High-temperature-resistant drag-reducing energy-saving heavy-duty anti-corrosion coating for thermal pipeline inner walls

A thermal pipeline and high temperature resistant technology, applied in the direction of anti-corrosion coatings, fire-proof coatings, epoxy resin coatings, etc., can solve the problems of increasing the operating costs of heating enterprises, polluting the environment with thermal energy circulating water, and increasing the cost of heating for residents. Low cost, reduce the number of pigging, and reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

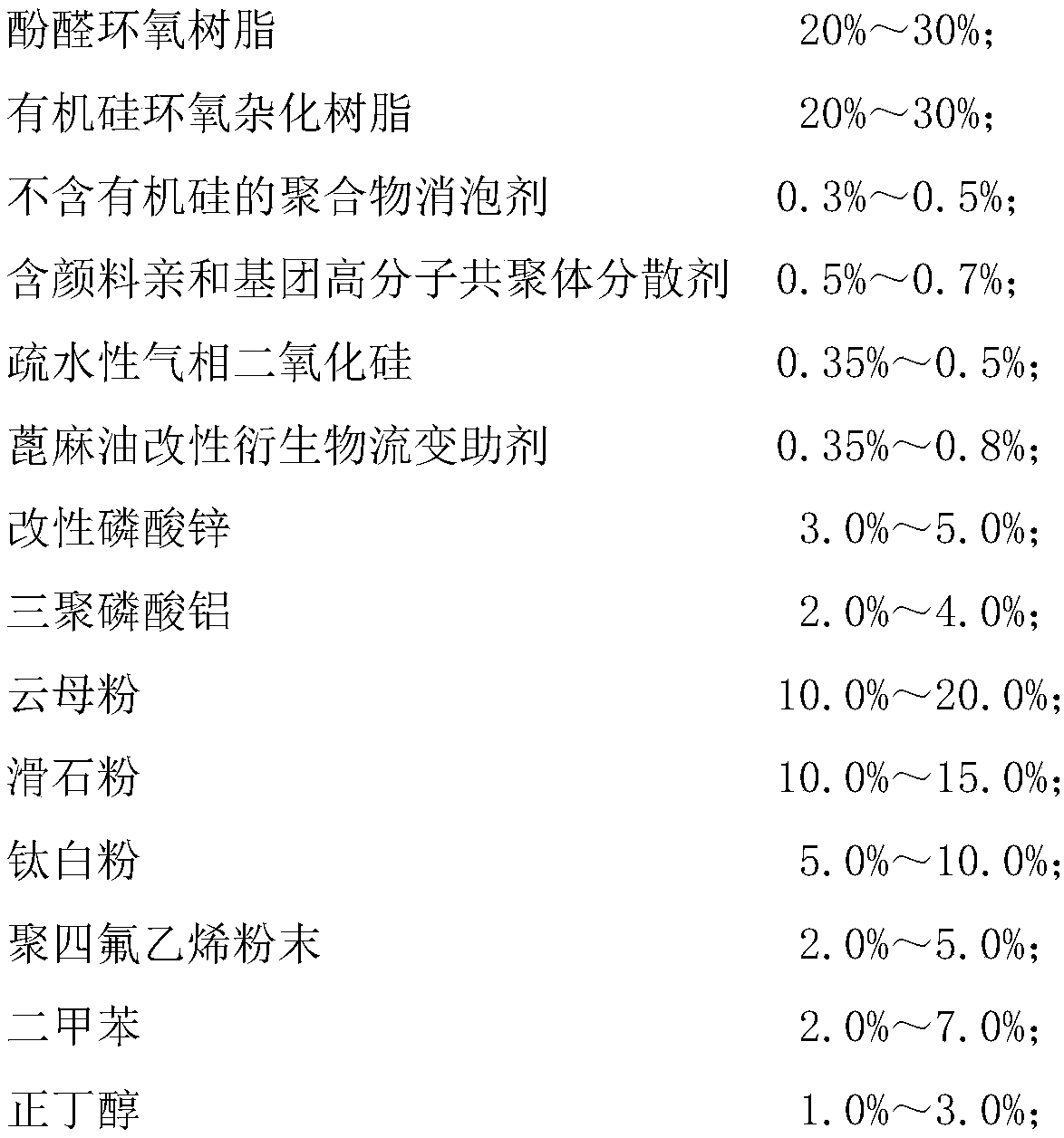

[0023] (1) A high-temperature-resistant, drag-reducing, energy-saving and heavy-duty anti-corrosion coating for the inner wall of a thermal pipeline contains two components, A and B, and the weight percentage of the A component is:

[0024] Novolak epoxy resin 20%, adopt Nan Ya epoxy resin NPPN-631, its epoxy equivalent is 168-178 (g / eq).

[0025] Silicone epoxy hybrid resin 30%, adopts SILIKOPON EF resin from Evonik Specialty Chemicals (Shanghai) Co., Ltd., and its epoxy equivalent is about 450 (g / eq).

[0026] 0.3% silicone-free polymer defoamer, BYK-057 product from BYK Chemical Company.

[0027] 0.7% polymer interpolymer dispersant containing pigment-affinity group is used AFCONA4570 product of Afcona Chemical Co., Ltd.

[0028] Hydrophobic fumed silica 0.35%, using R972 product from Evonik Degussa Specialty Chemicals Co., Ltd.

[0029] Castor oil modified derivative rheological additive 0.35%, using THIXATROL ST product of Hemings Deqian Chemical Company.

[0030] Modi...

Embodiment 2

[0057] (1) A high-temperature-resistant, drag-reducing, energy-saving and heavy-duty anti-corrosion coating for the inner wall of a thermal pipeline contains two components, A and B, and the weight percentage of the A component is:

[0058]Novolak epoxy resin 21%, (the product that adopts is with embodiment 1).

[0059] Organosilicon epoxy hybrid resin 21%, (the product that adopts is with embodiment 1).

[0060] Polymer defoamer 0.4% that does not contain organic silicon, (the product that adopts is the same as embodiment 1).

[0061] 0.6% polymer interpolymer dispersant containing pigment affinity group, (the product that adopts is the same as embodiment 1).

[0062] Hydrophobic fumed silica 0.42%, (the product that adopts is with embodiment 1).

[0063] Castor oil modified derivative rheology additive 0.5%, (the product that adopts is the same as embodiment 1).

[0064] Modified zinc phosphate 4.0%, (the product that adopts is with embodiment 1).

[0065] Aluminum tripo...

Embodiment 3

[0078] (1) A high-temperature-resistant, drag-reducing, energy-saving and heavy-duty anti-corrosion coating for the inner wall of a thermal pipeline contains two components, A and B, and the weight percentage of the A component is:

[0079] Novolak epoxy resin 30%, (the product that adopts is with embodiment 1).

[0080] Organosilicon epoxy hybrid resin 20%, (the product that adopts is with embodiment 1).

[0081] Polymer defoamer 0.5% that does not contain organic silicon, (the product that adopts is the same as embodiment 1).

[0082] 0.5% polymer interpolymer dispersant containing pigment affinity group, (the product that adopts is the same as embodiment 1).

[0083] Hydrophobic fumed silica 0.5%, (the product that adopts is with embodiment 1).

[0084] Castor oil modified derivatives rheology additive 0.8%, (the product that adopts is the same as embodiment 1).

[0085] Modified zinc phosphate 3.0%, (the product that adopts is with embodiment 1).

[0086] Aluminum trip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com