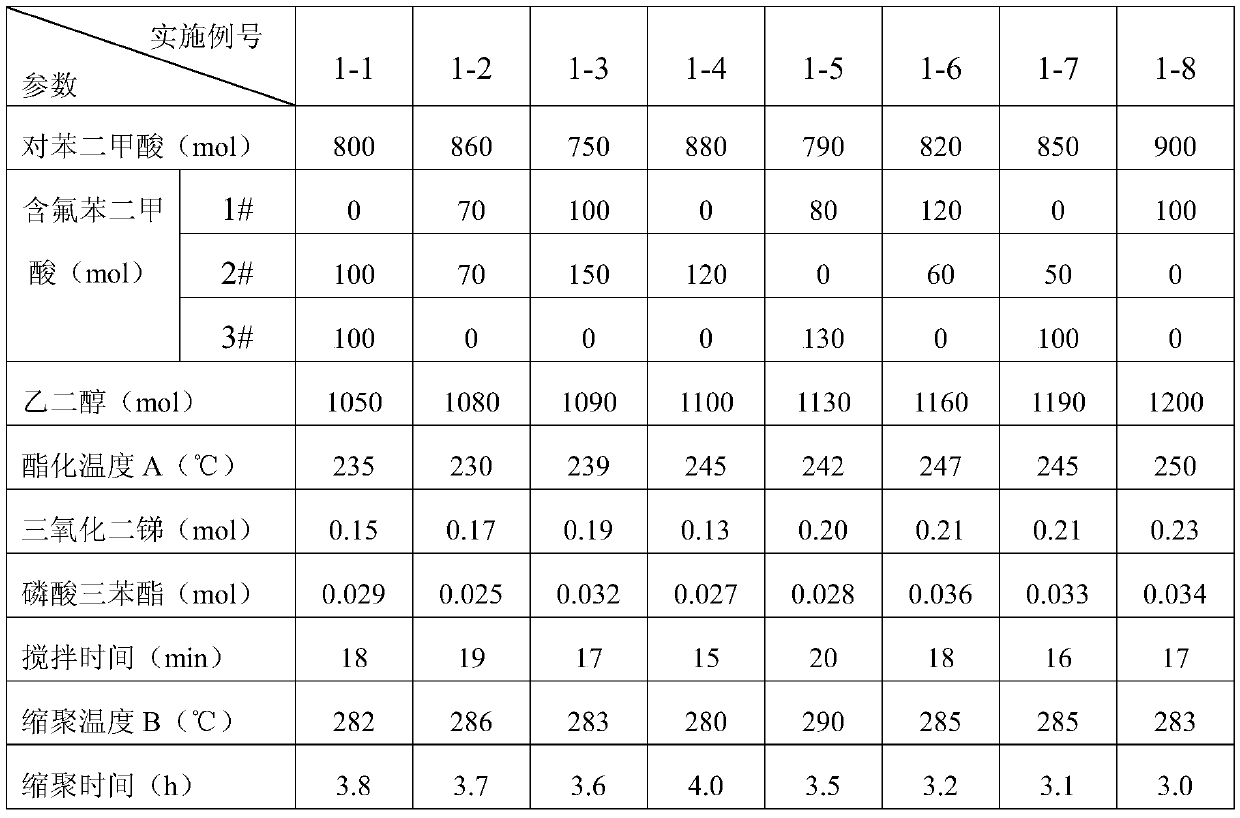

Hydrophobic silicon dioxide/polyimide aerogel composite material and preparation method

ActiveCN108727818AImprove hydrophobicityImprove mechanical propertiesTemperature resistanceSilicon dioxide

The invention provides a hydrophobic silicon dioxide / polyimide aerogel composite material. The hydrophobic silicon dioxide / polyimide aerogel composite material comprises hydrophobic modified silicon dioxide aerogel and polyimide aerogel, wherein the polyimide aerogel is used as a substrate of the composite material, and hydrophobic modified silicon dioxide aerogel fillers are embedded into pores of the polyimide aerogel. According to the hydrophobic silicon dioxide / polyimide aerogel composite material, the silicon dioxide aerogel is added to the polyimide aerogel; the polyimide aerogel is usedas the substrate and a framework of a composite heat insulation material to realize the supporting reinforcing effect, so that the mechanical strength of the composite heat insulation material is improved; and the silicon dioxide aerogel is used as the filler and has the hydrophobic function and outstanding heat insulation performance, so that the heat insulation effect is realized in the composite material. The hydrophobic silicon dioxide / polyimide aerogel composite material comprehensively considers the physical performance and the mechanical performance of the composite heat insulation material and has the advantages of being high in strength, high in high temperature resistance, low in volume weight, low in heat conductivity, and high in waterproofing performance, and meets the requirements on performances of the heat insulation material in actual application.

Owner:UNIV OF SCI & TECH OF CHINA

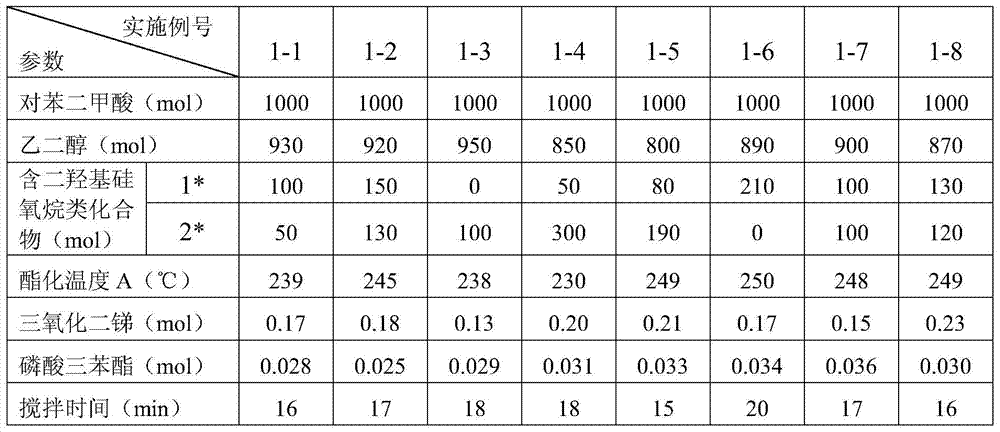

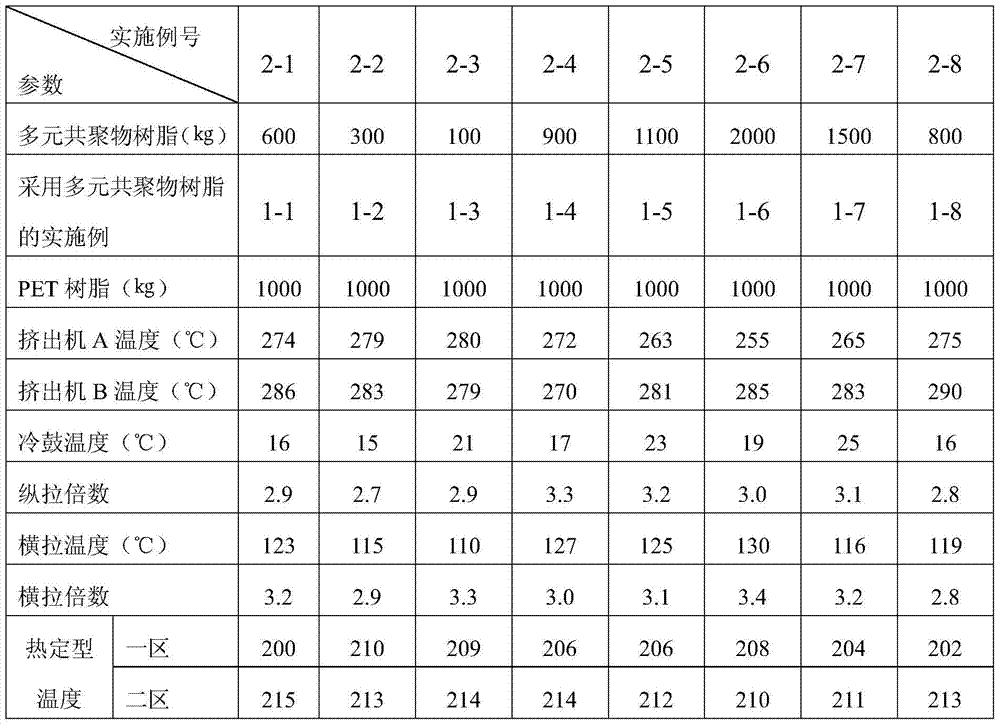

Siloxane-polyester copolymer resin, siloxane-polyester copolymer compound substrate membrane, and methods for preparing siloxane-polyester copolymer resin and siloxane-polyester copolymer compound substrate membrane

ActiveCN105504253AImprove hydrolysis resistanceSimple preparation processSynthetic resin layered productsElectrical equipmentHeat settingTerephthalic acid

The invention discloses siloxane-polyester copolymer resin, a siloxane-polyester copolymer compound substrate membrane, and methods for preparing the siloxane-polyester copolymer resin and the siloxane-polyester copolymer compound substrate membrane. The molecular weight of the siloxane-polyester copolymer resin is 10000-25000. The siloxane-polyester copolymer resin is prepared through reaction between terephthalic acid and a compound containing dyhydroxy. The siloxane-polyester copolymer resin and PET resin are molten through an extruder based on the mass ratio of (10-200) : 100, and then delamination coextrusion with a resin melting distributor, casting strip combination, longitudinal drawing, horizontal drawing, heat setting, cooling and coiling are conducted to obtain the siloxane-polyester copolymer compound substrate membrane. The thickness of the compound substrate membrane prepared from the siloxane-polyester copolymer is 100-300 microns, and the compound substrate membrane is especially suitable for manufacturing of release films and hydrolysis resistance materials for solar photovoltaic cell backboards and is high in performance and practicality.

Owner:SHANDONG SNTON OPTICAL MATERIALS TECH CO LTD

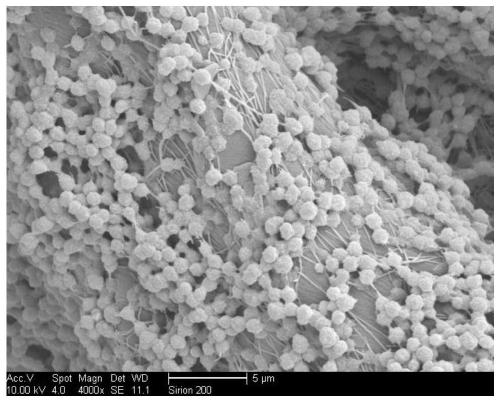

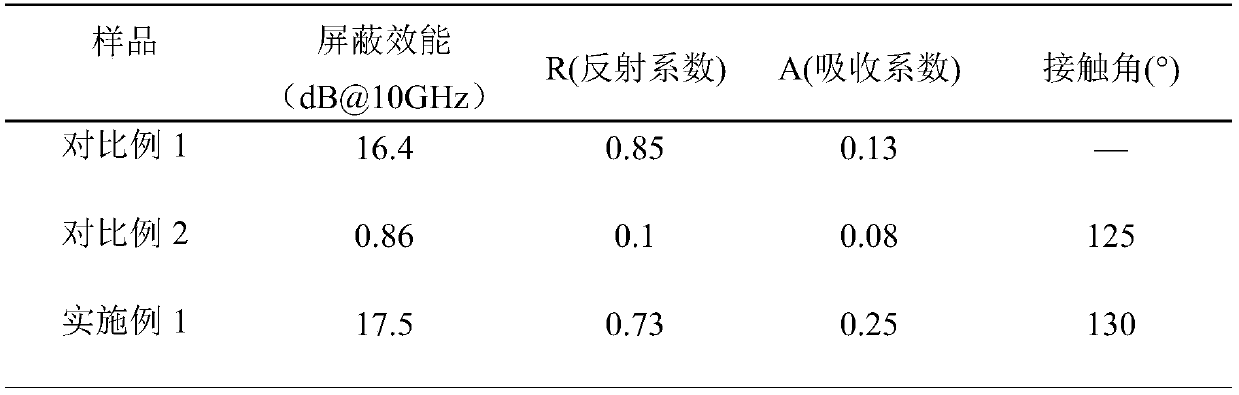

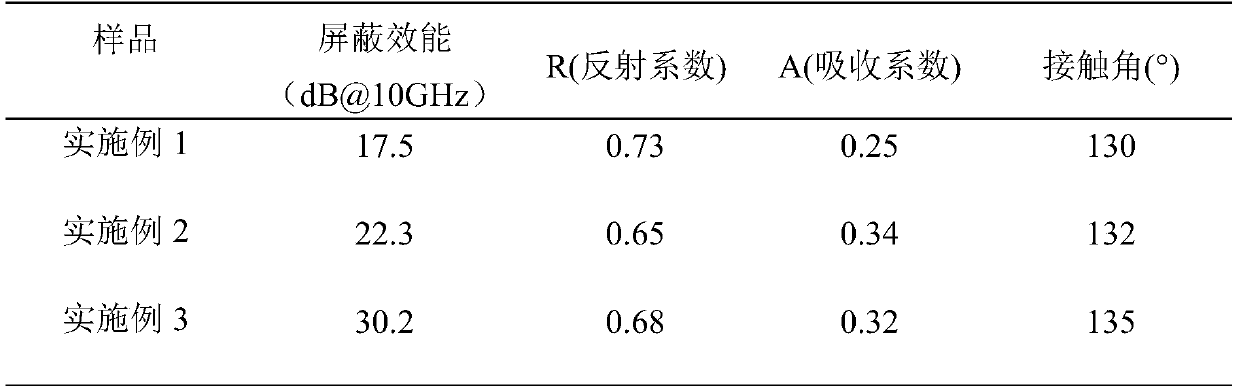

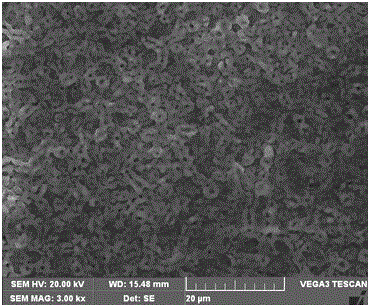

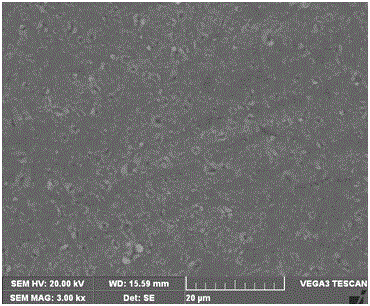

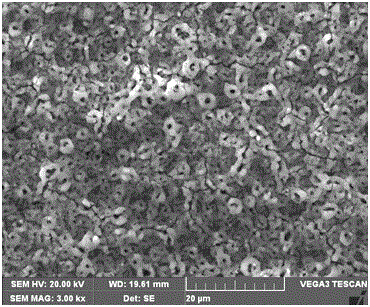

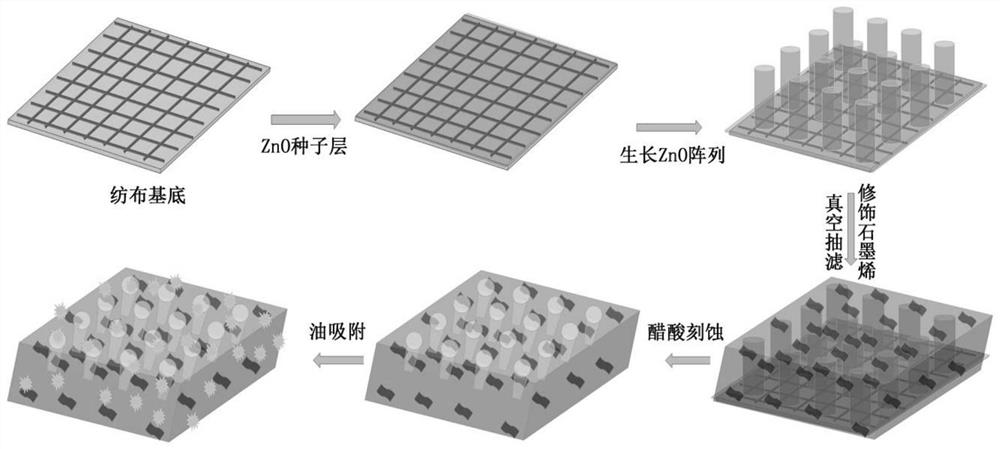

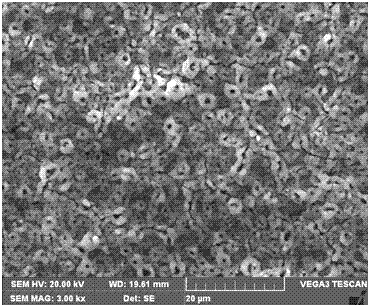

Electromagnetic shielding and hydrophobic functional fabric with high absorption characteristics and preparation method thereof

ActiveCN111535044AGood electromagnetic shieldingWith hydrophobic functionTextiles and paperPolymer scienceHydrophobic polymer

The invention discloses an electromagnetic shielding and hydrophobic functional fabric with high absorption characteristics and a preparation method thereof. The preparation method comprises the mainoperation steps of coating a textile with conductive filler dispersion liquid to obtain a conductive coating; and preparing a hydrophobic polymer nanoparticle composite solution, and coating the obtained conductive cotton fabric with the hydrophobic polymer nanoparticle composite solution to prepare a polymer composite microsphere coating. The fabric prepared by the method has good electromagneticshielding performance on the basis of keeping the softness of the fabric, the absorption loss of the fabric is increased by regulating and controlling electromagnetic parameters of the fabric, the reflection and secondary radiation of electromagnetic waves are greatly reduced, meanwhile, the prepared electromagnetic shielding fabric also has a hydrophobic function, and the preparation method is simple, convenient, feasible and low in cost.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Silane coupling agent arc-suppressed micro arc oxidation electrolyte solution and micro arc oxidation film preparation method

ActiveCN105063722AImprove corrosion resistanceControllable structureAnodisationMicro arc oxidationCorrosion resistant

The invention discloses a silane coupling agent arc-suppressed micro arc oxidation electrolyte solution and a micro arc oxidation film preparation method. The electrolyte solution comprises a base solution and a silane coupling agent, wherein the base solution is composed of one or two or three of inorganic salts, fluorides and hydroxides, and is alkaline; and the silane coupling agent is neutral or alkaline after hydrolysis and has a general formula of R<4-x>Si(OR'). The preparation method comprises the steps of: placing a magnesium alloy substrate serving as an anode or cathode and stainless steel serving as a counter electrode in the electrolyte solution, carrying out micro arc oxidation, taking out the magnesium alloy substrate after oxidation, washing, and drying to obtain a micro arc oxidation film layer on the surface of the magnesium alloy. The electrolyte solution can inhibit point discharge; the prepared micro arc oxidation film is controllable in structure, and has good corrosion resistance and wear resistance; a micro arc oxidation transition layer with excellent compatibility can be prepared according to the requirement of a surface composite coating layer.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

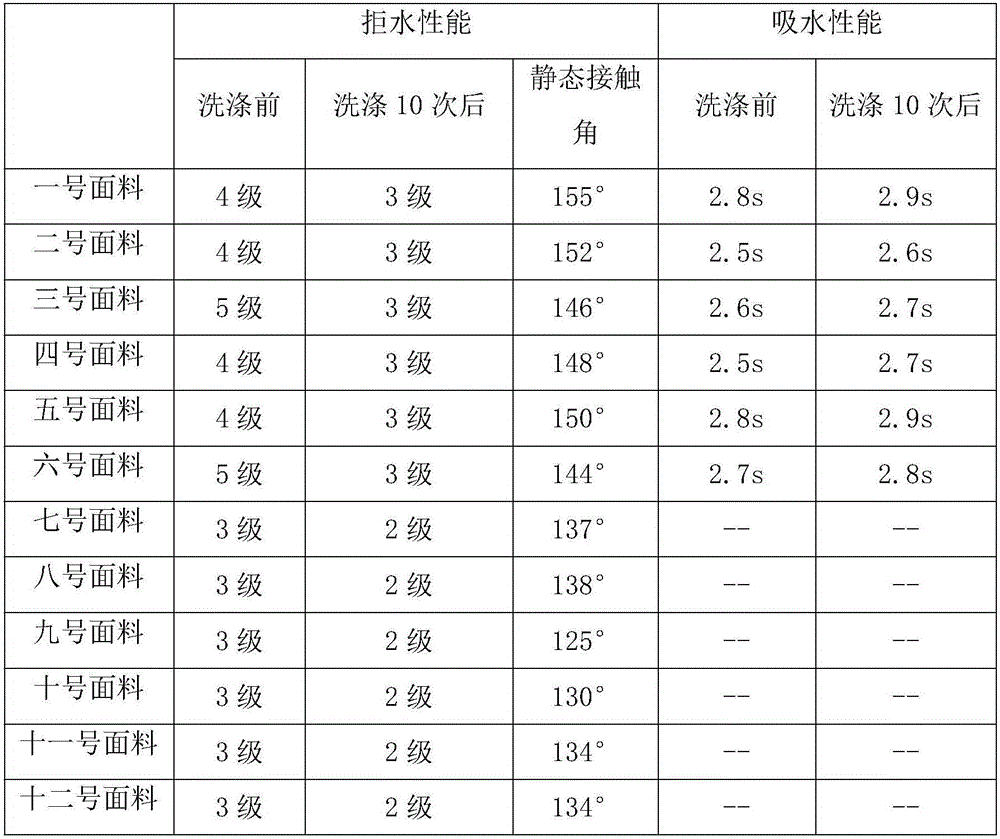

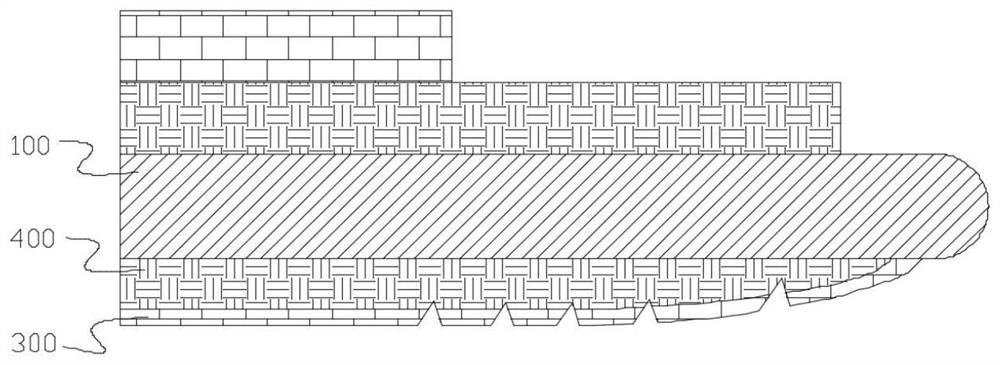

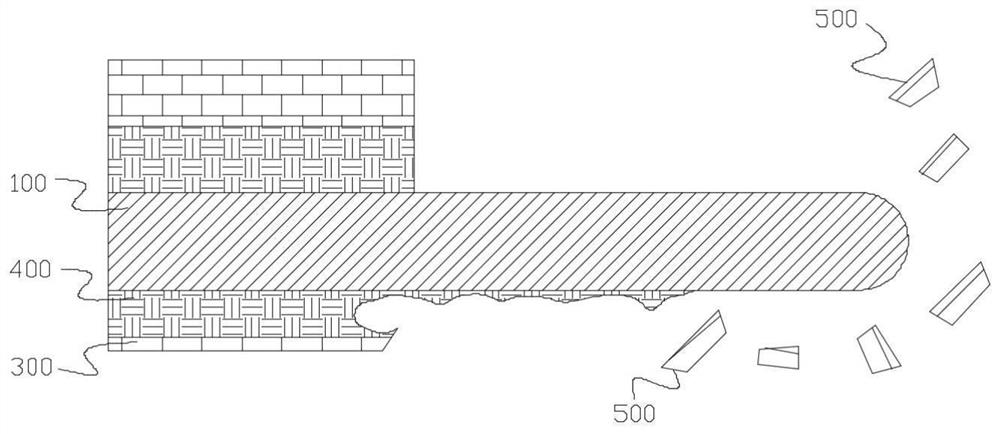

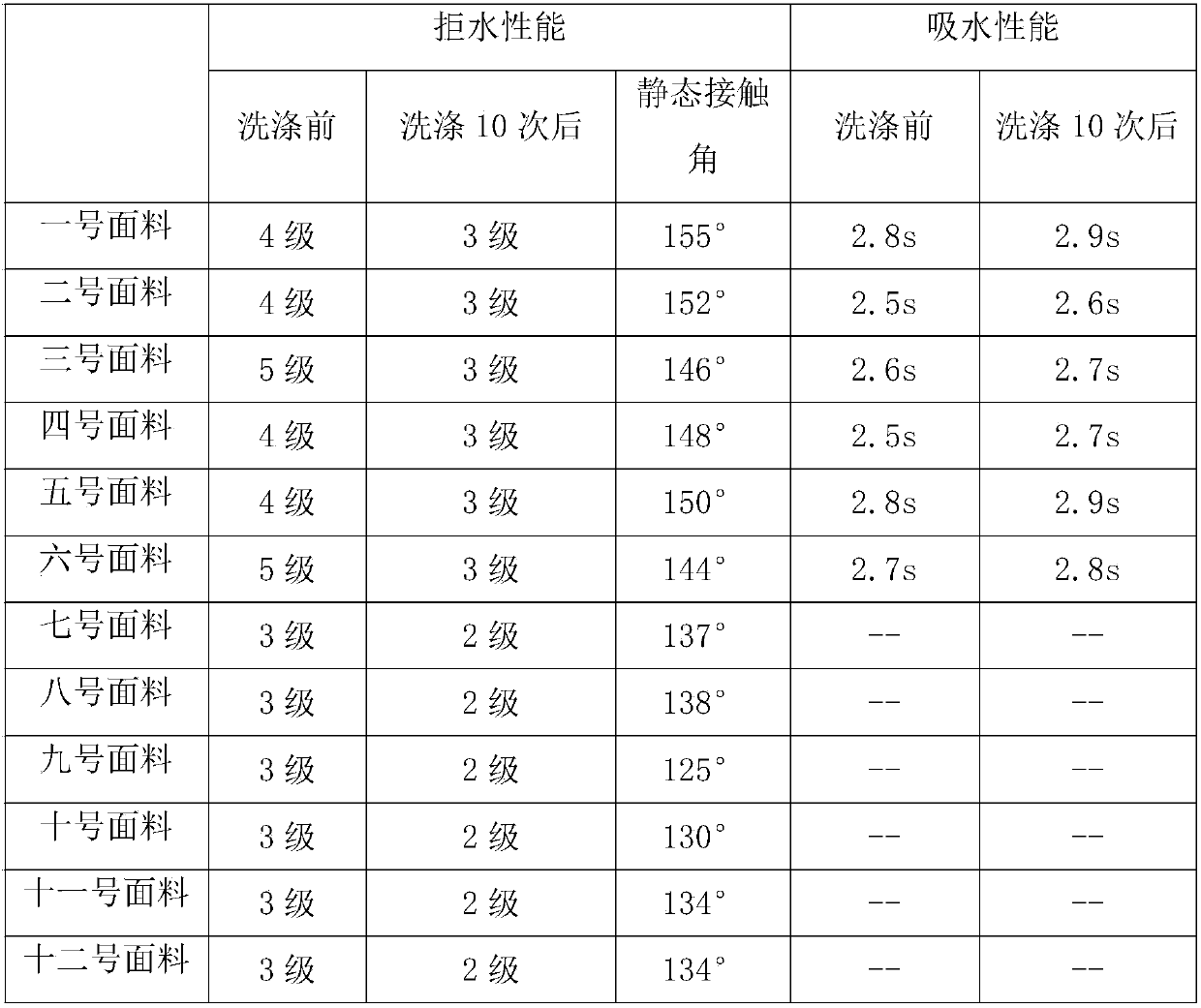

Single-face water-repellent single-face water-absorptive fabric and processing technology thereof

ActiveCN106283338ALow manufacturing costShort production cycleWeft knittingOrnamental textile articlesSurgical GownsAfter treatment

The invention belongs to the field of textiles and garments, and discloses single-face water-repellent single-face water-absorptive fabric and a processing technology of the single-face water-repellent single-face water-absorptive fabric. The single-face water-repellent single-face water-absorptive fabric comprises a water absorptive layer and a water repellent layer, and is formed by means of pretreating textile fabric, performing dyeing water-absorption bathing, performing single-face water-repellent processing and performing after-treatment integral processing. The fabric disclosed by the invention has the beneficial effects that for the fabric obtained according to the processing technology disclosed by the invention, the water repellent property reaches level 4 or higher before washing, the water repellent property still reaches level 3 or higher after washing 10 times, and the single-face water-absorptive property is within 3 seconds before washing and after washing 10 times, so that sputtered blood can be quickly adsorbed and cannot permeate the inner fabric of a user, and the fabric can be widely applied to products, such as surgical gowns for medical use and the like.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

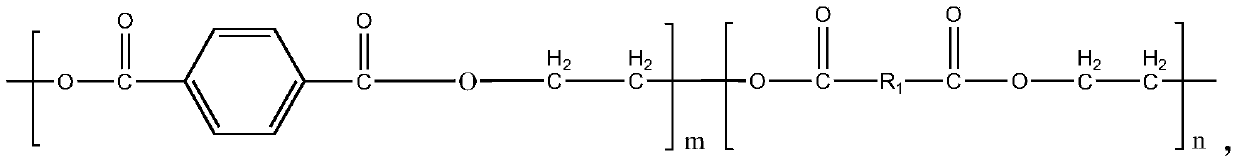

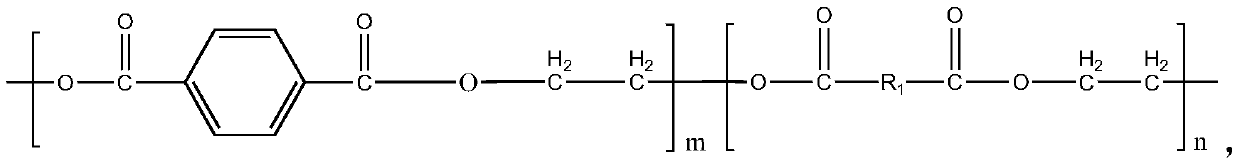

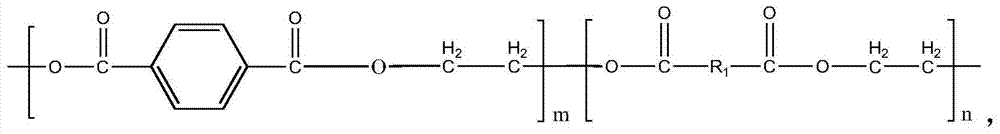

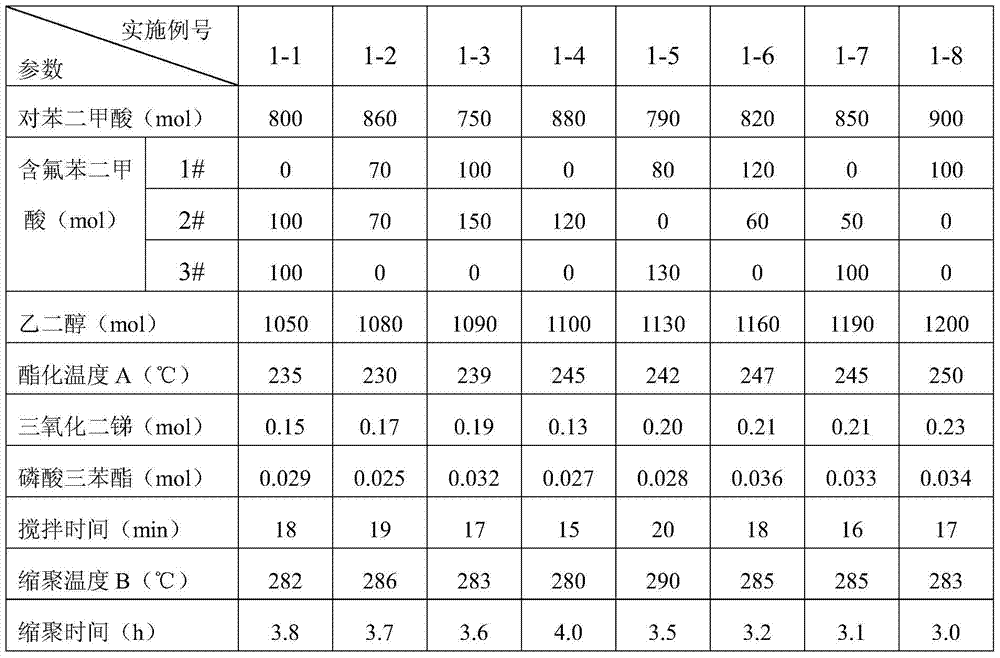

Hydrolysis-resistant fluorine-containing copolyester resin, hydrolysis-resistant fluorine-containing copolyester composite basal membrane and preparation method thereof

ActiveCN105504249AImproves the efficacy of hydrolysis resistanceImprove hydrolysis resistancePolyester resinCopolyester

The invention discloses hydrolysis-resistant fluorine-containing copolyester resin, a hydrolysis-resistant fluorine-containing copolyester composite basal membrane and a preparation method thereof. The molecular weight of the hydrolysis-resistant fluorine-containing copolyester resin ranges from 14,000 to 25,000; the hydrolysis-resistant fluorine-containing copolyester resin is prepared through binary formic acid and ethanediol, the hydrolysis-resistant fluorine-containing copolyester resin and PET resin are fused through an extruder according to the mass ratio of (10-200) to 100, layered coextrusion through a resin fusion distributor, casting strip compound, longitudinal stretching, transverse stretching, heat setting, cooling and rolling are conducted, and the hydrolysis-resistant fluorine-containing copolyester composite basal membrane is prepared. According to the hydrolysis-resistant fluorine-containing copolyester resin, the hydrolysis-resistant fluorine-containing copolyester composite basal membrane and the preparation method thereof, the thickness of the hydrolysis-resistant fluorine-containing copolyester composite basal membrane ranges from 100 micrometers to 300 micrometers, and the hydrolysis-resistant fluorine-containing copolyester composite basal membrane is specially suitable for manufacturing of a release membrane and solar energy photovoltaic cell backplane materials, good in performance and strongin practicability.

Owner:四川东方绝缘材料股份有限公司

Preparation method of high-strength sound-absorbing board

The invention relates to the technical field of preparation of building boards and specifically relates to a preparation method of a high-strength sound-absorbing board. The preparation method provided by the invention is as follows: firstly removing proteins in frozen beancurd to enable the frozen beancurd to be of a porous structure with a large specific surface area, modifying zeolite powder toobtain modified foamed zeolite slurry, smearing the modified foamed zeolite slurry on the surface of fermented beancurd, performing drying treatment, and taking out a porous foamed material, so thatthe porosity of the structure in zeolite is improved and the sound-absorbing effect is further achieved, the filling of the zeolite improves the strength of the sound-absorbing board, and the additionof nano-montmorillonite improves the crystallinity of the material; continuously adding ceramsite, a foaming agent and a waterproofing agent, wherein the foaming agent produces bubbles in the stirring process so as to achieve the sound-absorbing effect, the ceramsite with a certain hardness is filled into the sound-absorbing board to improve the strength, the waterproofing agent enables the sound-absorbing board to have a hydrophobic function, the surface and voids of the sound-absorbing board can be automatically purified, and the sound-absorbing effect is stabilized, so that the preparationmethod has broad application prospects.

Owner:CHANGZHOU SIYU ENVIRONMENTAL PROTECTION MATERIAL SCI & TECH

A kind of hydrophobic silica/polyimide airgel composite material and its preparation method

Owner:UNIV OF SCI & TECH OF CHINA

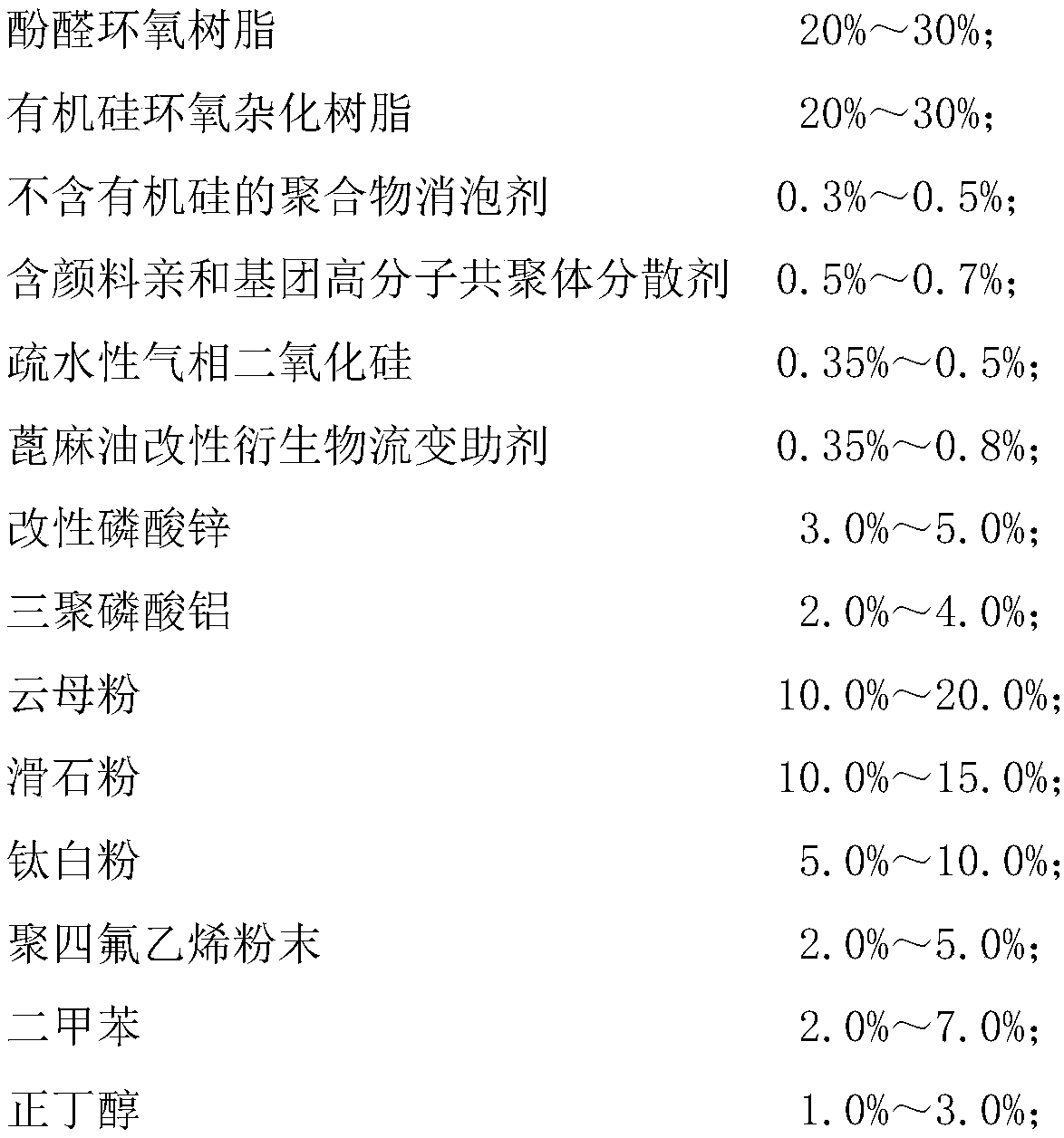

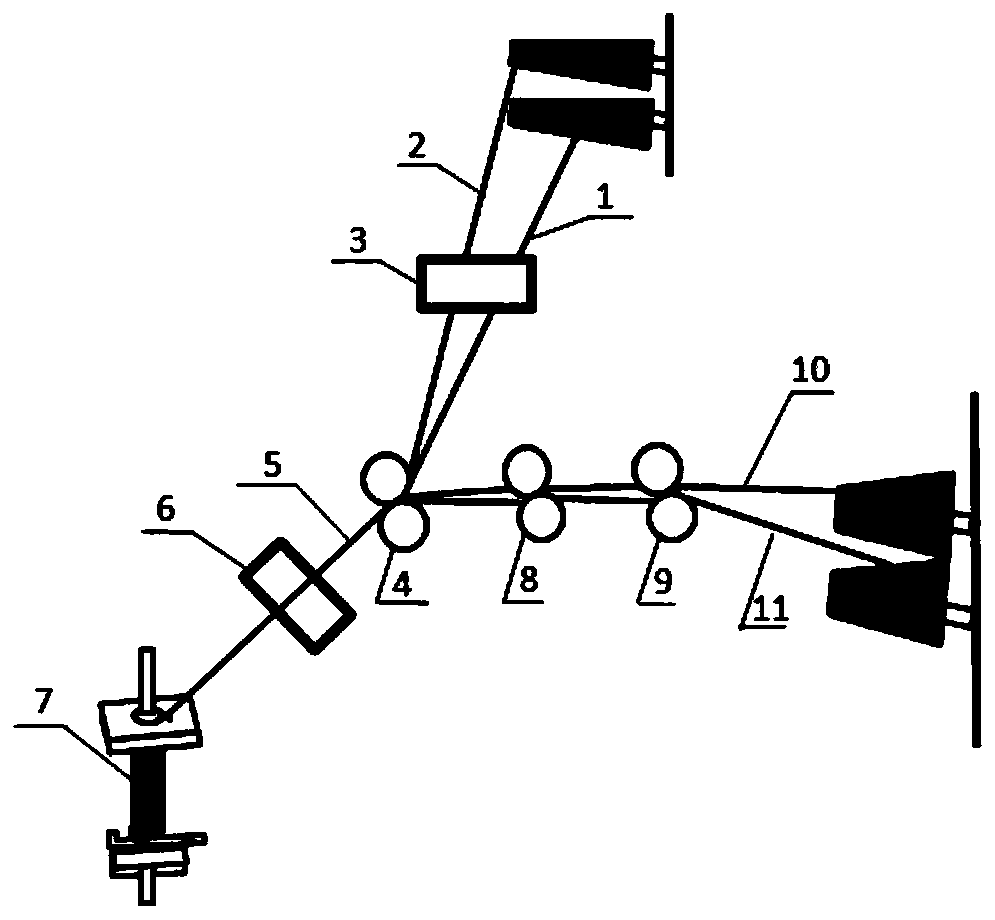

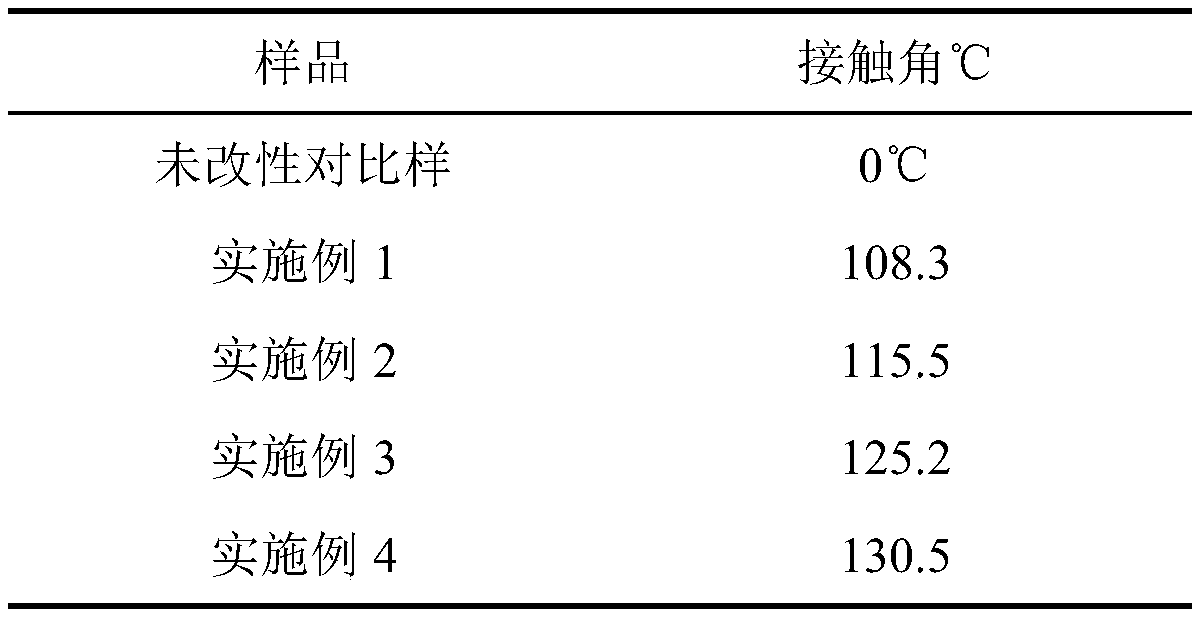

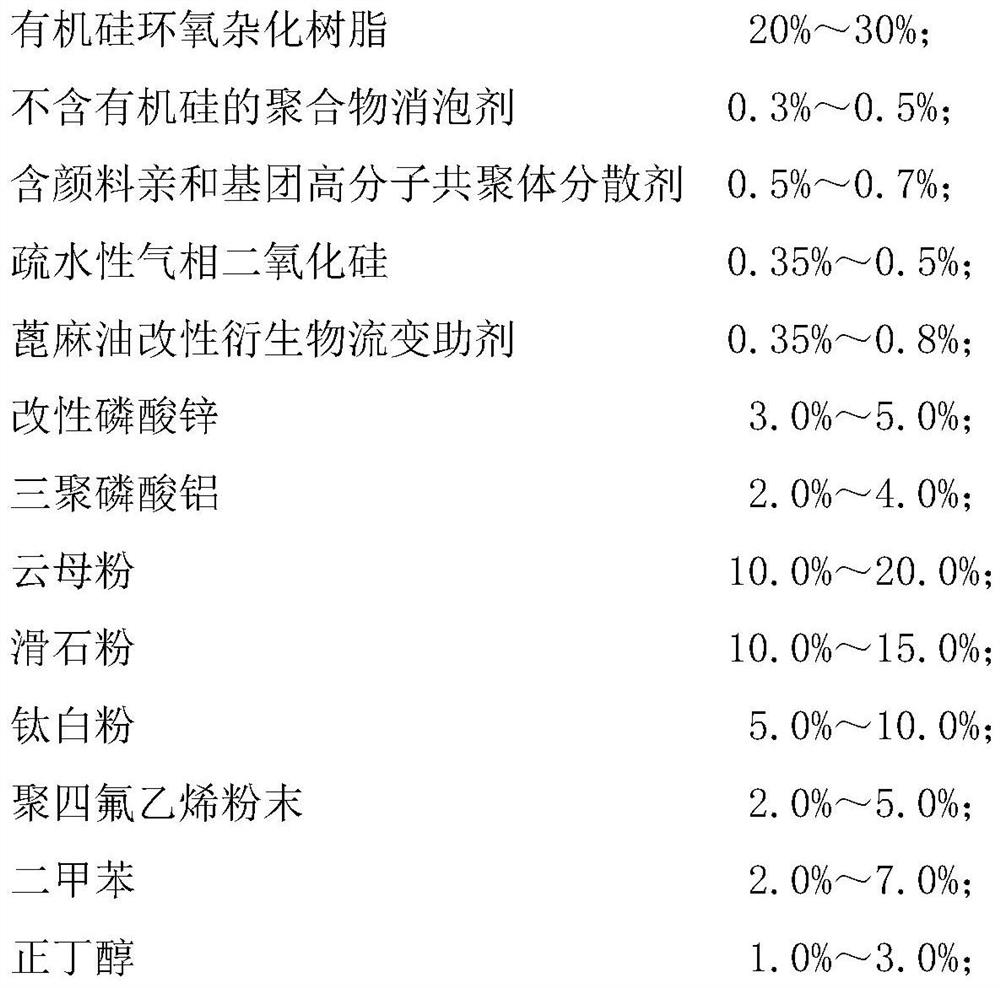

High-temperature-resistant drag-reducing energy-saving heavy-duty anti-corrosion coating for thermal pipeline inner walls

ActiveCN108912964AHigh trafficReduce drag and reduce frictionFireproof paintsAnti-corrosive paintsEpoxyGas phase

The invention discloses a high-temperature-resistant drag-reducing energy-saving heavy-duty anti-corrosion coating for thermal pipeline inner walls. The coating contains two components of A and B, wherein the weigth percentages of the component A comprise: phenolic epoxy resin 20%-30%, organosilicone epoxy hybrid resin 20%-30%, silicone-free polymer defoamer 0.3%-0.5%, pigment-affine-group-containing polymer interpolymer dispersant 0.5%-0.7%, hydrophobic fumed silica 0.35%-0.5%, castor oil modified derivative rheological additive 0.35%-0.8%, modified zinc phosphate 3.0% to 5.0%, aluminum tripolyphosphate 2.0%-4.0%, mica powder 10.0%-20.0%, talcum powder 10.0%-15.0%, titanium dioxide 5.0%-10.0%, polytetrafluoroethylene powder 2.0%-5.0%, xylene 2.0%-7.0%, and n-butanol 1.0%-3.0%; and the weight percentages of the component B comprise: modified alicyclic amine 72.5%-75.5%, and aminoalkoxysilane 24.5%-27.5%. The coating can effectively protect thermal pipelines, and reduce maintenance andpipe cleaning frequency, and has a positive effect on urban central heating.

Owner:SHANGHAI HILONG SHINE NEW MATERIAL +1

Preparation method of composite membrane with hydrophobization function

ActiveCN103537196AExtensive sources of raw materialsEasy to getSemi-permeable membranesChemistryPolytetrafluoroethylene

The invention discloses a preparation method of a composite membrane with a hydrophobization function. The preparation method comprises the following steps: performing membrane scraping for multiple times on a glass plate by a mixed polytetrafluoroethylene liquid and curing for forming a membrane in a gelling bath to obtain a base membrane layer; dissolving poly-perfluoroalkyl ethyl acrylic ester granules in a mixed solution of monofluoride dichloroethane (HCFC-141b) and fluorosilane and stirring; adding epoxy resin and a phenolic aldehyde amine epoxy hardener to obtain a new mixed solution; mixing the new mixed solution with E type epoxy resin to obtain a mixture and applying the mixture onto the base membrane layer; and performing drying to obtain the composite membrane with the hydrophobization function. In the way, the preparation method of the composite membrane with the hydrophobization function has the advantages that the raw materials are extensive in source and easy to obtain, the preparation process is simple, and the preparation method is easy to operate without over-high requirements on the operation technique of operators and can effectively save cost; the obtained composite membrane with the hydrophobization function has certain hardness and strength and is excellent in hydrophobization performance.

Owner:无锡和烁丰新材料有限公司

A kind of siloxane-polyester copolymer resin, siloxane-polyester copolymer composite base film and preparation method thereof

ActiveCN105504253BWith hydrophobic functionImproves the efficacy of hydrolysis resistanceSynthetic resin layered productsElectrical equipmentHydrolysisHeat setting

The invention discloses siloxane-polyester copolymer resin, a siloxane-polyester copolymer compound substrate membrane, and methods for preparing the siloxane-polyester copolymer resin and the siloxane-polyester copolymer compound substrate membrane. The molecular weight of the siloxane-polyester copolymer resin is 10000-25000. The siloxane-polyester copolymer resin is prepared through reaction between terephthalic acid and a compound containing dyhydroxy. The siloxane-polyester copolymer resin and PET resin are molten through an extruder based on the mass ratio of (10-200) : 100, and then delamination coextrusion with a resin melting distributor, casting strip combination, longitudinal drawing, horizontal drawing, heat setting, cooling and coiling are conducted to obtain the siloxane-polyester copolymer compound substrate membrane. The thickness of the compound substrate membrane prepared from the siloxane-polyester copolymer is 100-300 microns, and the compound substrate membrane is especially suitable for manufacturing of release films and hydrolysis resistance materials for solar photovoltaic cell backboards and is high in performance and practicality.

Owner:SHANDONG SNTON OPTICAL MATERIALS TECH CO LTD

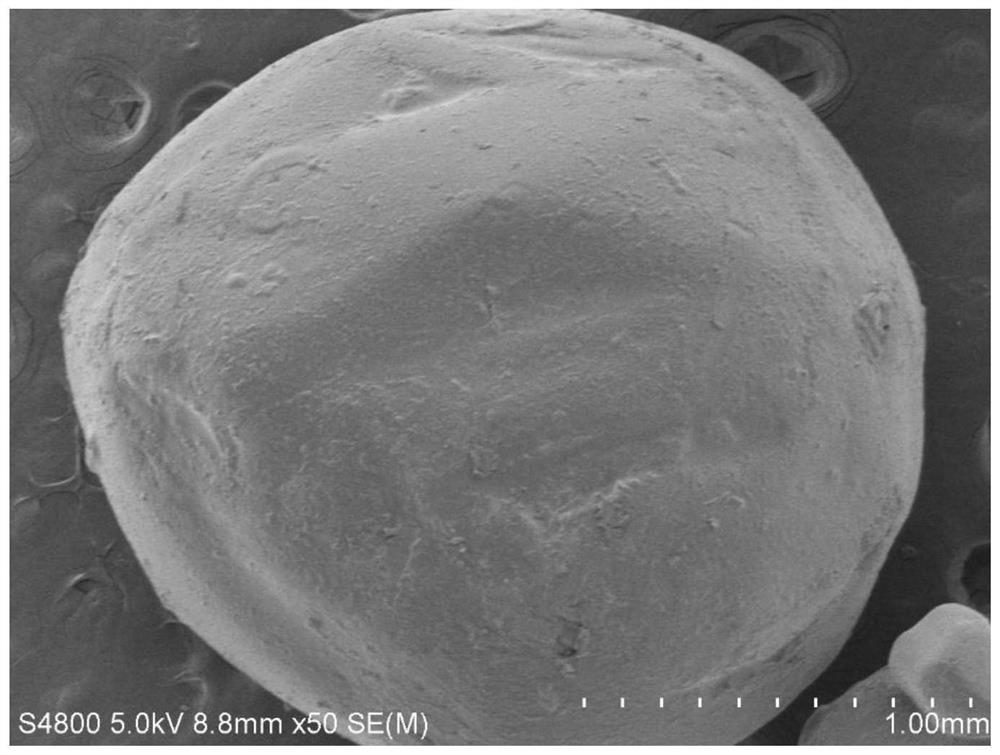

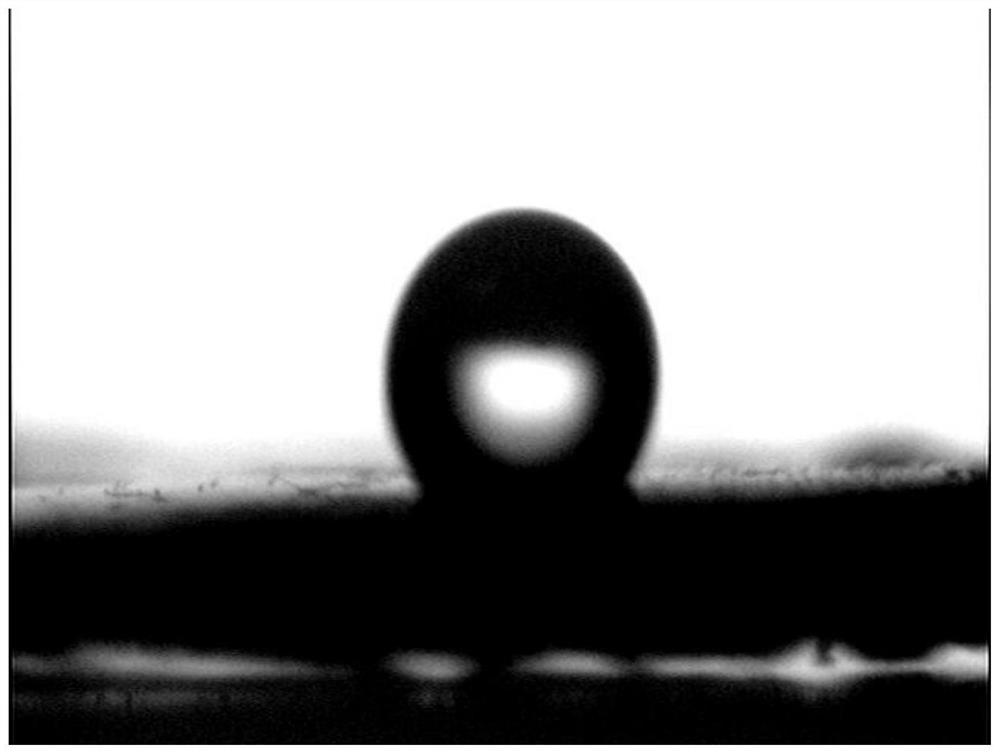

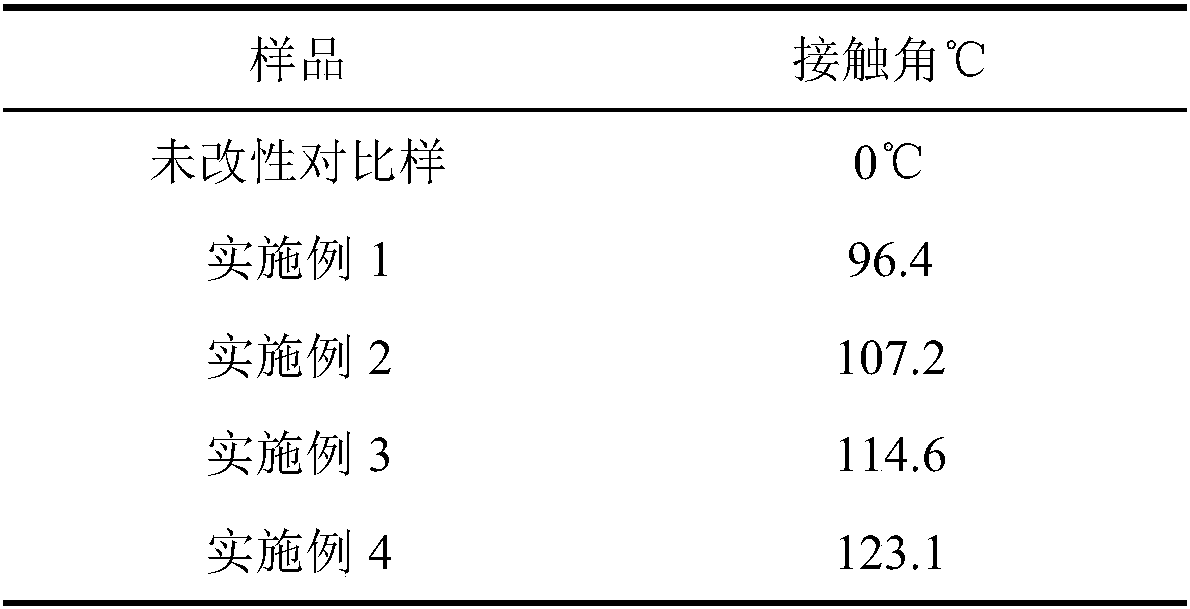

Hydrophobic modified bio-based coated controlled-release fertilizer and preparation method thereof

ActiveCN113880609AImprove hydrophobicityLower surface energySolid/semi-solid fertilisersUrea compound fertilisersHydrophobeMaterials science

The invention discloses a hydrophobic modified bio-based coated controlled-release fertilizer and a preparation method thereof, and belongs to the technical field of fertilizer preparation. According to the coated controlled-release fertilizer, fertilizer particles serve as a core material, bagasse liquefied matter serves as a raw material, bagasse-based polyurethane with hydrophobic performance is prepared through modification of a silane coupling agent and reaction with isocyanate, and then the fertilizer particles are coated to prepare the hydrophobic bio-based coated fertilizer. The coated controlled-release fertilizer prepared by the method has surface hydrophobicity, and can reduce the rate of dissolving the core fertilizer by moisture through a membrane layer material, so that the nutrient release period is controlled, and the improvement of the controlled-release performance of the bio-based coated fertilizer is realized.

Owner:SOUTH SUBTROPICAL CROPS RES INST CHINESE ACAD OF TROPICAL AGRI SCI

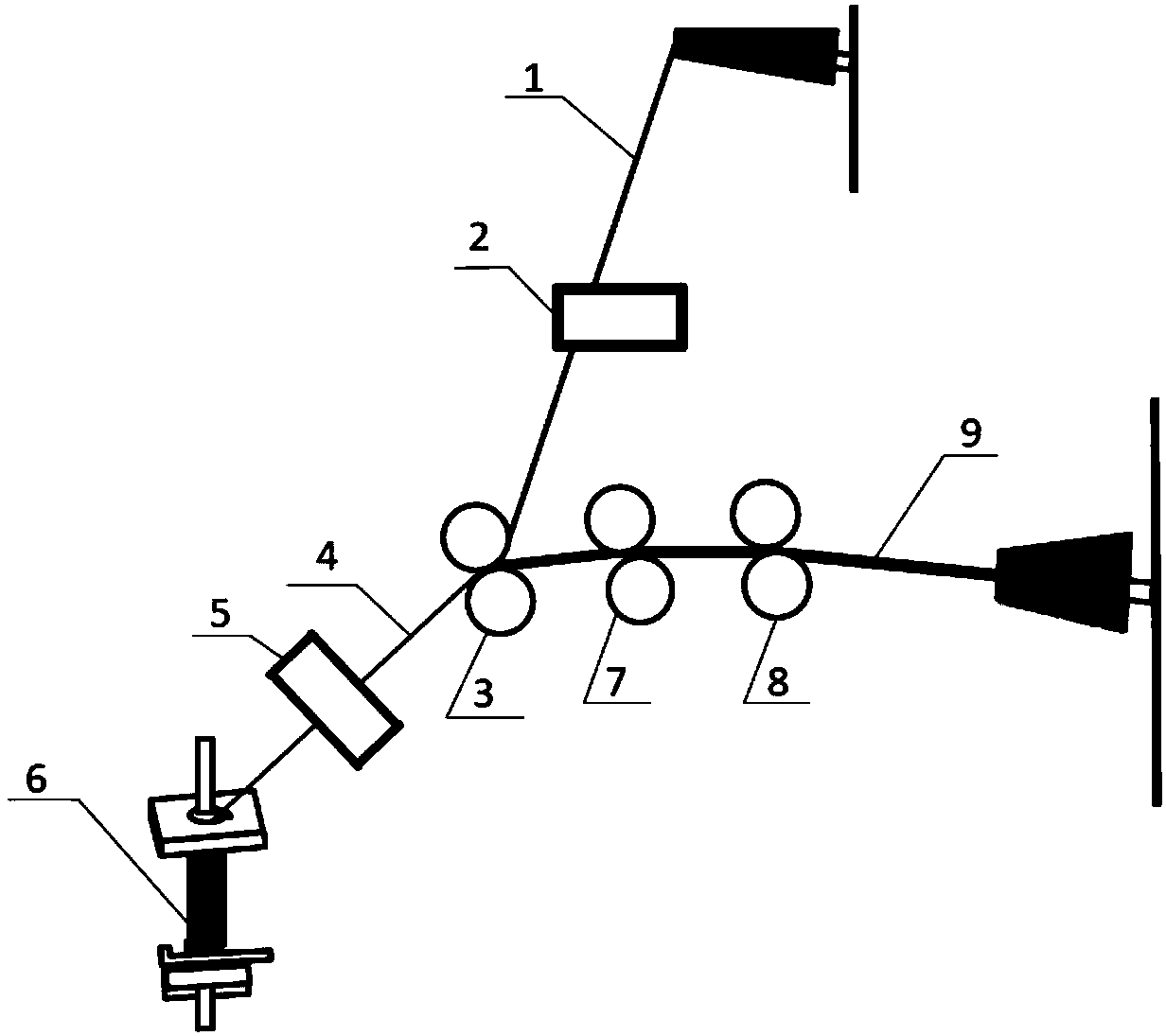

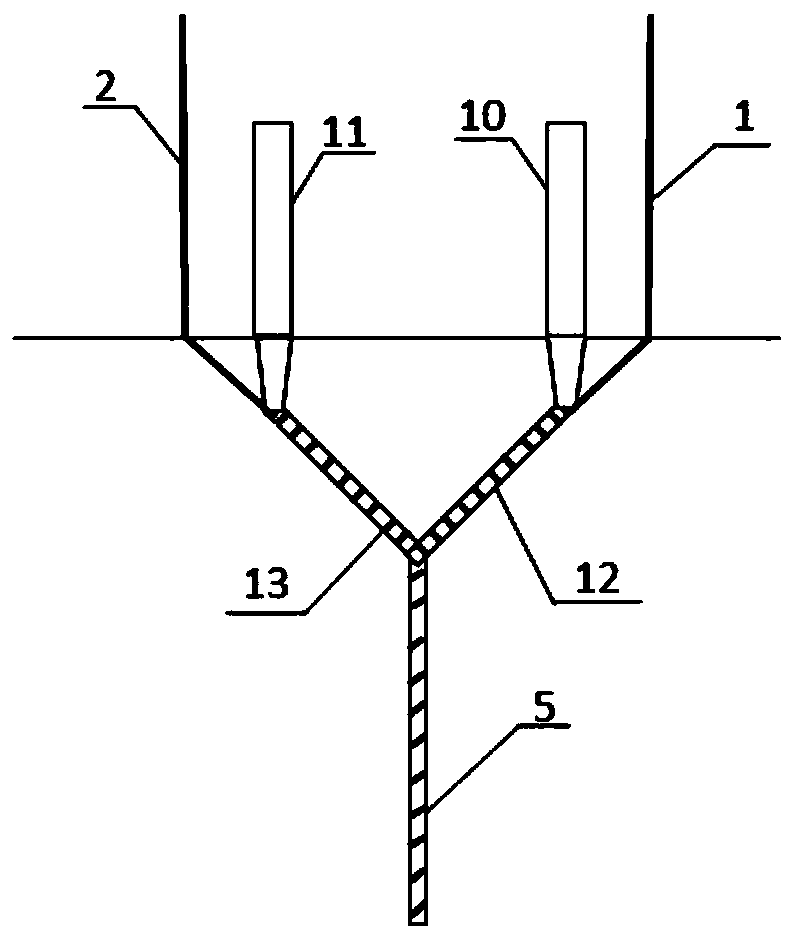

Online preparation method of hydrophobic yarn of sirofil composite spinning

InactiveCN108035023ASpeed up evaporationReduce manufacturing costYarnVegetal fibresViscoseEngineering

The invention relates to an online preparation method of a hydrophobic yarn of sirofil composite spinning, and belongs to the technical field of textile processing. The method has a characteristic oflong filament winding to short fiber by using a method of sirofil composite spinning, a modification device is arranged at the operation path portion of viscose filament yarn between a filament cylinder and a front roller, and a drying device is arranged at the operating path portion of spun yarn between the front roller and a spun yarn tube. The modification device applies modifying liquid to viscose filament yarn, the drying device dries the twisted spun yarn, and the viscose filament yarn in a shape of spatial spiral is used to wrap on the outer side of cotton roving, the hydrophobic yarn is prepared by transferring the modifying liquid on the viscose filament yarn to cotton fiber in contact with the viscose filament yarn. The method changes a method of subsequent modification of an existing yarn or fabric in general, spinning is synchronized with modification, the method shortens the production cycle, saves the production cost, and simplifies the operation steps.

Owner:WUHAN TEXTILE UNIV

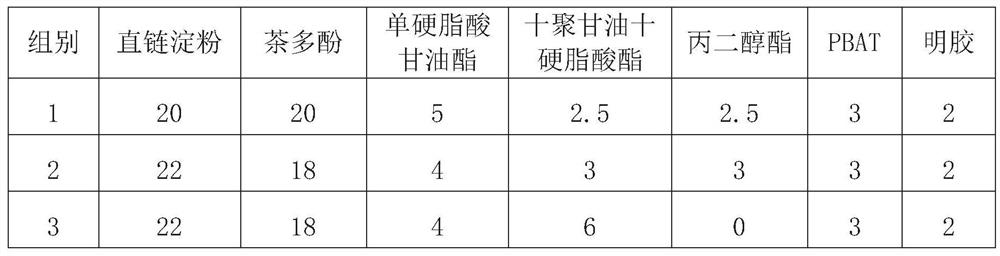

Antibacterial water-resistant material and preparation method thereof

InactiveCN112920471AHas antibacterial and antioxidative effectsPromote degradationPhenolic content in teaPolyphenol

The invention belongs to the field of preparation of antibacterial and water-resistant materials, and particularly relates to an antibacterial water-resistant material and a preparation method thereof. The specific technical scheme is as follows: the antibacterial water-resistant material comprises the following components in parts by weight: 15-40 parts of amylose, 15-30 parts of tea polyphenol, and 5-15 parts of fatty acid ester for compounding and fatty acid ester for dewatering in total. The amylose and the tea polyphenol are cross-linked to form a matrix material with a net structure, the matrix material is compounded with the fatty acid ester and then is filled with the fatty acid ester for dewatering, a denser grid structure material is formed, the grid structure material hasexcellent degradation performance and has antibacterial and antioxidant effects at the same time, and the water resistance of the material is improved.

Owner:杭州拜迪戈雷生物材料有限公司 +1

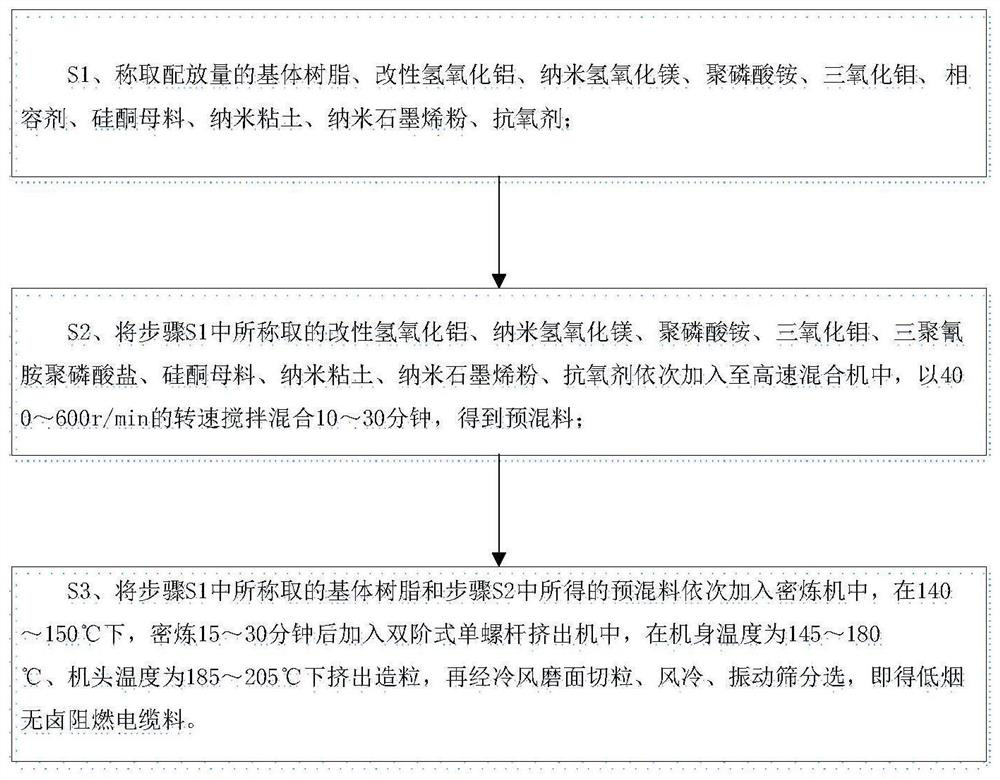

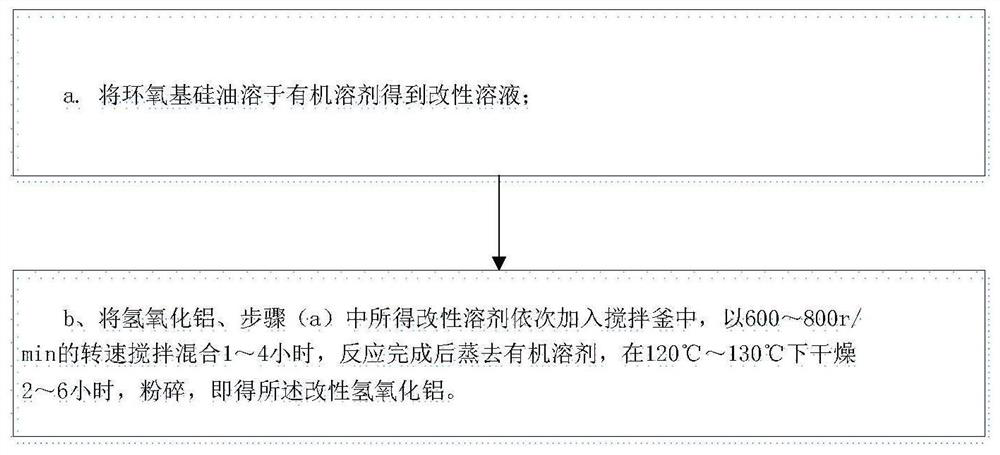

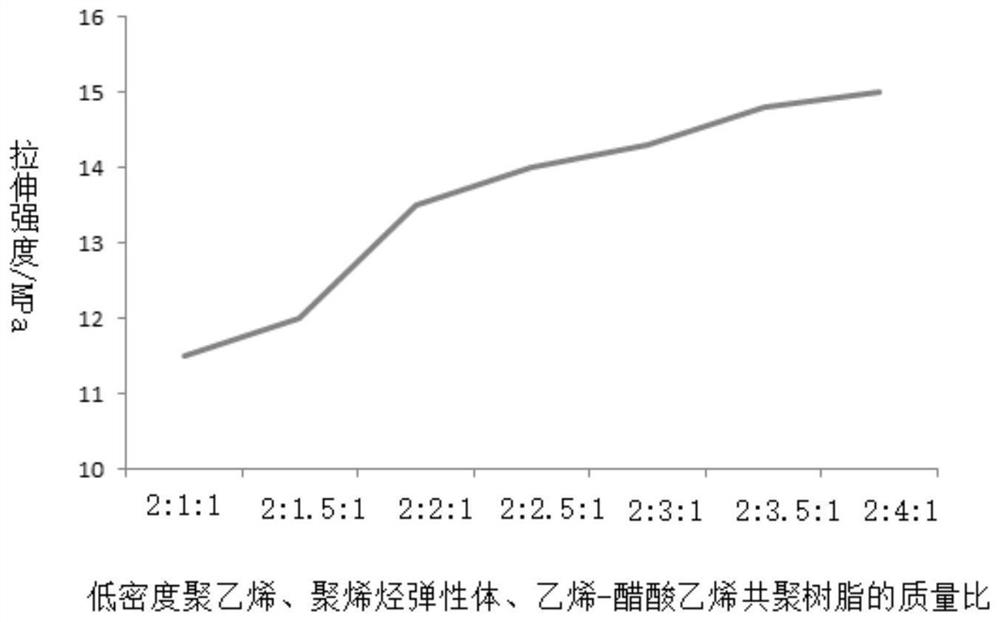

Low-smoke halogen-free flame-retardant cable material and preparation method thereof

ActiveCN113717450AGuaranteed insulation performanceGuaranteed mechanical propertiesPlastic/resin/waxes insulatorsClimate change adaptationLow-density polyethyleneElastomer

The invention discloses a low-smoke halogen-free flame-retardant cable material and a preparation method thereof. The low-smoke halogen-free flame-retardant cable material is prepared from the following raw materials in parts by weight: 100 parts of matrix resin, 50 to 80 parts of modified aluminum hydroxide, 50 to 80 parts of nano magnesium hydroxide, 10 to 35 parts of ammonium polyphosphate, 1 to 3 parts of molybdenum trioxide, 15 to 20 parts of compatilizer, 0.4 to 1.8 parts of silicone master batch, 1 to 10 parts of nano clay, 5 to 7 parts of nano graphene powder and 0.5 to 2.8 parts of antioxidant, wherein the matrix resin is prepared from low-density polyethylene, a polyolefin elastomer and ethylene-vinyl acetate copolymer resin. According to the low-smoke halogen-free flame-retardant cable material, on the basis of ensuring the insulating property and the mechanical property of the cable material, the flame-retardant effect is excellent, low-smoke and non-toxic effects are realized during combustion, meanwhile, the temperature resistance and the aging resistance of the cable material are improved, and the service life of the cable material is prolonged.

Owner:苏州史泰诺科技股份有限公司

Octadecanol methyl propionate, preparation method thereof, water-soluble thickener and preparation method of water-soluble thickener

InactiveCN109912411ASimple methodEasy to implementOrganic compound preparationCarboxylic acid esters preparationMethallyl sulfonateOil production

The invention relates to the technical field of thickeners, in particular to octadecanol methyl propionate, a preparation method thereof, a water-soluble thickener and a preparation method of the water-soluble thickener. The water-soluble thickener comprises raw materials including acrylamide, 2-acrylamide-2-methallyl sulfonate, octadecanol methyl propionate, hexadecyl trimethyl ammonium chloride,sodium bisulfite, ammonium persulfate, ethylene diamine tetraacetic acid, urea, sodium carbonate and deionized water. The preparation methods of the octadecanol methyl propionate and the water-soluble thickener are simple and easy to implement, the water-soluble thickener is convenient to use, can be applied to oil production and increase the recovery ratio and has a hydrophobic function as wellas hydrophilic performance, besides, the water-soluble thickener has good viscoelasticity after being dissolved in water, and by comparison of the water-soluble thickener with conventional polymer thickeners commonly used at present in oil field sewage and water with mineralization degree of 150,000 mg / L after application, and the water-soluble thickener is found to better increase viscosity of liquids.

Owner:KARAMAY ZHENGCHENG

Manufacturing method of semiconductor structure

PendingCN113823549AWith hydrophobic functionImprove yieldSemiconductor/solid-state device manufacturingWaferSemiconductor structure

The invention provides a manufacturing method of a semiconductor structure, and relates to the technical field of semiconductor manufacturing. The method comprises the steps: providing a substrate with well injection completed; performing bigrid oxide deposition; performing silicon nitride deposition; and forming hydrophobic layers on the front surface, the side surface and at least one part of the back surface of the substrate on which the silicon nitride film is deposited. According to the technical scheme, after a proper hydrophobic layer is formed on the back surface of the wafer (namely the substrate), permeation of chemical liquid to the damaged position of the outermost coating of the wafer can be effectively reduced due to the hydrophobic function of the back surface of the wafer, so that fragments falling off from the coating on the back surface of the wafer are reduced or eliminated, the front surface of the wafer is not influenced by falling of the fragments, and the product yield of the wafer is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI +1

One-side water-repellent and one-side water-absorbent fabric and its processing technology

ActiveCN106283338BGood water repellencyFeel goodWeft knittingOrnamental textile articlesEngineeringWater processing

The invention belongs to the field of textiles and garments, and discloses a single-side water-repellent and single-side water-absorbent fabric and its processing technology, including a water-absorbing layer and a water-repellent layer. Finished and processed in one. The beneficial effects of this patent are: the water repellency of the fabric obtained by the process of the present invention reaches above level 4 before washing, and still reaches above level 3 after washing 10 times, and the water absorption performance of one side is all above 3 before washing and after washing 10 times. Within seconds, it can quickly absorb splashed blood without penetrating into the user's inner clothing, which can be widely used in products such as medical surgical gowns.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

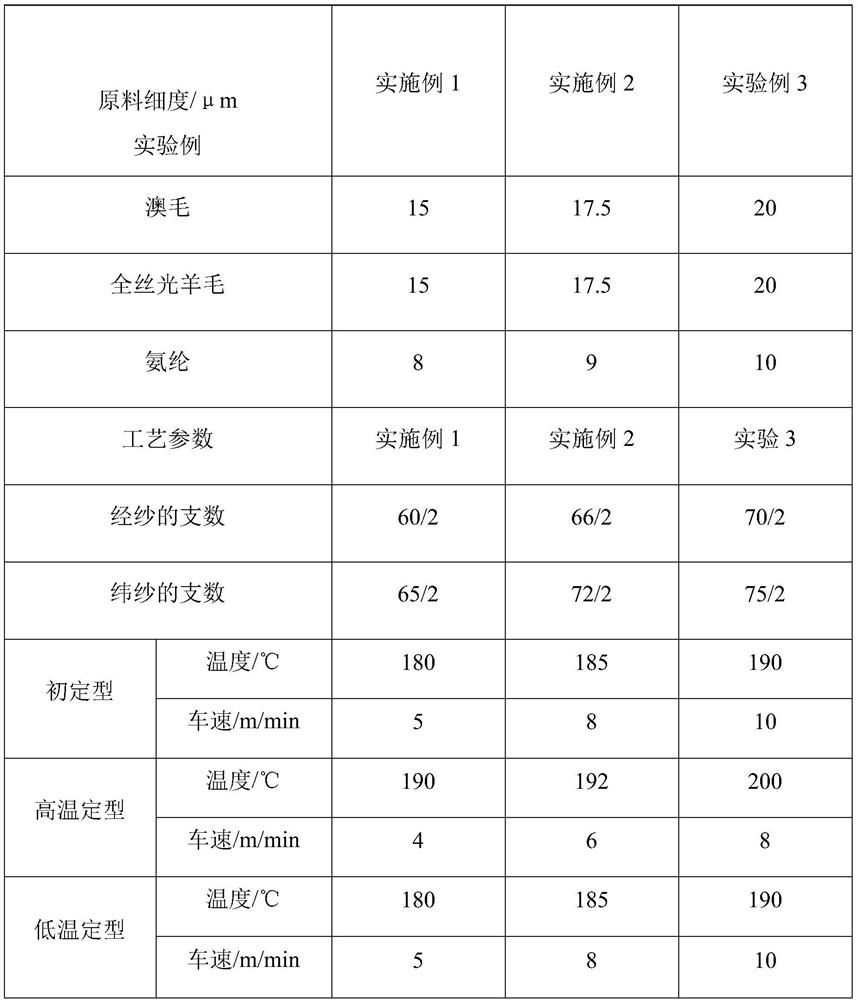

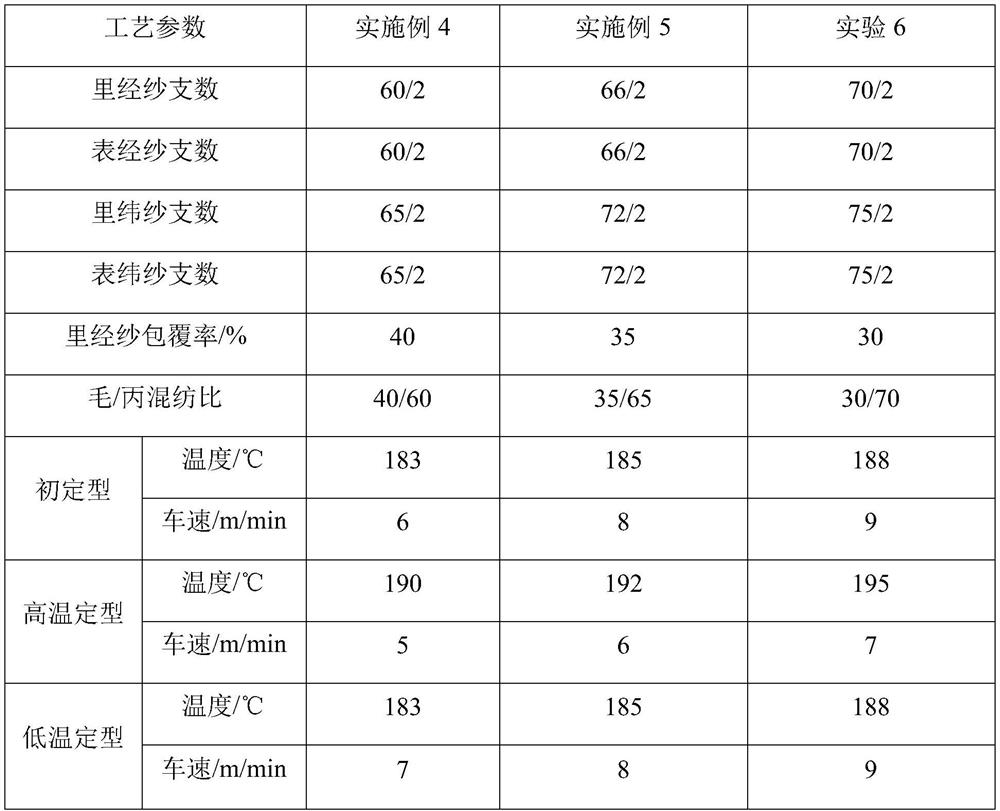

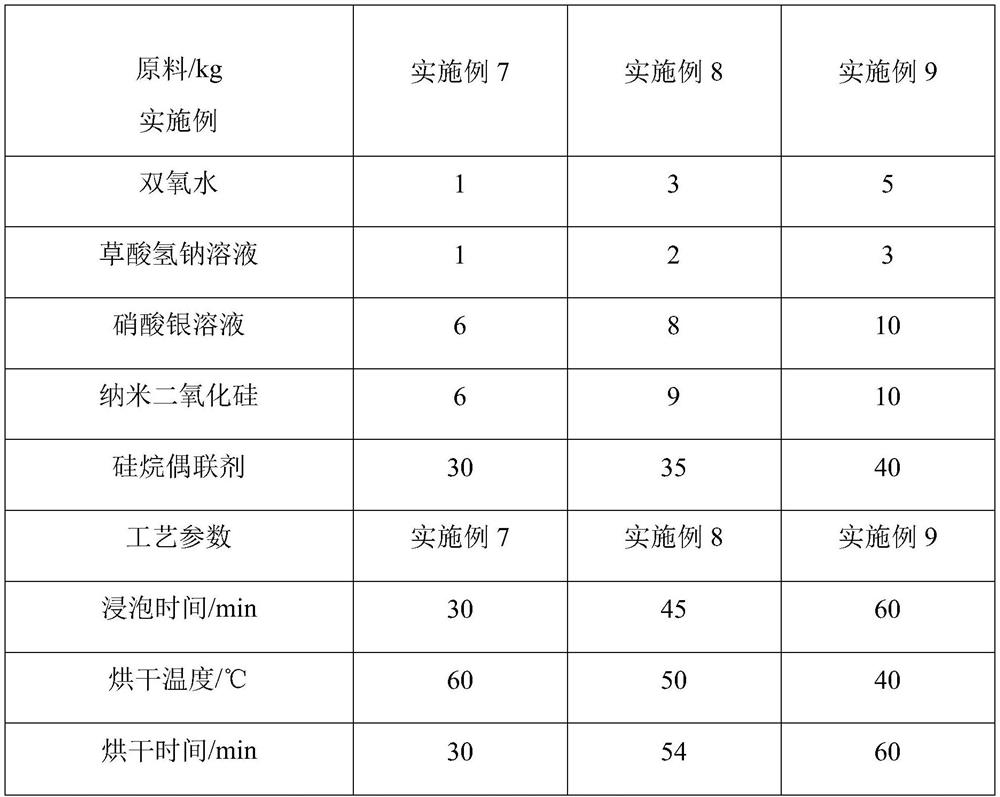

Preparation method of thin elastic double-faced woolen cloth

ActiveCN114790598ALow steam shrinkageLow water shrinkageHeating/cooling textile fabricsTextile/flexible product manufacturePolymer scienceCarbon fibers

The invention relates to the technical field of fabrics, and particularly discloses a preparation method of thin elastic double-faced woolen goods, which specifically comprises the following preparation steps: firstly pretreating wool, then selecting wool for spinning to prepare wool yarns as warp yarns, and selecting wool, elastic yarns and two strands of spun yarns for twisting and spinning to prepare yarns as weft yarns; preparing gray fabric by adopting a 2 / 2 double-layer structure; and finally, carrying out primary shaping, milling, napping, shearing and teasing on the gray fabric, then carrying out high-temperature shaping and ironing shearing, and finally carrying out low-temperature shaping and decating to obtain the thin elastic double-faced woolen cloth. In the preparation process, coffee carbon fibers can be added into the inner warp yarns, and polypropylene filament yarns can be added into the surface warp yarns. According to the scheme, the preparation method is simple, the preparation cost is low, the prepared thin elastic double-faced woolen cloth is fine in woolen cloth surface, soft in hand feeling, excellent in elasticity, breathable, light, thin and good in antibacterial and antistatic performance, and the function of double-faced different effects is achieved.

Owner:江苏东图纺织有限公司

Hydrolysis-resistant fluorine-containing copolyester resin, hydrolysis-resistant fluorine-containing copolyester composite base film and preparation method thereof

ActiveCN105504249BWith hydrophobic functionImproves the efficacy of hydrolysis resistanceCopolyesterPolyester resin

The invention discloses hydrolysis-resistant fluorine-containing copolyester resin, a hydrolysis-resistant fluorine-containing copolyester composite basal membrane and a preparation method thereof. The molecular weight of the hydrolysis-resistant fluorine-containing copolyester resin ranges from 14,000 to 25,000; the hydrolysis-resistant fluorine-containing copolyester resin is prepared through binary formic acid and ethanediol, the hydrolysis-resistant fluorine-containing copolyester resin and PET resin are fused through an extruder according to the mass ratio of (10-200) to 100, layered coextrusion through a resin fusion distributor, casting strip compound, longitudinal stretching, transverse stretching, heat setting, cooling and rolling are conducted, and the hydrolysis-resistant fluorine-containing copolyester composite basal membrane is prepared. According to the hydrolysis-resistant fluorine-containing copolyester resin, the hydrolysis-resistant fluorine-containing copolyester composite basal membrane and the preparation method thereof, the thickness of the hydrolysis-resistant fluorine-containing copolyester composite basal membrane ranges from 100 micrometers to 300 micrometers, and the hydrolysis-resistant fluorine-containing copolyester composite basal membrane is specially suitable for manufacturing of a release membrane and solar energy photovoltaic cell backplane materials, good in performance and strongin practicability.

Owner:四川东方绝缘材料股份有限公司

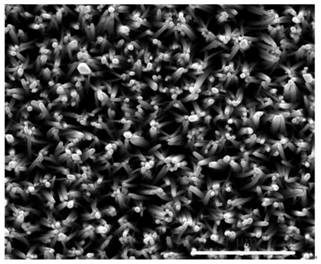

A graphene-based three-dimensional fiber paper for oil-water separation and preparation method thereof

ActiveCN110180217BWith hydrophobic functionImprove ductilityOther chemical processesFibre treatmentPorous grapheneGraphite

The invention discloses a graphene-based three-dimensional fiber paper for oil-water separation and a preparation method thereof. The graphene-based three-dimensional fiber paper is prepared with a porous graphene composite material on a non-woven fabric substrate, and the graphene in the graphene composite material The surface is modified with metal ions, and the combination of metal ions and the hydrophilic groups on the surface of graphene makes graphene non-hydrophilic. At the same time, because the surface of graphene has more C=O hydrophobic functional groups, graphene is hydrophobic. Function; the combination of graphene composite material is porous, so that the fiber paper has a honeycomb multi-layer porous structure, and graphene itself has a large specific surface area, so that the material can fully absorb oil and gas molecules, so that the material is in the oil A small oil storage chamber is formed during the adsorption process to increase oil adsorption efficiency and oil-water separation efficiency. At the same time, it has a good ability to remove oil on the water surface and can be used for environmental protection.

Owner:XI'AN PETROLEUM UNIVERSITY

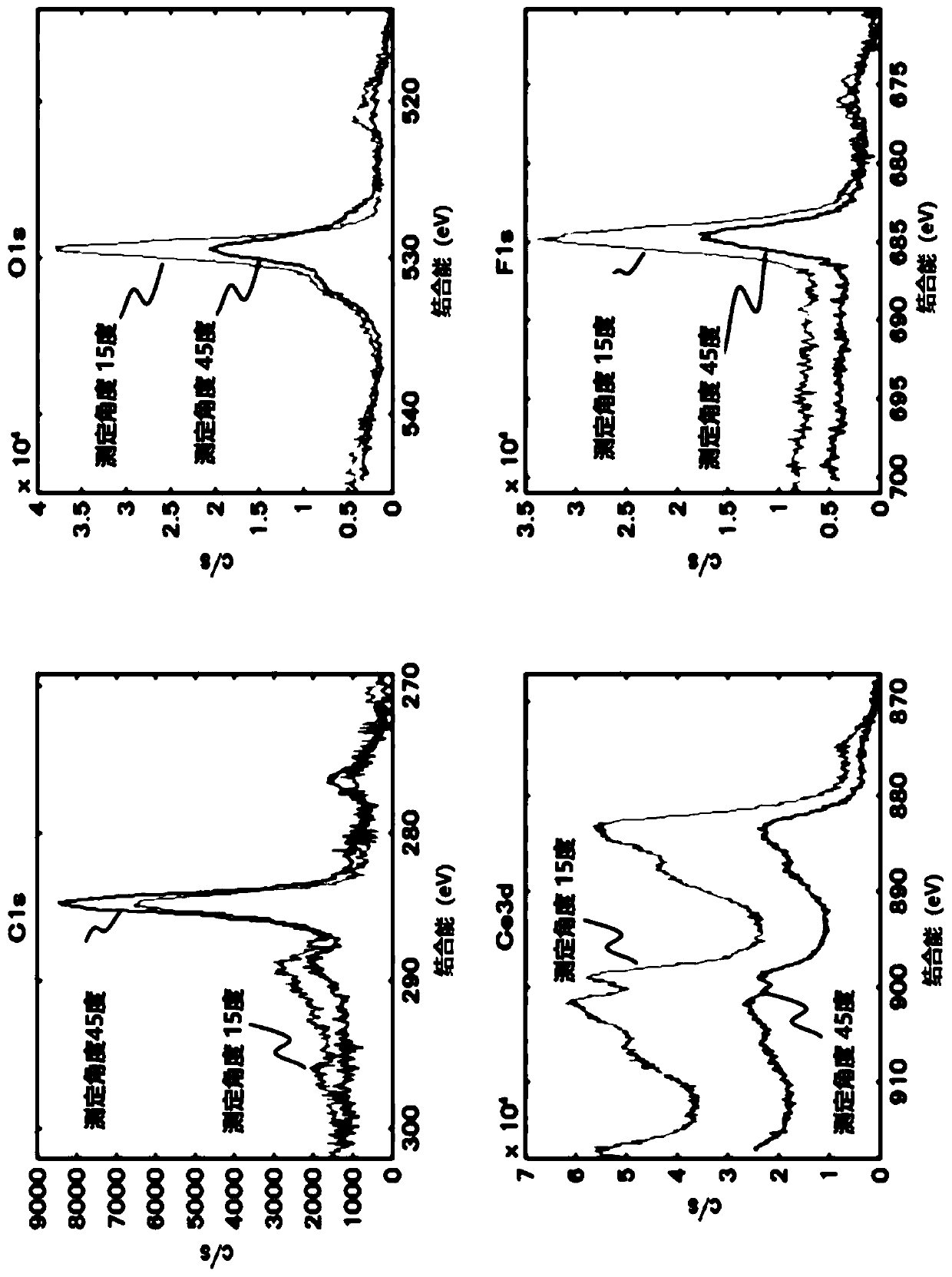

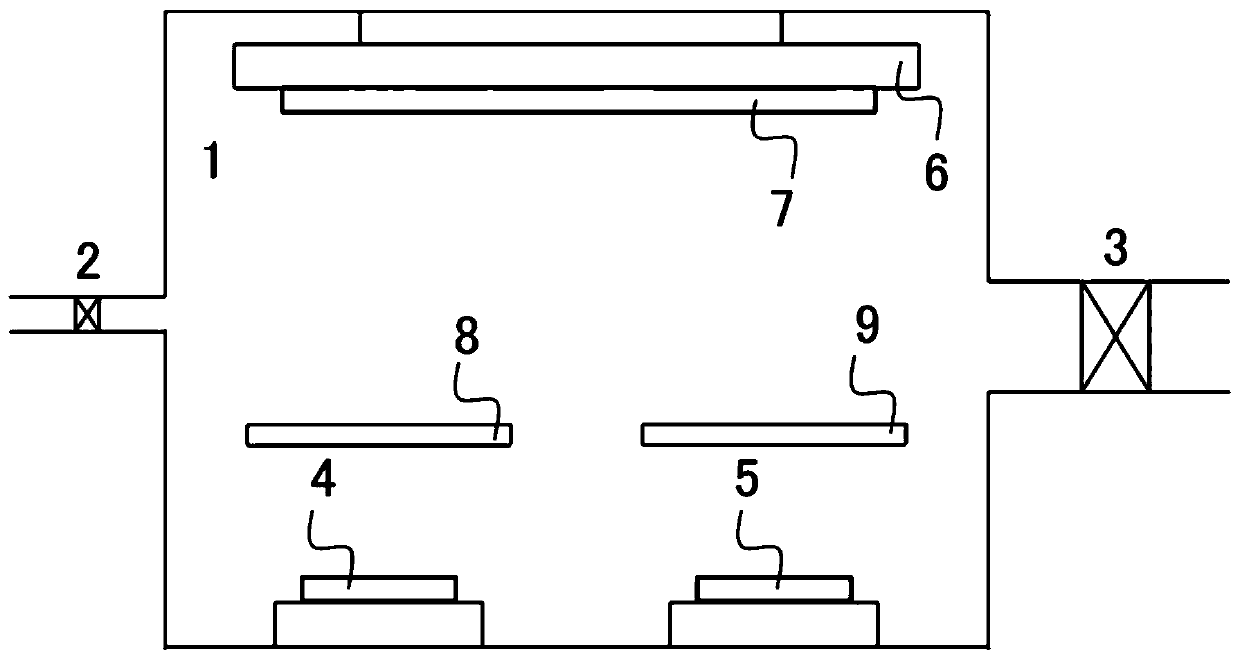

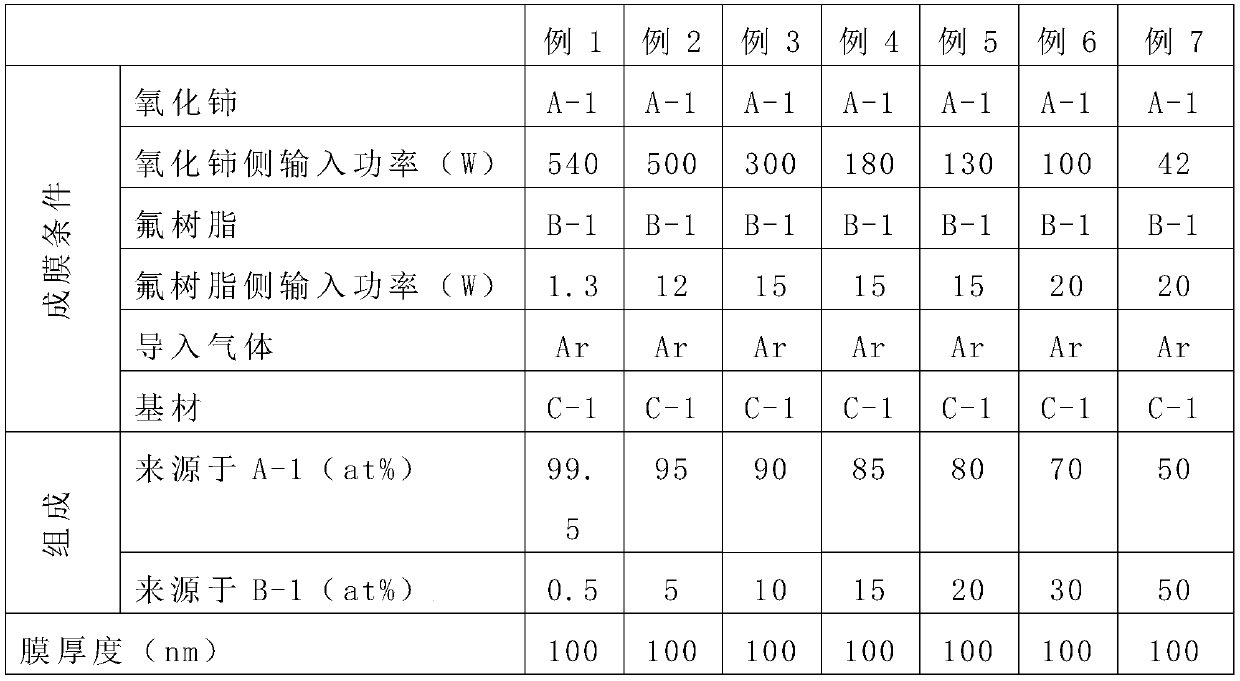

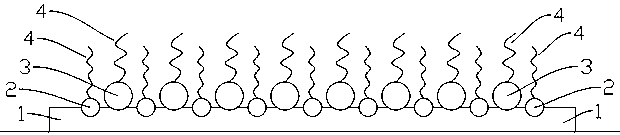

Organic-inorganic hybrid membrane

ActiveCN111511814ALow UV transmittanceHigh Visible Light TransmissionWindowsWindscreensTransmittanceCompounds of fluorine

In one aspect, the present invention is an organic-inorganic hybrid membrane of a cerium oxide and an organic fluorine compound, the organic-inorganic hybrid membrane satisfying the following (a), (b), and (c): (a) the visible-light transmittance is 70% or higher; (b) the UV transmittance at a wavelength of 380 nm is 60% or lower; and (c) the water contact angle of the surface of the organic-inorganic hybrid membrane is 80 degrees or higher. In another aspect, the present invention is an organic-inorganic hybrid membrane of a cerium oxide and an organic fluorine compound, the organic-inorganichybrid membrane satisfying the following (a), (b), and (c'): (a) the visible-light transmittance is 70% or higher; (b) the UV transmittance at a wavelength of 380 nm is 60% or lower; and (c') the water contact angle of the surface of the organic-inorganic hybrid membrane is 90 degrees or higher. The organic fluorine compound may include a fluorine-based resin. Also disclosed are a laminate and anarticle that include the organic-inorganic hybrid membrane.

Owner:HYOMEN KAIMEN KOBO CORP +1

Thermal insulation water-based paint capable of being constructed at low temperature and preparation method thereof

PendingCN114163886ALow thermal conductivityReduce risk of defectsCoatingsCelluloseThermal insulation

The invention relates to the technical field of water-based paint, in particular to heat-preservation water-based paint capable of being constructed at low temperature and a preparation method of the heat-preservation water-based paint. The heat-preservation water-based paint is prepared from the following raw materials in percentage by weight: 0.2 to 0.6 percent of dispersing agent, 0.1 to 0.4 percent of hydroxyethyl cellulose, 0.1 to 0.4 percent of defoaming agent, 0.2 to 0.5 percent of wetting leveling agent, 1 to 4 percent of anti-freezing agent, 0.8 to 2 percent of coalescing agent, 14 to 18 percent of titanium dioxide, 0.4 to 1.2 percent of fumed silica, 0.7 to 1.7 percent of sericite, 4 to 7 percent of nano coated ceramic microbeads, 1.5 to 6 percent of expanded perlite, 7 to 13 percent of floating beads, 6 to 12 percent of aerogel, 0.3 to 0.7 percent of thickening agent, 0.05 to 0.25 percent of mildew preventive and the balance of water. The coating is prepared from the following components in percentage by weight: 0.05-0.25% of a light stabilizer, 0.2-0.6% of an ultraviolet light absorber, 1.5-4% of a silane coupling agent, 9-14% of deionized water and the balance of hydroxyl acrylic emulsion. The thermal-insulation water-based paint has the advantage that the thermal-insulation water-based paint can be constructed at a low temperature.

Owner:北京安连科技股份有限公司

Preparation method of multifunctional micro-nano structure modified wood

InactiveCN114505935AGood modification effectEasy to modifyRadiation/waves wood treatmentWood treatment detailsCellulosePolymer science

The invention discloses a preparation method of multifunctional micro-nano structure modified wood, a modification solution A comprises the following components in parts by weight: 0.1-5 parts of a silane coupling agent, 1-20 parts of sodium silicate, 1-50 parts of furfuryl alcohol, 0.1-5 parts of a catalyst and 100 parts of deionized water, after a wood board is soaked in a soaking tank for a period of time, the modification solution A is absorbed by the wood board, and then the wood board is soaked in a soaking tank for a period of time; a proper amount of a modified solution B is added into a soaking tank, and through later-stage high-temperature drying, the modified solution absorbed to cell walls and cell gaps of the wood is promoted to be subjected to a cross-linking reaction with hydroxyl and carboxyl on the surface of lignocellulose of the wood to generate a micro-nano net structure, so that the mechanical structure of the wood is changed, and the mechanical property of the wood is improved. The hardness, the elastic modulus and the bending strength of the modified wood are remarkably improved.

Owner:深圳碳十四科技创新有限公司

Aerodynamic glass insulator and manufacturing method thereof

InactiveCN110819180AGood adhesionHydrophobicAntifouling/underwater paintsPaints with biocidesNano carbonSilicon dioxide

The invention belongs to the field of insulators and especially relates to an aerodynamic glass insulator and a manufacturing method thereof. According to the invention, a coating is arranged on the surface of the aerodynamic glass insulator and comprises at least four layers from bottom to top, wherein the first layer is fluorocarbon resin, the second layer is nanometer silicon dioxide particles,the third layer is nanometer calcium carbonate particles, and the fourth layer is long-chain silane; the bottom surface of the fluorocarbon resin is adhered to the surface of the insulator; the bottoms of the nanometer silicon dioxide particles are embedded in the fluorocarbon resin; the bottoms of the nanometer calcium carbonate particles are embedded in the nanometer silicon dioxide particles;and the head of the long-chain silane is connected with the nanometer calcium carbonate particles or the nanometer silicon dioxide particles, and the tail of the long-chain silane extends outwards. The aerodynamic glass insulator has hydrophobic and antifouling functions.

Owner:江西泉新电气有限公司

On-line preparation method of hydrophobic yarn for embedded composite spinning

The invention relates to an on-line preparation method for hydrophobic yarn in embedded type composite spinning and belongs to the technical field of textile processing. An embedded type composite spinning method is characterized in that filaments tightly wrap short fibers; by utilizing the characteristic, a modification device is arranged at a running route of viscose filaments between a filamentdrum on a ring spinning frame and a front roller, and a drying device is disposed at the position of a spun yarn running route between the front roller and a spun yarn pipe. The modification device applies a modification liquid to the viscose filaments, the drying device dries spun yarn formed by twisting, and the hydrophobic yarn is prepared by using the viscose filaments to wrap the outer sideof rough cotton yarn in a spatial spiral shape and transferring the modification liquid on the viscose filaments to cotton fibers in contact with the modification liquid. The on-line preparation method is modified based on a method for follow-up modification on existing yarn or fabrics, causes the spinning and the modification to be performed simultaneously, shortens the production cycle, reducesthe production cost and simplifies operation steps.

Owner:WUHAN TEXTILE UNIV

Preparation method of composite membrane with hydrophobization function

ActiveCN103537196BWith hydrophobic functionHave gotSemi-permeable membranesHardnessUltimate tensile strength

The invention discloses a preparation method of a composite membrane with a hydrophobization function. The preparation method comprises the following steps: performing membrane scraping for multiple times on a glass plate by a mixed polytetrafluoroethylene liquid and curing for forming a membrane in a gelling bath to obtain a base membrane layer; dissolving poly-perfluoroalkyl ethyl acrylic ester granules in a mixed solution of monofluoride dichloroethane (HCFC-141b) and fluorosilane and stirring; adding epoxy resin and a phenolic aldehyde amine epoxy hardener to obtain a new mixed solution; mixing the new mixed solution with E type epoxy resin to obtain a mixture and applying the mixture onto the base membrane layer; and performing drying to obtain the composite membrane with the hydrophobization function. In the way, the preparation method of the composite membrane with the hydrophobization function has the advantages that the raw materials are extensive in source and easy to obtain, the preparation process is simple, and the preparation method is easy to operate without over-high requirements on the operation technique of operators and can effectively save cost; the obtained composite membrane with the hydrophobization function has certain hardness and strength and is excellent in hydrophobization performance.

Owner:无锡和烁丰新材料有限公司

High temperature resistance, drag reduction, energy saving and heavy anticorrosion coating for the inner wall of thermal pipeline

ActiveCN108912964BHigh trafficReduce drag and reduce frictionFireproof paintsAnti-corrosive paintsXylylenePhosphoric acid

Owner:SHANGHAI HILONG SHINE NEW MATERIAL +1

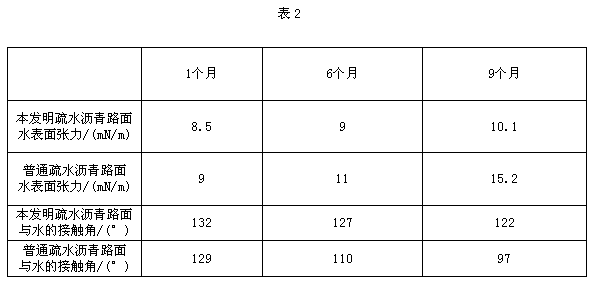

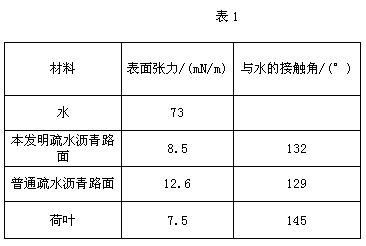

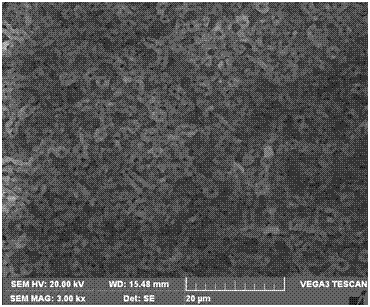

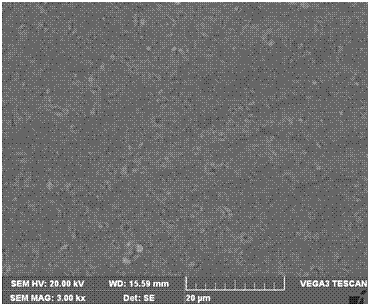

Hydrophobic asphalt with slow release effect and preparation method thereof

InactiveCN111171588AWith hydrophobic functionExtended service lifeBuilding insulationsRoad surfaceStearic acid

The invention relates to the field of road materials, in particular to hydrophobic asphalt with a slow-release effect and a preparation method thereof. The service life of an asphalt pavement in a frequently wet state is prolonged. The hydrophobic asphalt is prepared by mixing matrix asphalt and a hydrophobic asphalt modifier according to a weight ratio of (95-96.5): (3.5-5), and the hydrophobic asphalt modifier is prepared by mixing siloxane, lignin fibers and calcium stearate. The hydrophobic asphalt modifier is added into the matrix asphalt according to a weight ratio, and stirring is carried out continuously for 1 hour to obtain the hydrophobic asphalt. According to the hydrophobic asphalt and the preparation method thereof, siloxane is used as a hydrophobic substance, adsorbed into acavity of lignocellulose through a capillary adsorption effect and then slowly released in an asphalt pavement along with time, so that the pavement has a hydrophobic function within a relatively longtime, and the service life is prolonged.

Owner:周凯 +1

Micro-arc oxidation electrolyte solution and micro-arc oxidation film preparation method for arc suppression by silane coupling agent

ActiveCN105063722BSuppress tip dischargeControllable surface structureAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a micro-arc oxidation electrolyte solution and a micro-arc oxidation film preparation method for arc suppression by a silane coupling agent. The electrolyte solution includes a base solution and a silane coupling agent; the base solution is composed of inorganic salts, fluorides and hydroxides One, two or three components, the basic solution is alkaline; the silane coupling agent is neutral or alkaline after hydrolysis, and the general formula is R4‑xSi (OR'). The magnesium alloy substrate is used as an anode or cathode, and stainless steel is used as a counter electrode, placed in the electrolyte solution of the present invention, and subjected to micro-arc oxidation treatment. After the oxidation is completed, the magnesium alloy substrate is taken out, rinsed and dried, and the surface of the magnesium alloy is obtained by micro-arc oxidation. Oxide film layer. The electrolytic solution can suppress tip discharge, and the structure of the prepared micro-arc oxidation film is controllable, with good corrosion resistance and wear resistance; and according to the requirements of the surface composite coating, a micro-arc oxidation transition film with excellent compatibility can be prepared Floor.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com