Organic-inorganic hybrid membrane

A hybrid film, organic technology, applied in chemical instruments and methods, synthetic resin layered products, windows, etc., can solve problems such as insufficient weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0121] Hereinafter, although an Example demonstrates this invention, this invention is not limited to this.

[0122] Method for measuring and evaluating physical properties of laminates comprising organic-inorganic hybrid films

[0123] (i) Visible light transmittance

[0124] The visible light transmittance was measured using a Shimadzu Corporation spectrophotometer "SolidSpec-3700" (trade name) in accordance with the visible light transmittance test in 6.4 of JIS A5759:2008.

[0125] (ii) UV transmittance 1 (UV transmittance at a wavelength of 380nm)

[0126] According to the ultraviolet transmittance test of 6.4 of JIS A5759:2008, the transmittance at a wavelength of 380 nm is read from the transmittance spectrum measured using a spectrophotometer "SolidSpec-3700" (trade name) of Shimadzu Corporation, and the value is As UV transmittance 1.

[0127] (iii) Water contact angle

[0128] For the organic-inorganic hybrid film surface of the laminate, use the automatic contac...

example 1

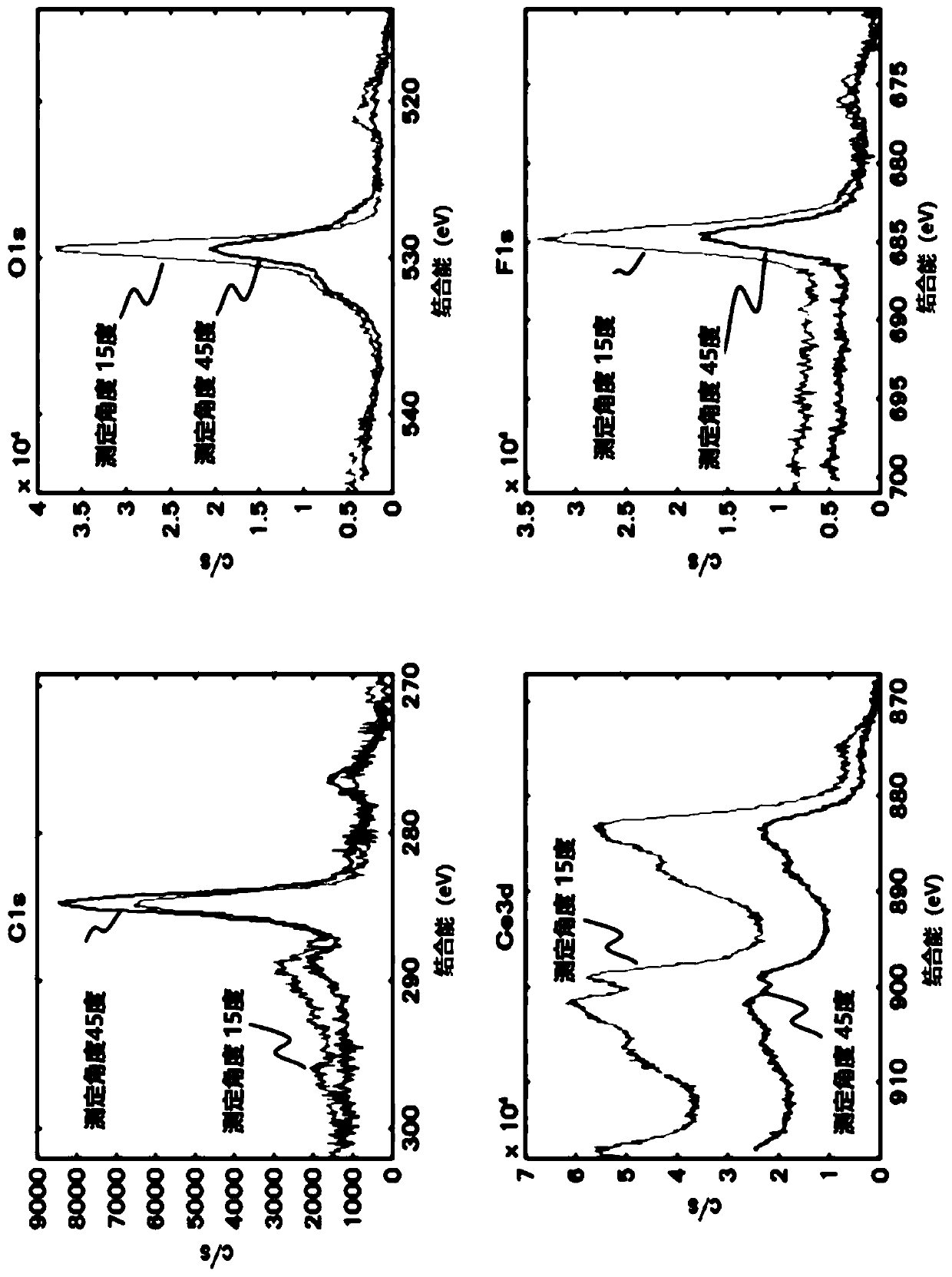

[0141] (1) Use APP company's atmospheric pressure plasma treatment device "MyPL Auto200" (trade name), will contain 0.5 volume % of oxygen (O 2 ) of argon (use argon at a volume flow rate of 6 liters / minute, use oxygen (O 2 )) As the discharge gas, under the conditions of input power 180W, scanning times of 0.5 reciprocating, scanning speed of 20mm / sec, and distance between the electrode and the surface to be treated of 2mm, the above (C-1) was subjected to surface treatment.

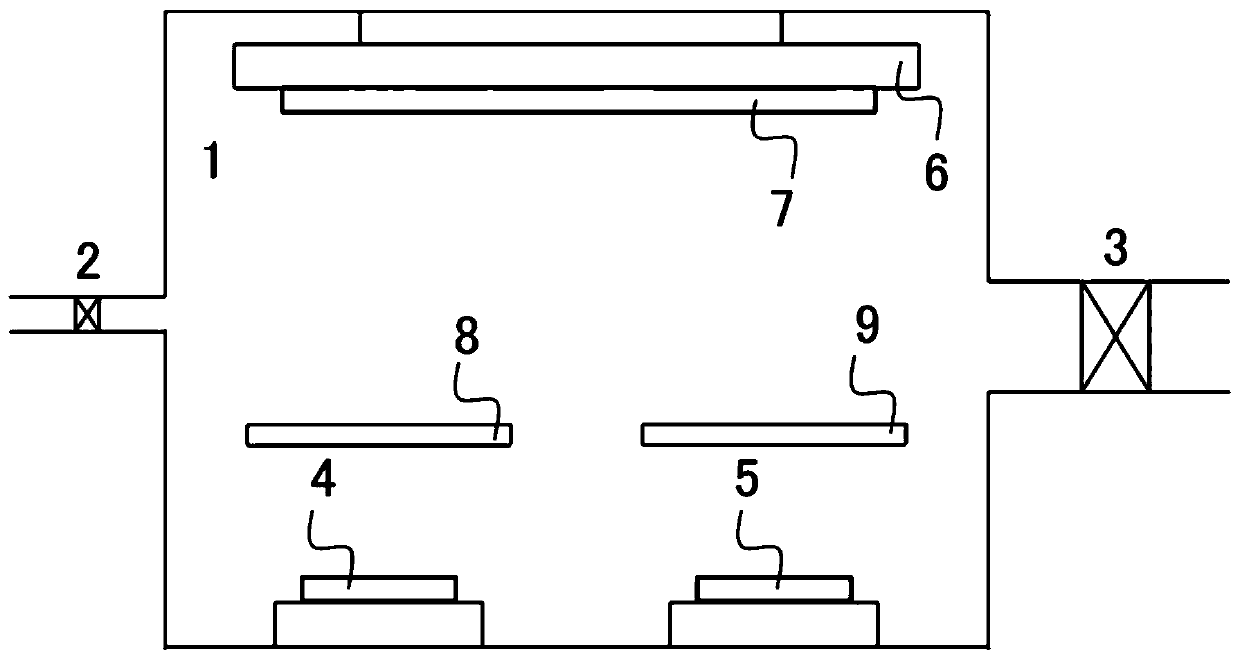

[0142] (2) Next, using the diode sputtering device of VIC International Corporation, using the above-mentioned (A-1) and the above-mentioned (B-1) as targets, at a film formation pressure of 1Pa, the introduction gas is argon gas of 100% by volume (Table marked as "Ar" in ), the volume flow rate of the introduced gas is 10sccm, the distance between the above (C-1) and the target is 5cm, the input power (frequency 13.56MHz) is 540W on the above (A-1) side, and the above Sputtering film formation was sim...

example 2~7

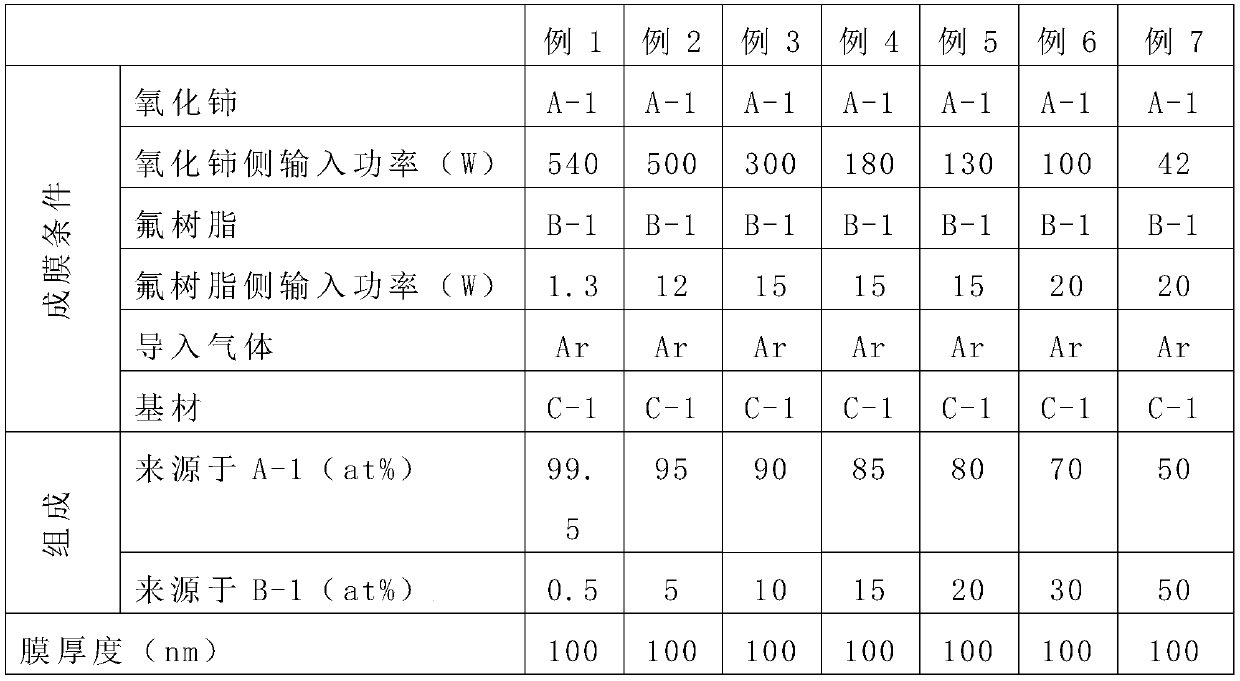

[0146] Except for changing the input power at the time of film formation as shown in Table 1, in the same manner as in Example 1, the production and physical properties of a laminate including an organic-inorganic hybrid film were measured and evaluated. The results are shown in Table 1.

[0147] [Table 1]

[0148] Table 1

[0149]

[0150]

[0151] From these results, it was confirmed that the organic-inorganic hybrid film of the present invention having a low ultraviolet transmittance and a high visible light transmittance was obtained. In addition, the organic-inorganic hybrid membrane of the present invention has a hydrophobic function.

[0152] In addition, in the above-mentioned examples, a laminated body including the organic-inorganic hybrid film of the present invention was obtained using a glass plate as a base material. However, the organic-inorganic hybrid film of the present invention has low ultraviolet transmittance, high visible light transmittance, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com