Water-based resin sand stone-like paint and preparation method thereof

A technology of water-based resin and real stone paint, applied in the field of coatings, can solve problems such as serious color difference, increased pressure on environmental protection, and increased difficulty in mining colored sand, achieving the effects of fast dispersion, improved heat resistance, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

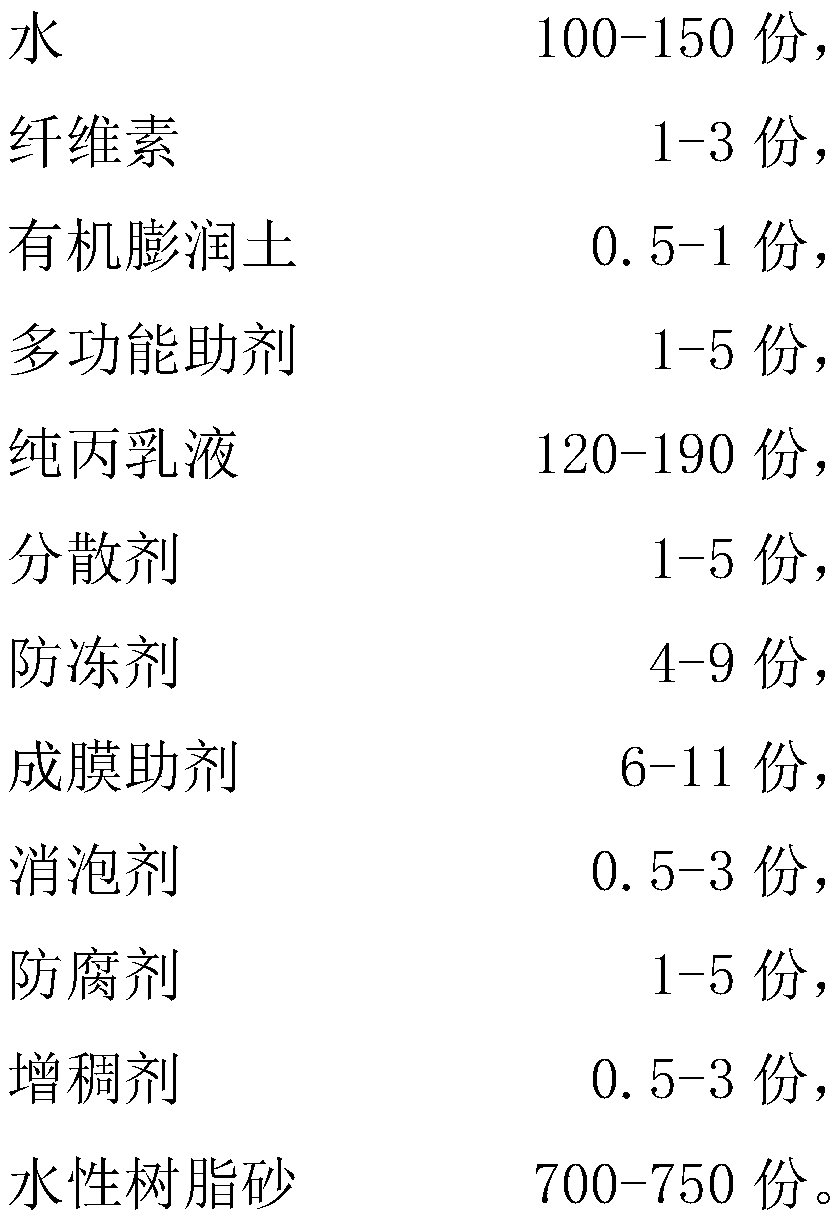

[0034] A kind of water-based resin sand genuine stone paint comprises following components by weight:

[0035]

[0036] The preparation method of above-mentioned water-based resin sand real stone paint, comprises the steps:

[0037] (1) Select a suitable container, weigh 3 parts of cellulose and add it to 120 parts of water under stirring, and stir at room temperature for 20 minutes at a speed of 750 rpm, until the state does not change;

[0038] (2) Weigh 2 parts of organic bentonite and add 80 parts of water under stirring state, stir at room temperature for 20 minutes at a speed of 750 rpm, and stir until the state no longer changes;

[0039] (3) Mix the prepared cellulose solution and bentonite solution in proportion, and stir for 10 minutes at a speed of 900 rpm;

[0040] (4) Add multifunctional additives, emulsions, dispersants, antifreezes, film-forming aids, defoamers, preservatives, and thickeners in turn at a speed of 750 rpm. It needs to be stirred for 2 minute...

Embodiment 2

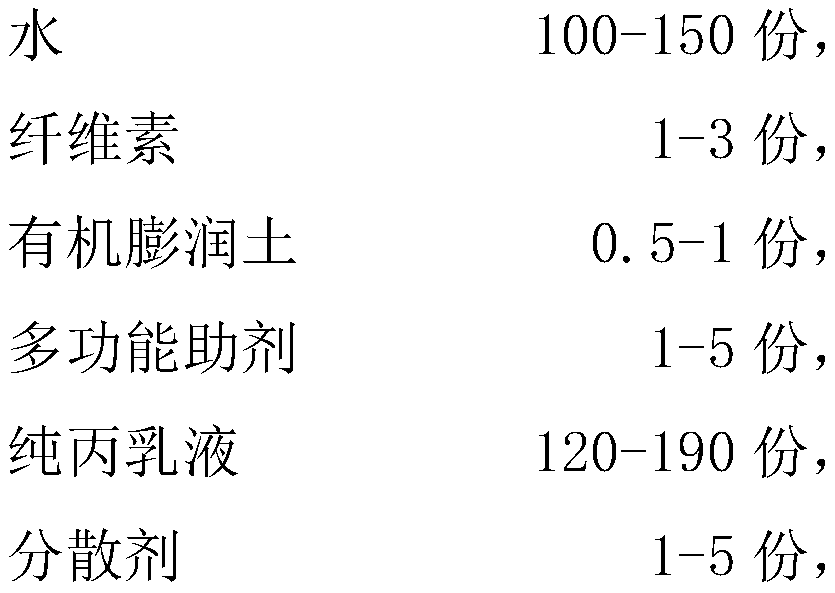

[0043] A kind of water-based resin sand genuine stone paint comprises following components by weight:

[0044]

[0045] The preparation method of above-mentioned water-based resin sand real stone paint, comprises the steps:

[0046] (1) Select a suitable container, weigh 2 parts of cellulose and add it to 80 parts of water while stirring, and stir at room temperature for 20 minutes at a speed of 600 rpm, until the state does not change;

[0047](2) Weigh 1.5 parts of organobentonite and add it into 70 parts of water while stirring, and stir at room temperature for 20 minutes at a speed of 800 rpm, until the state no longer changes;

[0048] (3) Mix the prepared cellulose solution and bentonite solution in proportion, and stir for 10 minutes at a speed of 850 rpm;

[0049] (4) Add multifunctional additives, emulsions, dispersants, antifreezes, film-forming aids, defoamers, preservatives and thickeners in sequence at a speed of 700 rpm, and each component is It needs to be ...

Embodiment 3

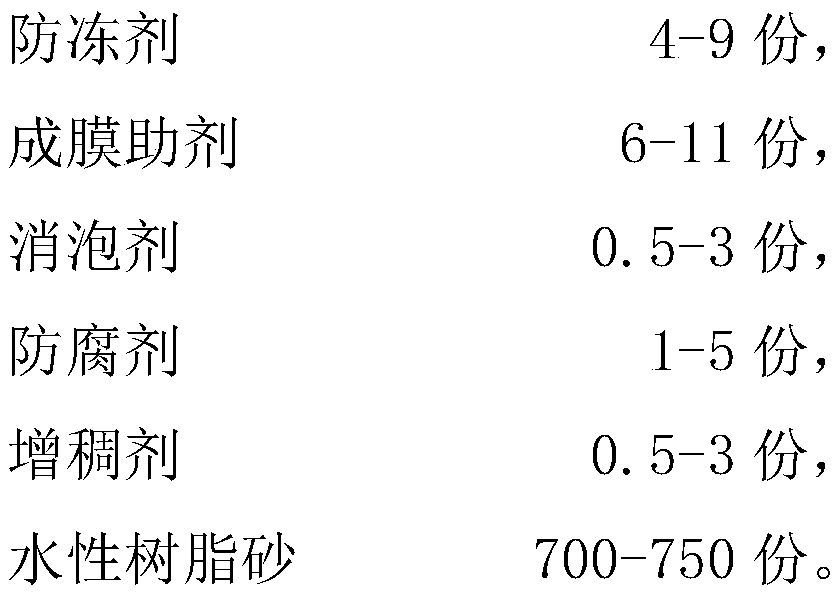

[0052] A kind of water-based resin sand genuine stone paint comprises following components by weight:

[0053]

[0054] Above-mentioned water-based resin sand real stone paint and preparation method thereof, comprises the steps:

[0055] (1) Select a suitable container, weigh 2 parts of cellulose and add 80 parts of water under stirring state, stir at room temperature for 20 minutes at a speed of 900 rpm, and stir until the state does not change;

[0056] (2) Weigh 1.5 parts of organic bentonite and add it into 70 parts of water under stirring, and stir at room temperature for 20 minutes at a speed of 600 rpm, until the state does not change;

[0057] (3) Mix the prepared cellulose solution and bentonite solution in proportion, and stir for 10 minutes at a speed of 900 rpm;

[0058] (4) Add multifunctional additives, emulsions, dispersants, antifreezes, film-forming aids, defoamers, preservatives, and thickeners in turn at a speed of 900 rpm. It needs to be stirred for 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com