Flexible photosensitive resin plate and preparation method thereof

A photosensitive resin, flexible technology, applied in the field of photographic plate making, can solve the problems of reducing the photosensitive speed of flexo plate, large exposure latitude of flexo plate, complicated process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

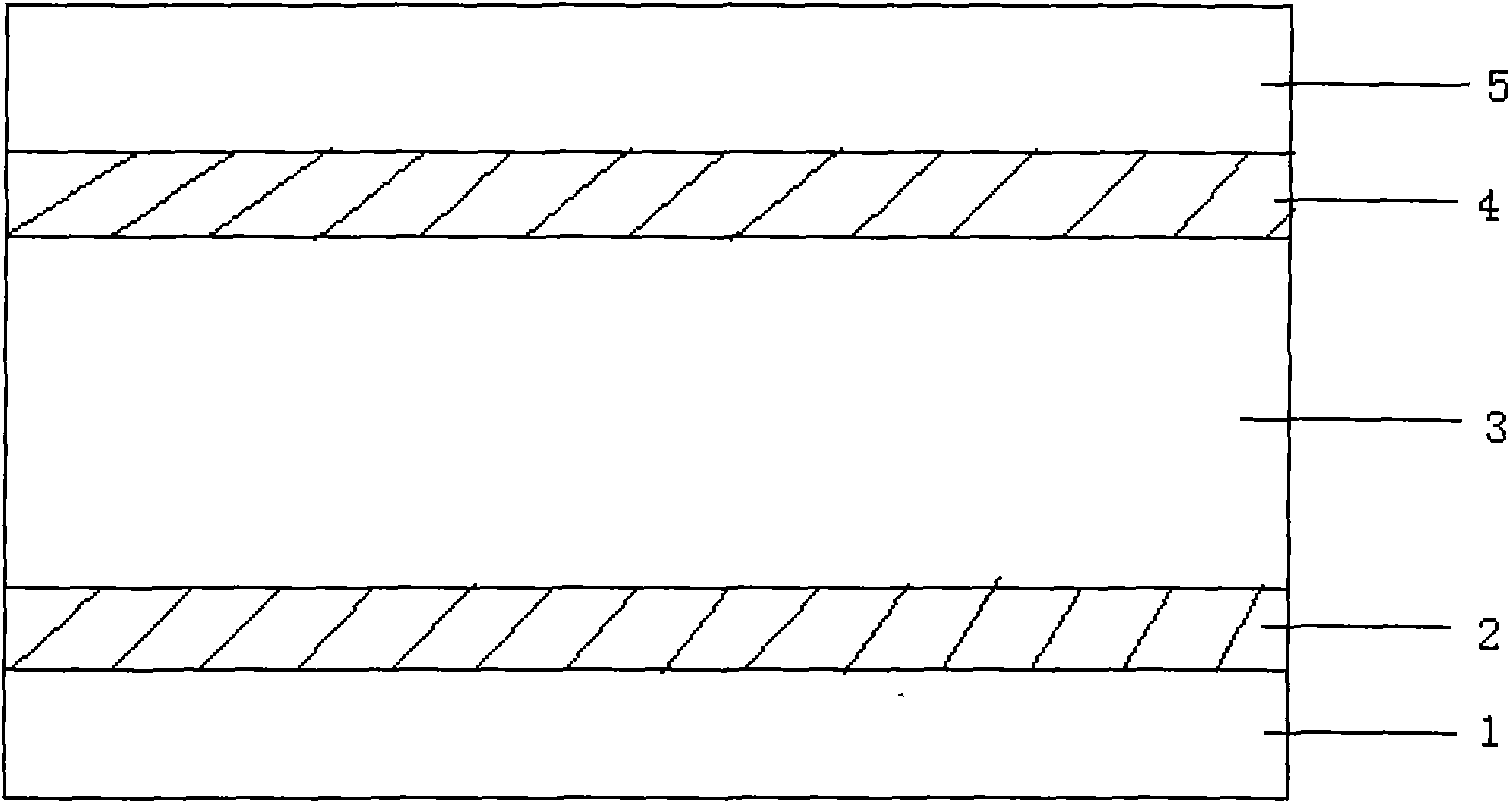

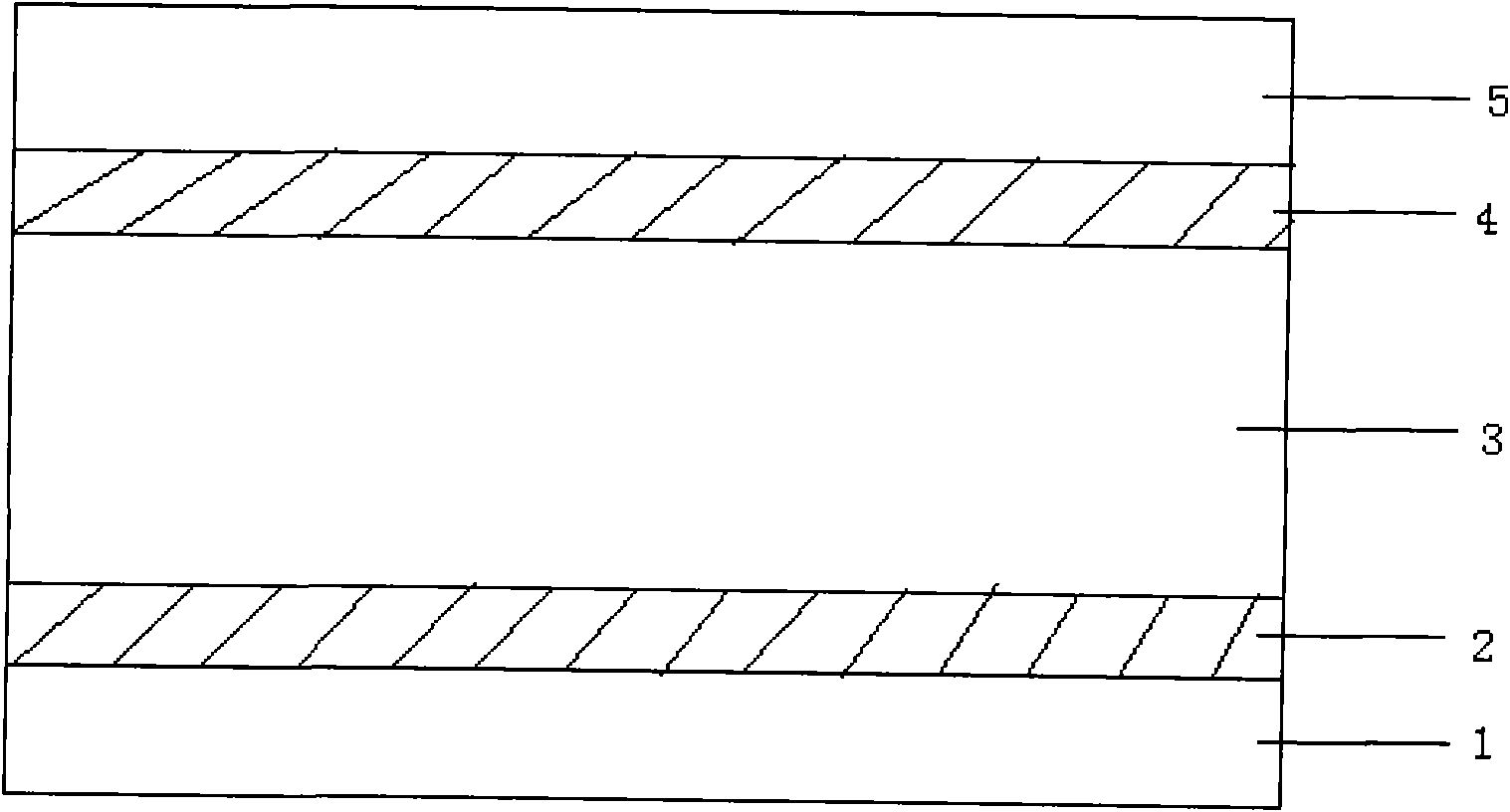

[0030] Add thermoplastic elastomer SIS D-1160, plasticizer polybutadiene Ricon 154, photoinitiator 651, stabilizer 264, unsaturated monomer, dye transparent green G (Solvent Green 20, anthraquinone) in proportion to dense In the mill, mix at 110 ° C for 35 minutes to obtain a photosensitive resin; take a certain amount of photosensitive resin and put it into the mold, and compound the protective film 5 with the release layer 4 and the support with the adhesive layer 2 on both sides respectively. 1. Use a flat vulcanizer to heat press for 190 seconds at a temperature of 20°C and a pressure of 0.15MPa, and obtain a flexible photosensitive resin plate after cooling. Plate thickness 1.14mm. The amount of dye transparent green G used was 0.01% by weight of the photosensitive resin layer 3 .

[0031] The protective film 5 with the release layer 4 is produced by the second film factory of Lucky Group.

[0032] The support body 1 with the adhesive layer 2 is produced by the second f...

Embodiment 2

[0034] Add thermoplastic elastomer SIS D-1165, plasticizer polybutadiene Ricon 154, photoinitiator 651, stabilizer 264, unsaturated monomer, dye transparent green 6G (Solvent Green 28, anthraquinone) in proportion to dense In the mill, mix at 150°C for 25 minutes to obtain a photosensitive resin; take a certain amount of photosensitive resin and put it into a mold, and composite a protective film 5 with a release layer 4 on both sides and a support with an adhesive layer 2 on both sides. 1. Use a flat vulcanizer to heat press for 180 seconds at a temperature of 150 ° C and a pressure of 14 MPa, and after cooling, a flexible photosensitive resin plate is obtained, and the thickness of the plate is 1.70 mm. The amount of the dye transparent green 6G is 0.05% by weight of the photosensitive resin layer 3 .

[0035] The protective film 5 with the release layer 4 is produced by the second film factory of Lucky Group.

[0036] The support body 1 with the adhesive layer 2 is produce...

Embodiment 3

[0038]The thermoplastic elastomer SIS D-1107, plasticizer polybutadiene Ricon 154, photoinitiator 184, stabilizer 264, unsaturated monomer, neutral red, dye transparent green 5B (Solvent Green 3, anthraquinones) The photosensitive resin is prepared by adding a certain amount of photosensitive resin into the internal mixer according to the proportion, and mixing at 120°C for 30 minutes. The support 1 of 2 was hot-pressed with a flat vulcanizer at a temperature of 50° C. and a pressure of 2 MPa for 182 seconds, and after cooling, a flexible photosensitive resin plate was obtained, and the plate thickness was 3.94 mm. The amount of the dye transparent green 5B is 1.0% by weight of the photosensitive resin layer 3 .

[0039] The protective film 5 with the release layer 4 is produced by the second film factory of Lucky Group.

[0040] The support body 1 with the adhesive layer 2 is produced by the second film factory of Lucky Group.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com