800DEG C-1250DEG C multi color-changing irreversible thermopaint

A temperature-indicating paint and paint technology, which is applied to heat-sensitive paints, thermometers with physical/chemical changes, coatings, etc. The effect of sensitive color change, obvious color difference and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Weigh 50g epoxy-modified silicone resin (50%), 15g xylene, stir and mix, then add 35g zinc titanium yellow, 5g cobalt carbonate, 8g talc, 15g kaolin, 7g potash feldspar powder, 2g of barium carbonate, 2g of magnesium carbonate, and 1g of calcium carbonate. Stir while adding materials to make a color paste. Send the prepared color paste to a ball mill, grind and disperse, and measure the fineness to no more than 30μm with a scraper fineness meter. , Add the remaining 10g of xylene to the milled and dispersed color paste, mix well, filter and pack, and get a light iron yellow paint.

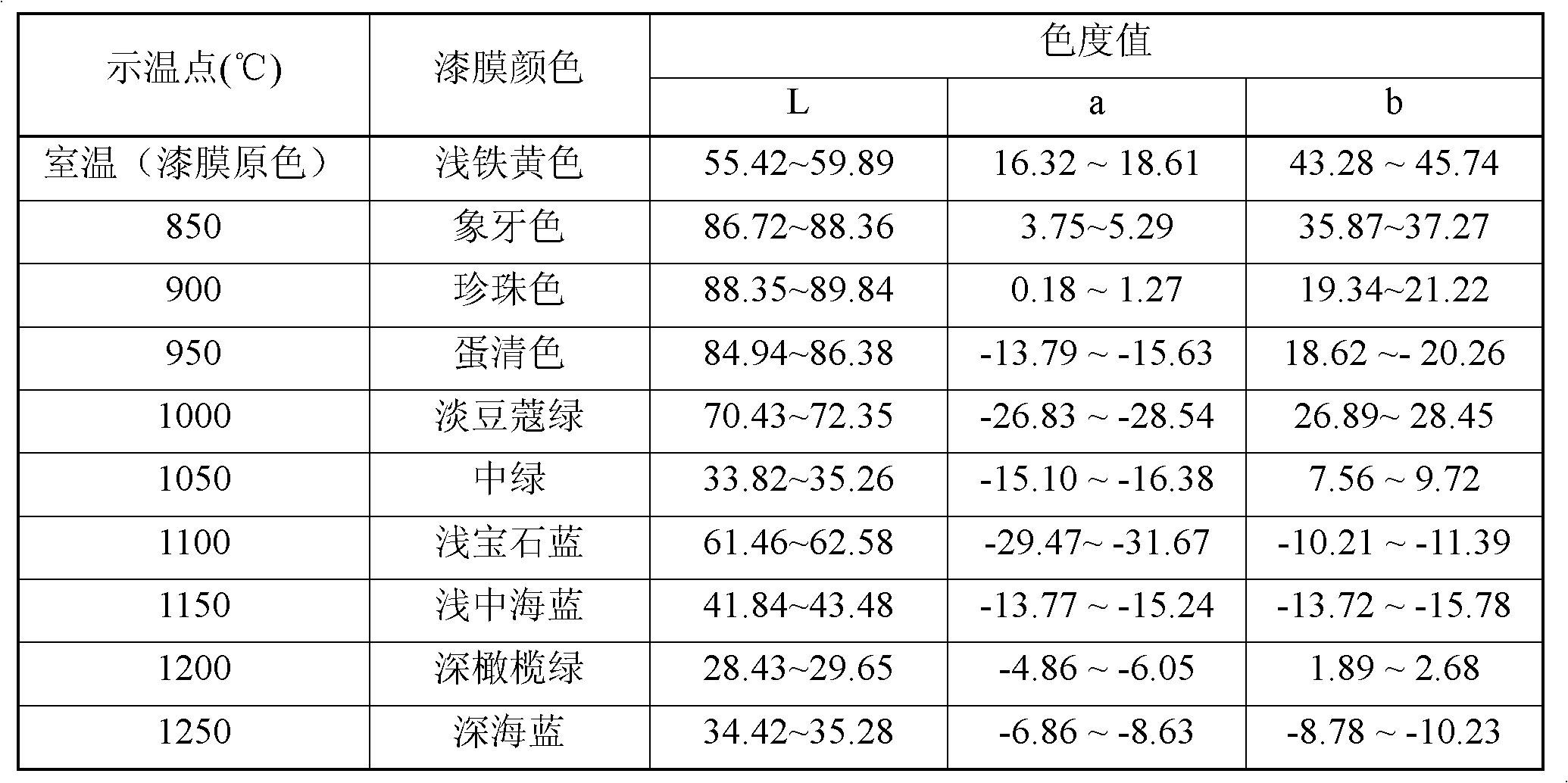

[0034] Prepare the paint film on a 200×200mm high-temperature alloy steel plate according to the "General Preparation Method of Paint Film" (GB1727-79). After the paint film is completely dry, ablate it with an oxyacetylene flame for 3 minutes to 5 minutes. Minutes later, cool down naturally to room temperature. From the low temperature zone to the high temperature zone, the coating ...

Embodiment 2

[0035] Example 2. Weigh 50g of epoxy-modified silicone resin (50%), 20g of xylene, stir and mix, then add 35g of zinc titanium yellow, 6.5g of cobalt sulfate, 7g of talc, 18g of kaolin, and 7g of potash feldspar powder. , Barium carbonate 2g, Magnesium carbonate 2g, Calcium carbonate 2g, stir while adding materials to make color paste, send the prepared color paste to a ball mill, grind and disperse, use a scraper fineness meter to measure the fineness to no more than 30μm. Yes, add 10g of the remaining xylene to the milled and dispersed color paste, mix well, filter and pack, and get a light iron yellow paint.

[0036] Prepare the paint film on a 200×200mm high-temperature alloy steel plate according to the "General Preparation Method of Paint Film" (GB1727-79). After the paint film is completely dry, ablate it with an oxyacetylene flame for 3 minutes to 5 minutes. Minutes later, cool down naturally to room temperature. From the low temperature zone to the high temperature zone,...

Embodiment 3

[0037] Example 3. Weigh 50g of epoxy-modified silicone resin (50%), 15g of xylene, stir and mix, and then add 35g of zinc titanium yellow, 7g of cobalt phosphate, 5g of talc, 20g of kaolin, and 8g of potash feldspar powder. 1.5g of barium carbonate, 2g of magnesium carbonate, and 1g of calcium carbonate. Stir while adding materials to make a color paste. Send the prepared color paste to a ball mill, grind and disperse, and measure the fineness to no more than 30μm with a scraper fineness meter. Yes, add 11g of remaining xylene to the milled and dispersed color paste, mix well, filter and pack, and get a light iron yellow paint.

[0038] Prepare the paint film on a 200×200mm high-temperature alloy steel plate according to the "General Preparation Method of Paint Film" (GB1727-79). After the paint film is completely dry, ablate it with an oxyacetylene flame for 3 minutes to 5 minutes. Minutes later, cool down naturally to room temperature. From the low temperature zone to the high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com