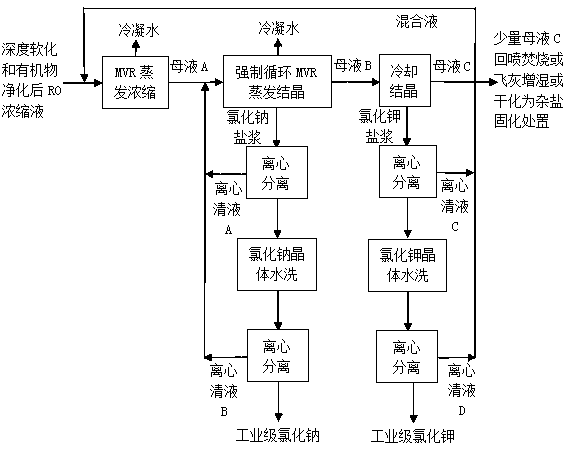

Landfill leachate RO concentrated solution evaporation, concentration and staged crystallization method

A landfill leachate, evaporation and concentration technology, which is applied in the full treatment of landfill leachate RO concentrate and the field of resource utilization, to achieve the effects of stable operation, wide process applicability, and simplicity and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The present invention will be further described below by taking the evaporative concentration segmented crystallization of RO concentrate in a leachate treatment project of a household waste incineration power plant as an example.

[0034] The scale of the leachate treatment project of the domestic waste incineration power plant is 500 tons per day, and the combined process of UASB+secondary A / O+UF (MBR)+NF+RO is adopted. The treatment project produces about 100 tons of RO concentrate per day, and its water quality is as follows: pH is 7.6~8.3, TOC is between 45~94mg / L, conductivity is between 56.8~74.6mS / cm, Ca 2+ and Mg 2+ The concentration ranges are 103~394mg / L and 90~396mg / L respectively. The main water quality of the RO concentrate after deep softening and organic oxidation pretreatment is as follows: pH is 4~6, TOC is between 13~18mg / L, TDS is between 34000~41000mg / L, Na + Between 8000~10000mg / L, K + Between 6200~7200mg / L, Cl - Between 17000~21000mg / L, Ca 2+...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com