Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81 results about "Exposure latitude" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exposure latitude is the extent to which a light-sensitive material can be overexposed or underexposed and still achieve an acceptable result. This measure is used for digital and analogue processes, i.e. optical microlithography or photography.

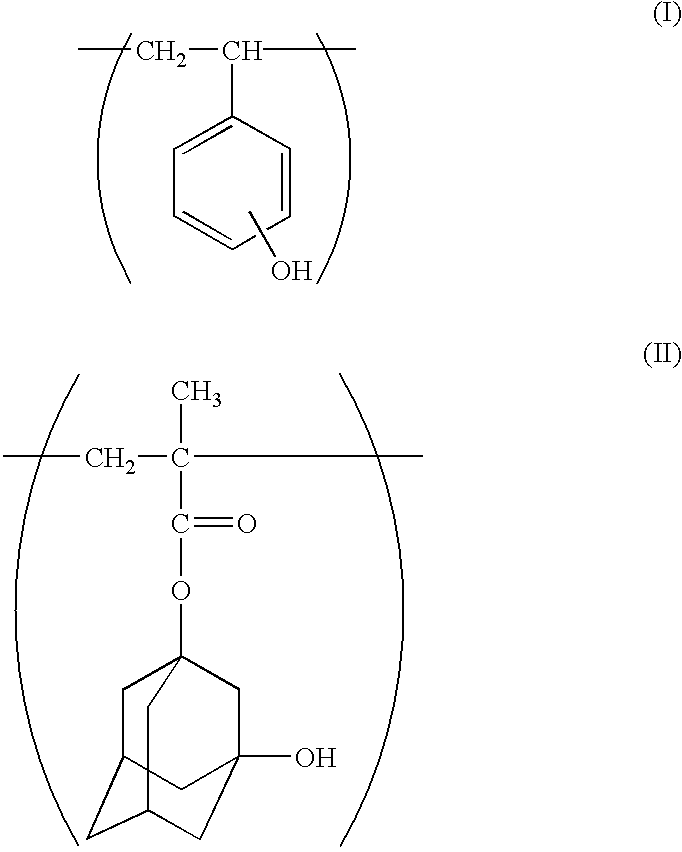

Chemical amplification type positive resist composition

InactiveUS6627381B1Maintain good propertiesImproved in exposure latitudePhotosensitive materialsSemiconductor/solid-state device manufacturingMethacrylateImage resolution

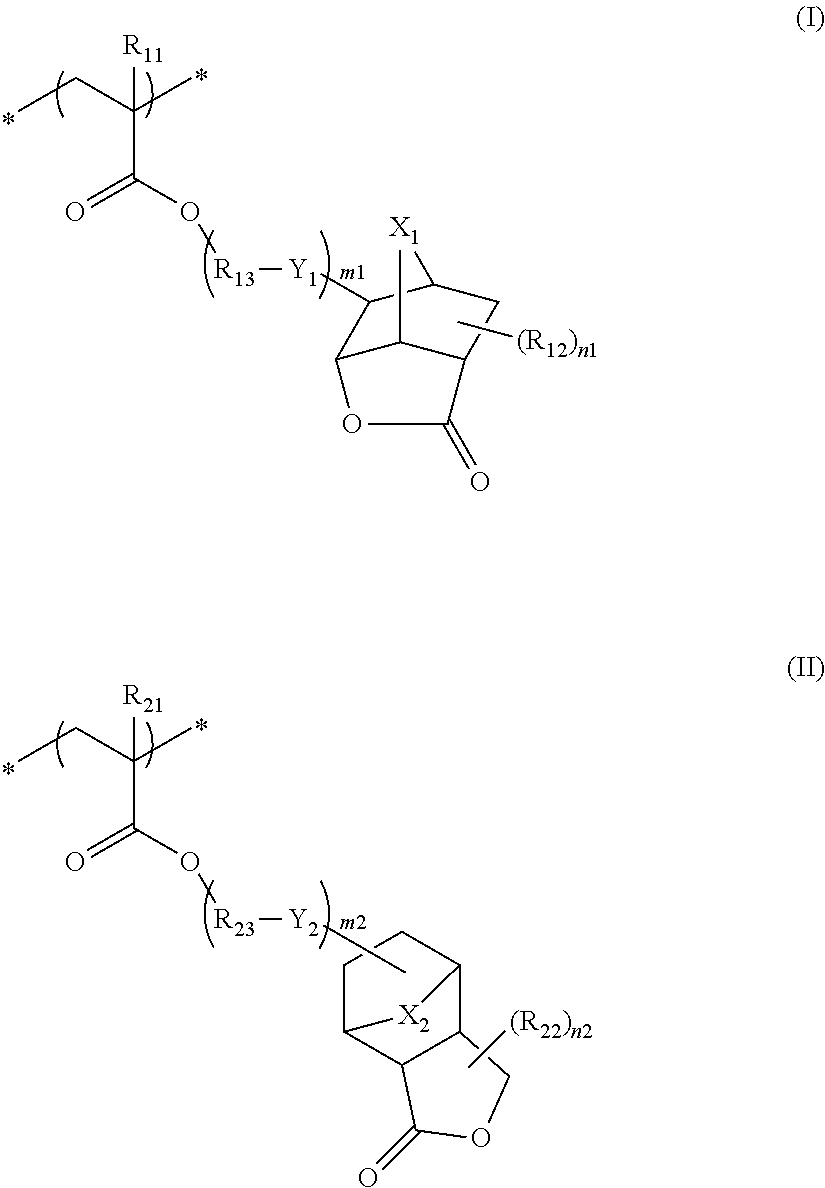

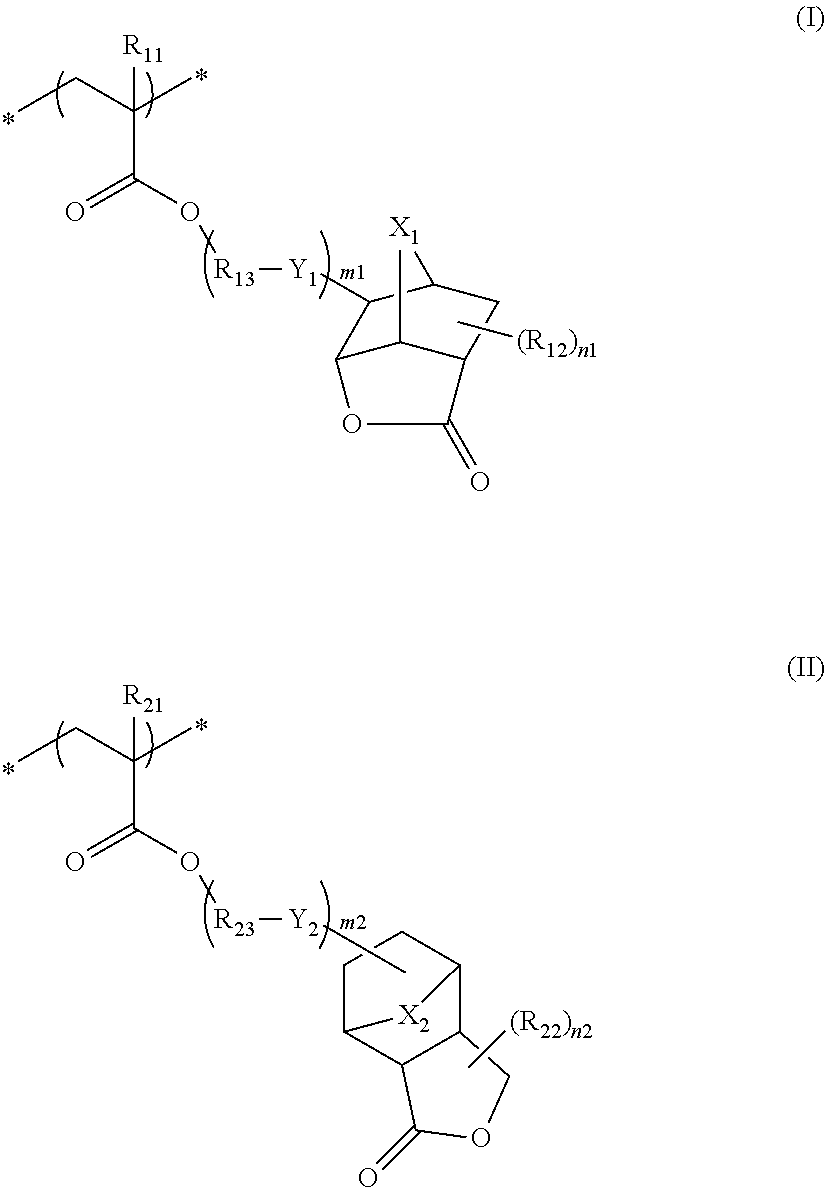

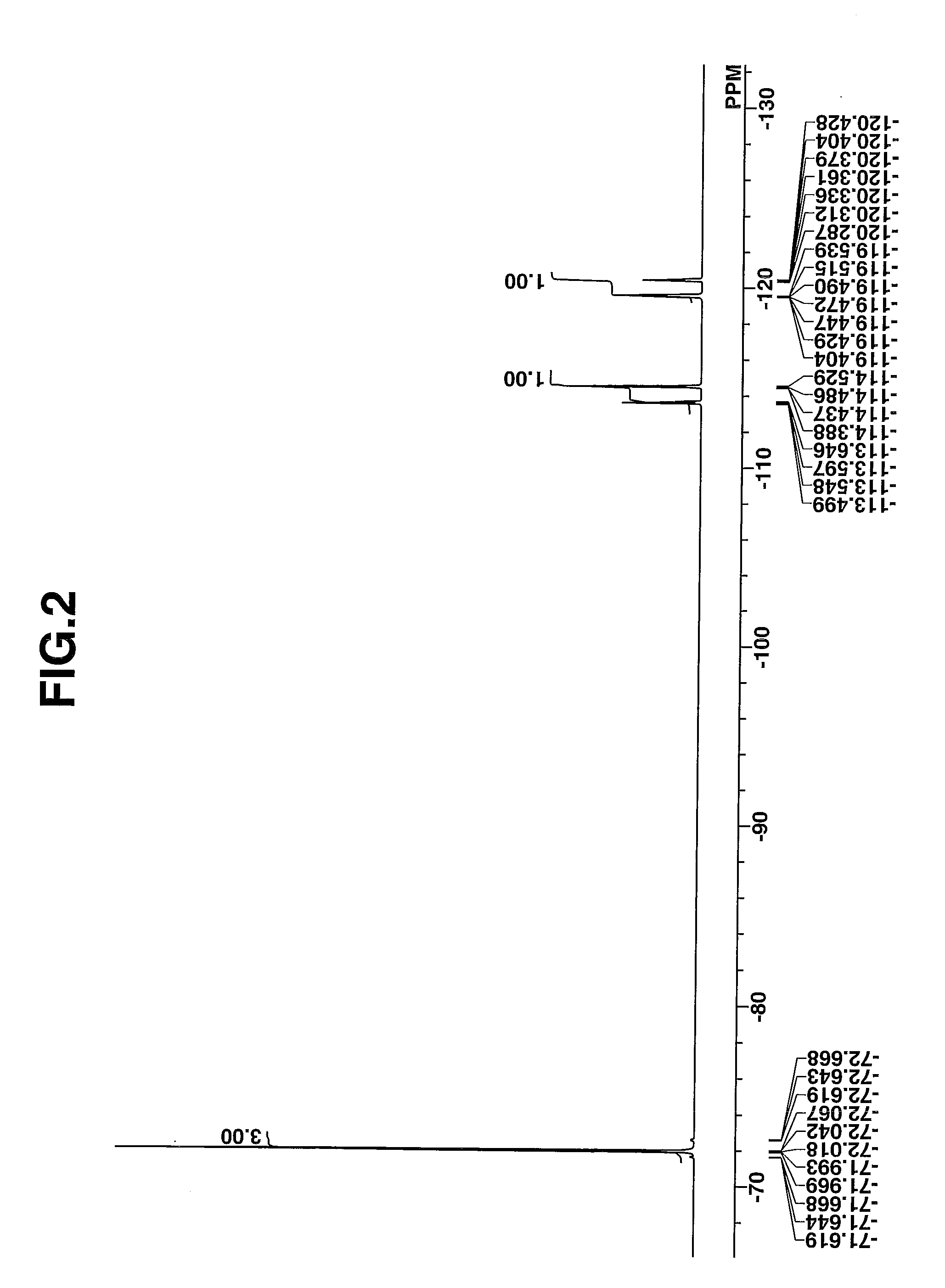

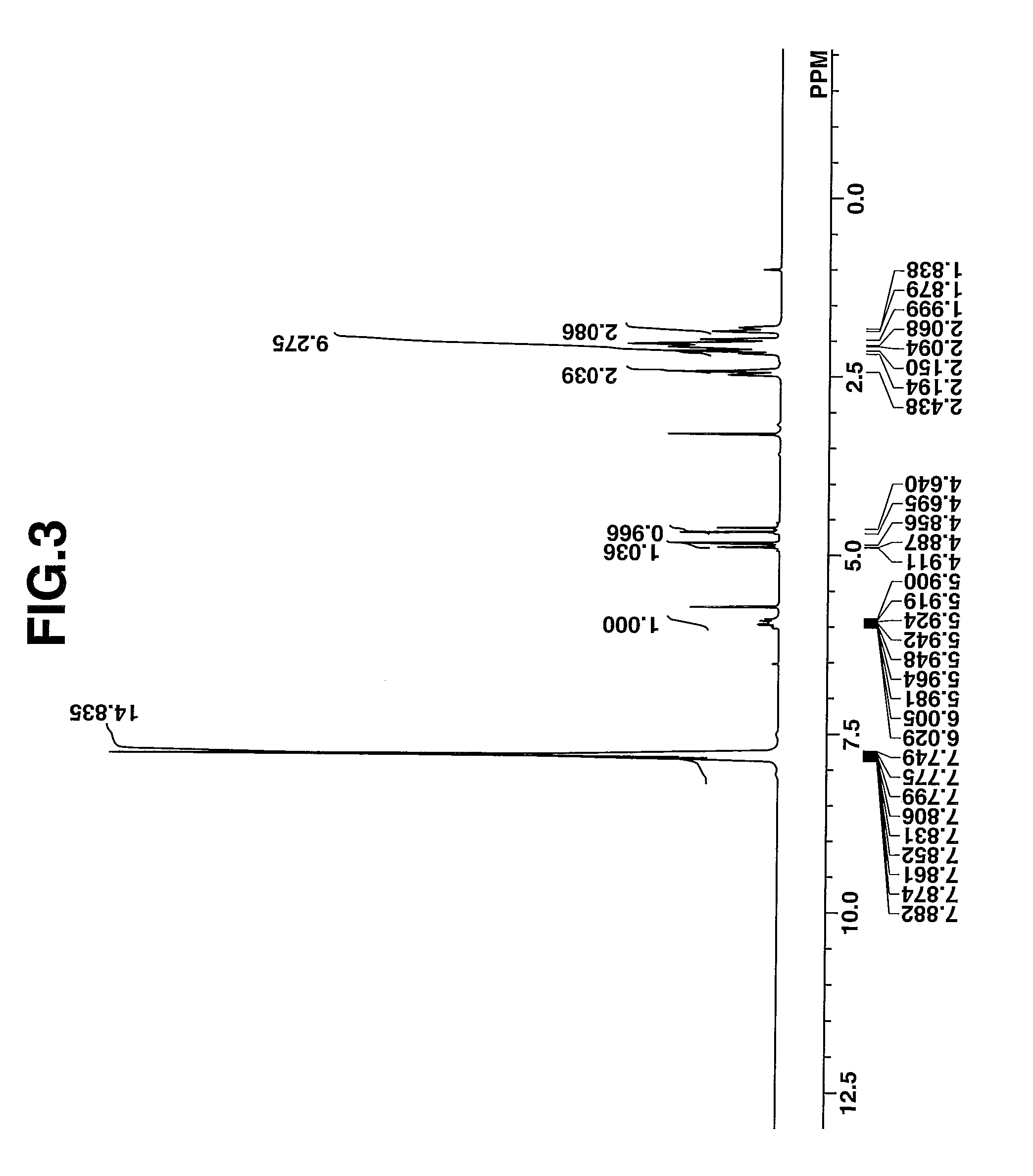

A chemical amplification type positive resist composition comprising: a resin which has a hydroxystyrene-based polymerization unit, a 3-hydroxy-1-adamantyl methacrylate-based polymerization unit and a polymerization unit having a group unstable toward an acid, and, though insoluble or hardly soluble in an alkali in itself, becomes alkali-soluble after the acid-unstable group has been cleaved by the action of an acid; and an acid generating agent is provided. This resist composition is improved in exposure latitude and resolution. Moreover, such properties as sensitivity, heat resistance, the ratio of residual thickness, coatability, and dry etching resistance are also maintained good. Thus, through the use of this composition, a fine resist pattern can be formed with high precision.

Owner:SUMITOMO CHEM CO LTD

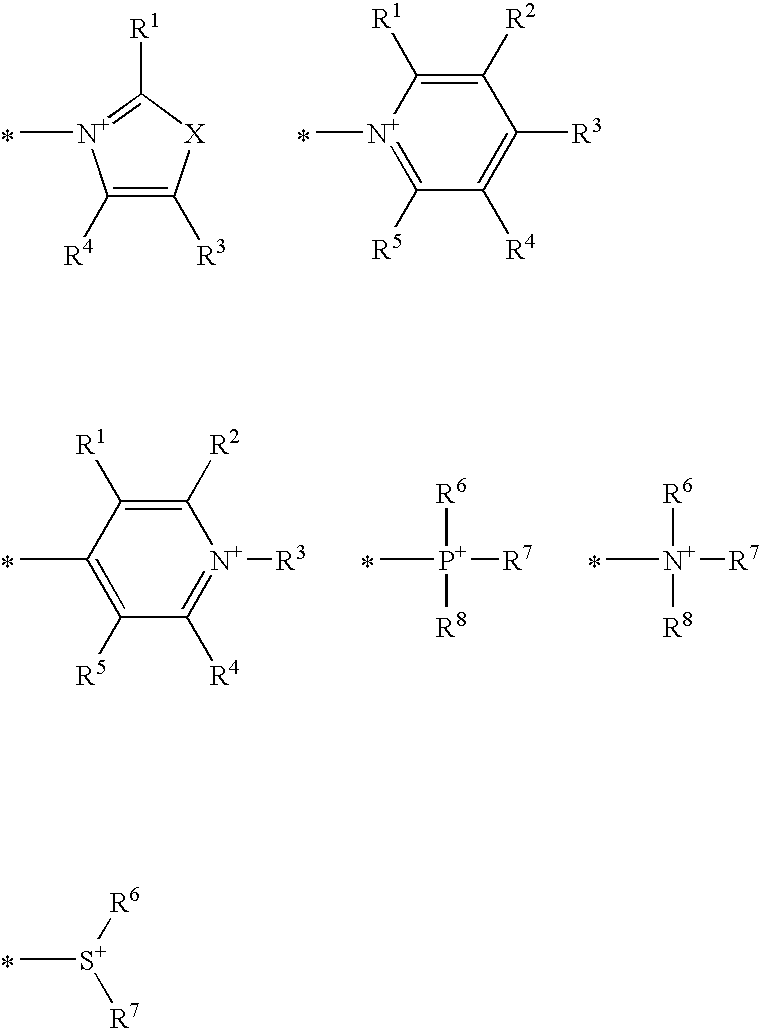

Pattern forming method, actinic-ray-sensitive or radiation-sensitive resin composition, and resist film

ActiveUS20120219913A1Improve performancePhotosensitive materialsPhotomechanical exposure apparatusOrganic solventActinic Rays

Provided is a pattern forming method that is excellent in roughness performance such as line width roughness and exposure latitude, and an actinic-ray-sensitive or radiation-sensitive resin composition and a resist film used for the pattern forming method.The pattern forming method includes (1) forming a film using an actinic-ray-sensitive or radiation-sensitive resin composition containing a resin that includes 65 mol % or more of a repeating unit having a group which generates a polar group by being degraded by the action of an acid based on all repeating units in the resin and at least one kind of repeating unit represented by the following General Formula (I) or (II), (2) exposing the film, and (3) developing the exposed film using a developer that contains an organic solvent.

Owner:FUJIFILM CORP

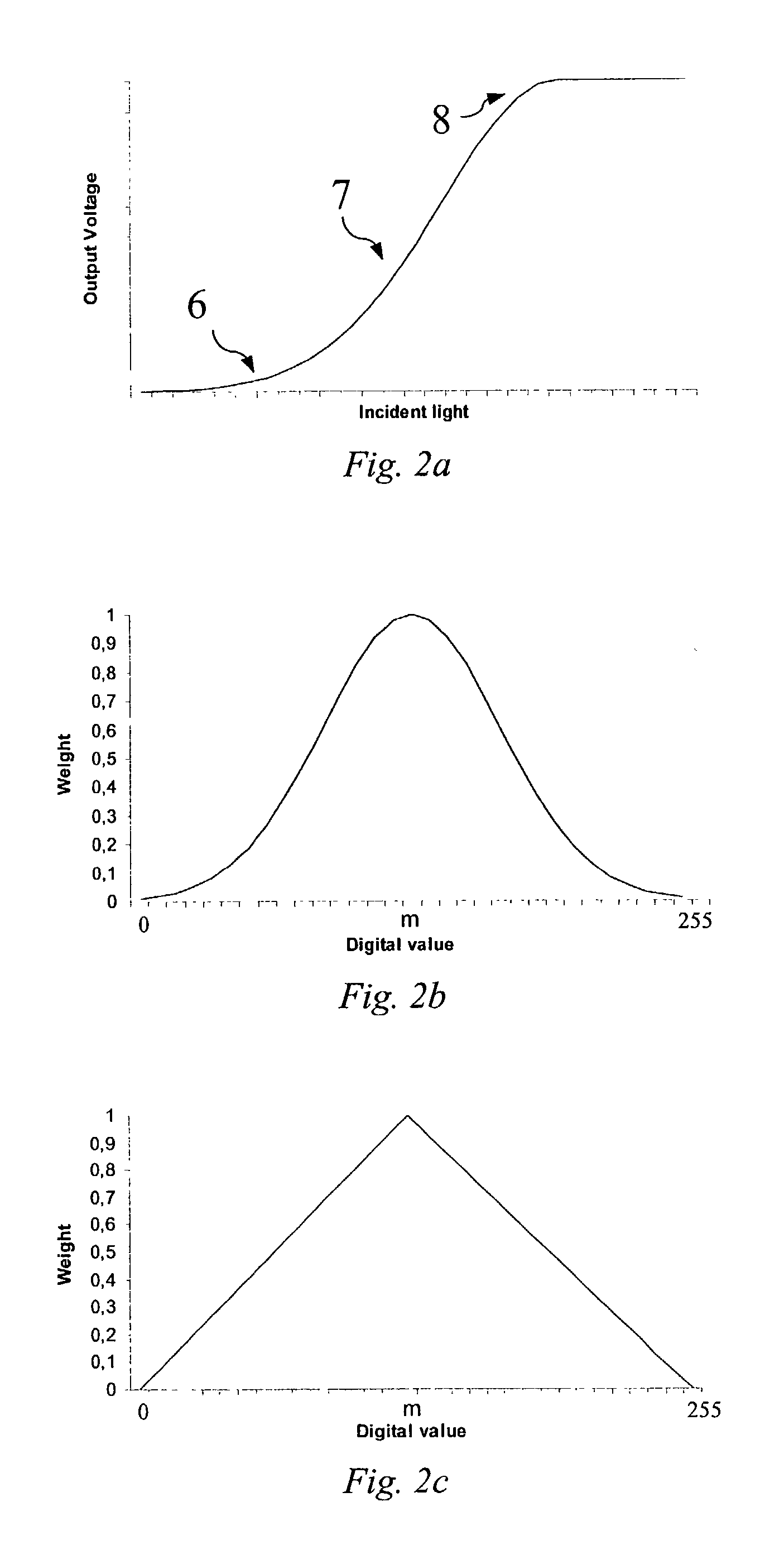

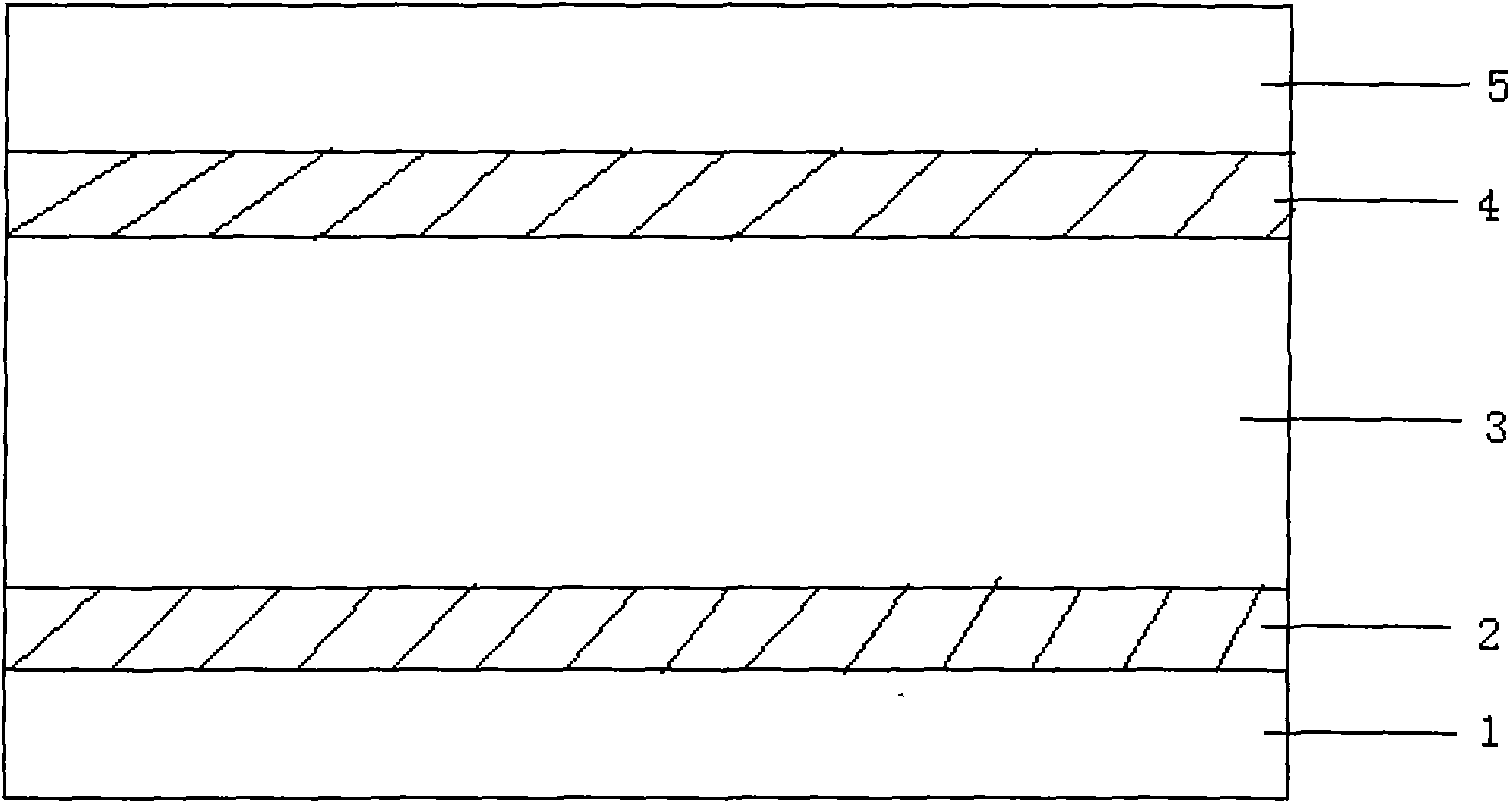

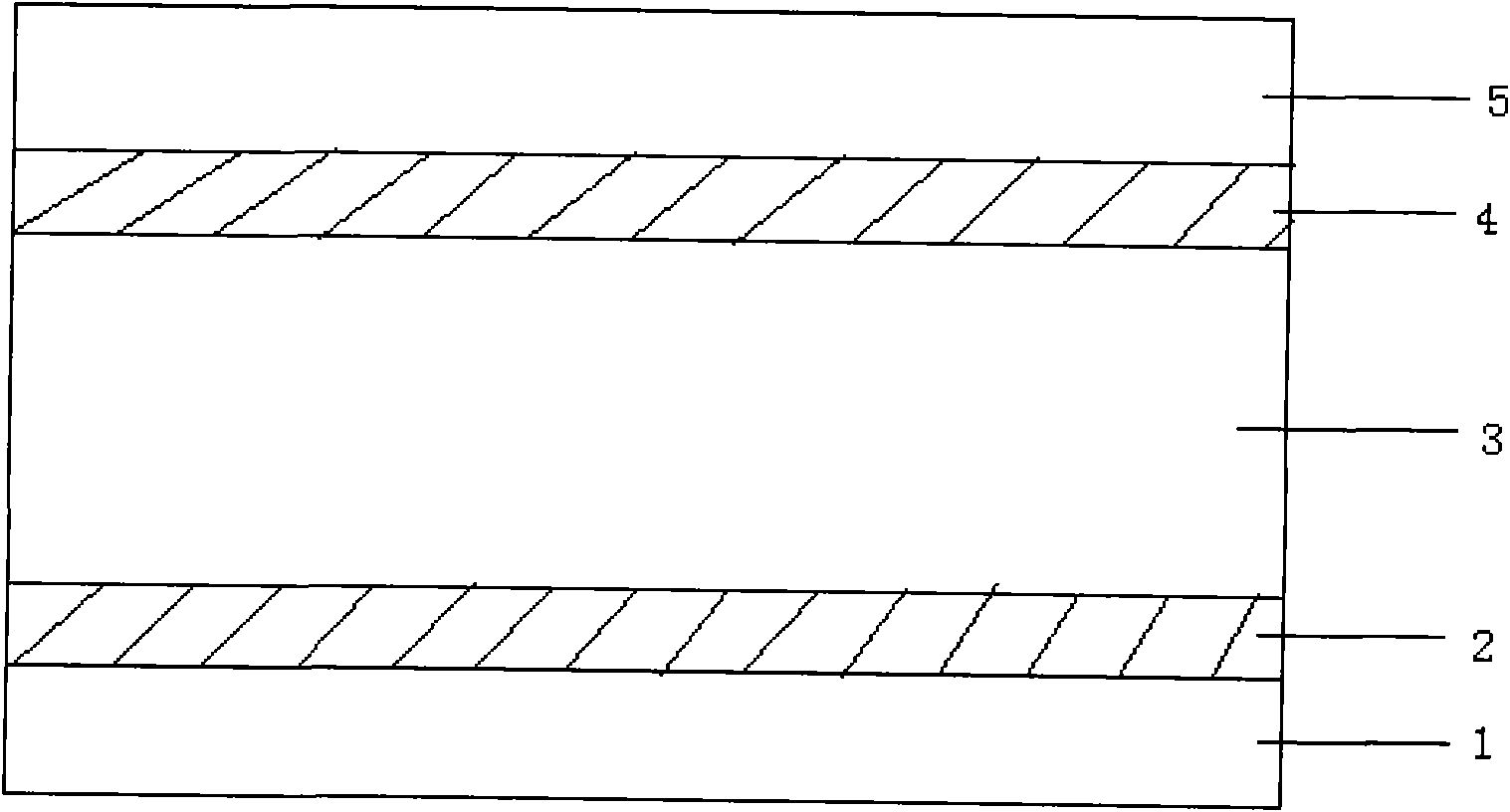

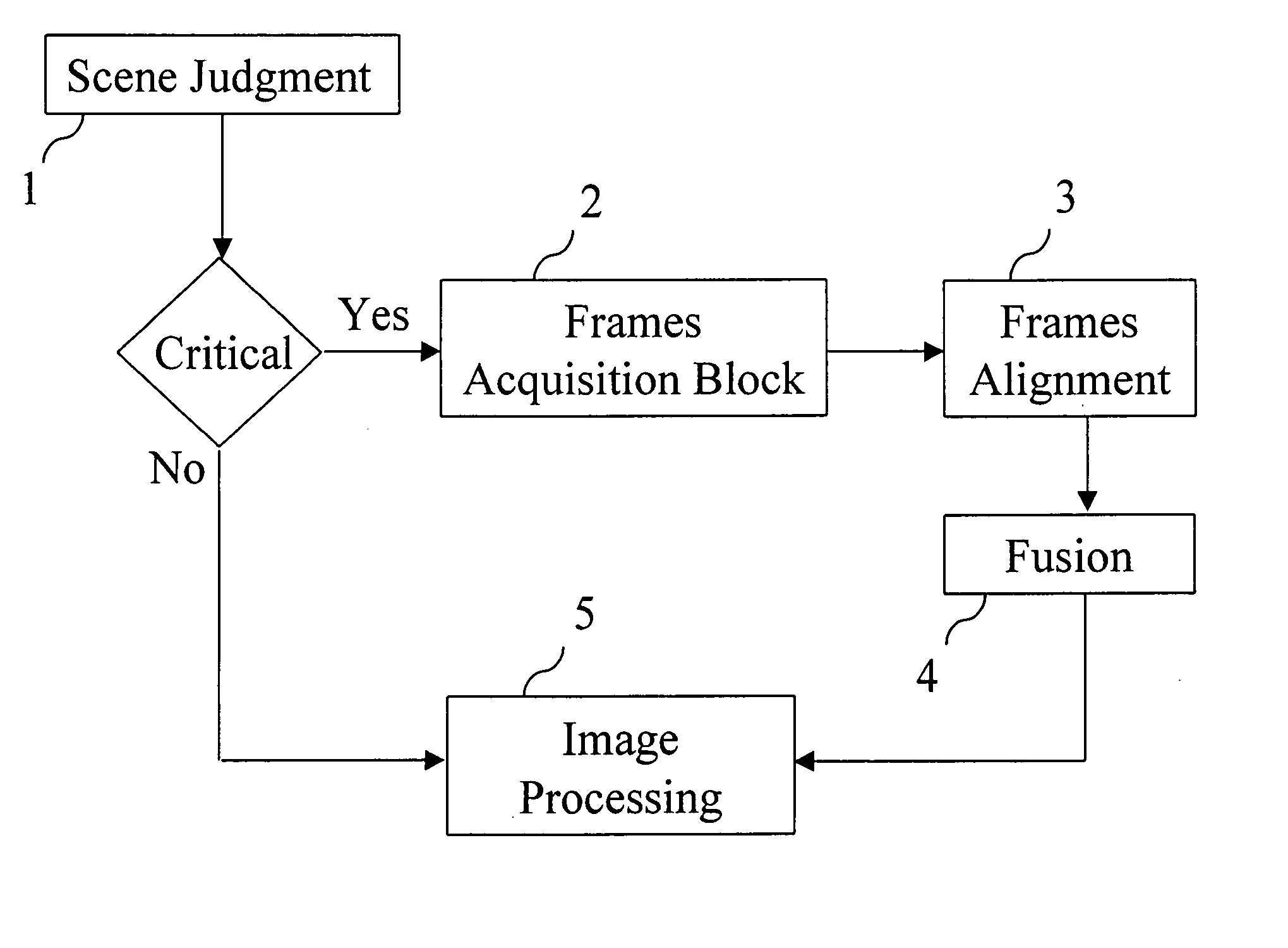

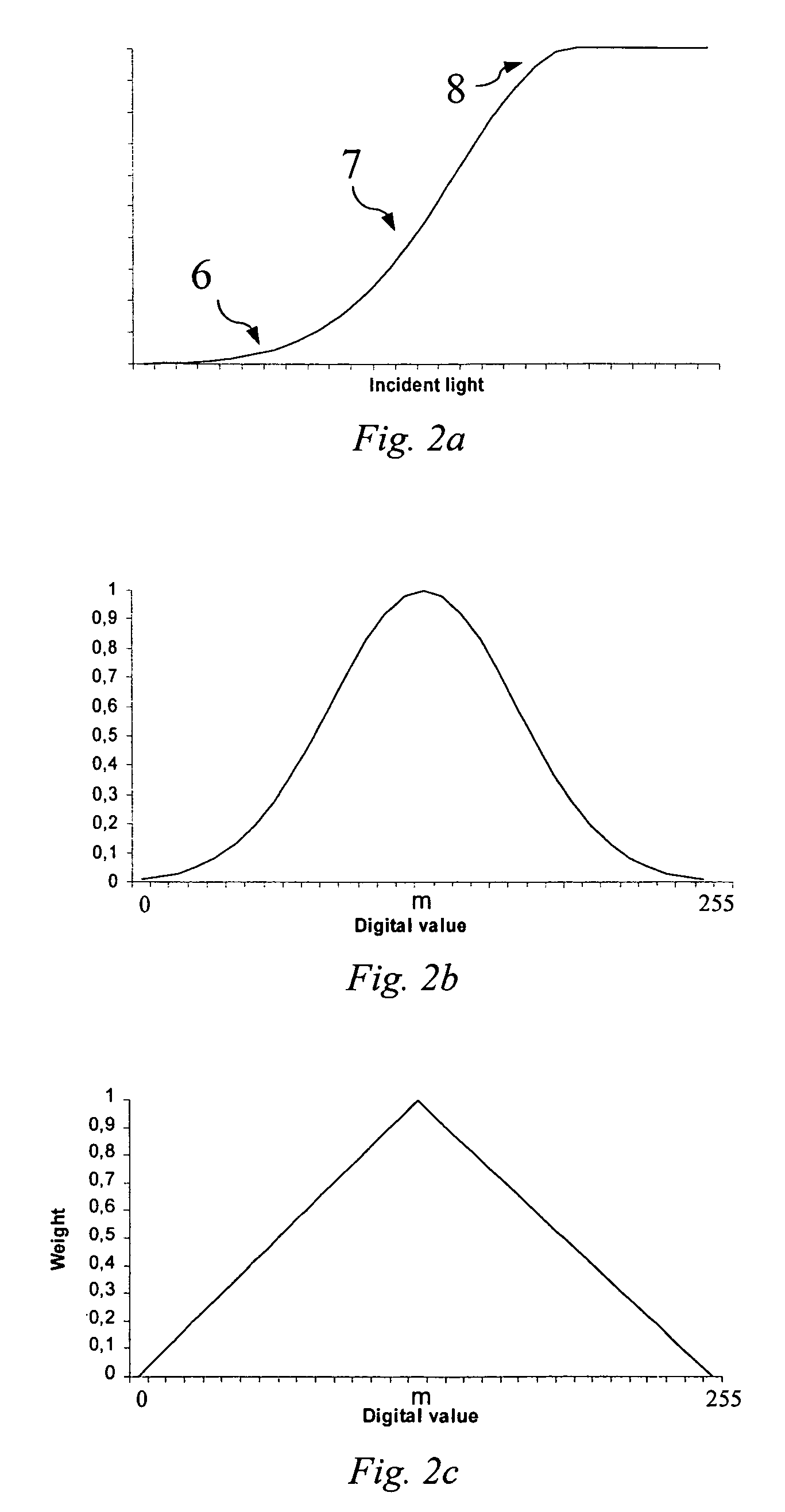

Method for merging digital images to obtain a high dynamic range digital image

ActiveUS7106913B2Quality improvementOptimization of detailsImage enhancementTelevision system detailsWeight coefficientExposure latitude

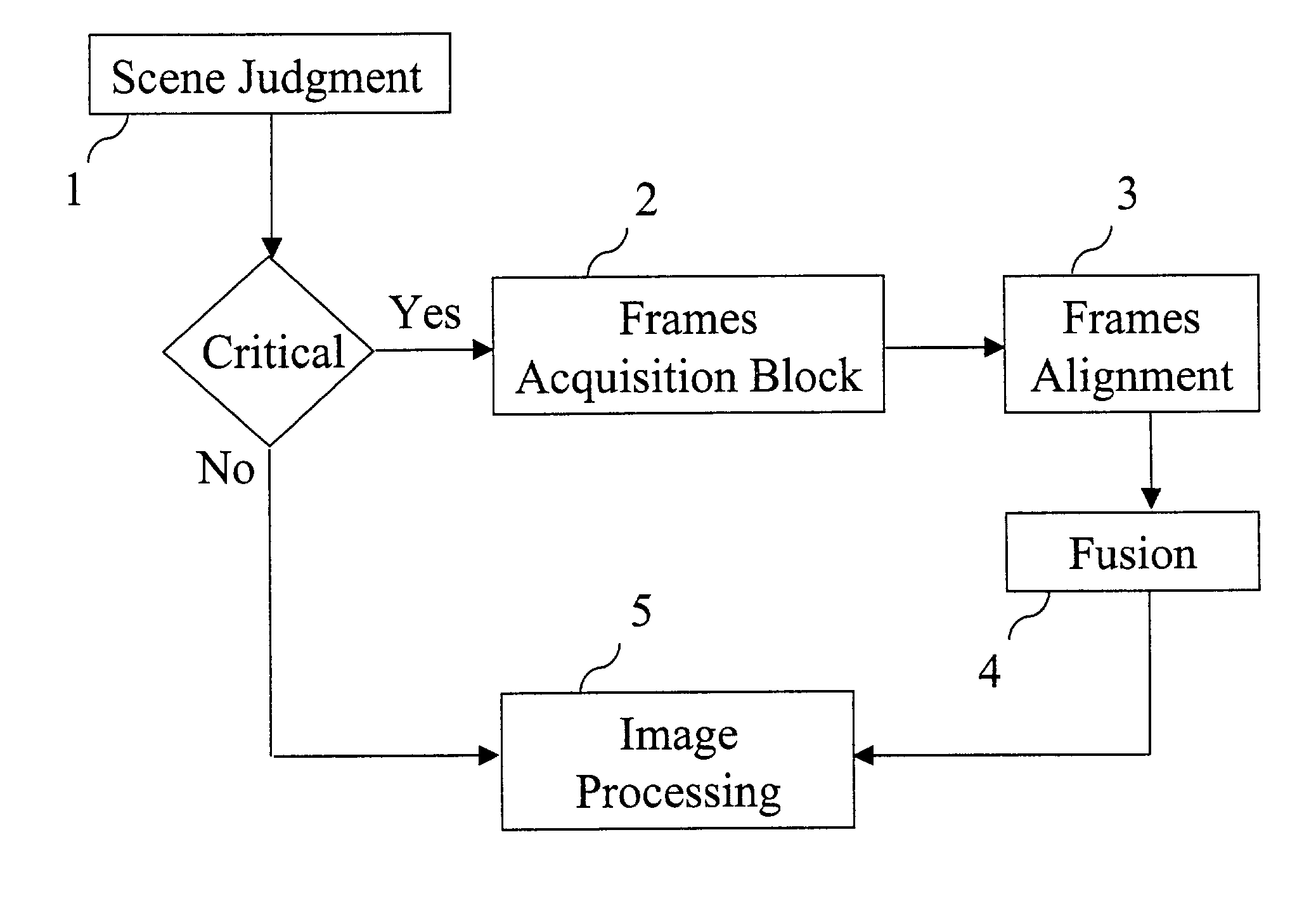

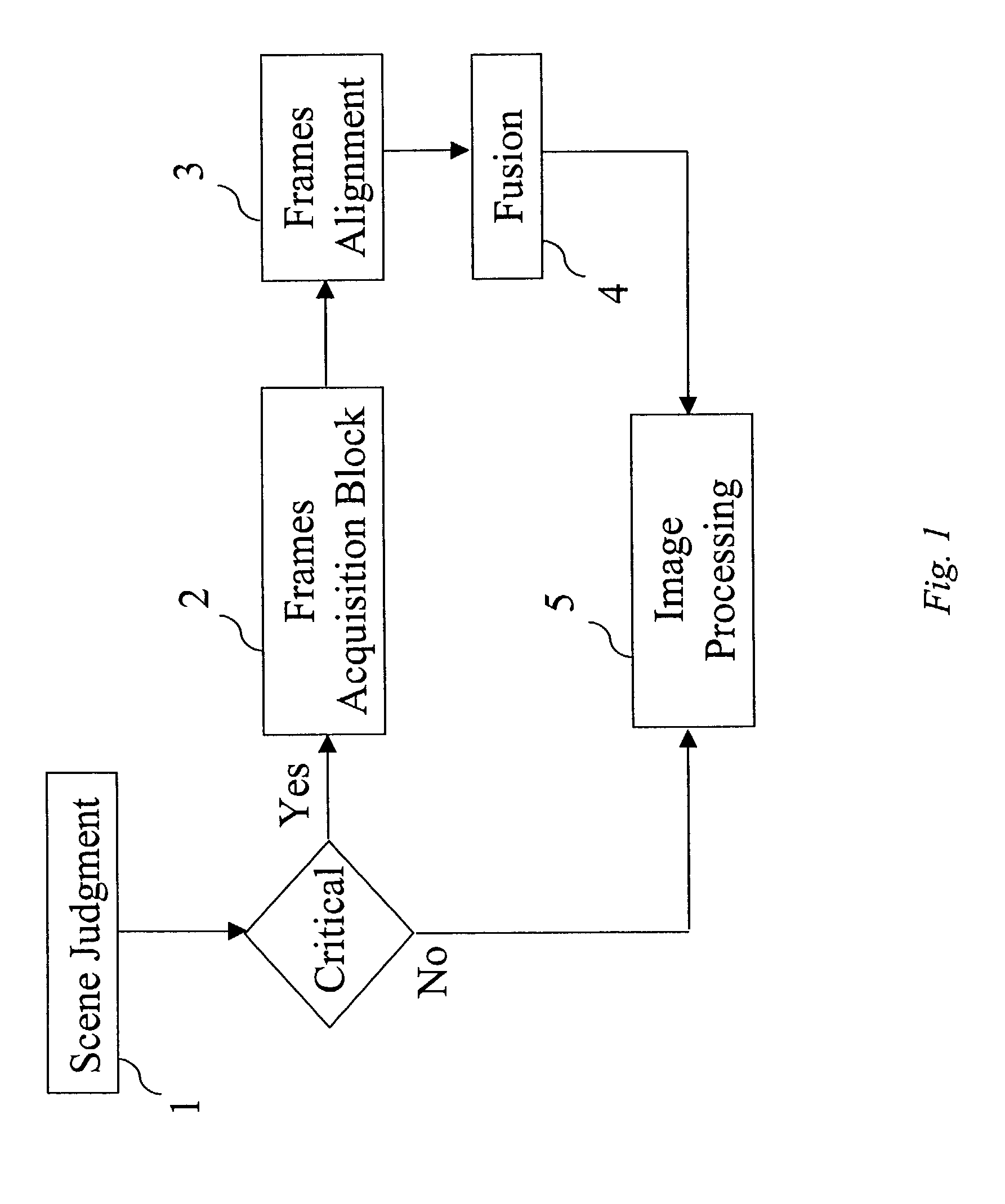

A method of processing digital source images, each represented by pixel matrices, to obtain from two or more source images, representing one and the same real scene and acquired by utilizing different exposure levels, a final digital image capable of reproducing the real scene with an exposure latitude greater than that of each of the source images. The method, which can be advantageously used in digital still cameras, produces the final image by combining the source images with the help of a weighted average constructed pixel by pixel. Thanks to a special filtering to which the weighting coefficients are subjected before the weighted mean operation, the method obtains a final image in which the source images are harmoniously combined with each other.

Owner:STMICROELECTRONICS SRL

Device manufacturing method

InactiveUS20050007573A1Improve toleranceUniform processingSemiconductor/solid-state device manufacturingDiffraction gratingsExposure latitudeOptoelectronics

Owner:ASML NETHERLANDS BV

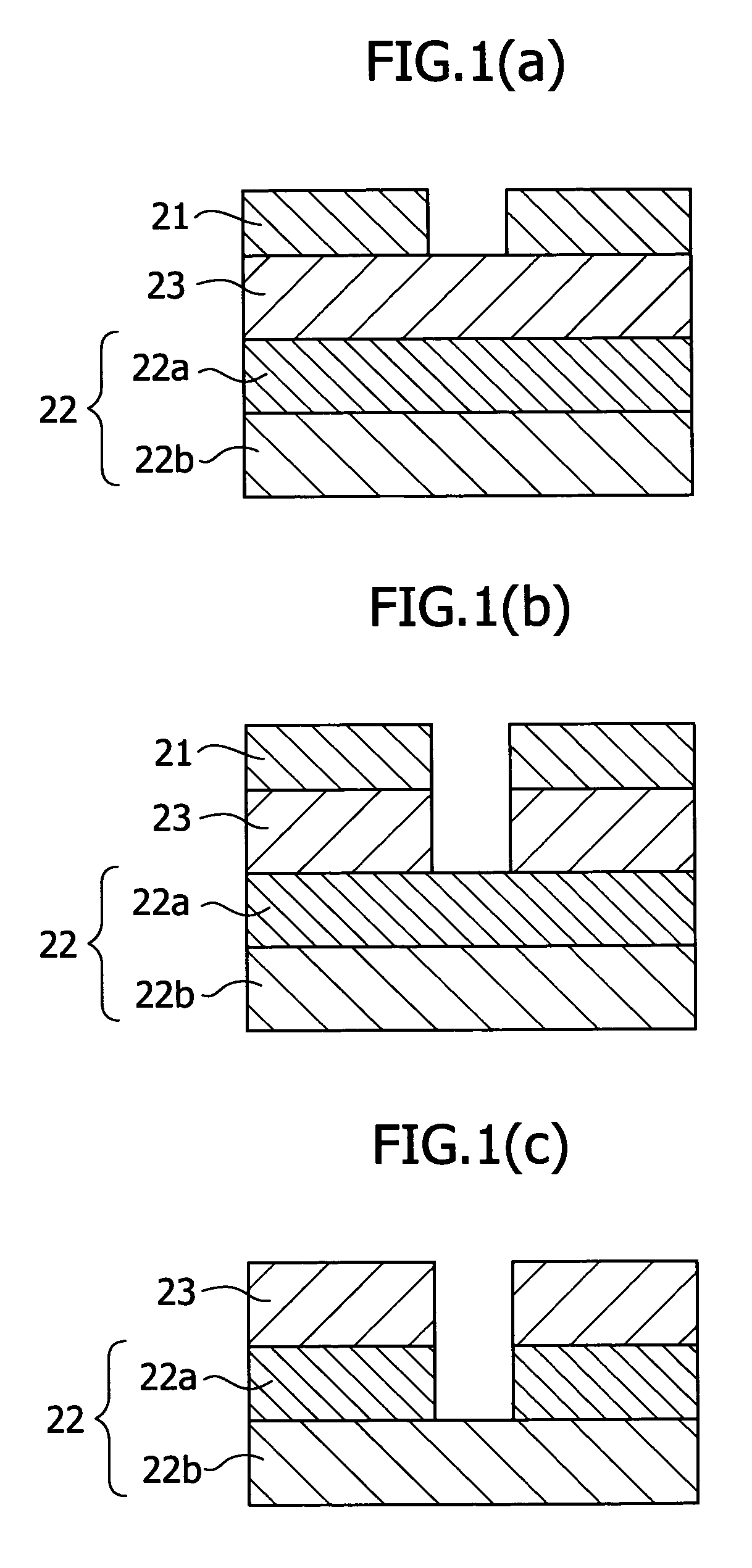

Flexible photosensitive resin plate and preparation method thereof

InactiveCN101770174AObvious color differenceImprove visual effectsPhotosensitive materials for photomechanical apparatusTectorial membraneExposure latitude

The invention relates to a flexible photosensitive resin plate, which comprises a support body (1), a bonding layer (2), a photosensitive resin layer (3), an anti-sticking layer (4) and a protective film (5) from bottom to top. The photosensitive resin layer (3) comprises at least one photochromic dye. The usage amount of the photochromic dye is 0.001-1% of the solid amount of the photosensitive layer. In the plate making process of the flexible photosensitive resin plate, the vision contrast is good, so that the operator can conveniently judge the plate making effects of patterns, characters and the like, and the plate has good exposure tolerance at the same time.

Owner:LUCKY HUAGUANG GRAPHICS

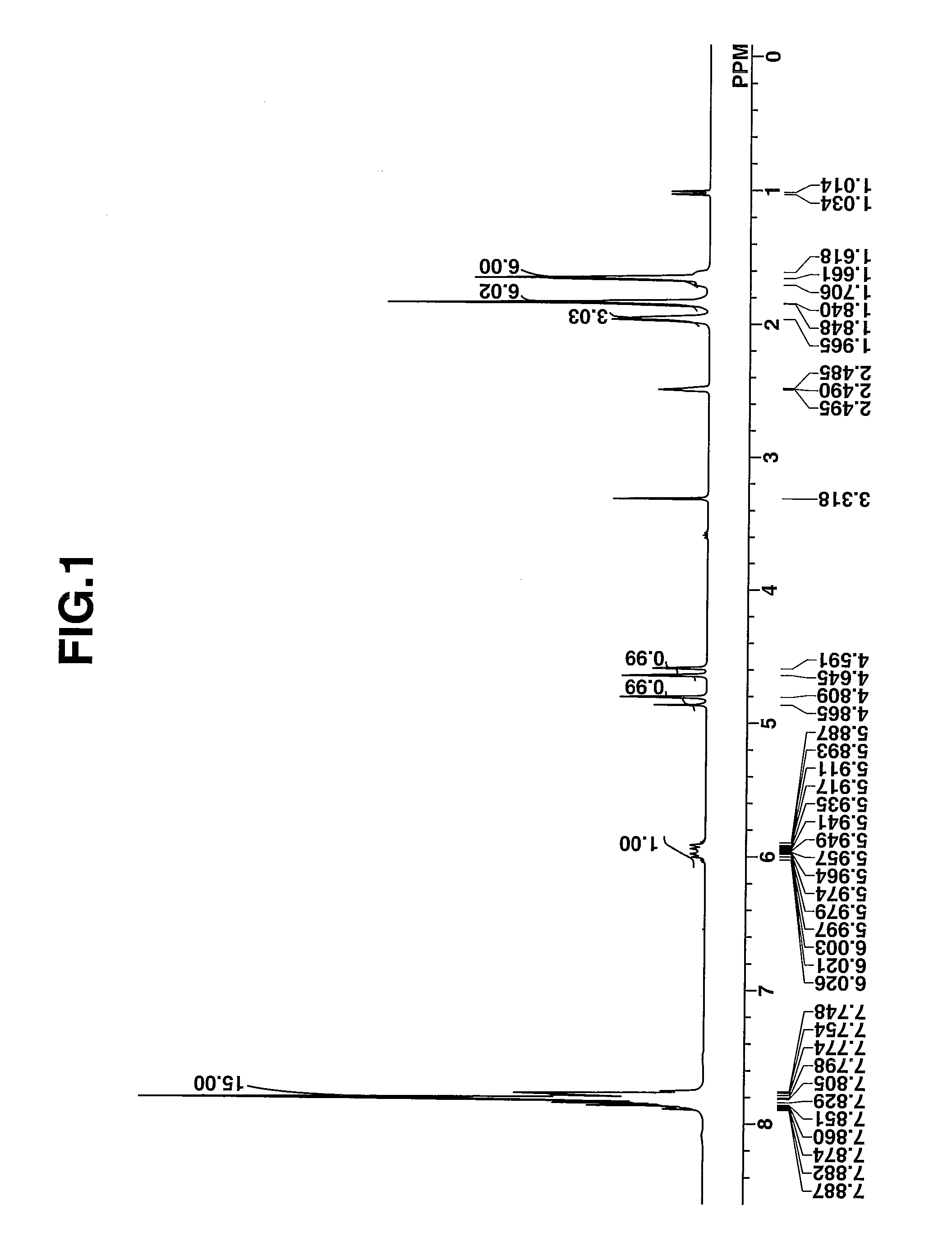

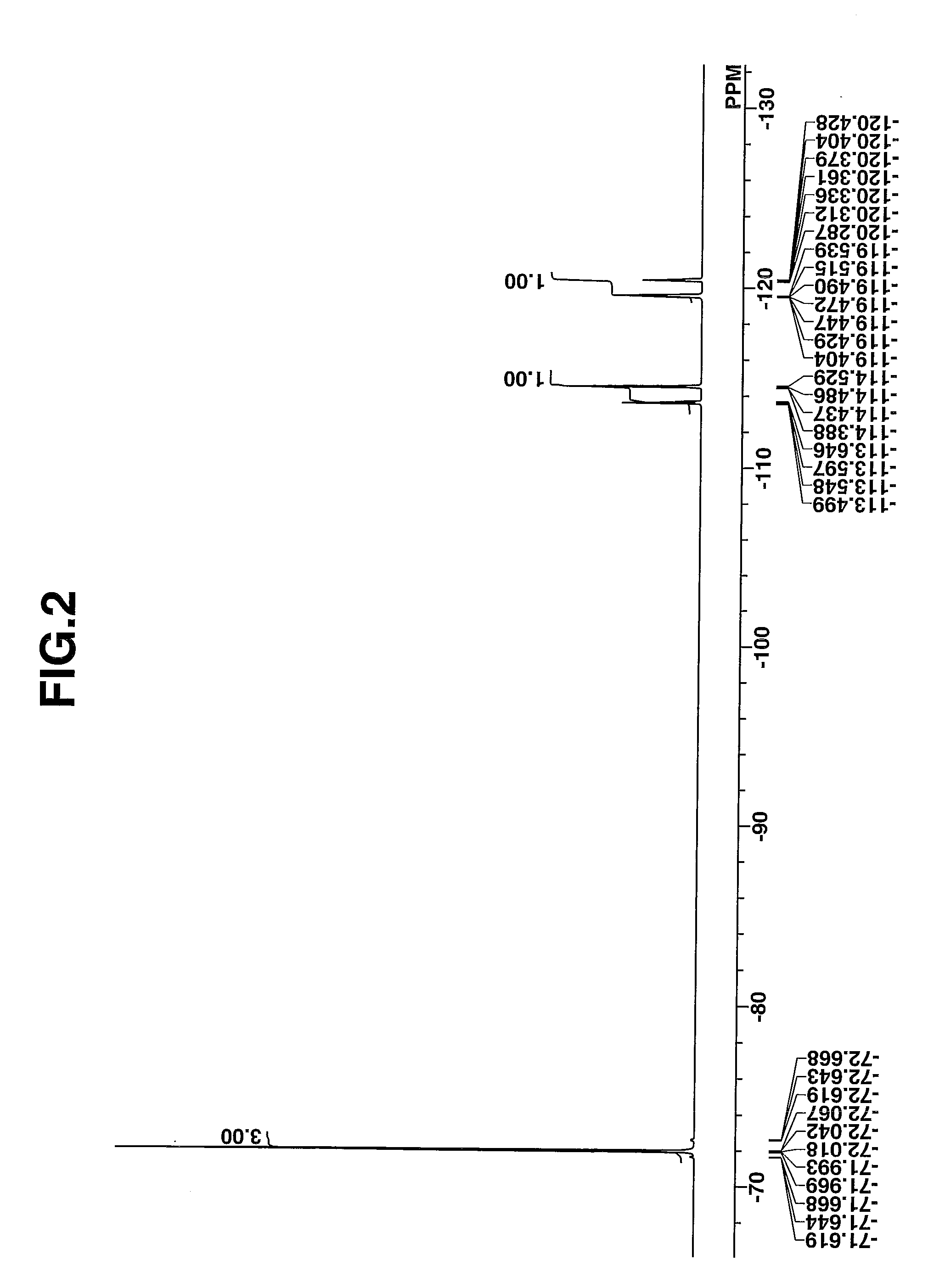

Photoacid generator, resist composition, and patterning process

ActiveUS20110003247A1Reduce molecular weightPromote adequate diffusionOrganic chemistryOrganic compound preparationImage resolutionExposure latitude

The photoacid generator produces a sulfonic acid which has a bulky cyclic structure in the sulfonate moiety and a straight-chain hydrocarbon group and thus shows a controlled acid diffusion behavior and an adequate mobility. The PAG is fully compatible with a resin to form a resist composition which performs well during the device fabrication process and solves the problems of resolution, LWR, and exposure latitude.

Owner:SHIN ETSU CHEM IND CO LTD

Heat-sensitive lithographic printing plate precursor

InactiveUS20050136356A1High sensitivityGood chemical resistanceRadiation applicationsSemiconductor/solid-state device manufacturingCresolExposure latitude

A heat-sensitive lithographic printing plate precursor is disclosed which comprises a hydrophilic support and an oleophilic coating thereon which comprises an infrared light-to-heat converter, an alkali-soluble binder and a polymeric developer accelerator. The polymeric developer accelerator is preferably a phenolic formaldehyde resin comprising at least 70 mol % of meta-cresol as recurring unit or at least 40 mol % of monohydroxy benzene cresol as recurring unit. The PDA may also be a phenolic resin which comprises at least 5 mol % of a recurring monomeric unit having at least one phenolic hydroxyl group and at least one alkali solubilising group. The polymeric developer accelerator improves the sensitivity while maintaining a good under-exposure latitude and a good developer resistance of the printing plate.

Owner:AGFA NV

Pattern forming method and actinic-ray- or radiation-senstive resin composition

ActiveUS20130040096A1ExcelsLimiting exposurePhotosensitive materialsLayered productsActinic RaysOrganic solvent

Provided is a method of forming a pattern and an actinic-ray- or radiation-sensitive resin composition that excels in the limiting resolving power, roughness characteristics, exposure latitude (EL) and bridge defect performance. The method of forming a pattern includes (1) forming an actinic-ray- or radiation-sensitive resin composition into a film, (2) exposing the film to light, and (3) developing the exposed film with a developer containing an organic solvent. The actinic-ray- or radiation-sensitive resin composition contains (A) a resin containing a repeating unit with a structural moiety that is configured to decompose when exposed to actinic rays or radiation to thereby generate an acid, and (B) a solvent.

Owner:FUJIFILM CORP

Resist polymer, making method, and chemically amplified positive resist composition

InactiveUS20050271978A1Superior in resist film dissolution contrastHigh resolutionPhotomechanical apparatusSemiconductor/solid-state device manufacturingDispersityExposure latitude

A polymer is prepared by radical polymerization of a monomer using an organotellurium or organoselenium compound as a polymerization initiator. The polymer has a narrower dispersity Mw / Mn and is adequately random. A resist composition comprising the polymer as a base resin has advantages including a dissolution contrast of resist film, high resolution, exposure latitude, process flexibility, good pattern profile after exposure, and minimized line edge roughness.

Owner:SHIN ETSU CHEM IND CO LTD

Minute pattern photoetching method

InactiveCN1828422AReduce thicknessImprove uniformitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusImage resolutionExposure latitude

With improved DUV photoresist and bottom resin, this invention can decrease photoresist thickness to less than 0.11ª–m for safe height-width ratio to improve picture resolution and size evenness, exposure tolerance and focusing depth of key parts, and reduces cost.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Pattern forming method and resist composition

ActiveUS20120321855A1High sensitivityControl roughnessPhotosensitive materialsLayered productsSolubilityImage resolution

Provided is a method of forming a pattern, ensuring excellent sensitivity, limiting resolving power, roughness characteristic, exposure latitude (EL), dependence on post-exposure bake (PEB) temperature and focus latitude (depth of focus DOF), and a resist composition for use in the method. The method comprises (A) forming a film from a resist composition comprising a resin containing a repeating unit containing a group that is decomposed when acted on by an acid to thereby produce an alcoholic hydroxyl group, which resin thus when acted on by an acid decreases its solubility in a developer containing an organic solvent, (B) exposing the film to light, and (C) developing the exposed film using a developer containing an organic solvent.

Owner:FUJIFILM CORP

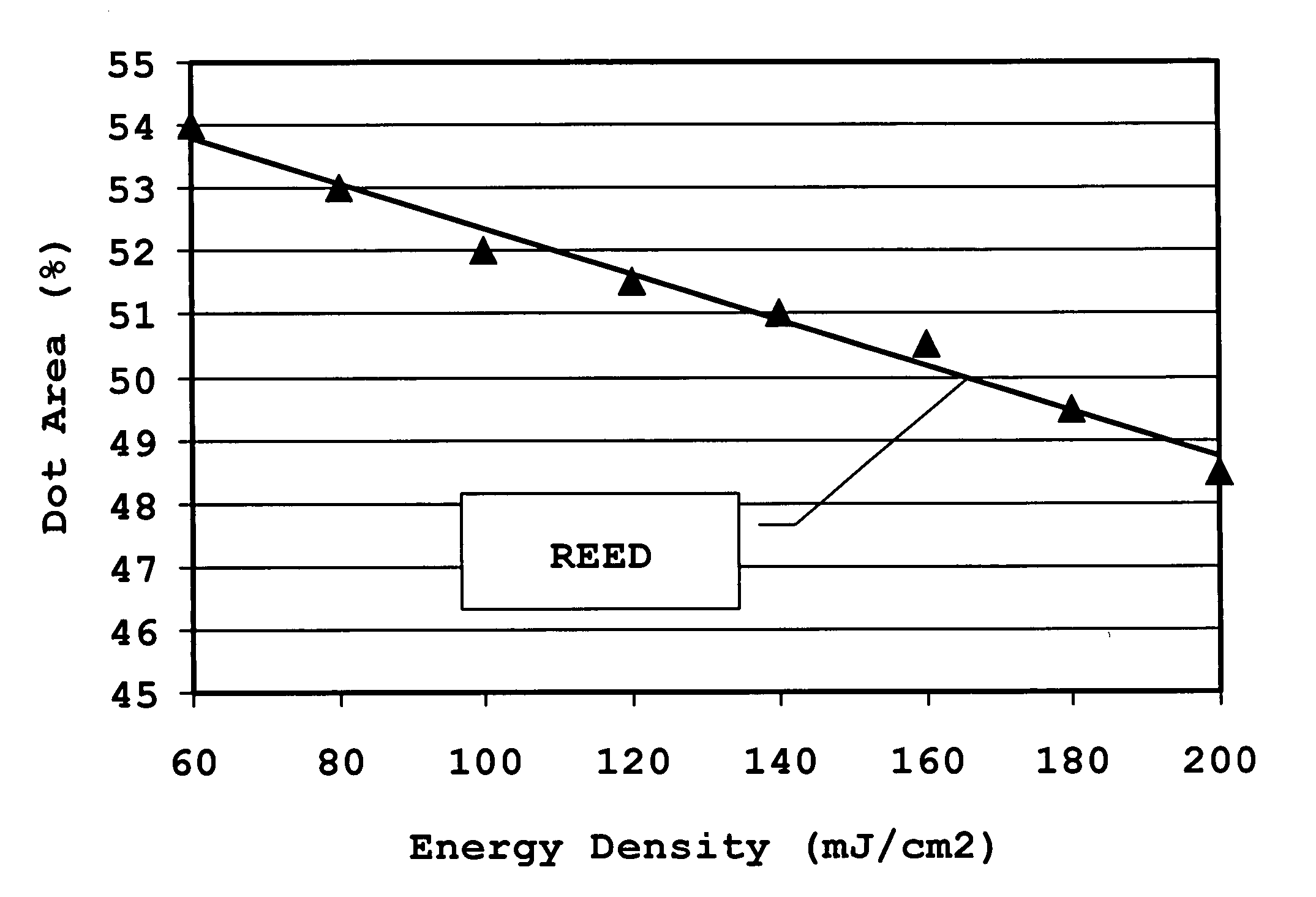

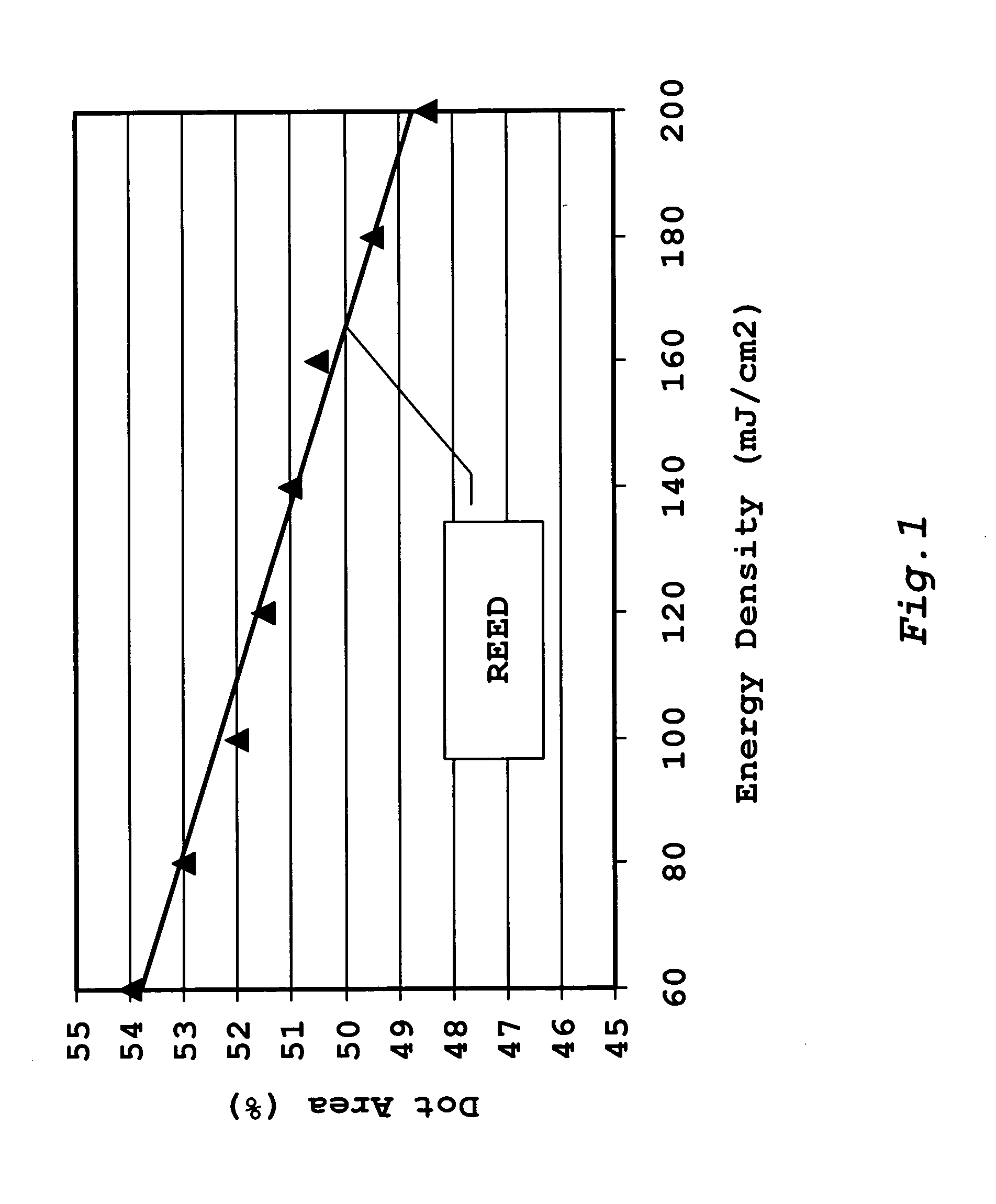

Plate burning process of precise screen

ActiveCN102736406AGood tangentHigh graphic precisionPhotomechanical apparatusExposure latitudePeak value

The present invention provides a plate burning process of a precise screen. The process employs a way of secondary exposure way to complete the film graphic transfer to the screen, and specifically comprises steps of: A) film production: first compensating the film, then adding composing and positioning to ensure a composing position deviation no more than 100 mum in a secondary plate burning of the screen; B) plate burning: carrying out composing and plate burning according to composing position required by printing, wherein the first plate burning energy set value is a minimum value of the exposure latitude, and the secondary plate burning energy value is set at a peak value of the optimum exposure. The method of the invention employs a parallel light plate burning machine to achieve clear text and effectively control edge jag and side virtual exposure; meanwhile, as the screen is treated with exposure for two times, the exposure energy is sufficient, and the pressrun of the screen film is improved.

Owner:昆山良品丝印器材有限公司

Positive lithograph plate photosensitive composition with high resolution and high sensitivity

ActiveCN101770169APhotosensitive materials for photomechanical apparatusImage resolutionExposure latitude

Owner:LUCKY HUAGUANG GRAPHICS +1

Positive resist composition and pattern forming method using the same

ActiveUS20100203451A1Reduce developmentPhoto-taking processesPhotosensitive materialsSide chainExposure latitude

Provided is a positive resist composition using a resin having, in the polymer main chain, a specific acid decomposable structure and further having, in the side chain thereof, several specific acid decomposable groups, satisfactory in an exposure latitude, a focus latitude, and pattern collapse prevention at a high level, and having reduced development defects; and a pattern forming method.

Owner:FUJIFILM CORP

Photosensitive resin composition for screen printing, photosensitive film, and screen plate

ActiveUS20150212413A1Improve stabilityWide exposure latitudePhotosensitive materialsDecorative surface effectsScreen printingWater insoluble

A photosenstive resin composition is prepared by dispersing at least one of a hydrophobic polymer and a mixture of an oil-soluble photopolymerization initiator and a water-insoluble or sparingly water-soluble compound having at least one photoactive, ethylenically unsaturated group in an aqueous solution that contains both a water-soluble polymer and a diazo resin is obtained by condensing a water-soluble salt of an optionally substituted 4-diazodiphenylamine with formaldehyde in the presence of sulfuric acid and phosphoric acid. This photosensitive resin composition gives a photosensitive film having excellent stability over time and a wide exposure latitude. By adding a specific fluorine compound to the photosensitive resin composition, a screen plate has an excellent discharge performance.

Owner:SUNTYPE

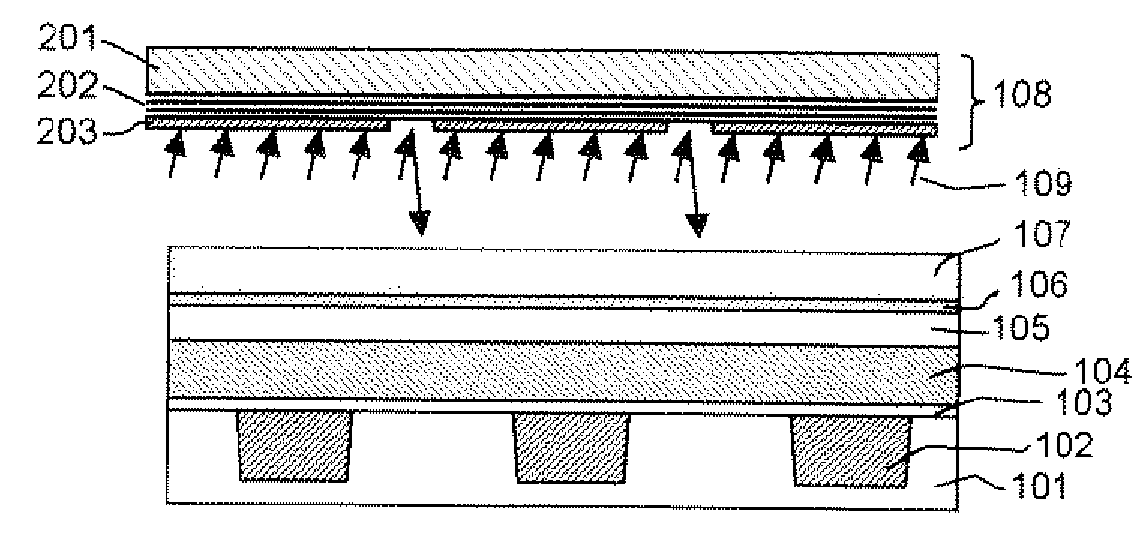

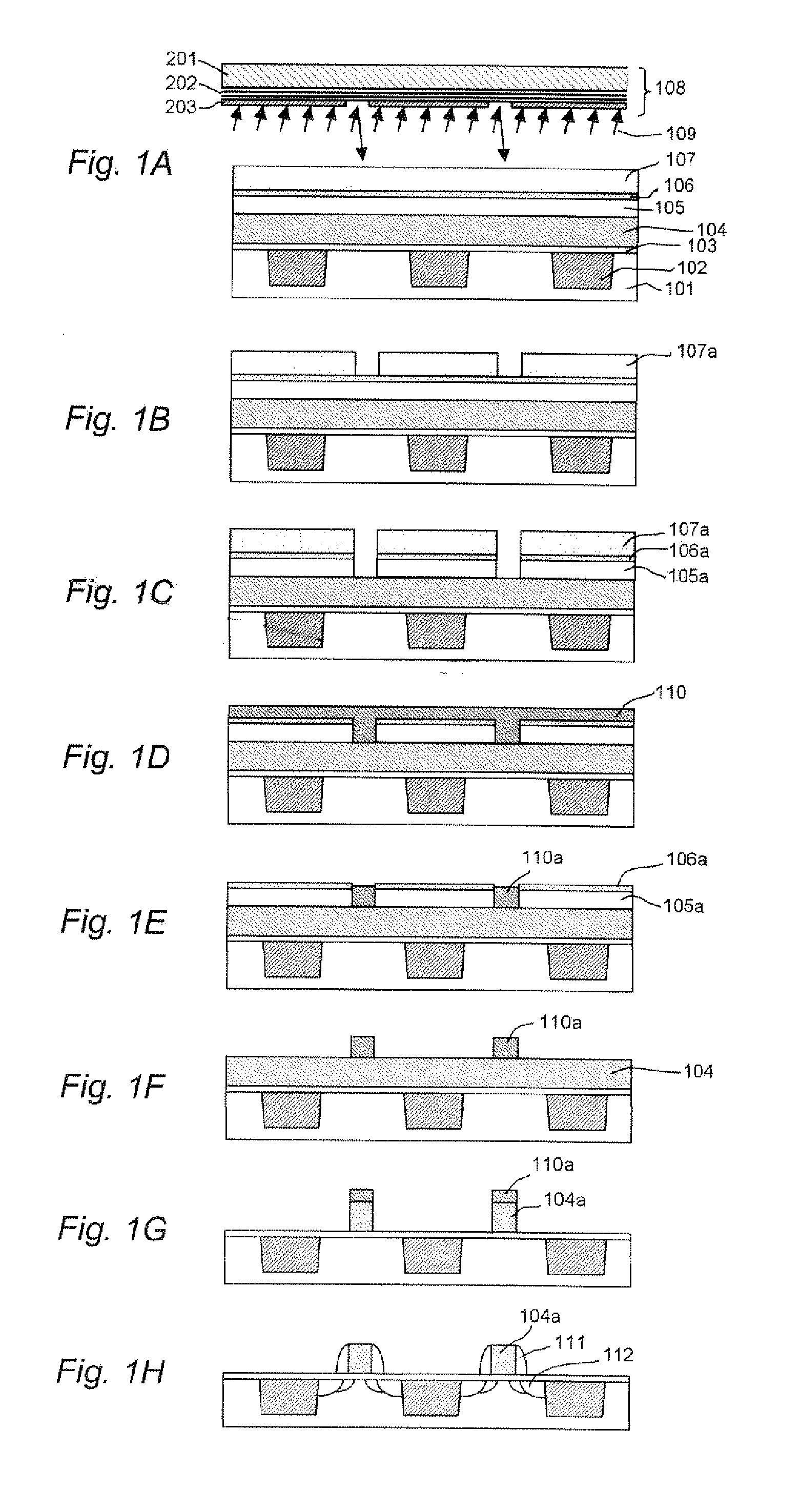

Method for manufacturing semiconductor device

ActiveUS20100285409A1High exposure latitudeHigh yieldSolid-state devicesSemiconductor/solid-state device manufacturingExposure latitudeSemiconductor

A reverse pattern is formed once by combining a negative exposure mask having a wiring pattern with a positive resist, and then a positive wiring pattern is formed by use of the reverse pattern. That is, a positive resist applied on a semiconductor substrate is exposed by use of the exposure mask having an opening part in a region corresponding to the wiring pattern, and then the exposed part is removed by development to form a resist pattern, thereby forming the wiring pattern in the region corresponding to the opening part of the resist pattern. Consequently, it is hardly affected by flare during EUV exposure, thereby fabricating a fine wiring pattern with higher exposure latitude.

Owner:RENESAS ELECTRONICS CORP

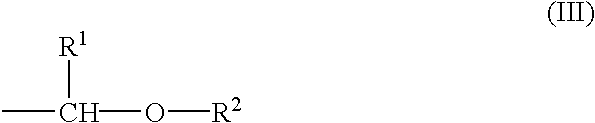

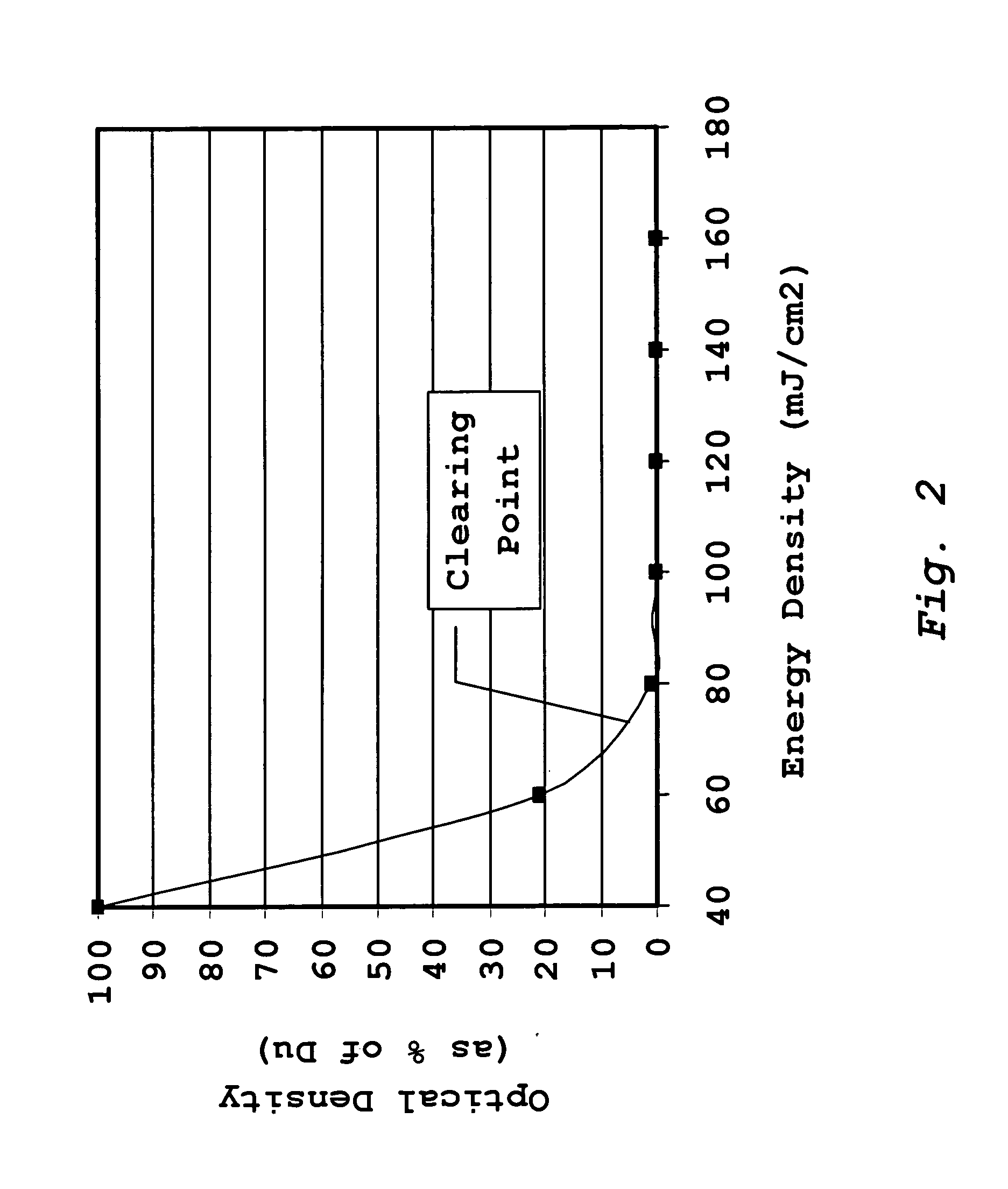

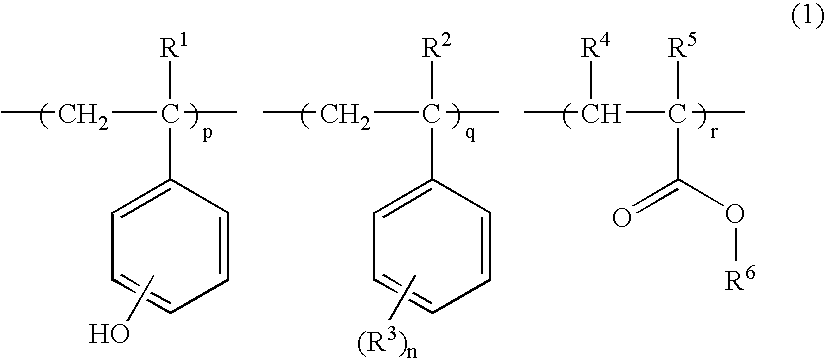

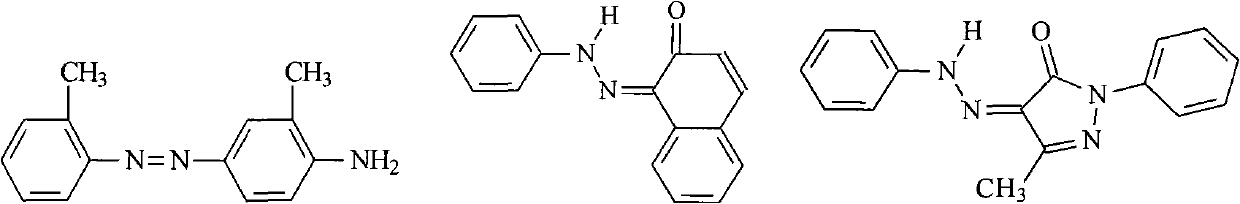

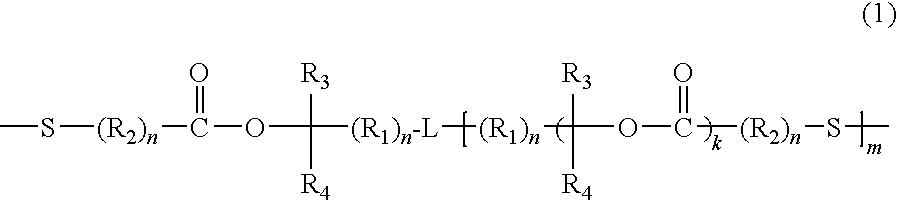

Positive resist material and pattern formation method using the same

InactiveUS7651829B2Pattern in good shapeExcellent etch resistanceRadiation applicationsSemiconductor/solid-state device manufacturingOrganic solventChemical compound

Provided is a positive resist material, particularly a chemically amplified positive resist material having higher sensitivity, higher resolution, a higher exposure latitude and better process adaptability than conventional positive resist materials, and providing a good pattern profile after exposure, particularly having lessened line edge roughness and exhibiting excellent etching resistance. These materials may contain, preferably an organic solvent and acid generator, more preferably a dissolution inhibitor or a basic compound and / or a surfactant. Provided is a positive resist material comprising a polymer comprising at least one monomer unit selected from a group consisting of a monomer unit (A), a monomer unit (B) and a monomer unit (C) represented by the following formula (1); and having a glass transition temperature (Tg) of 100° C. or greater.

Owner:SHIN ETSU CHEM IND CO LTD

Pattern forming method and resist composition

ActiveUS20130011785A1Excellent exposure latitudeIncrease exposurePhotosensitive materialsLayered productsActinic RaysOrganic solvent

Provided is a method of forming a pattern, ensuring excellent exposure latitude (EL) and focus latitude (depth of focus DOF). The method of forming a pattern includes (A) forming a film from a resist composition, the resist composition, (B) exposing the film to light, and (C) developing the exposed film using a developer containing an organic solvent, thereby forming a negative pattern. The resist composition contains (a) a resin that is configured to decompose when acted on by an acid and ΔSP thereof represented by formula (1) below is 2.5 (MPa)1 / 2 or above, (b) a compound that is composed to generate an acid when exposed to actinic rays or radiation, and (c) a solvent.ΔSP=SPF−SPI (1)

Owner:FUJIFILM CORP

Photosensitive planography printing plate

ActiveCN1519649AHigh sensitivityExcellent developabilityElectrolysis componentsPhotomechanical coating apparatusExposure latitudeImage formation

The object of the invention is to solve the problems in the related art, and to provide a photosensitive lithographic printing plate which is processable for image formation thereon with argon ion laser, FD-YAG laser, violet laser or the like, which has high sensitivity, which satisfies both the requirement of staining resistance in printing and the requirement of printing durability, and which has good developability, good ink acceptability, good image formability and broad exposure latitude.

Owner:FUJIFILM CORP

Method for making a lithographic printing plate

ActiveUS20090081583A1Improve printing effectReduce solubilityPhotosensitive materialsDuplicating/marking methodsExposure latitudeEngineering

A method for making a lithographic printing plate includes the steps of: (1) providing a heat-sensitive lithographic printing plate precursor including on a support having a hydrophilic surface or which is provided with a hydrophilic layer, a heat-sensitive coating, (2) image-wise exposing the precursor with IR-radiation or heat, and (3) developing the image-wise exposed precursor with an alkaline developing solution including a compound having at least two onium groups. According to the above method, a printing plate is formed with an improved developing latitude or an improved exposure latitude.

Owner:AGFA OFFSET BV

Photosensitive composition, compound for use in the photosensitive composition and pattern forming method using the photosensitive composition

ActiveUS7691558B2Excellent in sensitivity and resolutionIncrease exposurePhotosensitive materialsSemiconductor/solid-state device manufacturingImage resolutionExposure latitude

A photosensitive composition for use in the production process of a semiconductor such as IC, in the production of a circuit substrate of liquid crystal, thermal head and the like or in other photofabrication processes, a compound for use in the photosensitive composition, and a pattern forming method using the photosensitive composition, are provided, which are a photosensitive composition excellent in the sensitivity, resolution and pattern profile, assured of large exposure latitude and small pitch dependency, and improved in the sensitivity and dissolution contrast at the exposure with EUV light, a pattern forming method using the photosensitive composition, and a compound useful for the photosensitive composition.

Owner:FUJIFILM CORP +1

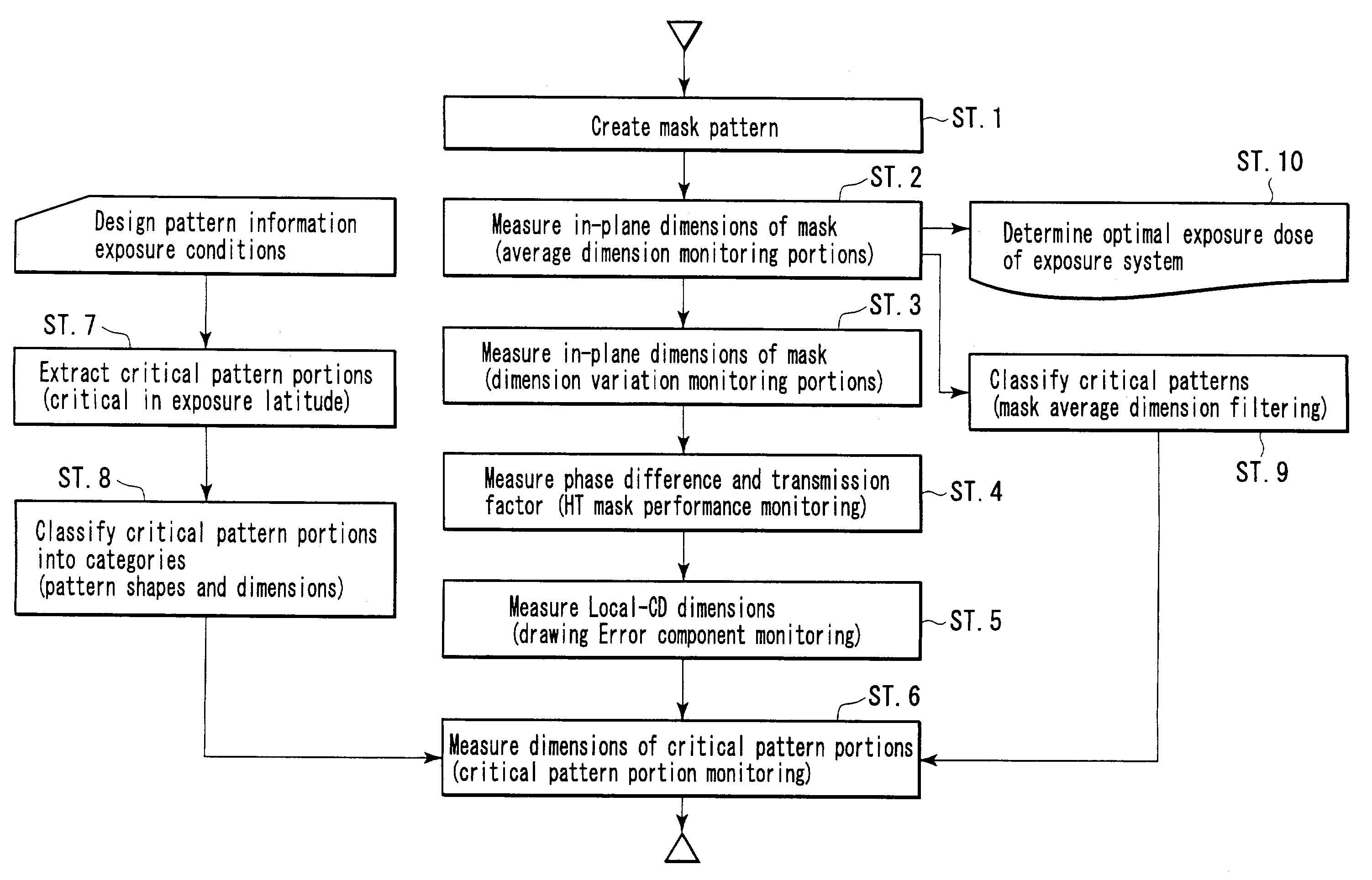

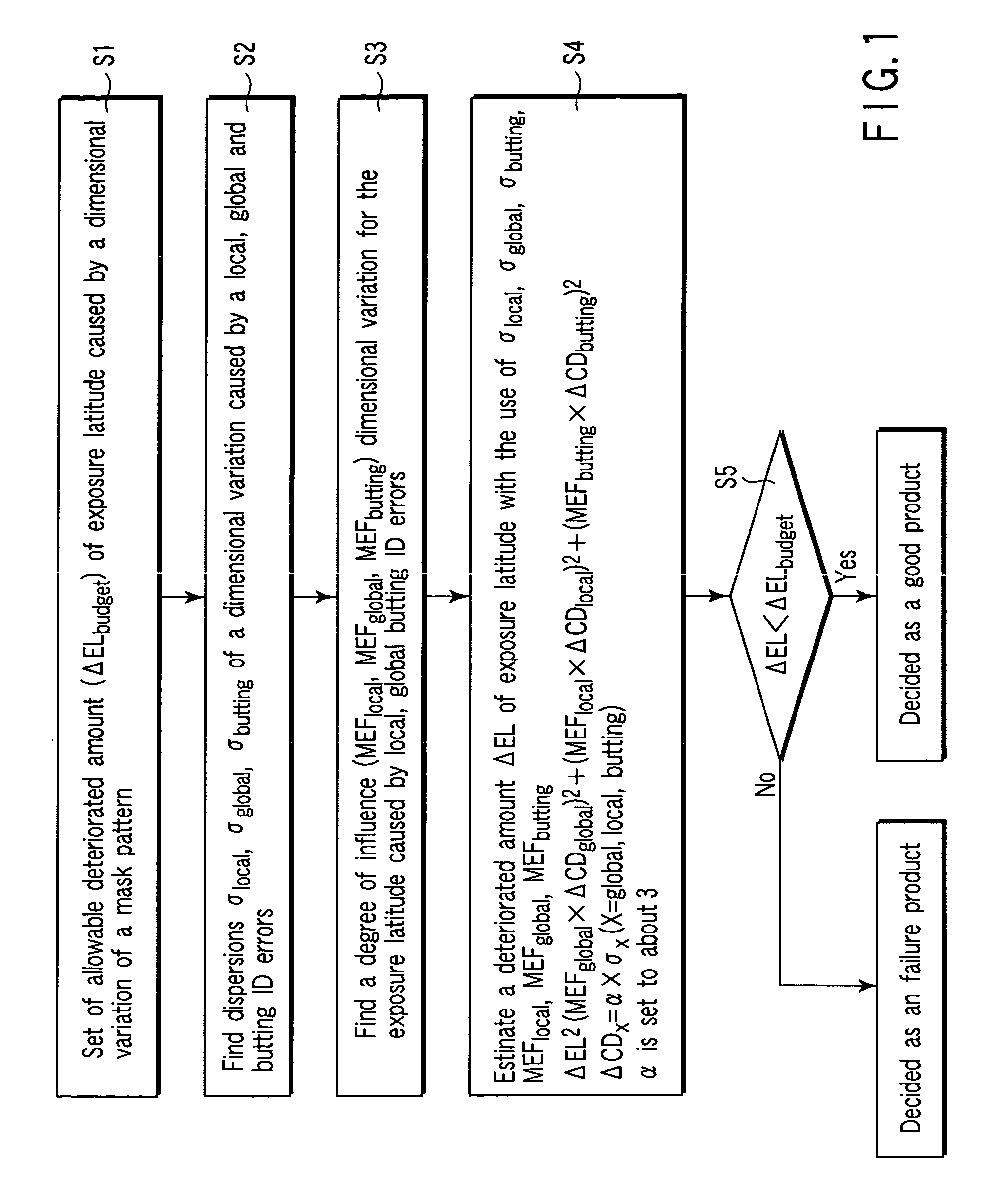

Method of manufacturing a photomask and method of manufacturing a semiconductor device using the photomask

A method of manufacturing a photomask includes determining dimensions of a pattern in a photomask, determining an exposure latitude on the basis of the dimensions of the mask, and judging if the photomask is defective or non-defective on the basis of whether or not the exposure latitude falls within a prescribed exposure latitude. The pattern in the photomask includes dimensions of critical pattern portions in which an exposure latitude is low.

Owner:KIOXIA CORP

Method for merging digital images to obtain a high dynamic range digital image

InactiveUS20060215932A1Quality improvementOptimization of detailsImage enhancementImage analysisComputer graphics (images)Weight coefficient

Owner:STMICROELECTRONICS SRL

Actinic-ray-sensitive or radiation-sensitive resin composition, and resist film and pattern forming method using the same composition

InactiveUS20120207978A1Excellent exposure latitudeReduce solubilityPhotosensitive materialsLayered productsActinic RaysExposure latitude

An object of the present invention is to provide an actinic-ray-sensitive or radiation-sensitive resin composition which is significantly excellent in terms of exposure latitude, is capable of forming a favorable rectangular pattern profile, and exhibits low dissolution of the components into an immersion liquid when performing immersion exposure, and a resist film and a pattern forming method each using the same composition. The actinic-ray-sensitive or radiation-sensitive resin composition contains (A) a compound represented by formula (I) and capable of generating an acid upon irradiation of actinic-rays or radiations, and (B) a resin capable of increasing the solubility in an alkaline developer by the action of an acid.

Owner:FUJIFILM CORP

Positive resist composition and pattern forming method using the same

ActiveUS7955780B2Reduce developmentPhotosensitive materialsPhoto-taking processesSide chainExposure latitude

Provided is a positive resist composition using a resin having, in the polymer main chain, a specific acid decomposable structure and further having, in the side chain thereof, several specific acid decomposable groups, satisfactory in an exposure latitude, a focus latitude, and pattern collapse prevention at a high level, and having reduced development defects; and a pattern forming method.

Owner:FUJIFILM CORP

Method for merging digital images to obtain a high dynamic range digital image

InactiveUS7680359B2Quality improvementOptimization of detailsImage enhancementImage analysisWeight coefficientExposure latitude

A method of processing digital source images, each represented by pixel matrices, to obtain from two or more source images, representing one and the same real scene and acquired by utilizing different exposure levels, a final digital image capable of reproducing the real scene with an exposure latitude greater than that of each of the source images. The method, which can be advantageously used in digital still cameras, produces the final image by combining the source images with the help of a weighted average constructed pixel by pixel. Thanks to a special filtering to which the weighting coefficients are subjected before the weighted mean operation, the method obtains a final image in which the source images are harmoniously combined with each other.

Owner:STMICROELECTRONICS SRL

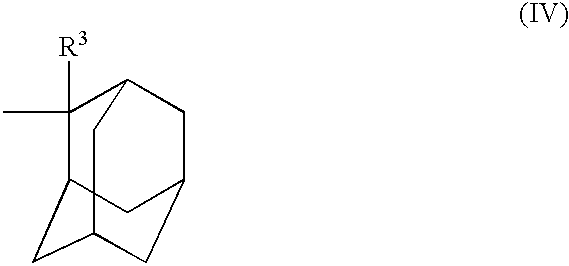

Chemical amplification type positive resist composition, and resist film, resist coated mask blanks and resist pattern forming method using the composition

InactiveUS20120202141A1High sensitivityHigh resolutionPhotomechanical apparatusOriginals for photomechanical treatmentMicrofabricationExposure latitude

The object of the present invention is to solve the technical problems in the microfabrication of photomasks or semiconductors and is, in particular, to provide a chemical amplification type positive resist film, and a resist film, resist coated mask blanks and a method of forming a resist pattern using the composition, which satisfy at the same time all of high sensitivity, high resolution (for example, high resolving power), good exposure latitude (EL), and good line edge roughness (LER).A chemical amplification type positive resist composition comprising: a high molecular compound (A) having a repeating unit represented by the following general formula (1), a repeating unit represented by the following general formula (2), and a repeating unit represented by the following general formula (3).

Owner:FUJIFILM CORP

Photoacid generator, resist composition, and patterning process

ActiveUS8609889B2Reduce molecular weightPromote adequate diffusionOrganic chemistryOrganic compound preparationImage resolutionExposure latitude

The photoacid generator produces a sulfonic acid which has a bulky cyclic structure in the sulfonate moiety and a straight-chain hydrocarbon group and thus shows a controlled acid diffusion behavior and an adequate mobility. The PAG is fully compatible with a resin to form a resist composition which performs well during the device fabrication process and solves the problems of resolution, LWR, and exposure latitude.

Owner:SHIN ETSU CHEM IND CO LTD

Method for evaluating photo mask and method for manufacturing semiconductor device

InactiveUS7229721B2Photomechanical exposure apparatusMicrolithography exposure apparatusEtchingExposure latitude

A method for evaluating a photo mask comprises preparing a photo mask including a unit drawing pattern, finding a dimensional variation relating to the photo mask, the dimensional variation including first and second dimensional variations, the first dimensional variation occurring due to a positional displacement and size mismatch of the unit drawing pattern in the photo mask and the second dimensional variation occurring due to etching and development relating to a manufacturing of the photo mask, estimating a deteriorated amount of an exposure latitude occurring due to the dimensional variation of the photo mask using the dimensional variation and a degree of influence of the dimensional variation for the exposure latitude, and judging quality of the photo mask by comparing the deteriorated amount of the exposure latitude and an allowable deteriorated amount of the exposure latitude.

Owner:KK TOSHIBA

Device manufacturing method

InactiveUS20080030708A1Uniform processingReduce thermal effectsSemiconductor/solid-state device manufacturingDiffraction gratingsExposure latitudeOptoelectronics

Owner:ASML NETHERLANDS BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com