Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Wide process applicability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-carbon-chromium bearing steel and manufacture method thereof

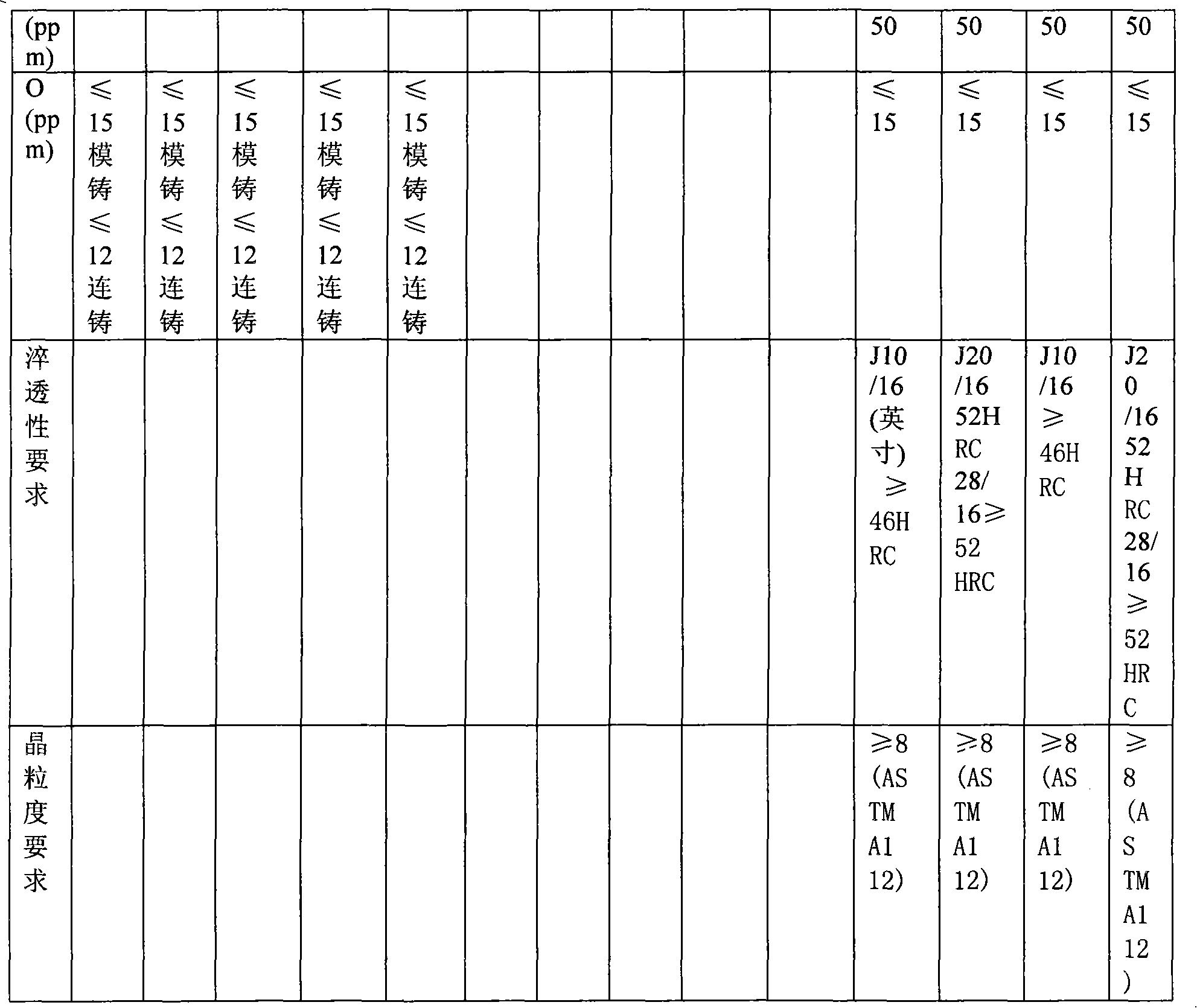

The invention discloses high-carbon-chromium bearing steel and a manufacture method thereof. The high-carbon-chromium bearing steel comprises the following chemical compositions by weight percentage: C: 0.90-1.05; Cr: 0.90-1.20; Mn: 0.90-1.25; Si: 0.45-0.75; Al: 0.02-0.04; oxygen is less than or equal to 0.0007; phosphorus is less than or equal to 0.010; sulfur is less than or equal to 0.005; titanium is less than or equal to 0.0025; copper is less than or equal to 0.15; nickel is less than or equal to 0.10; nitrogen is less than orequal to 0.0070; and the balance of unavoidable impurities and Fe. The manufacture method comprises the following steps: smelting in an electric furnace, refining in a ladle arc furnace, degassing in a vacuum furnace, pouring steel liquid into steel ingots, heating steel ingots in a heating furnace, rolling the steel ingots into square billets by a rolling mill, heating the steel ingots in a heating furnace and rolling the steel ingots into round steel by a rolling mill. Compared with the prior art, the invention has high hardenability, high crystal grain size of more than 8 grade, high commonality in technology and wide application.

Owner:BAOSHAN IRON & STEEL CO LTD

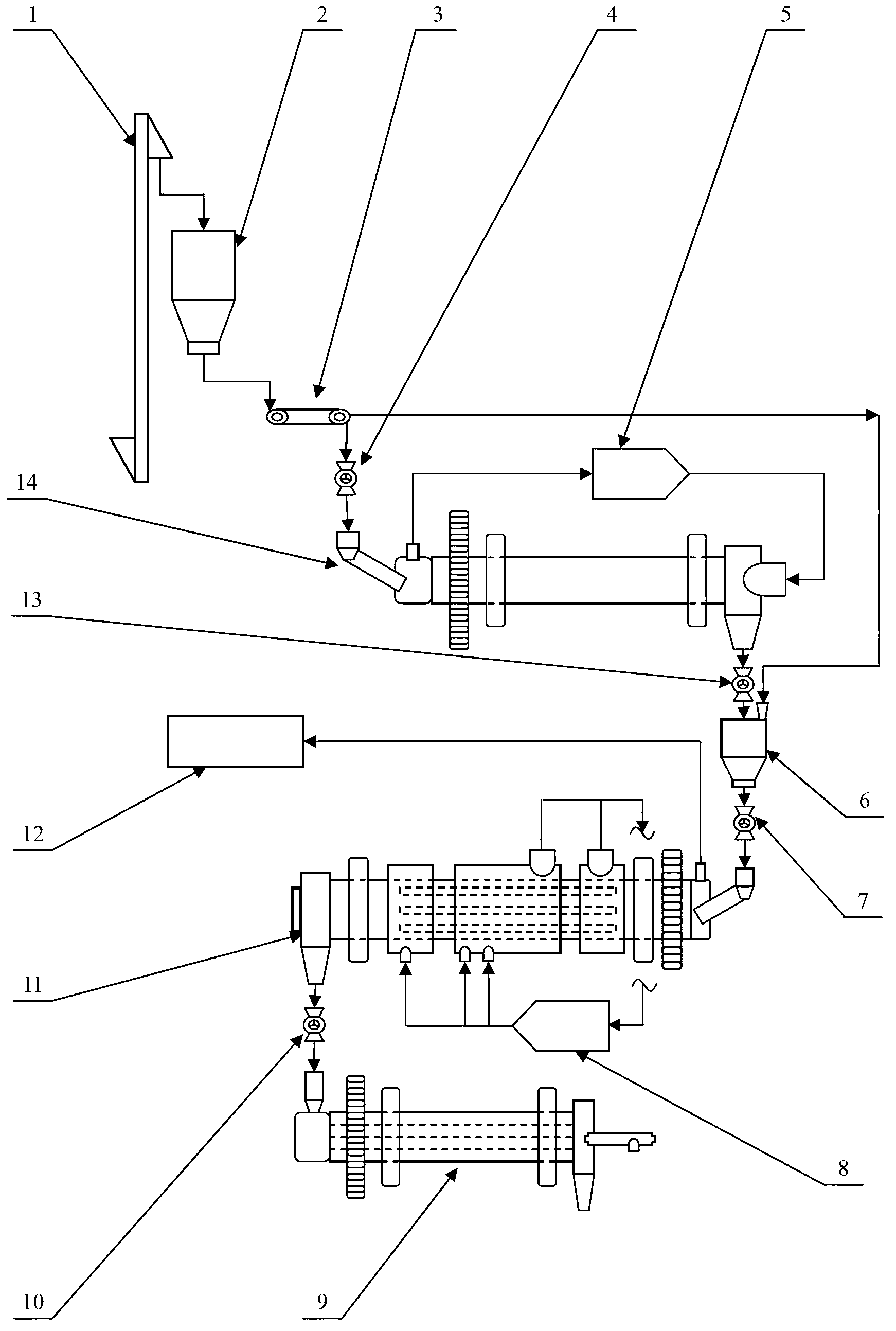

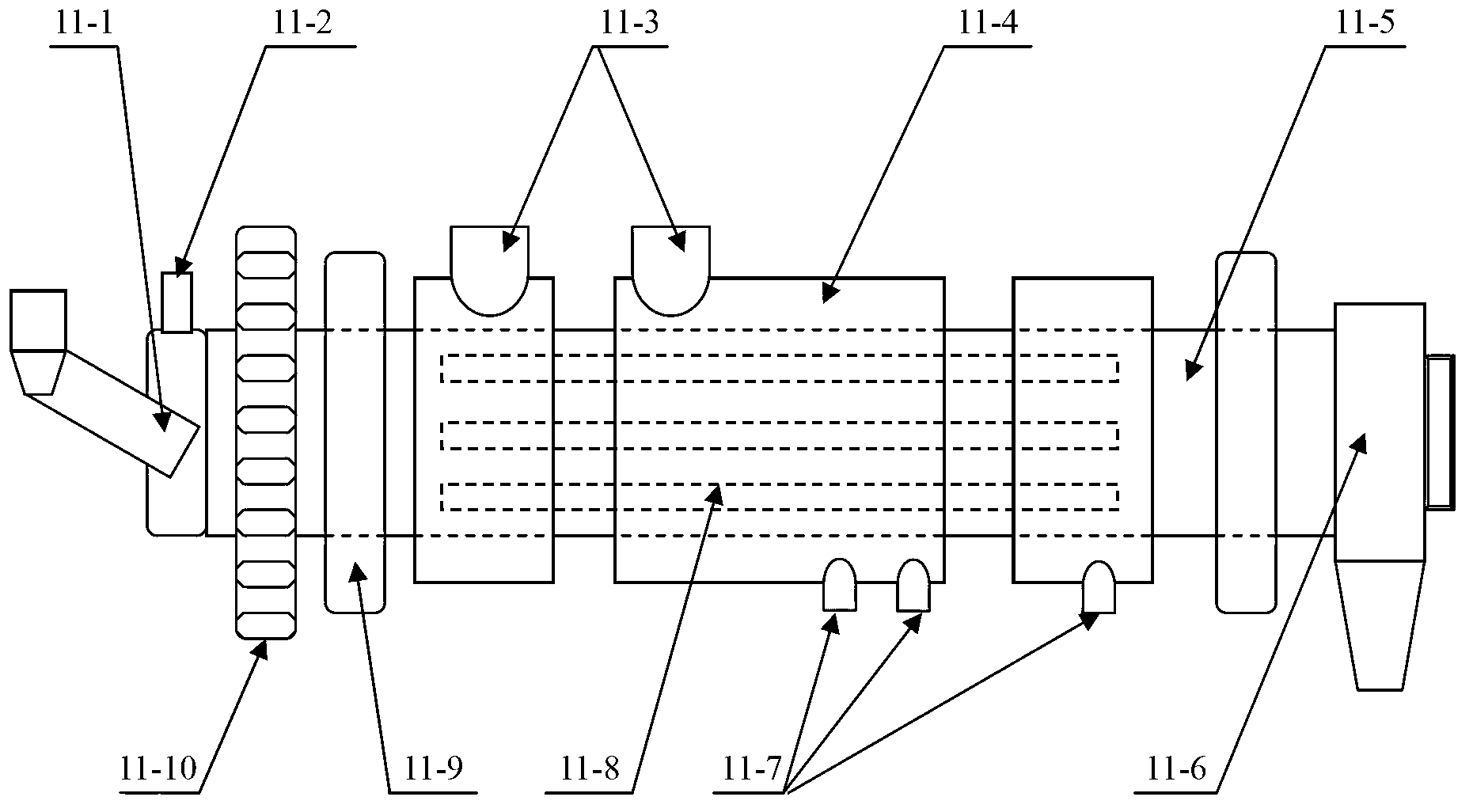

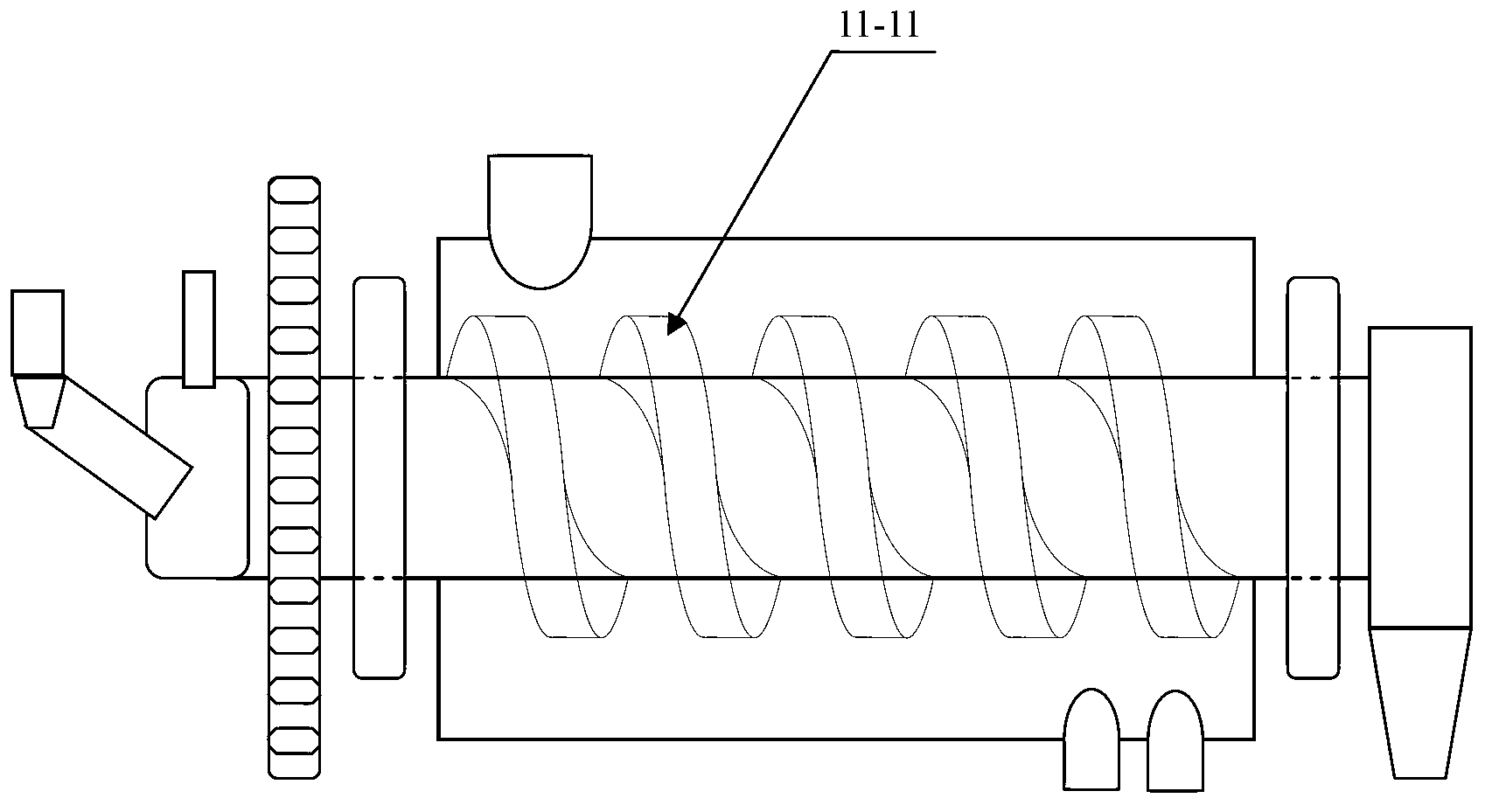

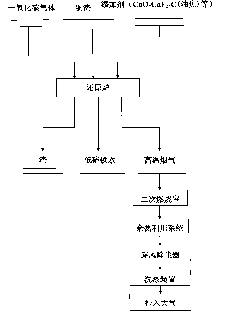

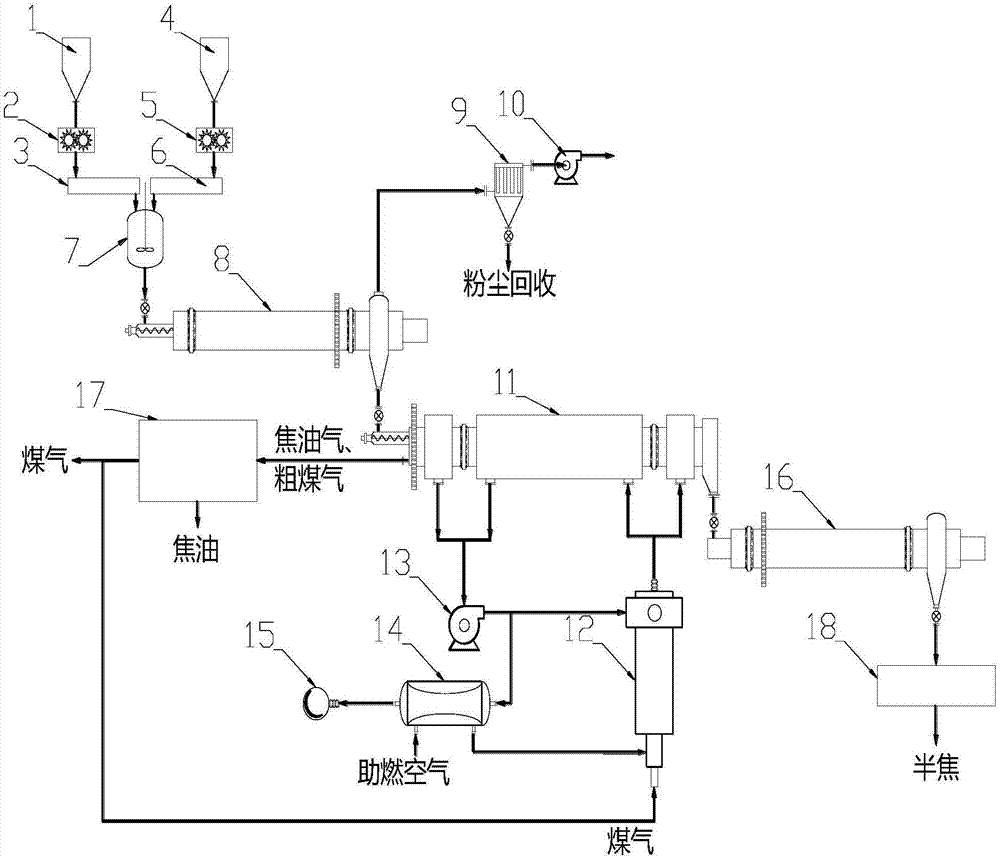

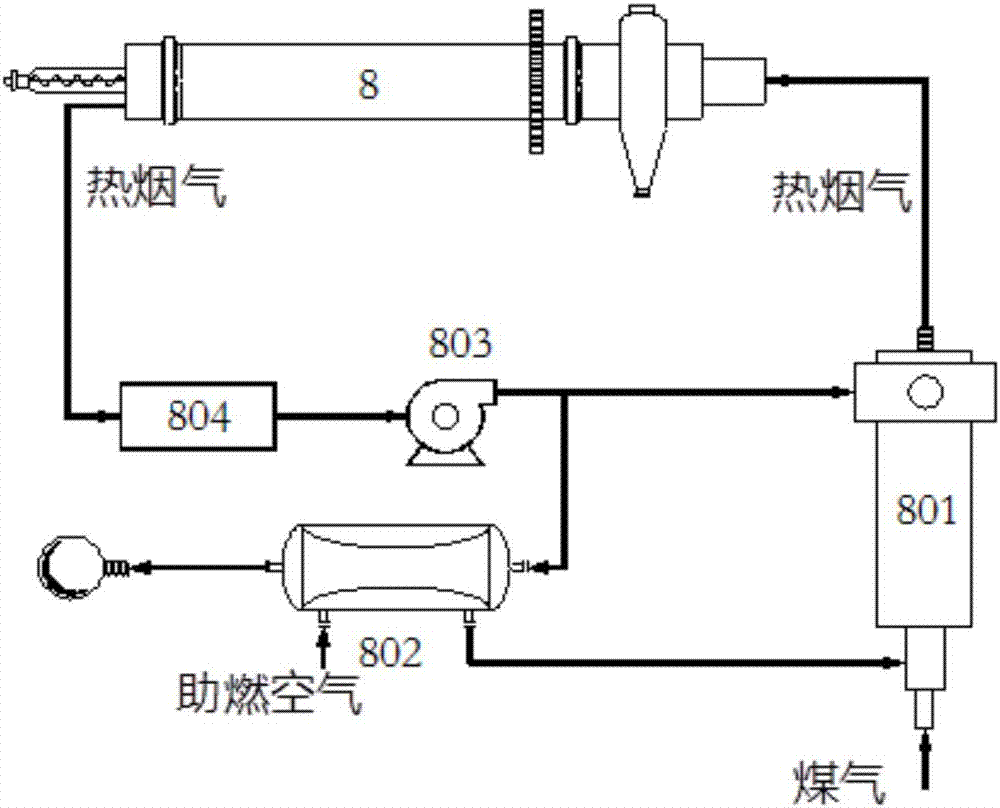

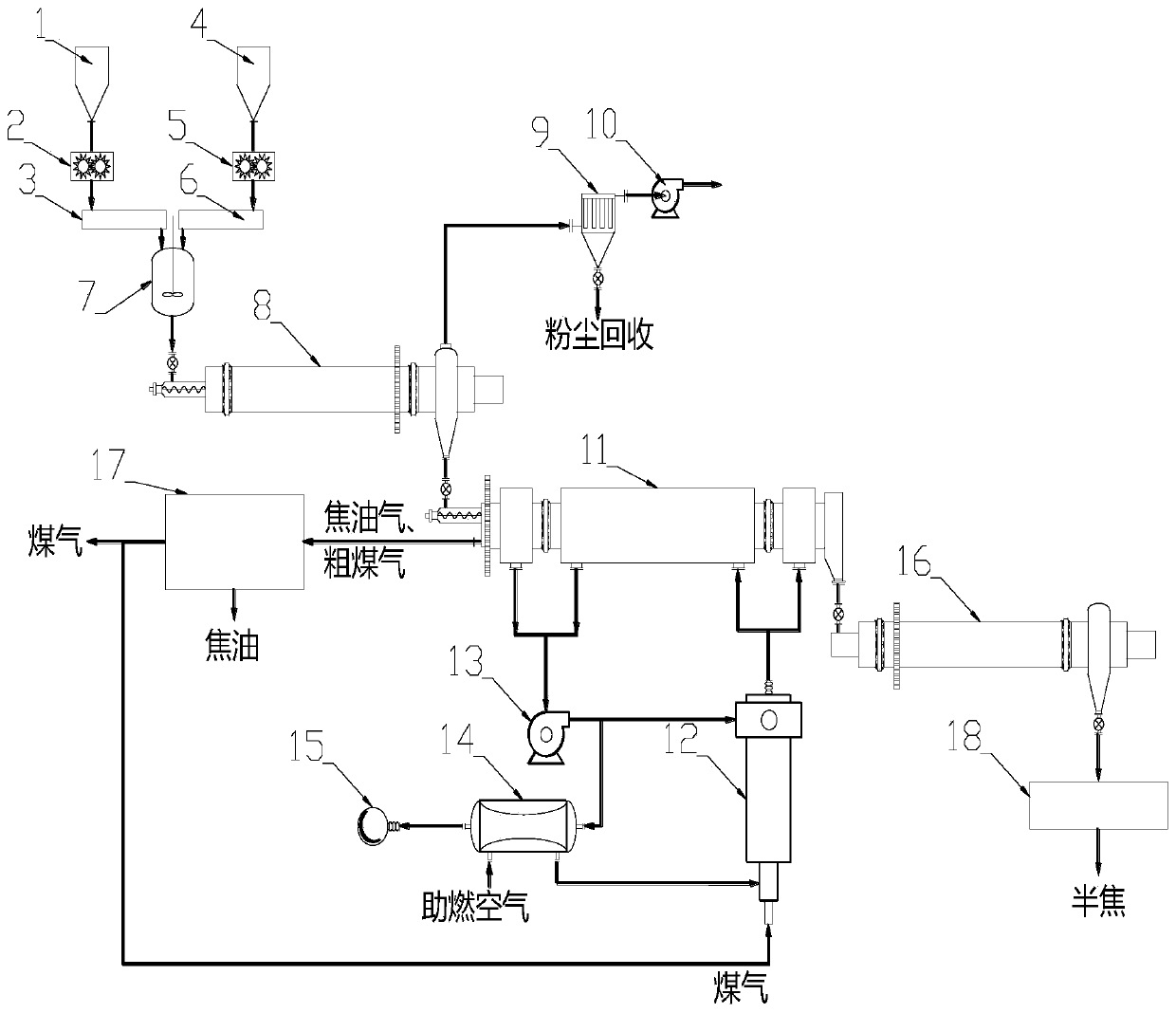

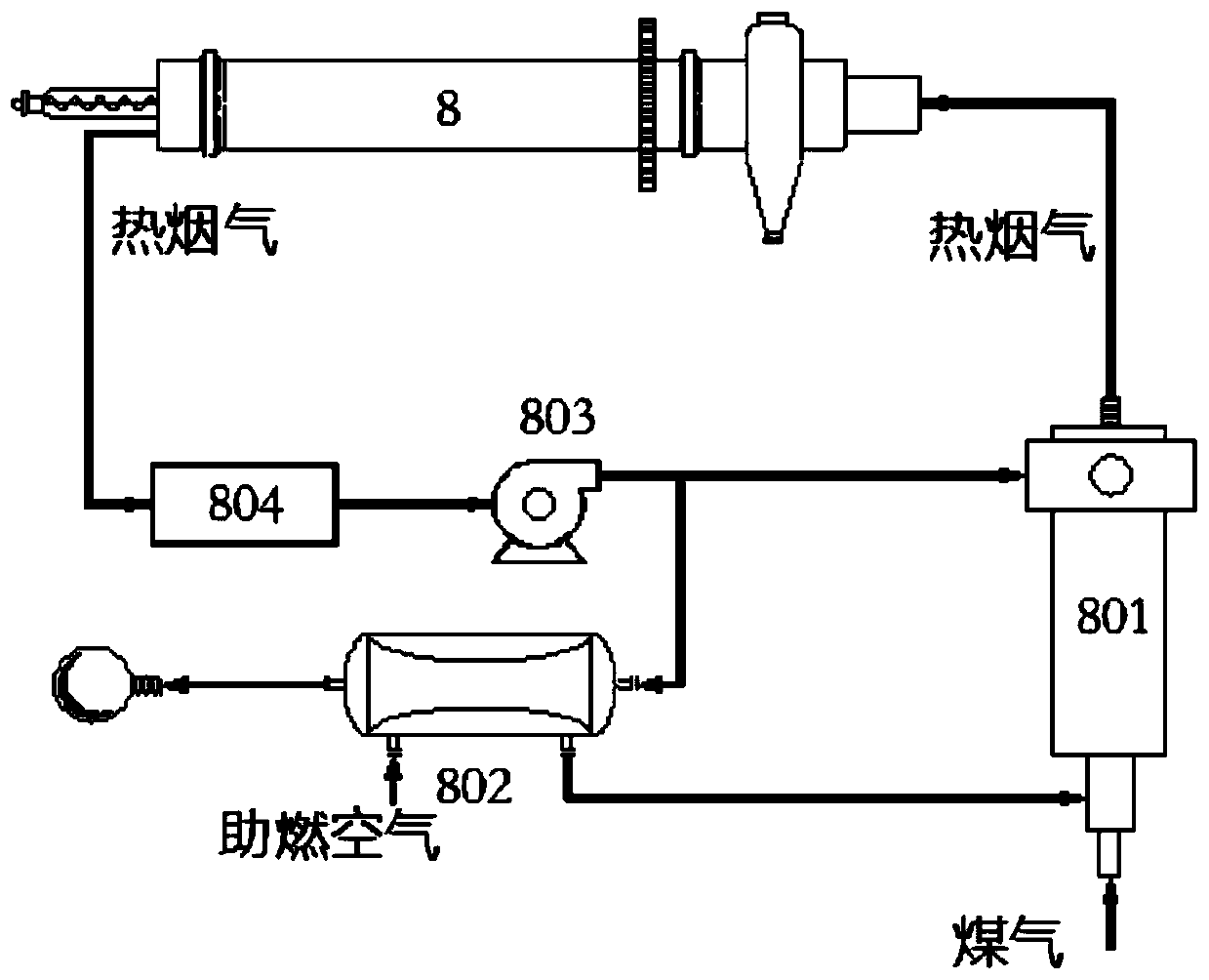

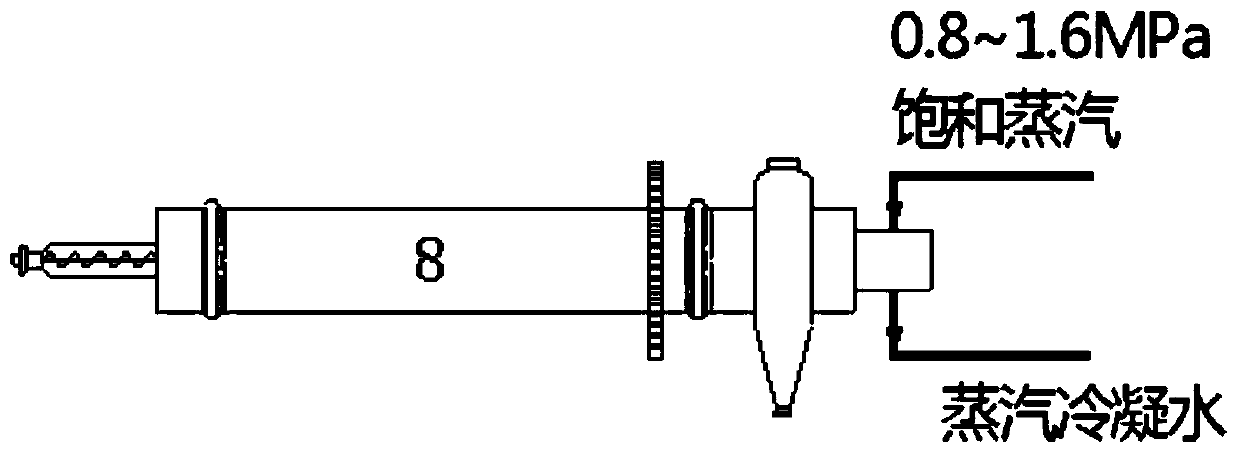

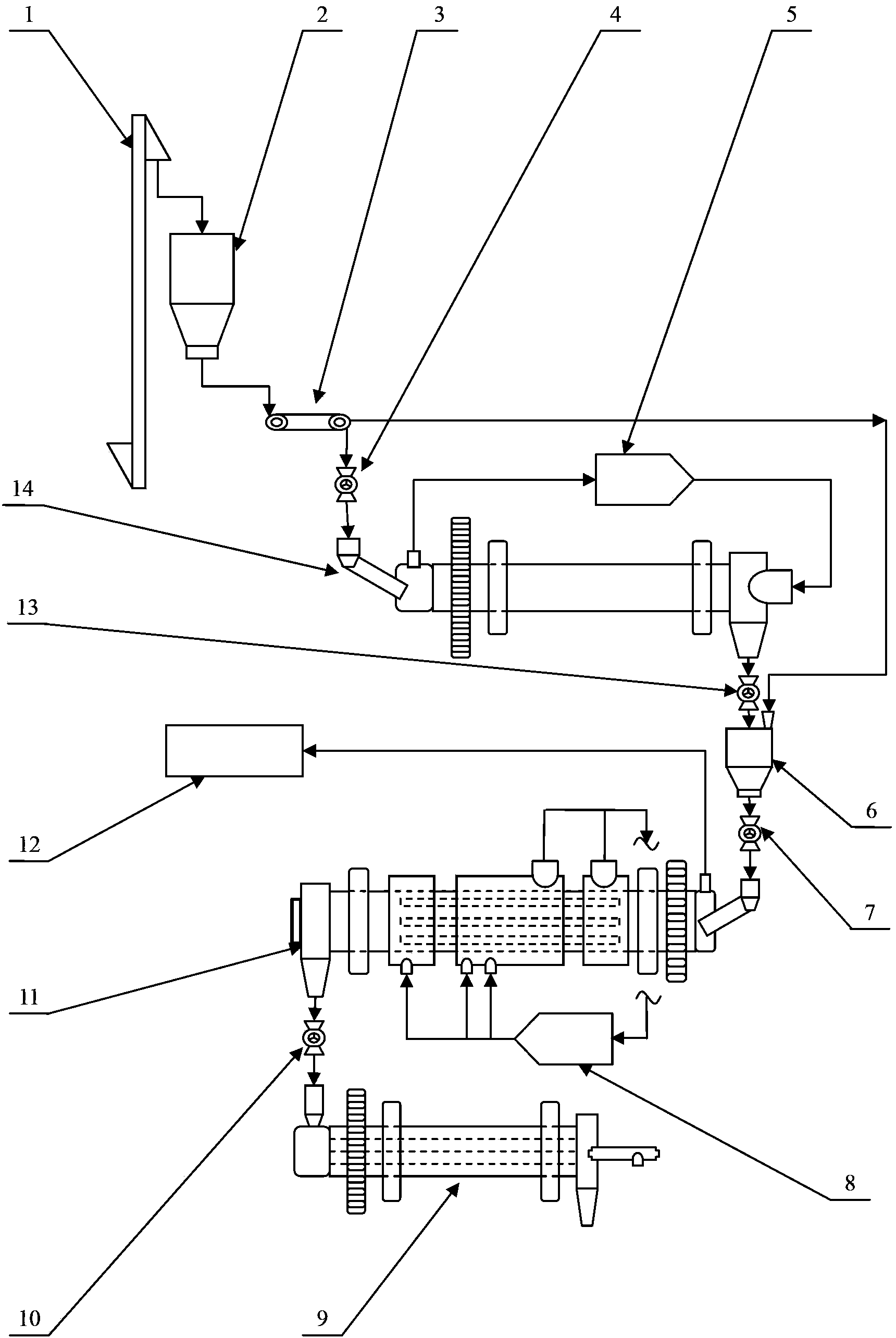

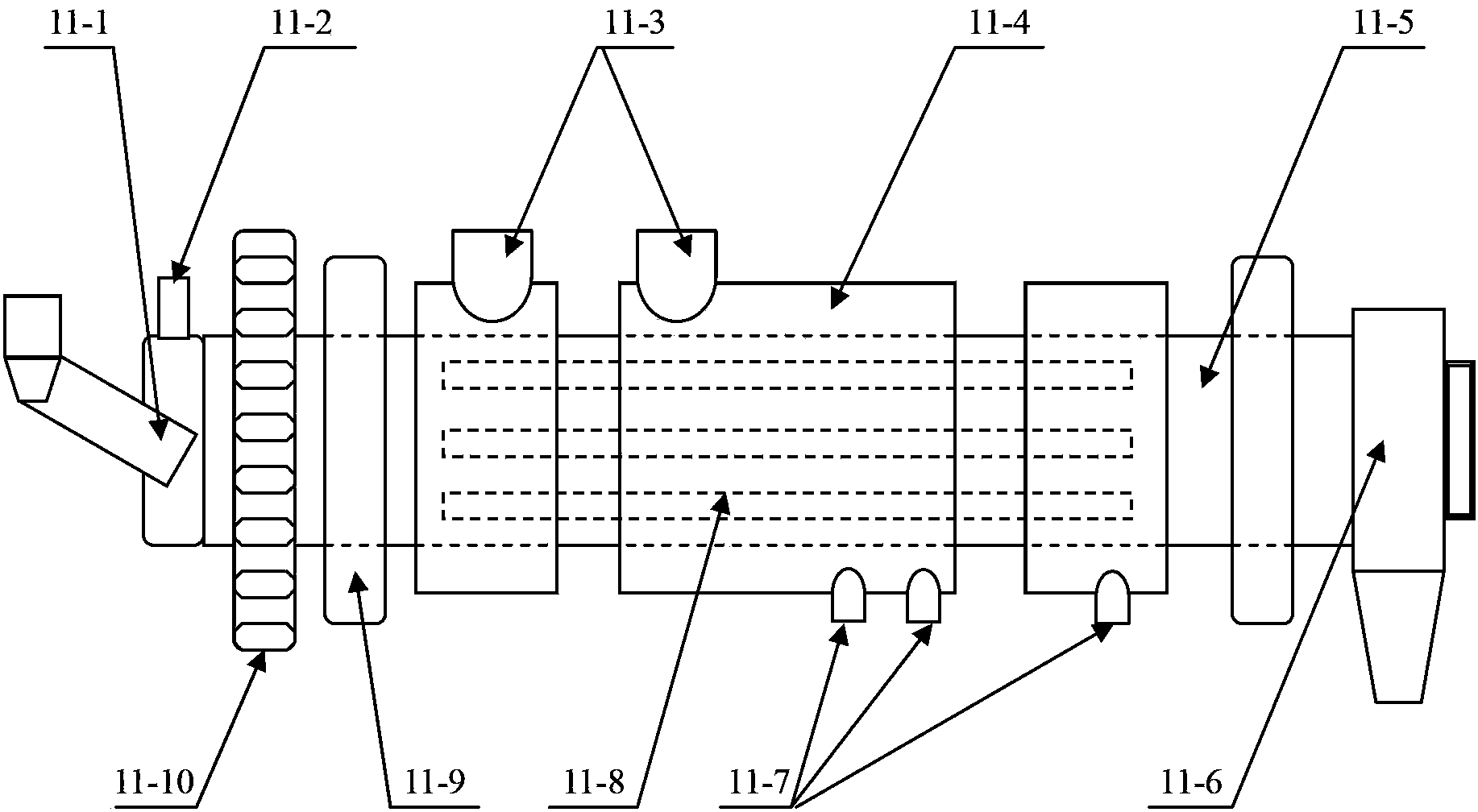

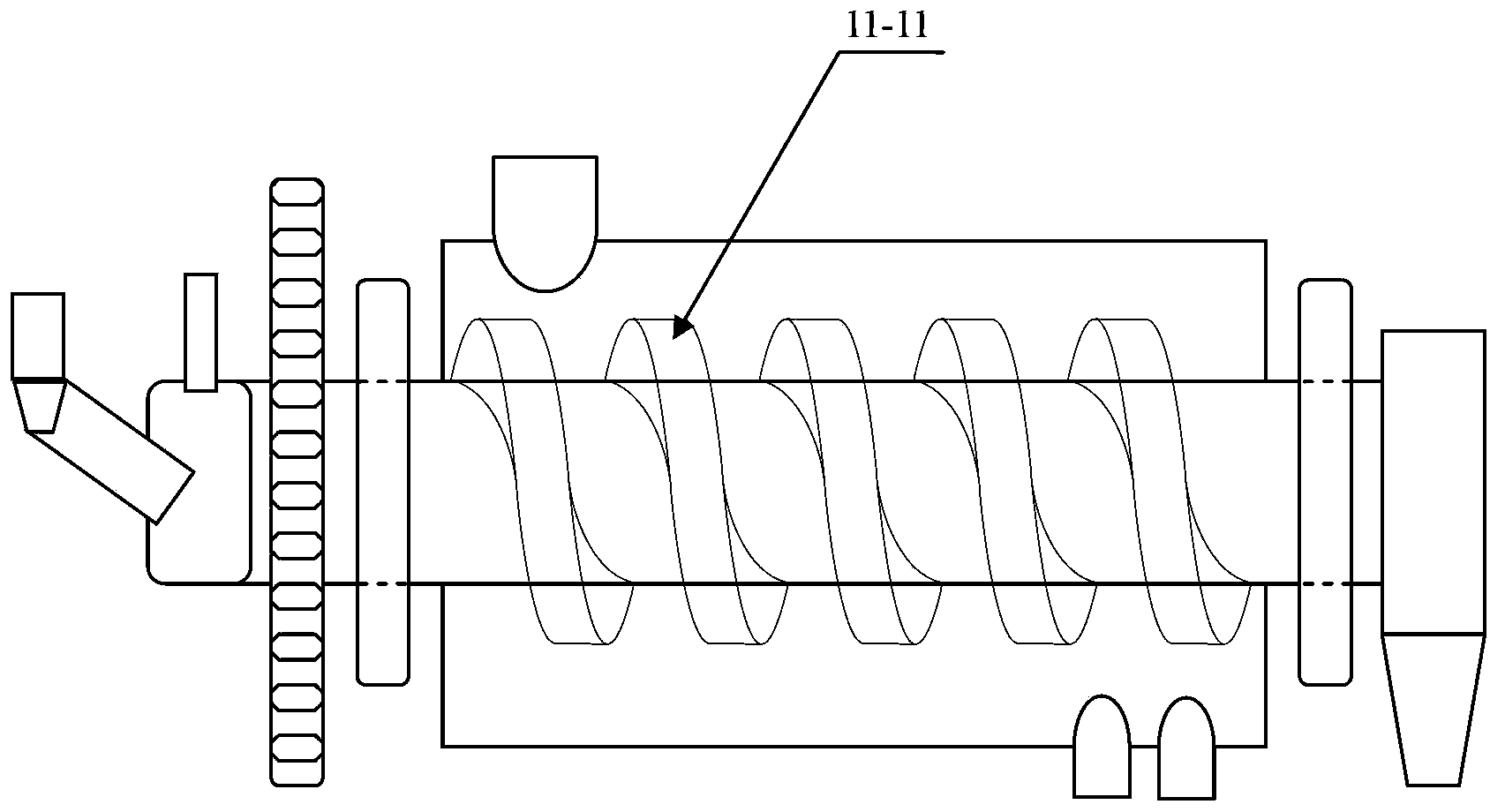

Low-temperature carbonization apparatus and method for oil sand, oil sludge, oil shale and biomass

ActiveCN103160301AIncrease profitReduce energy consumptionDirect heating destructive distillationBiofuelsCarbonizationOil shale gas

The invention discloses a low-temperature carbonization apparatus and method for oil sand, oil sludge, oil shale and biomass. The apparatus comprises a delivery apparatus, a storage bin, a metering apparatus, a drying furnace and a surge bin. The method comprises the following steps: drying, preheating, carbonizing, and cooling. The core of the invention is an external heating type rotary carbonization furnace which realizes the pyrolysis of oil sand, oil shale, oil sludge (oil sludge on the ground, oil sludge at the bottom of a tank and oil-containing sludge from oil refinery) and biomass, and the product is high in purity and low in loss. The invention effectively solves the problems of solid materials such as adhesion, wall accretion and the like in the pyrolysis process by material returning. The technology provided by the invention is simple in process and reliable and stable in operation, and has obvious advantages in the treatment of small particle materials such as oil shale, oil sand, oil sludge (oil sludge on the ground, oil sludge at the bottom of a tank and oil-containing sludge from oil refinery), biomass and the like.

Owner:何建祥

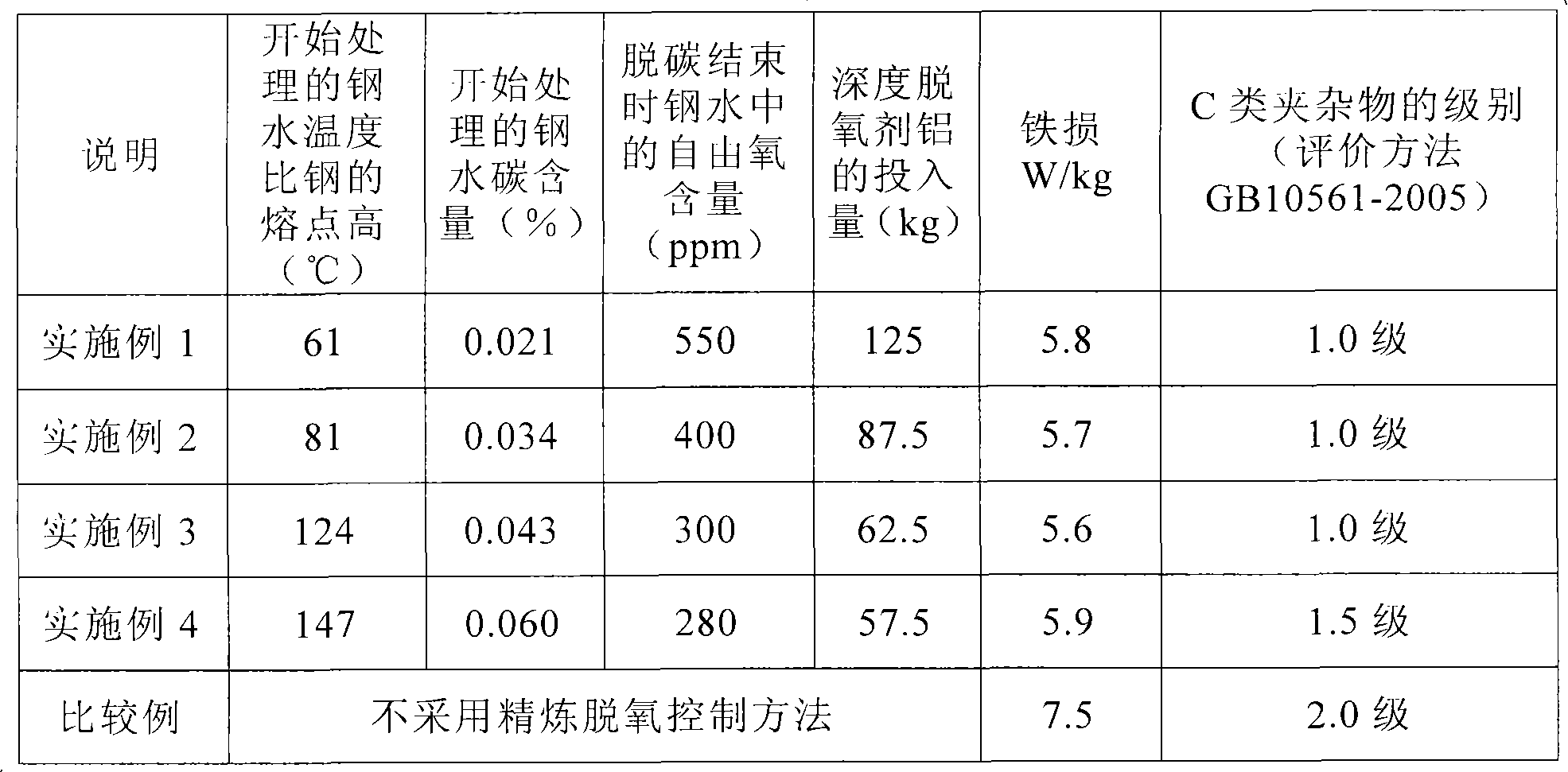

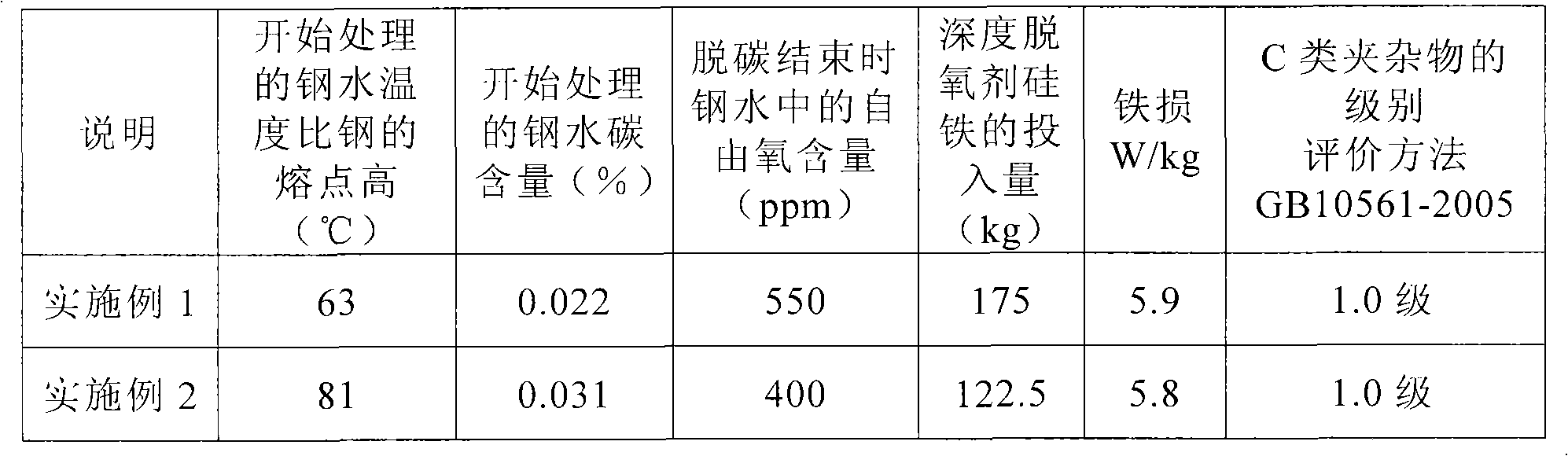

Non-oriented silicon steel RH refinement and deoxidation control method

InactiveCN101768653APrecise deoxygenation controlWide process applicabilityMolten steelOxygen content

The invention discloses a non-oriented silicon steel RH refinement and deoxidation control method. The method includes the following steps that firstly, the non-oriented silicon steel includes the following mass percent of smelted components: less than or equal to 0.005 percent of C, 0.25-2.5 percent of Si, 0.10-0.50 percent of Mn, less than or equal to 0.08 percent of P, less than or equal to 0.005 percent of Al, less than or equal to 0.008 percent of S, less than or equal to 0.003 percent of N, and the rest percent of Fe and unavoidable impurities; secondly, the smelted molten steel is processed by the RH refinement method and when the RH refinement begins, the molten steel temperature is higher than the melting point of steel by 60-150 DEG C and the carbon content of the molten steel is controlled within 0.02-0.06 percent which refers to mass percent; when decarbonization in RH refinement is ended, the free oxygen content in the molten steel is 250-550ppm; deep deoxidization is made after decarbonnization, and the input amount of the deoxidizing agent Y = K * (The oxygen concentration at the end of decarbonization (ppm)-50), wherein, the deoxidization agent is aluminum, silicoferrite or threadlike carbon. The invention has the advantages of reducing the impurity quantity in the steel, changing the morphology, realizing the deoxidized refinement control in the RH refinement process and improving the product performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for producing low-sulfur molten iron in one step by smelting and reducing copper slag

InactiveCN101824505ALower oxygen potentialReduce sulfur contentFluidised-bed furnacesMelting tankCyclone

The invention discloses a method for producing low-sulfur molten iron in one step by melting and reducing copper slag. The method is characterized in that the method includes the following processing steps that: the high-temperature molten copper slag is first reduced by reducing agent in a high-temperature reduction furnace, wherein, when the reduction reaction of iron is nearly finished, a certain amount of additive, which is theoretically calculated, is added in a melting bath based on the existing slag system in the reduction furnace, a jet gun is inserted into a slag-iron interface to blow carbon monoxide into the melting bath when the additive is completely molten, the blowing time is 30min to 40min, and desulphurization reaction is almost finished. The melting bath is kept still, and when slag and iron are completely separated, the high-temperature low-sulfur molten iron and the slag are respectively discharged out of a tap hole and a slag hole. In addition, after high-temperature flue gas passes through a secondary combustion chamber, a residual heat boiler recovers residual heat from the flue gas, dust is collected from the flue gas by cyclone, and the flue gas is washed. By sufficiently utilizing the high desulphurization of the refined slag and blowing the carbon monoxide, the invention solves the defect that the content of sulfur in the molten iron produced by melting and reducing the copper slag for ironmaking is high; the processing flow is short, the emission of pollutant is less, and moreover, the applicability is high.

Owner:KUNMING UNIV OF SCI & TECH

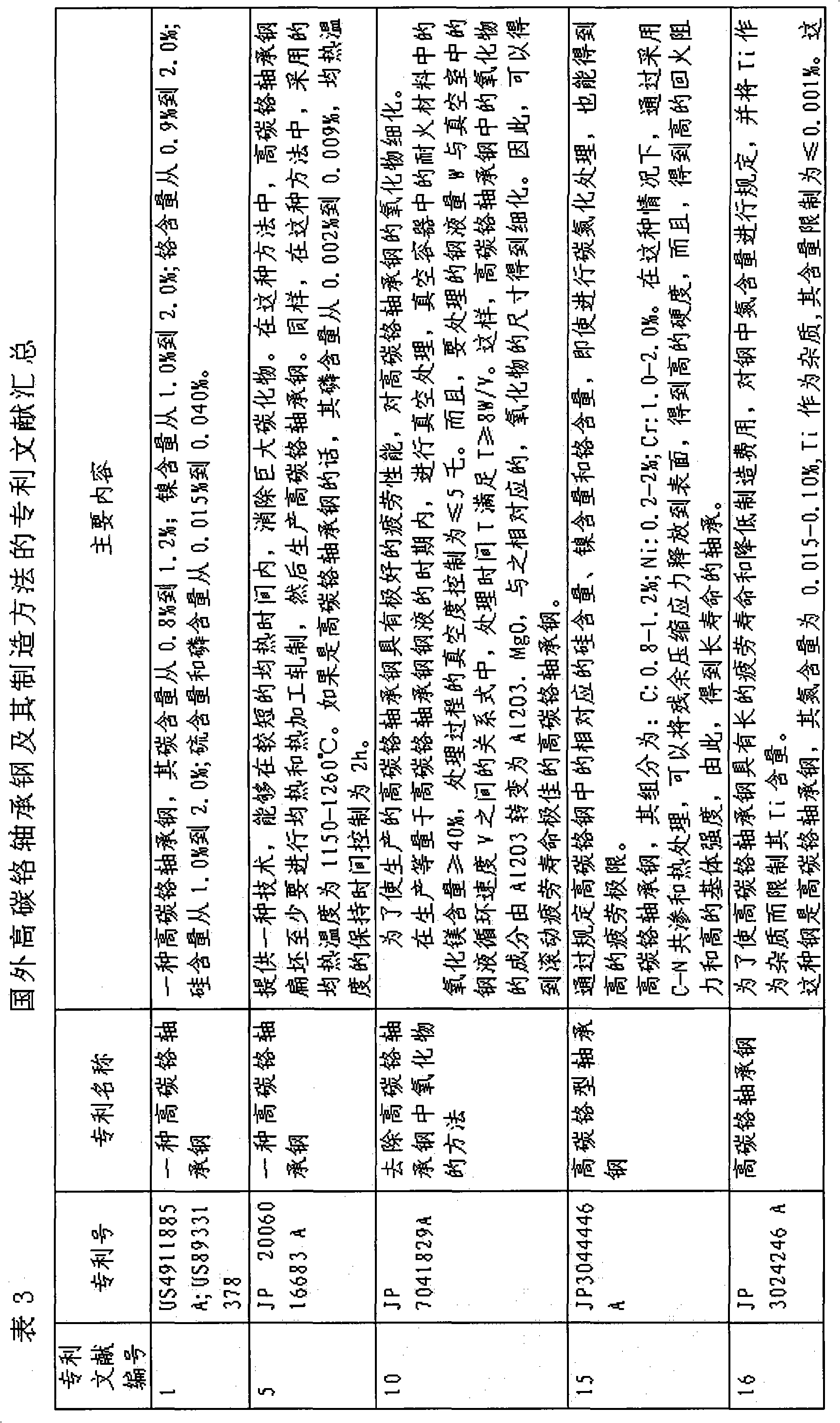

Technology for producing high-purity high-carbon high-chromium bearing steel

InactiveCN1369568AStrong equipmentStrong craftsmanshipElectric furnaceProcess efficiency improvementThermal energySlag

A process for preparing super-purity high-C high-Cr bearing steel includes smelting in electric furnace, intermittently flowing out oxidative slags while adding lime, inputting oxygen in molten steel, tapping in ladle while adding special slags, alloy, carbonizer and deoxidizing agent, blowing argon gas from bottom of ladle, refining for 40-60 min, vacuum treating for 20-35 min, and casting ingots. Its advantages are ultrahigh purity and low contents of oxygen and Cr.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

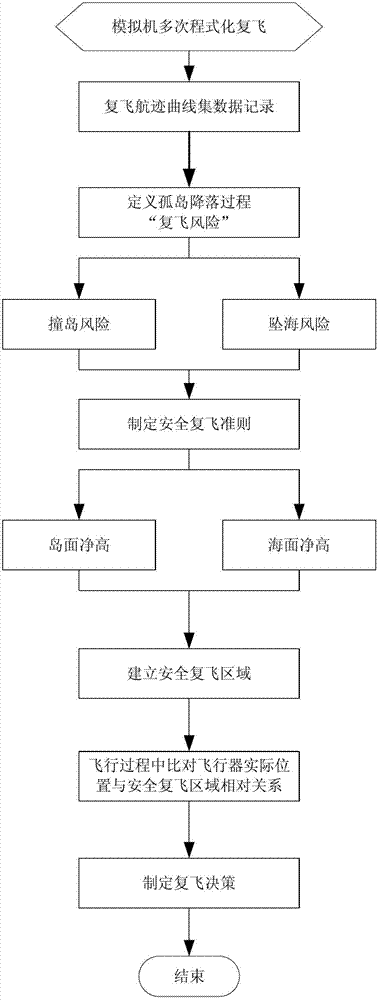

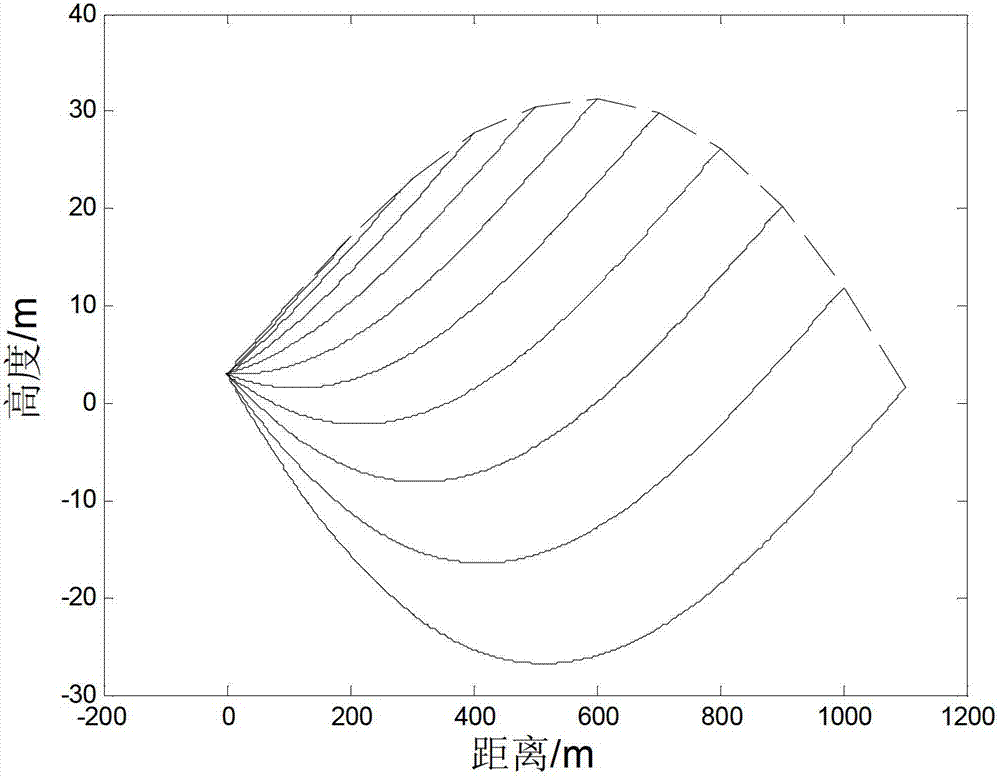

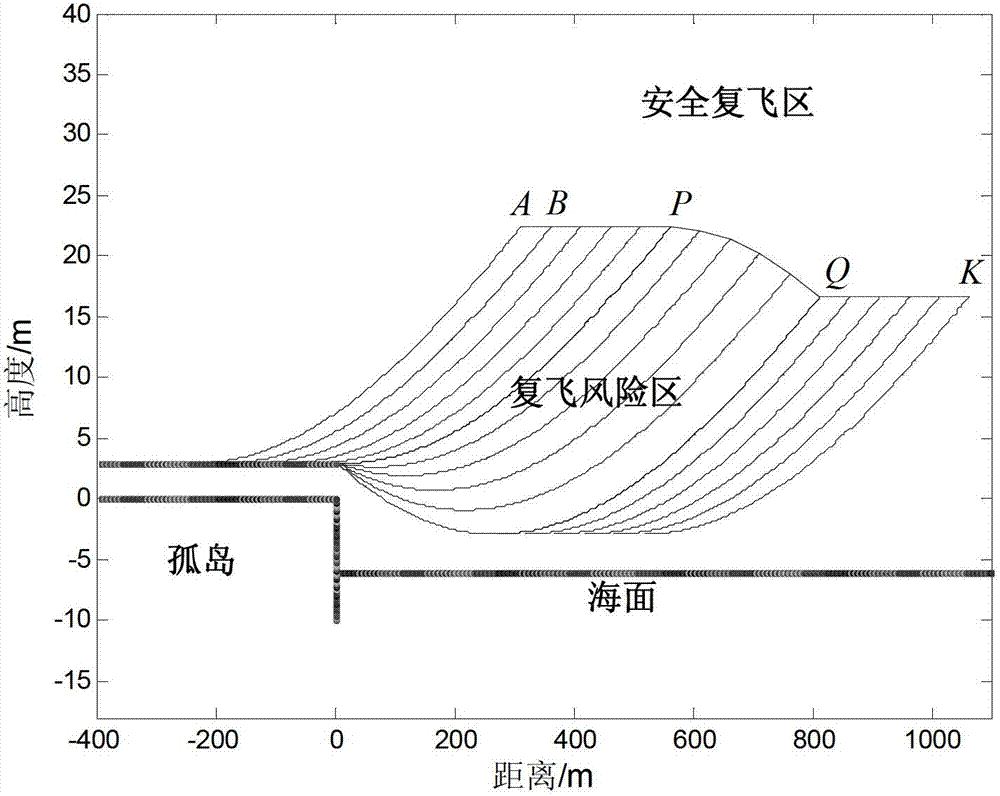

Aircraft islet landing wave-off decision method

ActiveCN102929284AWide process applicabilityRelieve the psychological pressure of go-aroundPosition/course control in three dimensionsAirplaneIslanding

The invention relates to an aircraft islet landing wave-off decision method, comprising the following steps: (1) establishing a wave-off flight path curve set; (2) establishing a wave-off safety region Ssafe and a wave-off risk region Srisk; (3) comparing airplane position information with a wave-off envelope curve; and (4) judging whether the current region of an aircraft has a wave-off risk or not. The invention firstly designs the wave-off decision method applicable to special flight maneuvering of islet landing; the adaptability of the process is wide and the wave-off risk measurement can be carried out aiming at any flight position of the aircraft; and reasonable references are provided for the wave-off maneuvering safety of the emergency condition of an islet landing process, so as to have effective helps to pilots to relieve psychological pressure and improve the wave-off safety.

Owner:HARBIN ENG UNIV

Plate burning process of precise screen

ActiveCN102736406AGood tangentHigh graphic precisionPhotomechanical apparatusExposure latitudePeak value

The present invention provides a plate burning process of a precise screen. The process employs a way of secondary exposure way to complete the film graphic transfer to the screen, and specifically comprises steps of: A) film production: first compensating the film, then adding composing and positioning to ensure a composing position deviation no more than 100 mum in a secondary plate burning of the screen; B) plate burning: carrying out composing and plate burning according to composing position required by printing, wherein the first plate burning energy set value is a minimum value of the exposure latitude, and the secondary plate burning energy value is set at a peak value of the optimum exposure. The method of the invention employs a parallel light plate burning machine to achieve clear text and effectively control edge jag and side virtual exposure; meanwhile, as the screen is treated with exposure for two times, the exposure energy is sufficient, and the pressrun of the screen film is improved.

Owner:昆山良品丝印器材有限公司

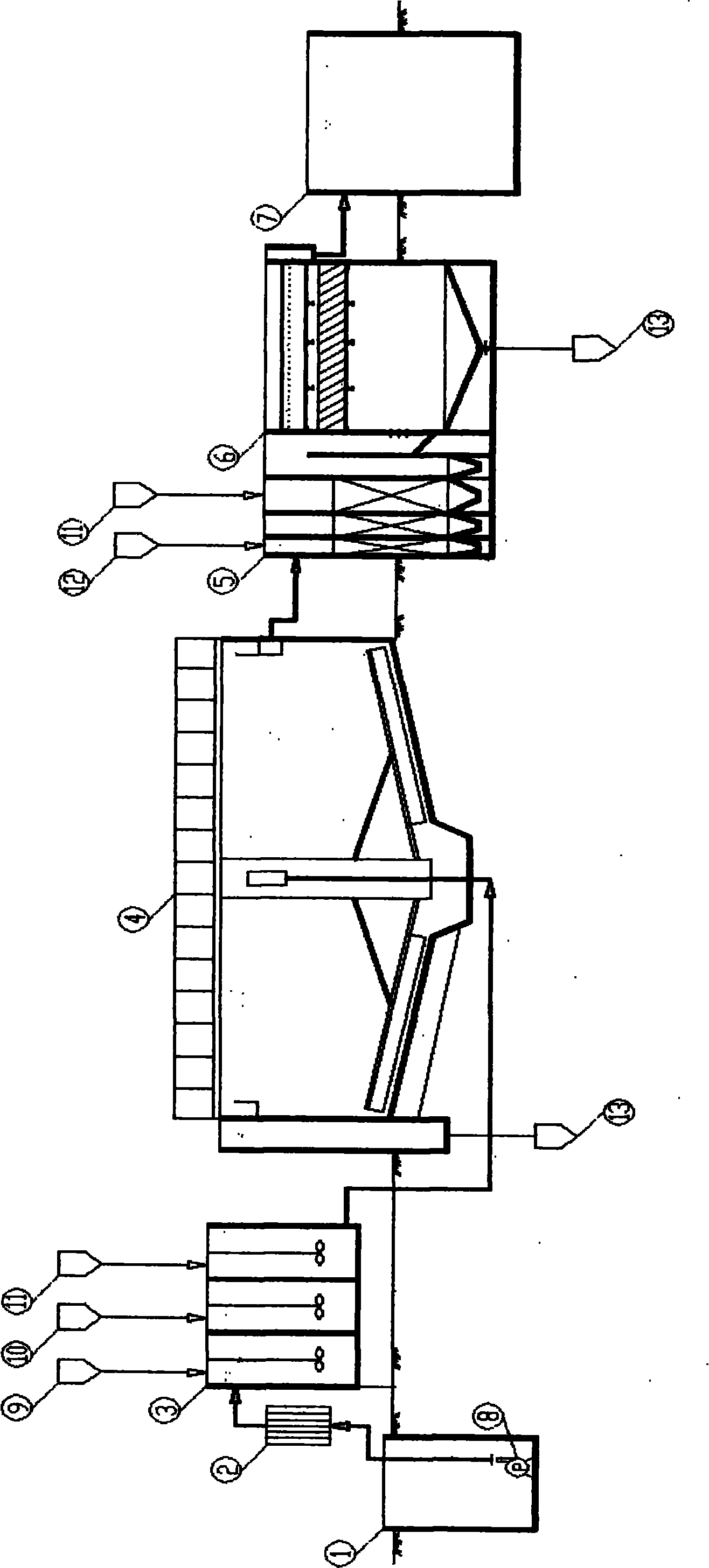

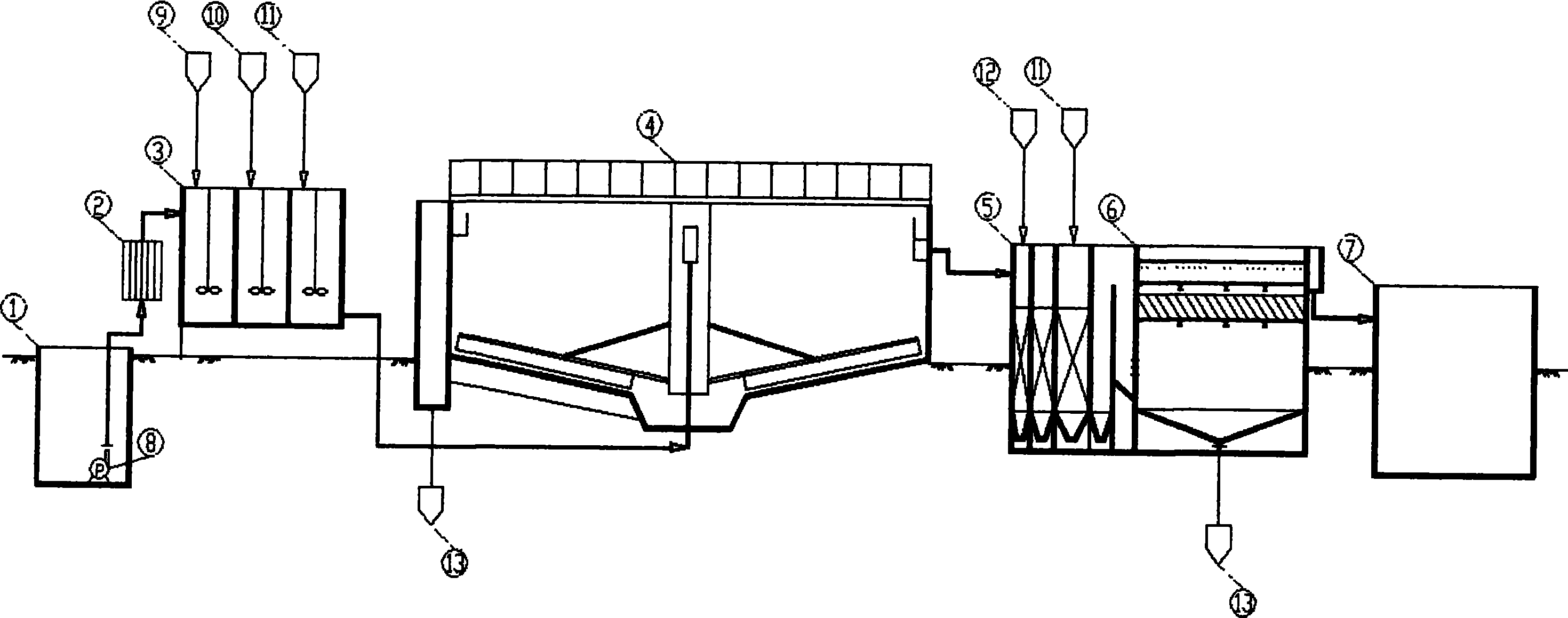

Method for co-pyrolysis of solid waste and coal

ActiveCN107057730ASolve resource problemsNo need for additional investmentProductsReagentsTarCo pyrolysis

The invention discloses a method for co-pyrolysis of solid waste and coal. The method comprises the following steps: mixing solid waste with coal metered, drying, heating, carrying out destructive distillation pyrolysis, so as to obtain solid-state pyrolysis product semi-coke and gas-state pyrolysis product coal gas containing tar gas; cooling and sieving the semicoke, so as to obtain semi-coke with different particle sizes; and carrying out oil-gas separation on coal gas containing tar gas, so as to obtain tar and coal gas, wherein partial coal gas is taken as a heat source for pyrolysis of mixed materials, and rest coal gas is taken as a coal gas product. According to the method, the co-pyrolysis of solid waste and coal is realized by virtue of a horizontal rotary kiln, and the semi-coke, tar oil and coal gas are obtained after the pyrolysis of the mixed materials in the rotary kiln at a certain temperature. The method has the beneficial effects that a technical process is simple, the operation is reliable and stable, the problem that coal gas produced by pyrolysis of solid waste is less than heat required by the pyrolysis of solid waste is solved, and the method has obvious superiority on the treatment of solid waste with great composition change.

Owner:西安三瑞实业有限公司

Method for preparing compound amino acid organic liquid fertilizer

ActiveCN101538179AIncrease valueImprove fertilizer efficiencyFood processingAnimal feeding stuffIndustrial waste waterFiltration

The invention provides a method for preparing a compound amino acid organic liquid fertilizer. The method takes cheap fermentation industrial waste water as raw material and carries out filtration, evaporation concentration, primary evaporation crystallization, second evaporation crystallization, cooling crystallization, standing, salting-out and other process steps, thereby obtaining the high-valued and high-fertilizer efficiency compound amino acid organic liquid fertilizer. The method does not occupy high-priced limited soybean meal, blood meal, starch, other acid and basic chemical medicaments and other resources and greatly reduces the product cost; meanwhile, water-insoluble substances produced by filtration during the process can be used as protein supplement feeds for ruminants, sulfate and amino acid organic solid fertilizers are good fertilizers, and the method leads the fermentation industrial waste water to be completely recovered and utilized, has wide range of applications and is not only suitable to be completed on a small-investment evaporator at normal pressure, but also suitable to be completed on an advanced energy-saving consumption-reducing vacuum evaporation crystallization device at negative pressure; furthermore, the method does not emit any substance to the outside and does not produce any pollution.

Owner:昆明隆祥化工有限公司

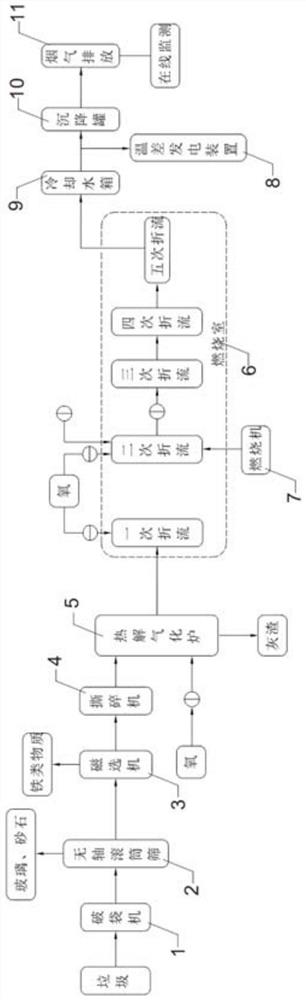

Waste paper pulping and papermaking advanced waste water treatment technique

InactiveCN101786758AImprove reaction speedIncrease responsivenessWater/sewage treatment by magnetic/electric fieldsMultistage water/sewage treatmentMagnetizationWastewater

The invention discloses a waste paper pulping and papermaking advanced waste water treatment technique, comprising the following steps of: waste water collection, magnetization, first-stage dosing reaction, first-stage precipitation, second-stage dosing reaction, second-stage precipitation and temporary storage of clear water. The technique has the advantages that (1) the technique is based on physicochemical technology, and the design is scientific and reasonable, so that good effect of advanced waste water treatment can be ensured; (2) the technique not only removes organic pollutant and chroma in the waste water with high efficiency, but also greatly reduces the hardness of the waster water and lays foundation for recycling the waste water; and (3) the technique has wide technical applicability and strong shock resistance capability.

Owner:SHANDONG ACAD OF ENVIRONMENTAL SCI

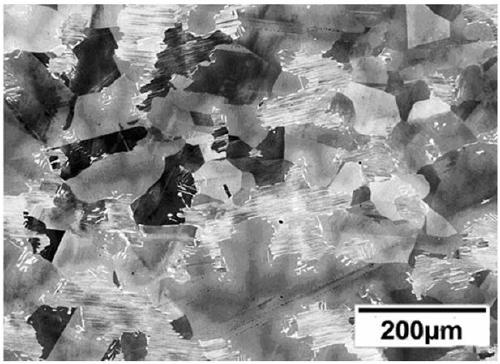

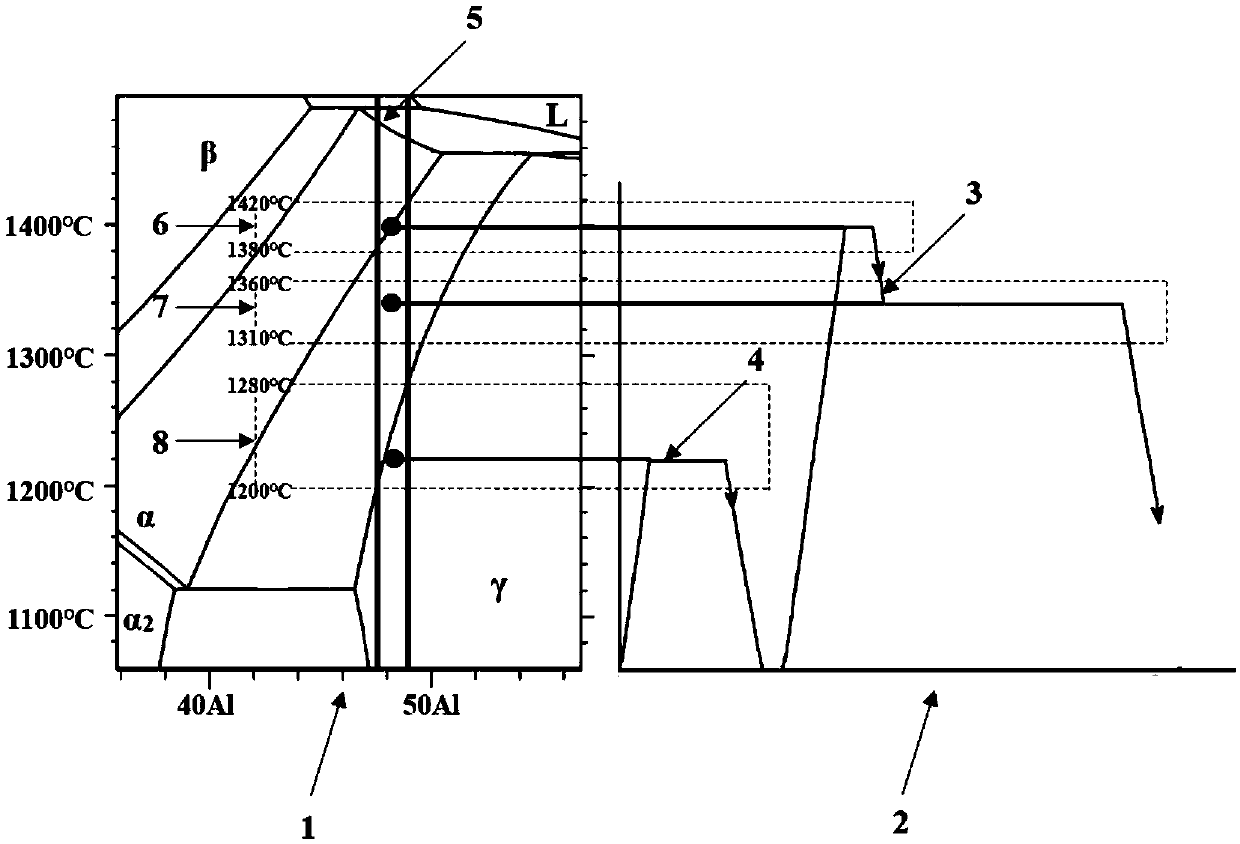

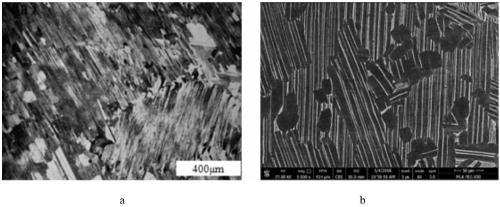

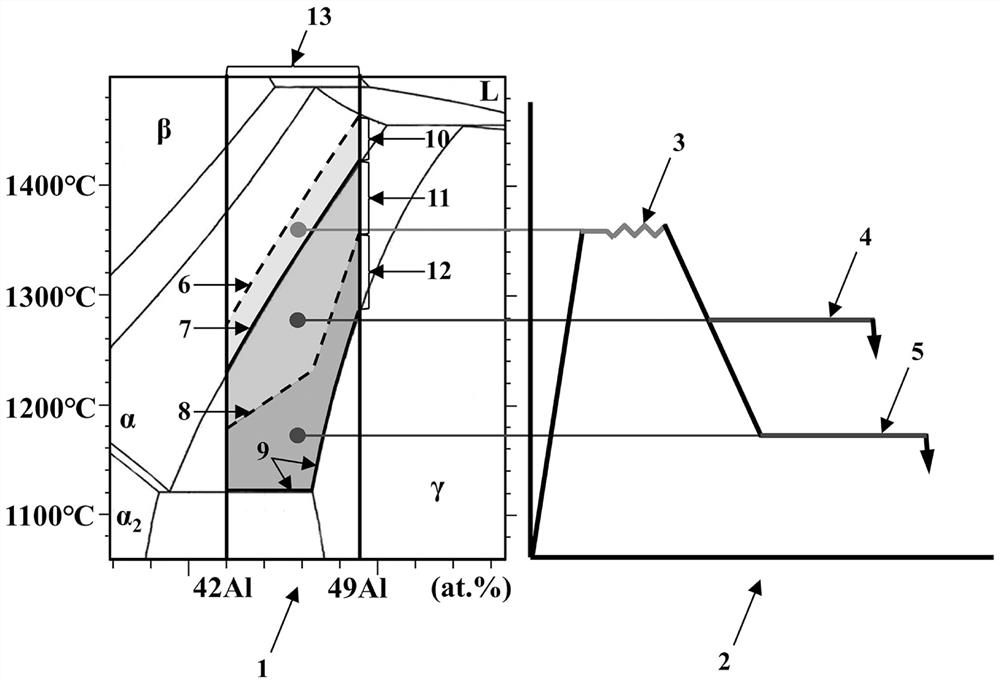

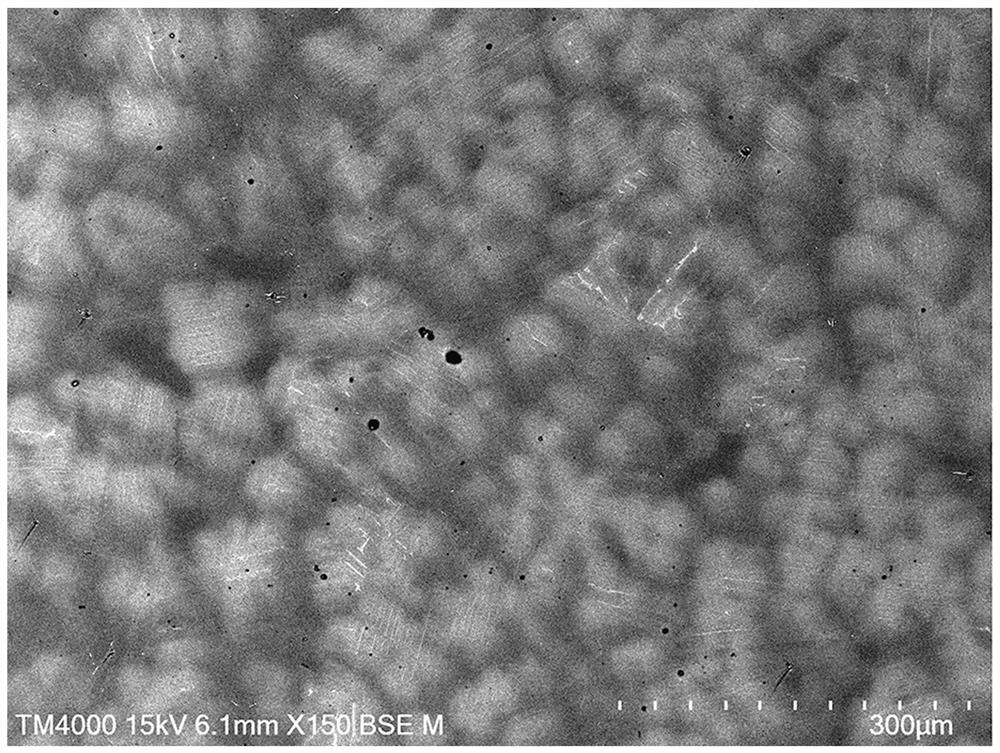

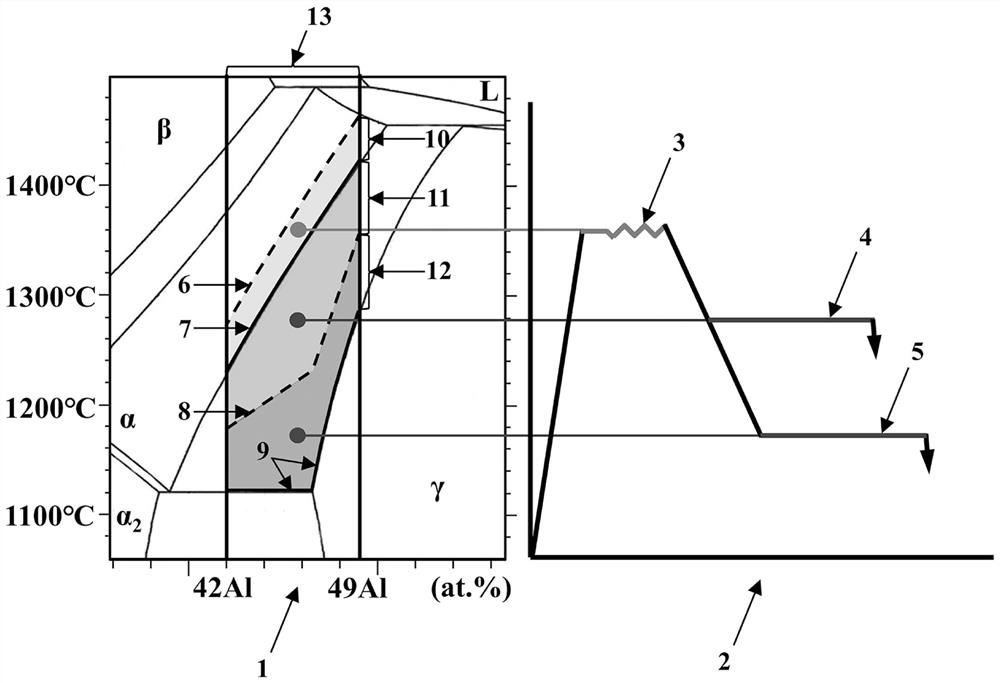

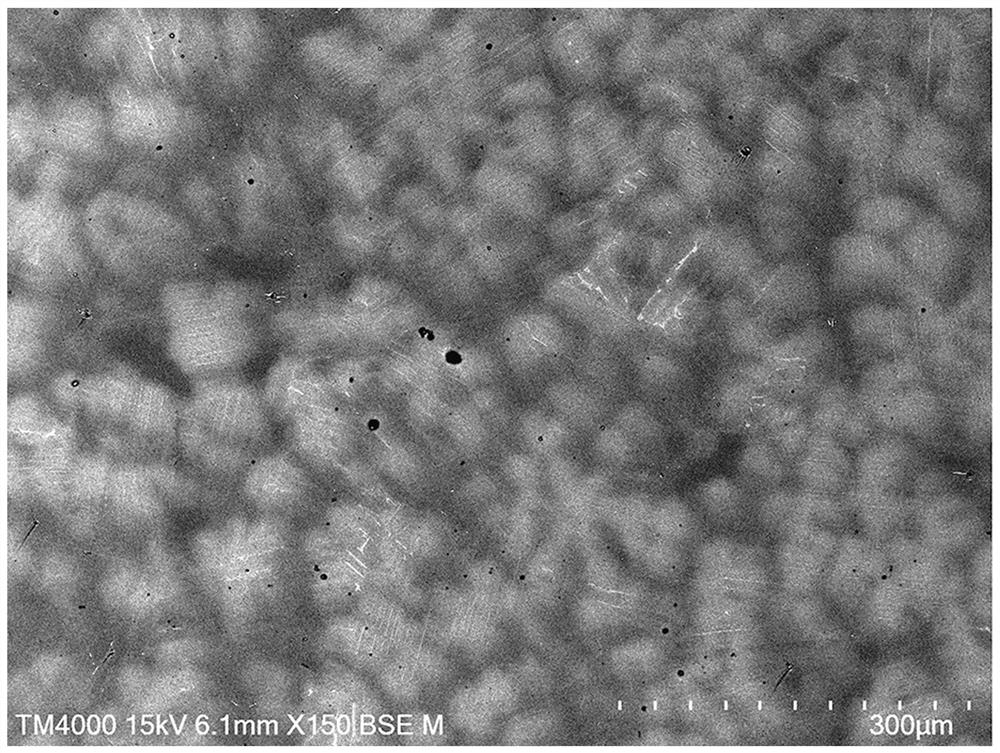

Heat treatment method for obtaining near-lamellar texture of peritectic casting TiAl alloy

The invention relates to a heat treatment method for obtaining a near-lamellar texture of a peritectic casting TiAl alloy. The near-lamellar texture of the peritectic casting TiAl alloy is obtained through hot isostatic pressure treatment, texture regulation and control heat treatment and stabilization heat treatment. According to the heat treatment method, the holding temperature, the holding time and the heating and cooling speed are controlled in the heat treatment process, control over the casting TiAl alloy texture having the peritectic solidification characteristic is achieved, the specific near-lamellar texture is obtained, and the shortcomings that in the prior art, a lamellar texture dissolves and degenerates so that original anisotropy can be lost, and poor influences and the long production period are caused by generation of stress and cracks due to quenching are overcome.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

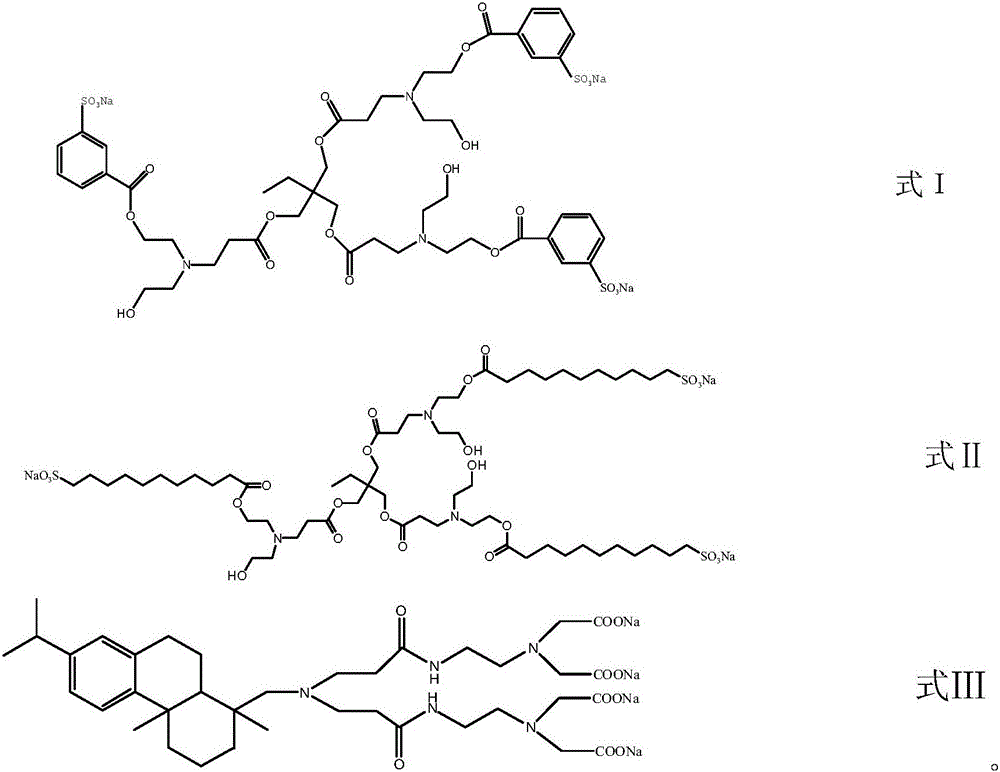

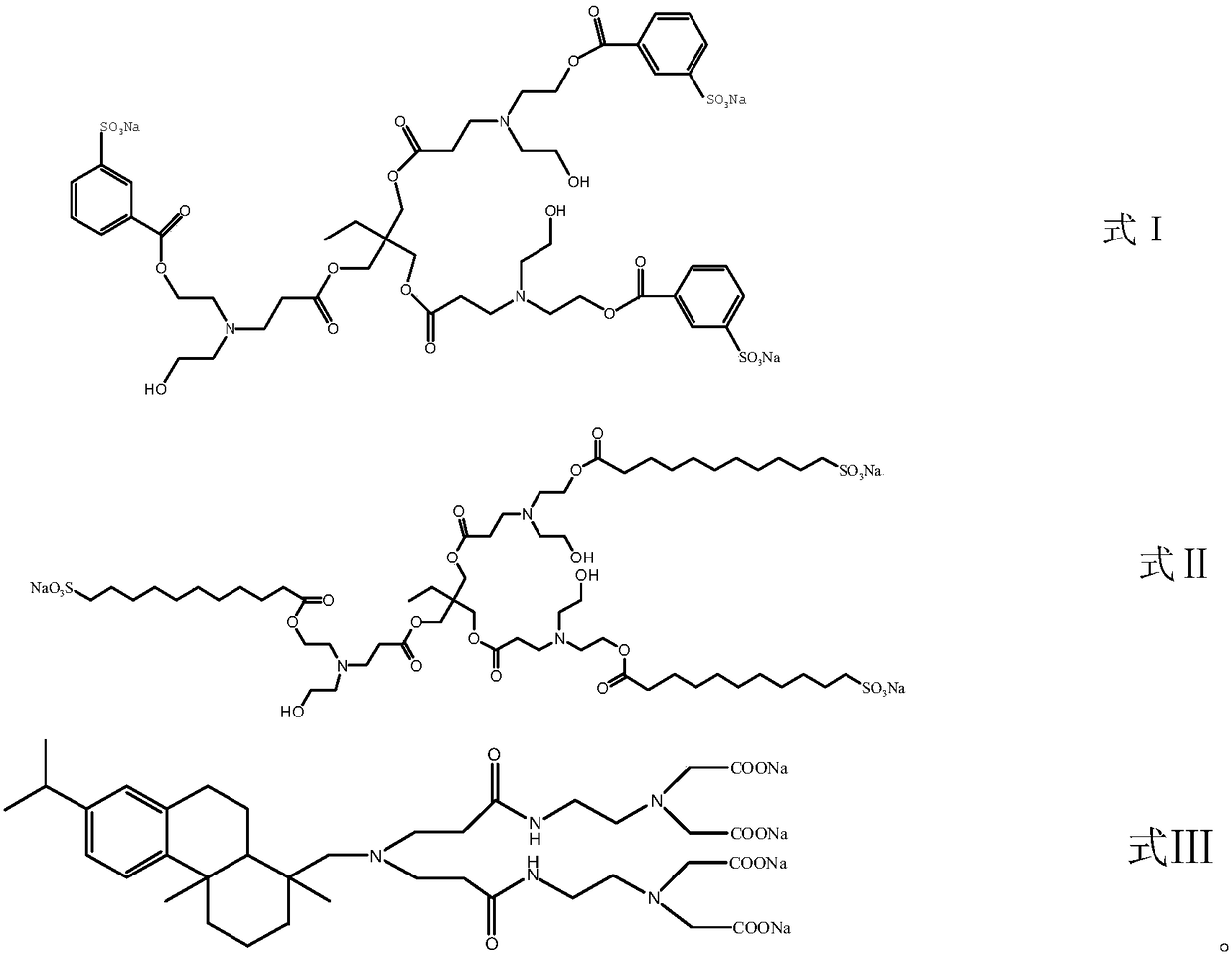

Continuous oxygen bleaching refining agent and preparation method thereof

The invention relates to a continuous oxygen bleaching refining agent and a preparation method thereof. The continuous oxygen bleaching refining agent comprises a rare-earth catalyst, a hydrogen peroxide stabilizer, biodegradable surfactant, Gemini surfactant, hyperbranched surfactant and water. Compared with a conventional refining agent, the continuous oxygen bleaching refining agent has the advantages that the continuous oxygen bleaching refining agent is efficient and environmental friendly and wide in process applicability, the NaOH use amount is lowered by about 40%, the COD value of discharged wastewater is lowered by more than 40%, and the whiteness, capillary effect and breaking strength of fabric treated by the continuous oxygen bleaching refining agent are evidently better.

Owner:SHANGHAI ARGUS NEW MATERIAL CO LTD

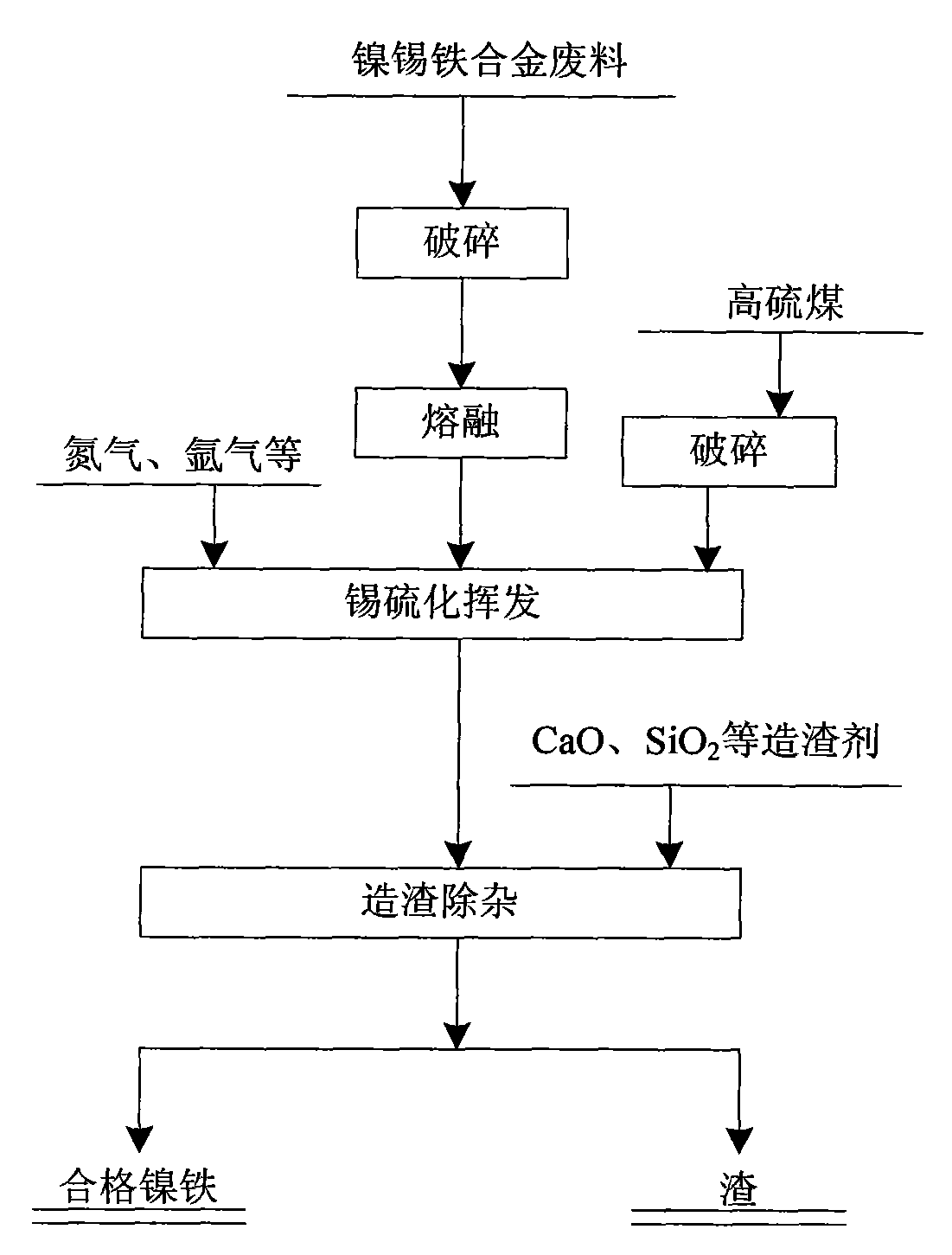

Method for Ni-Fe alloy production and Sn recovery from Ni-Sn ferroalloy scrap by high-sulfur coal sulfuration volatilization and oxidation slagging

InactiveCN104232904ARealize waste treatmentWide process applicabilityProcess efficiency improvementMolten stateMelting tank

The invention discloses a method for Ni-Fe alloy production and Sn recovery from Ni-Sn ferroalloy scrap by high-sulfur coal sulfuration volatilization and oxidation slagging. The method is characterized by comprising the process steps as follows: the Ni-Sn ferroalloy scrap is crushed to certain blockness, transferred into an intermediate frequency furnace or an electric furnace and then heated to certain temperature, a nitrogen gas spray gun is inserted into a molten pool for stirring after the material is in a molten state, and the high-sulfur coal is crushed to certain granularity and sprayed into the molten pool for a sulfuration volatilization reaction of Sn in the material; after the sulfuration reaction is finished, the high-sulfur coal is stopped from being sprayed into the furnace, certain slagging constituent is added into the molten pool for Ni-Fe liquid purification, and certain alkalinity of the molten pool is controlled in the process; after certain period, slag and Fe are completely separated, produced Ni-Fe liquid and slag are discharged from a Fe outlet and a slag outlet respectively, and resources including Ni, Fe and Sn are recovered effectively in the process. According to the method, the characteristic of high sulphur content of the high-sulfur coal is sufficiently utilized for Sn sulfidation treatment of the Ni-Sn ferroalloy scrap, the resources including Ni, Fe and Sn are recovered effectively, waste is treated by waste, the technological process is simple to operate, the production cost is lower, and broader industrial prospect is provided.

Owner:GLOBE FUTURE BEIJING TECH DEV CO LTD

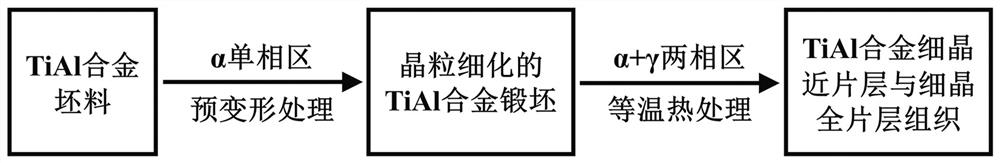

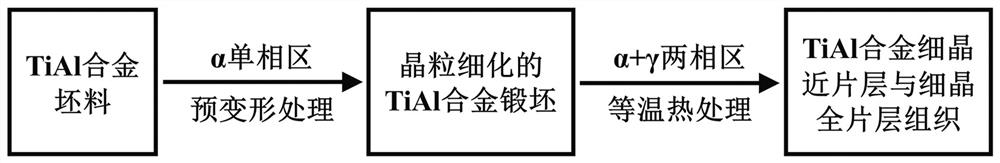

Thermo-mechanical treatment method for controlling TiAl alloy fine grain structure

ActiveCN112048690AEnables fine-tuned controlReduce deformation resistanceTemperature controlHot working

The invention discloses a thermo-mechanical treatment method for controlling a TiAl alloy fine grain structure, and relates to the technical field of hot working preparation of high-temperature structural materials. The thermo-mechanical treatment method is used for obtaining TiAl alloy fine grain near-lamellar structure and a fine grain full-lamella structure through combined use of pre-deformation treatment and isothermal thermal treatment means, a TiAl alloy blank is placed into a box-type heat treatment furnace, pre-heat-preservation is conducted, pre-deformation treatment is completed, then isothermal heat treatment is conducted, and the TiAl alloy fine grain structure is obtained. According to the thermo-mechanical treatment method, the thermo-mechanical treatment process with accurate temperature control is adopted, according to accurate analysis of the two-phase temperature interval range and accurate design and control of the deformation amount, the deformation rate and the heat preservation temperature in the deformation heat treatment process, accurate adjustment and control over the TiAl alloy structure can be achieved, and the fine grain near-lamellar structure and thefine grain full-lamellar structure are obtained.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

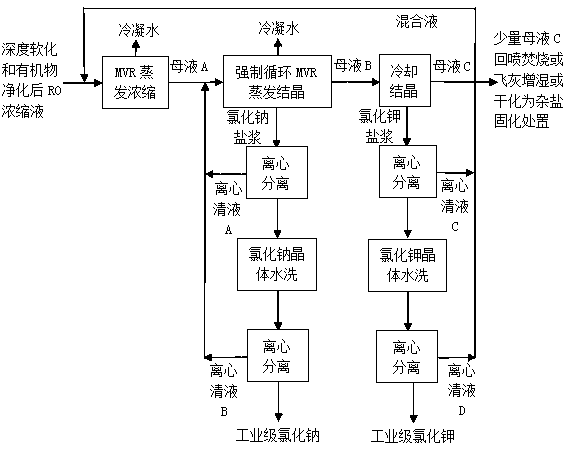

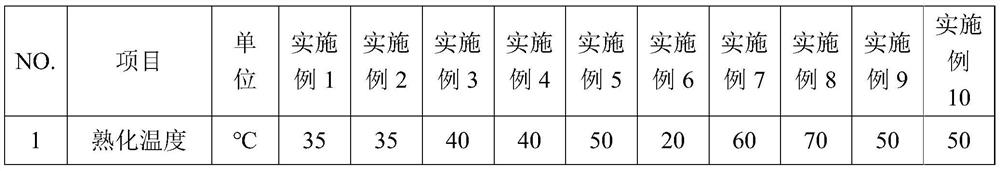

Landfill leachate RO concentrated solution evaporation, concentration and staged crystallization method

ActiveCN111056682AAchieving processing powerImplement resourcesWater/sewage treatment by centrifugal separationWater contaminantsEnvironmental engineeringOrganic matter

The invention belongs to the technical field of landfill leachate treatment, and particularly relates to a landfill leachate RO concentrated solution evaporation, concentration and staged crystallization method. The method comprises steps of: evaporating and concentrating the RO concentrated solution subjected to deep softening and organic matter purification pretreatment through an MVR evaporator, carrying out evaporative crystallization by using a forced circulation MVR evaporator, washing and drying the crystal to obtain industrial-grade sodium chloride, further cooling and crystallizing the crystallization mother liquor, and washing and drying the obtained crystal to obtain industrial-grade potassium chloride. According to the method, the MVR evaporator, the forced circulation MVR evaporator and the cooling crystallizer are adopted to carry out evaporation, concentration, staged crystallization, washing and purification on a pretreated RO concentrated solution; sodium chloride andpotassium chloride industrial salt products are obtained in a staged mode by respectively controlling process conditions such as evaporation, concentration, staged crystallization and the like, and condensed water is recycled as circulating cooling water, so that total treatment and resource utilization of RO concentrated solution are achieved. The method is effective, economical, simple, wide inadaptability and stable in operation.

Owner:FUZHOU UNIV

Epoxy resin composition capable of being quickly thickened and fiber reinforced composite material semi-cured material thereof

The invention discloses an epoxy resin composition capable of rapid thickening and a fiber reinforced composite material semi-cured material thereof, the epoxy resin composition is composed of rapid curing epoxy resin and an epoxy thickening agent containing active hydrogen, and the initial viscosity of the epoxy resin composition capable of rapid thickening at 25 DEG C is 5-100 Pa.s. The epoxy resin is low in viscosity and beneficial to infiltration of reinforced fibers, amino reactive hydrogen of an epoxy thickener and epoxy functional groups are subjected to a rapid cross-linking reaction at the temperature of 20-70 DEG C for thickening, the viscosity is 2,000-500,000 Pa.s at the temperature of 25 DEG C after thickening, and the epoxy resin fiber reinforced composite semi-cured materialstable in storage is formed. The invention also discloses a fiber reinforced composite material semi-cured material such as a chopped fiber sheet molding compound, a chopped fiber felt prepreg, a continuous fiber or fabric prepreg and the like, which is prepared by infiltrating a plurality of reinforced fibers into the epoxy resin composition and carrying out a thickening reaction at 20-70 DEG Cfor 1-200 hours.

Owner:ADESSO ADVANCED MATERIALS WUXI CO LTD

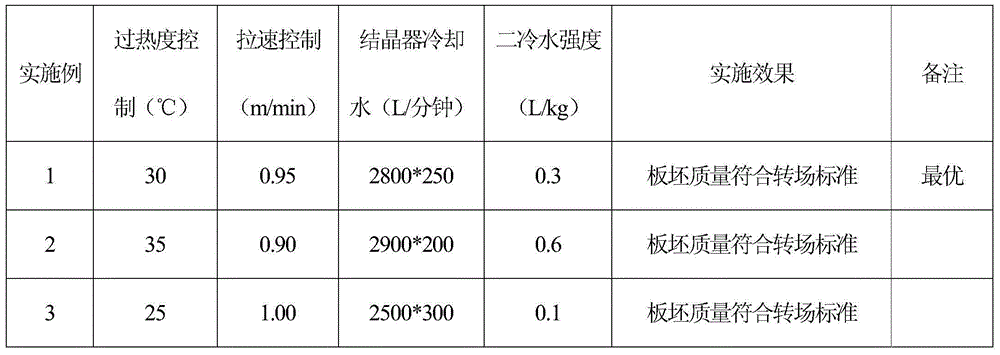

Slab continuous casting manufacturing method for medium-manganese wear-resistant steel

The invention provides a slab continuous casting manufacturing method for medium-manganese wear-resistant steel. The slab continuous casting manufacturing method mainly comprises the electric furnace primary smelting process, the ladle furnace refining process and the continuous casting process, wherein in the steel ladle furnace refining process, argon stirring is carried out before the crane ladle operation of the refining furnace, the stirring area is better to be greater than 40% of the area of a liquid steel surface, the stirring time needs to be longer than 5 min, the standing time after stirring can be longer than 5 min, 2.5-3.75 m / t of a silicon calcium line is fed in, and the crane ladle operation is conducted when the standing time is longer than 3 min; the degree of superheating of a steel liquid inside a tundish is controlled within 25-32 DEG C; the intensity of secondary cooling is controlled within 0.1-0.6 L / kg; meanwhile, the continuous casting speed is controlled. The slab continuous casting manufacturing method is suitable for medium-manganese wear-resistant steel, can effectively reduce the longitudinal crack defect of the medium-manganese wear-resistant steel, the obtained manganese amount is controlled within 6-9% (lower than 13% of high manganese wear-resistant steel), is mainly applied in the industries of coal machines and the like, and is good in processing performance, high in wearing resistance and low in cost meanwhile.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

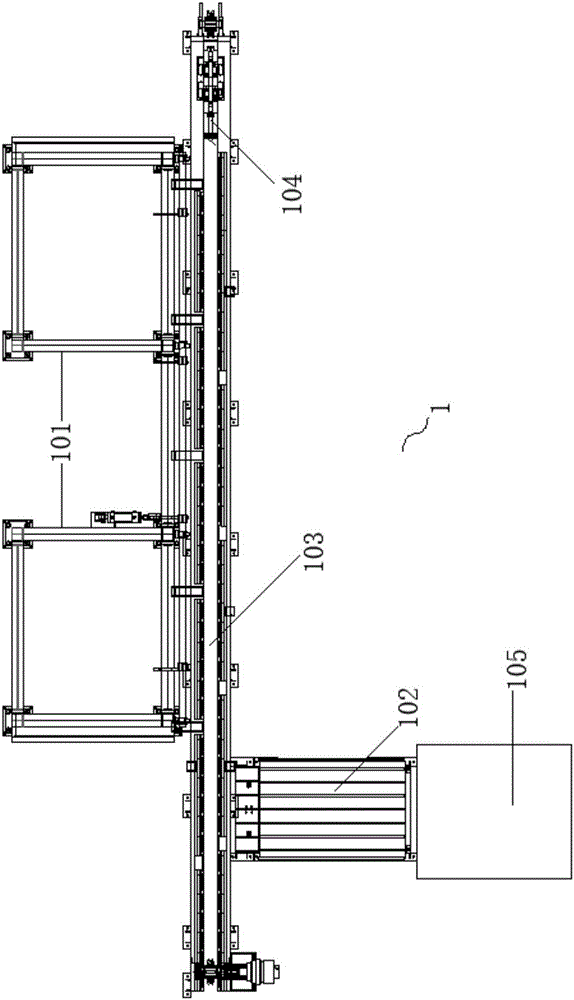

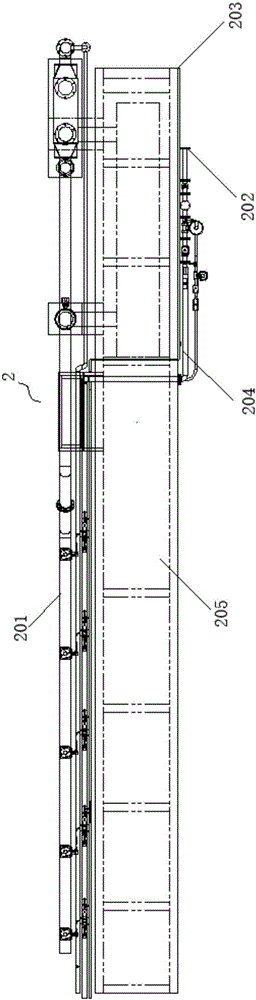

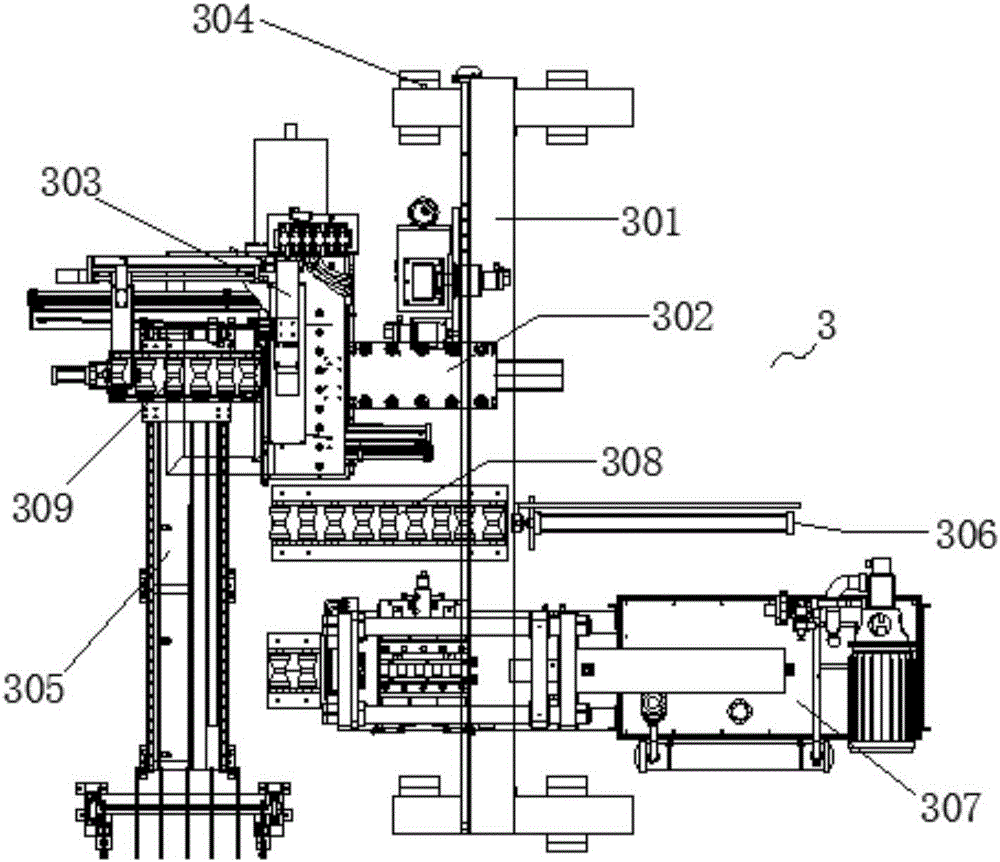

Fuel gas type universal rapid aluminum bar heating system for long bars and short bars

InactiveCN105728490AQuick changeHigh degree of mechanizationOther manufacturing equipments/toolsAlloyEngineering

The invention relates to the technical field of aluminum bar heating, in particular to a fuel gas type universal rapid aluminum bar heating system for long bars and short bars. The fuel gas type universal rapid aluminum bar heating system comprises a feeding unit, a heating unit and a peeling and shearing unit. The feeding unit, the heating unit and the peeling and shearing unit are sequentially connected through a conveying roller way. The peeling and shearing unit comprises a power aluminum bar conveying roller way. The other end of the power aluminum bar conveying roller way is connected with a hot shearing machine. A short bar conveying mechanism is connected beside the hot shearing machine. A hot peeling machine is arranged beside the power aluminum bar conveying roller way. A short bar pushing mechanism is arranged between the hot peeling machine and the power aluminum bar conveying roller way. A three-station gantry manipulator is arranged above the power aluminum bar conveying roller way, the hot peeling machine and the short bar pushing mechanism. By the adoption of the structure, the fuel gas type universal rapid aluminum bar heating system for long bars and short bars is high in mechanization degree and low in labor intensity; long bars and short bars can be replaced rapidly, energy consumption is low, the technological applicability is high, the fuel gas type universal rapid aluminum bar heating system is particularly suitable for production of various types of aluminum alloy and industrial aluminum products of various specifications and lengths, and the production yield is high.

Owner:JIANGSU YIHE NEW MATERIALS CO LTD

Innocent treatment device for domestic waste and method

ActiveCN112161273AReduce generationImprove resource utilizationIncinerator apparatusGenerators/motorsCombustion chamberFlue gas

The invention discloses an innocent treatment device for domestic waste and a method. The device comprises a bag breaking machine, a shaftless drum screen, a magnetic separator and a shredder, whereinthe shredder is connected to a stock bin of a pyrolysis gasification furnace, the pyrolysis gasification furnace is connected to a high-temperature combustion chamber, the high-temperature combustionchamber is connected to a cooling water tank, the cooling water tank is connected to a settling tank through a draft fan and a connecting pipeline, a thermoelectric generation device is arranged on the connecting pipeline, and the settling tank is connected to a flue gas emission device; and the innocent treatment device for the domestic waste further comprises a control device, and temperature sensors and pressure sensors are arranged at all positions. The invention further comprises a method for conducting innocent treatment on the biochemical waste by adopting the device. According to thedevice and the method, the innocent, reducing and recycling treatment of the domestic waste can be achieved, the power generation utilization is conducted, the finally-effluent flue gas can reach theemission standard, and the problems that an existing waste treatment method is large in environmental pollution, low in resource utilization rate, high in treatment cost and the like are effectively solved.

Owner:四川明日得投资管理咨询有限责任公司

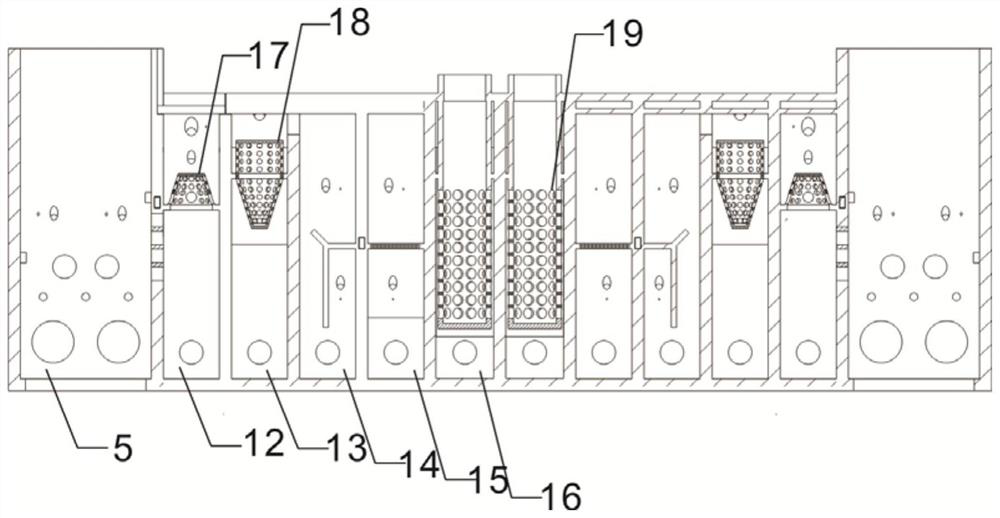

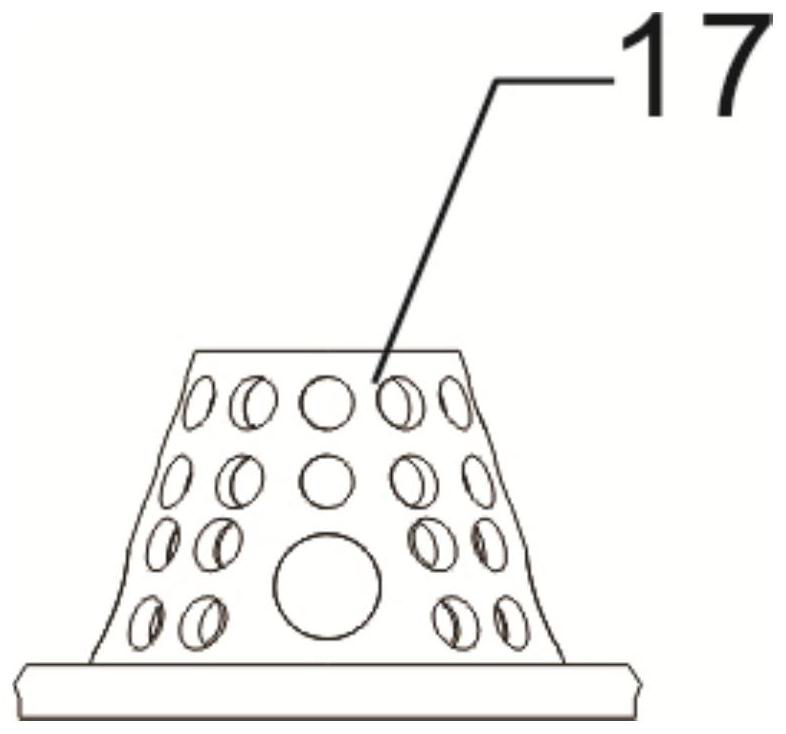

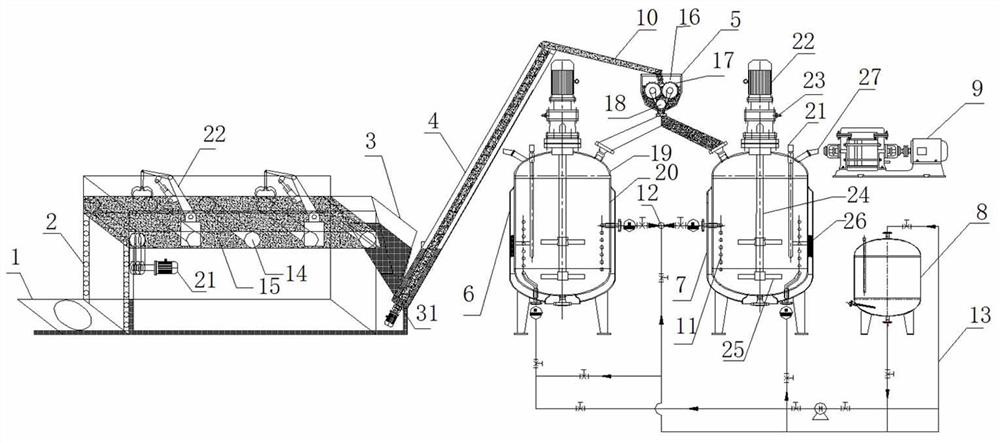

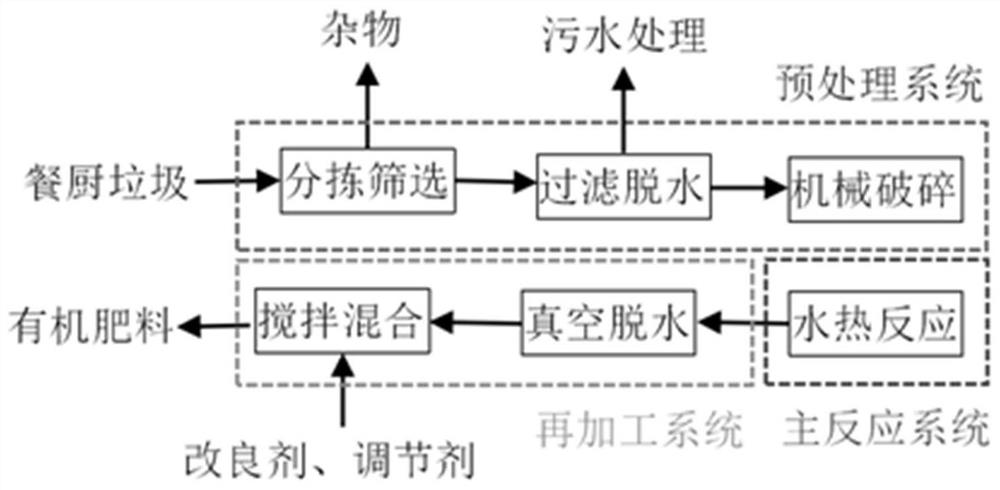

Device and process method for preparing fertilizers by using kitchen waste

PendingCN112047763AMeet the requirements of harmless processingRealize resource utilization goalsClimate change adaptationChemical/physical/physico-chemical stationary reactorsProcess engineeringWaste treatment

The invention discloses a device and process method for preparing fertilizers by using kitchen waste. The device comprises a pretreatment system, a main reaction system and a reprocessing system, thepretreatment system comprises a lifting table, a sorting table, a storage funnel, a spiral conveyor and a crushing device, and the main reaction system comprises a first reaction kettle, a second reaction kettle and an electric heating oil guide tank; the reprocessing system comprises a water ring type vacuum pump, a storage hopper is fixedly connected with the sorting table, a spiral conveyor iscommunicated with the storage hopper, the discharging end of the spiral conveyor communicates with a crushing device through a discharging pipeline, and the discharging end of the crushing device communicates with feeding openings of the first reaction kettle and the second reaction kettle. heat conduction coil pipes are arranged in the first reaction kettle and the second reaction kettle, the heat conduction coil pipes communicate with an electric heating oil guide tank in parallel through a three-way enamel valve and a heat conduction pipeline, and the first reaction kettle and the second reaction kettle communicate with a water ring vacuum pump; the invention is high in integration and automation degree, and can effectively meet regional centralized kitchen waste treatment.

Owner:HENAN POLYTECHNIC UNIV

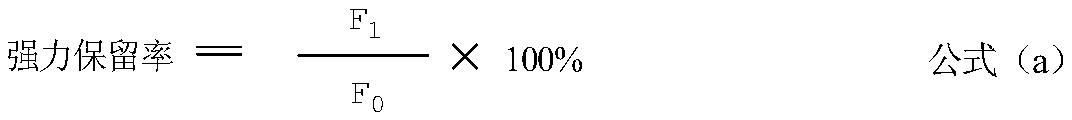

Self-repairing coating system

ActiveCN108929625AHigh mechanical strengthIncreased durabilityConjugated diene hydrocarbon coatingsPolyurea/polyurethane coatingsPolyesterCoating system

The invention belongs to the technical field of protection. An elastomer, which is prepared through co-curing between styrene-acrylate copolymer that contains hydroxyl groups and is well compatible with fuel oil and polyester and / or polyurethane, is taken as the middle coating. Through resilience and oil-absorbing swelling, holes can be rapidly blocked. The invention relates to a self-repairing coating system, which has a multi-coating composite structure and at least comprises a middle coating and a polyurethane elastomer / polyurea outer coating. The middle coating is a hydroxyl-containing styrene-acrylate copolymer-polyurethane elastomer, the styrene accounts for 6.5 to 25.2 wt.% of the hydroxyl-containing styrene-acrylate copolymer, and the thickness of the middle coating is not less than 1.5 mm. The provided self-repairing coating system has good mechanical properties, is convenient to construct, has the advantages of wide application range, quick blocking speed, good effect, and high strength maintaining rate, can be used to block holes or cracks of an oil storing container in time, and is especially suitable for preventing the leakage, when a fuel oil container is broken downor a crack or hole appears in the interior of a high pressure oil storage container.

Owner:SHANDONG NON METALLIC MATERIAL RES INST

Production process of A2-grade fireproof insulation board

InactiveCN109927320AImprove performanceWide process applicabilityHeat proofingFire proofingThermal insulation

The invention discloses a production process of an A2-grade fireproof thermal insulation board. The production process is characterized in that a formed insulation board is used as a substrate, and then a flame retardant material is uniformly sucked into or filled into or injected into the insulation board to obtain the A2-grade fireproof insulation board. According to the production process, an original non-flame-retardant insulation board is converted into an EPS board which can achieve the A2-grade fireproof effect. The using performance of the insulation board is improved to a great extent, and meanwhile, the problem of the presence of the non-flame-retardant insulation boards on the market is solved, so that the insulation board can be better applied to the building field. The production process has relatively wide process applicability and a good flame retardant effect and can meet the A2-grade fireproof grade requirements.

Owner:镇江兴谦新材料技术有限公司

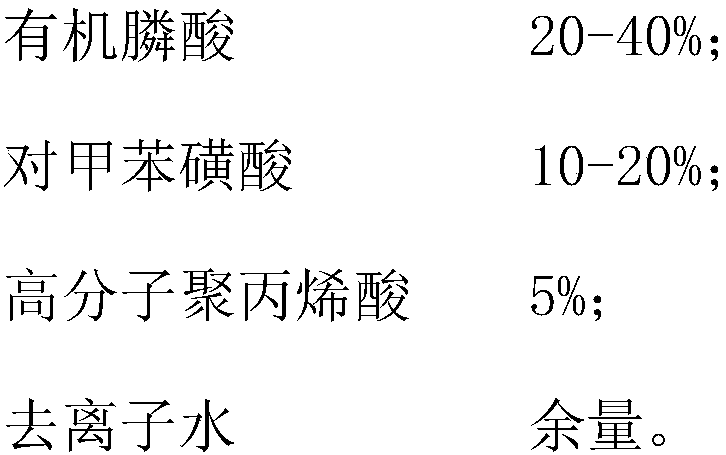

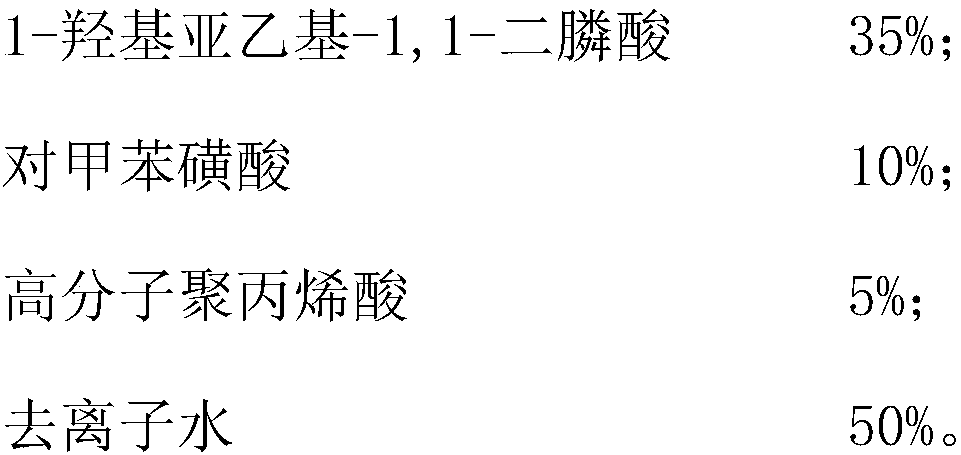

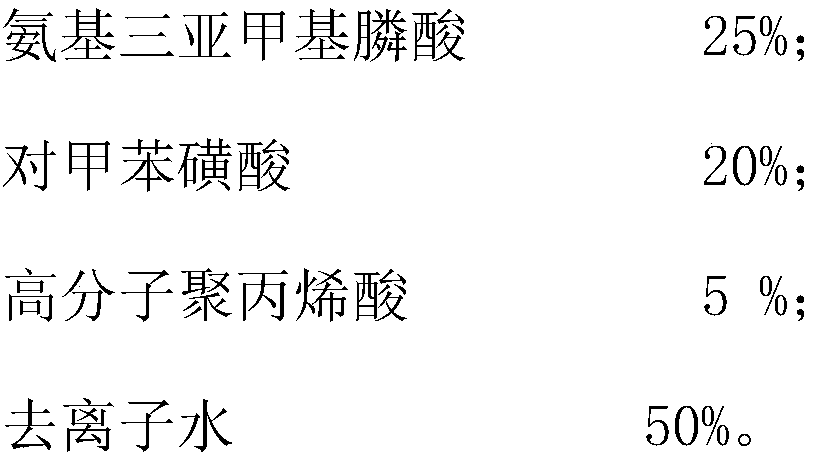

Modal fiber napping splitting agent with skin-core structure and preparation method of modal fiber napping splitting agent

The invention relates to a splitting agent and a preparation method thereof and discloses a modal fiber napping splitting agent with a skin-core structure and a preparation method of the modal fiber napping splitting agent. The modal fiber napping splitting agent with the skin-core structure is prepared from components in percentage by mass as follows: 20%-40% of organic phosphonic acid, 10%-20% of p-toluenesulfonic acid, 5% of polymeric polyacrylic acid and the balance of deionized water. The modal fiber napping splitting agent has the advantages and effects as follows: not only can the napping splitting purpose be achieved, but also little influence is produced on strength of fabric, and a machine cylinder cannot be damaged.

Owner:绍兴海成化工有限公司

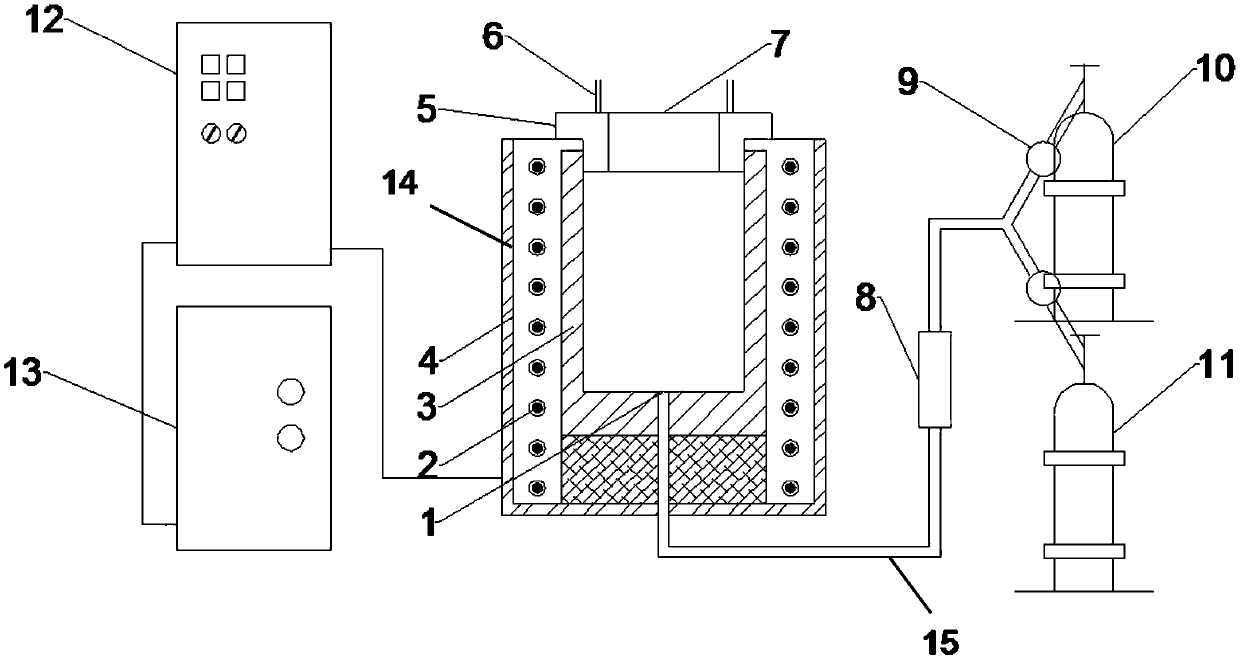

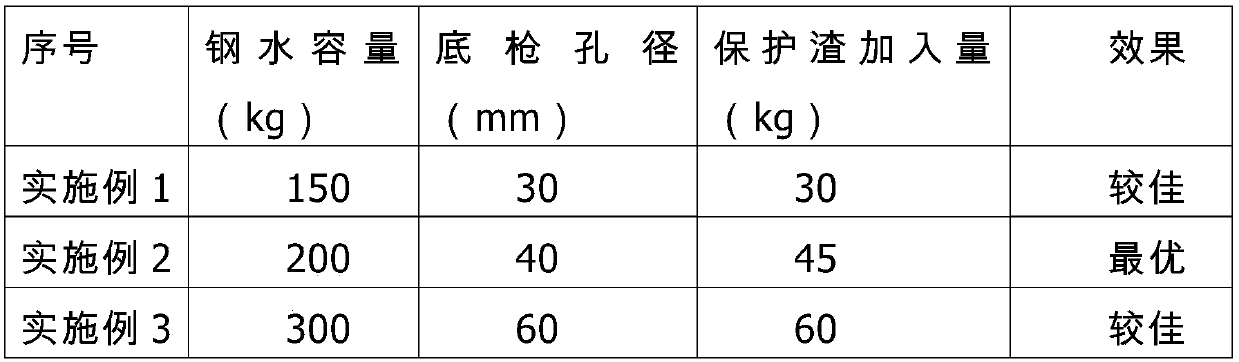

Slag-metal reaction simulation test device and method for continuous casting crystallizer covering slag

The invention discloses a slag-metal reaction simulation test device for continuous casting crystallizer covering slag. The device comprises a medium-frequency induction furnace and a bottom blowing device. The medium-frequency induction furnace comprises a graphite crucible, a furnace shell, an induction coil and a furnace cover. The furnace shell is arranged outside the graphite crucible, the induction coil is arranged between the graphite crucible and the furnace shell and arranged on the graphite crucible in a sleeving mode, and a feeding port is formed in the furnace cover and covers thetop of the graphite crucible; the bottom blowing device comprises a bottom gun and a protective gas source which are introduced into the bottom of the graphite crucible, and the bottom gun is externally connected to the protective gas source through a protective gas blowing pipe. The invention also discloses a simulation test method which can provide dynamic slag-metal reaction and can simulate continuous TiN precipitation and simulate the slag-metal reaction degree in production under the condition of continuous steel casting by switching a bottom blowing N method, thereby more accurately judging whether the crystallizer casting powder is applicable or not.

Owner:宝武特种冶金有限公司

Method for preparing compound amino acid organic liquid fertilizer

ActiveCN101538179BIncrease valueImprove fertilizer efficiencyFood processingAnimal feeding stuffIndustrial waste waterFiltration

The invention provides a method for preparing a compound amino acid organic liquid fertilizer. The method takes cheap fermentation industrial waste water as raw material and carries out filtration, evaporation concentration, primary evaporation crystallization, second evaporation crystallization, cooling crystallization, standing, salting-out and other process steps, thereby obtaining the high-valued and high-fertilizer efficiency compound amino acid organic liquid fertilizer. The method does not occupy high-priced limited soybean meal, blood meal, starch, other acid and basic chemical medicaments and other resources and greatly reduces the product cost; meanwhile, water-insoluble substances produced by filtration during the process can be used as protein supplement feeds for ruminants, sulfate and amino acid organic solid fertilizers are good fertilizers, and the method leads the fermentation industrial waste water to be completely recovered and utilized, has wide range of applications and is not only suitable to be completed on a small-investment evaporator at normal pressure, but also suitable to be completed on an advanced energy-saving consumption-reducing vacuum evaporation crystallization device at negative pressure; furthermore, the method does not emit any substance to the outside and does not produce any pollution.

Owner:昆明隆祥化工有限公司

A kind of phytosterol ester and its low-temperature preparation method

ActiveCN106632568BImprove conversion rateMild conditionsSteroids preparationChemical synthesisPlant sterol

The invention discloses phytosterol esters and a low-temperature preparation method thereof; the low-temperature preparation method comprises the steps of (1) esterifying, to be specific, adding a solvent to dissolve phytosterol and fatty acid that act as raw materials, and adding a catalyst to esterify at 30-65 DEG C, wherein the solvent is evaporatively condensed and is then dehydrated and refluxed; (2) carrying out acid-alkali neutralization, to be specific, after esterifying in step (1), adding a neutralizing agent to neutralize the catalyst and the redundant fatty acid, removing insoluble solid by filtering, and vacuum-drying by distillation to obtain phytosterol esters. The phytosterol esters are prepared through low-temperature catalytic reaction, both efficient reaction time in chemical synthesis and mild reaction conditions in enzymatic preparation are provided, singleness in enzymatic preparation is overcome, energy consumption is reduced, and industrial production is facilitated. The purity of the phytosterol esters prepared herein is up to 95% and above.

Owner:NINGBO DAHONGYING BIO ENG

A method for co-pyrolysis of solid waste and coal

ActiveCN107057730BSolve resource problemsNo need for additional investmentProductsReagentsThermodynamicsCoke

The invention discloses a method for co-pyrolysis of solid waste and coal. The method comprises the following steps: mixing solid waste with coal metered, drying, heating, carrying out destructive distillation pyrolysis, so as to obtain solid-state pyrolysis product semi-coke and gas-state pyrolysis product coal gas containing tar gas; cooling and sieving the semicoke, so as to obtain semi-coke with different particle sizes; and carrying out oil-gas separation on coal gas containing tar gas, so as to obtain tar and coal gas, wherein partial coal gas is taken as a heat source for pyrolysis of mixed materials, and rest coal gas is taken as a coal gas product. According to the method, the co-pyrolysis of solid waste and coal is realized by virtue of a horizontal rotary kiln, and the semi-coke, tar oil and coal gas are obtained after the pyrolysis of the mixed materials in the rotary kiln at a certain temperature. The method has the beneficial effects that a technical process is simple, the operation is reliable and stable, the problem that coal gas produced by pyrolysis of solid waste is less than heat required by the pyrolysis of solid waste is solved, and the method has obvious superiority on the treatment of solid waste with great composition change.

Owner:西安三瑞实业有限公司

A thermomechanical treatment method for controlling the fine-grain structure of tial alloy

The invention relates to a deformation heat treatment method for controlling the fine-grain structure of TiAl alloy, which relates to the technical field of thermal processing preparation of high-temperature structural materials, and specifically relates to a method for obtaining TiAl alloy fine-grained near-sheet layers and fine grains by combining pre-deformation treatment and isothermal heat treatment. The deformation heat treatment method of crystal full lamellar structure is to put the TiAl alloy billet into a box-type heat treatment furnace, carry out pre-insulation, complete the pre-deformation treatment, and then perform isothermal heat treatment to obtain the fine-grained structure of TiAl alloy; the precise control adopted by the present invention According to the accurate analysis of the phase temperature range, through the precise design and control of the deformation amount, deformation rate and holding temperature during the deformation heat treatment process, the precise adjustment and control of the TiAl alloy structure can be realized, and obtained Fine-grained sublamellar and fine-grained full-lamellar structures.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Low-temperature carbonization apparatus and method for oil sand, oil sludge, oil shale and biomass

ActiveCN103160301BIncrease profitReduce energy consumptionDirect heating destructive distillationBiofuelsParticulatesThermodynamics

Provided is a low-temperature dry distillation apparatus and method for oil sand, oil sludge, oil shale and biomass. The apparatus comprises: a delivery apparatus (1), a material bin (2), a metering apparatus (3), a drying furnace (14) and a surge bin (6) connected successively. Also provided is a method for using the above-mentioned dry distillation apparatus, which comprises: drying-preheating, dry distillation, and cooling. The advantages of the above-mentioned dry distillation method lie in that the method is simple in process, and reliable and stable in operation.

Owner:何建祥

A kind of continuous oxygen bleaching refining agent and preparation method thereof

The invention relates to a continuous oxygen bleaching refining agent and a preparation method thereof. The continuous oxygen bleaching refining agent comprises a rare-earth catalyst, a hydrogen peroxide stabilizer, biodegradable surfactant, Gemini surfactant, hyperbranched surfactant and water. Compared with a conventional refining agent, the continuous oxygen bleaching refining agent has the advantages that the continuous oxygen bleaching refining agent is efficient and environmental friendly and wide in process applicability, the NaOH use amount is lowered by about 40%, the COD value of discharged wastewater is lowered by more than 40%, and the whiteness, capillary effect and breaking strength of fabric treated by the continuous oxygen bleaching refining agent are evidently better.

Owner:SHANGHAI ARGUS NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com