Ultraviolet ray and infrared ray shielding glass capable of being subsequently processed

A technology for shielding glass and ultraviolet rays, applied in the field of special glass, can solve problems such as damage, damage to leather, furniture, artwork, accelerated skin aging, etc., and achieve the effect of low ultraviolet transmittance, avoiding film defects, and relieving internal stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

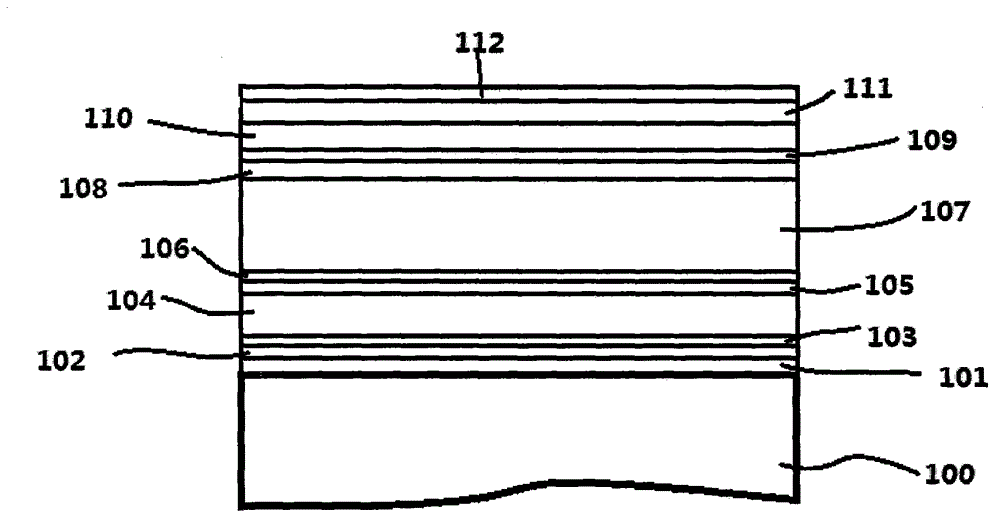

[0039] The following is the film system structure of an application example of the ultraviolet and infrared shielding glass that can be processed later provided by the present invention:

[0040] Glass substrate / ZnSnOx / ZnO / Ag / Ti / ZnO / ZnSnOx / ZnO / Ag / Ti / ZnO / ZnSnOx / ZnO / Ag / Ti / ZnO / ZnSnOx / CeO 2 / TiO 2 .

[0041] Wherein, the first oxide layer is a composite layer of ZnSnOx and ZnO with a thickness of 42-46nm, and transitions in a gradient growth manner.

[0042] The thickness of the first infrared reflective Ag layer is 11 nm.

[0043] The first barrier layer is a Ti layer with an areal density of 1.1 μg / cm 2 .

[0044] The second oxide layer is a composite layer of ZnSnOx and ZnO with a thickness of 70-75nm, and the two layers of ZnO and ZnSnOx are transitioned in the manner of gradient growth.

[0045]The thickness of the second infrared reflective Ag layer is 13 nm.

[0046] The second barrier layer is a Ti layer with an areal density of 1.2 μg / cm 2 .

[0047] The third oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com