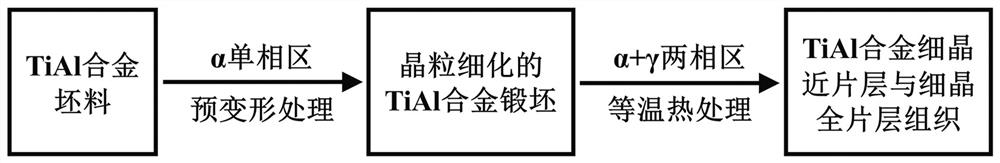

A thermomechanical treatment method for controlling the fine-grain structure of tial alloy

A deformation heat treatment and heat treatment furnace technology, which is applied in the field of thermal processing and preparation of high-temperature structural materials, can solve the problems of room temperature plasticity but poor high-temperature performance, poor mechanical properties near γ-structure, and no engineering application value, and achieves easy deformation and elimination of genetics. Sexual influences, the effect of eliminating bad structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

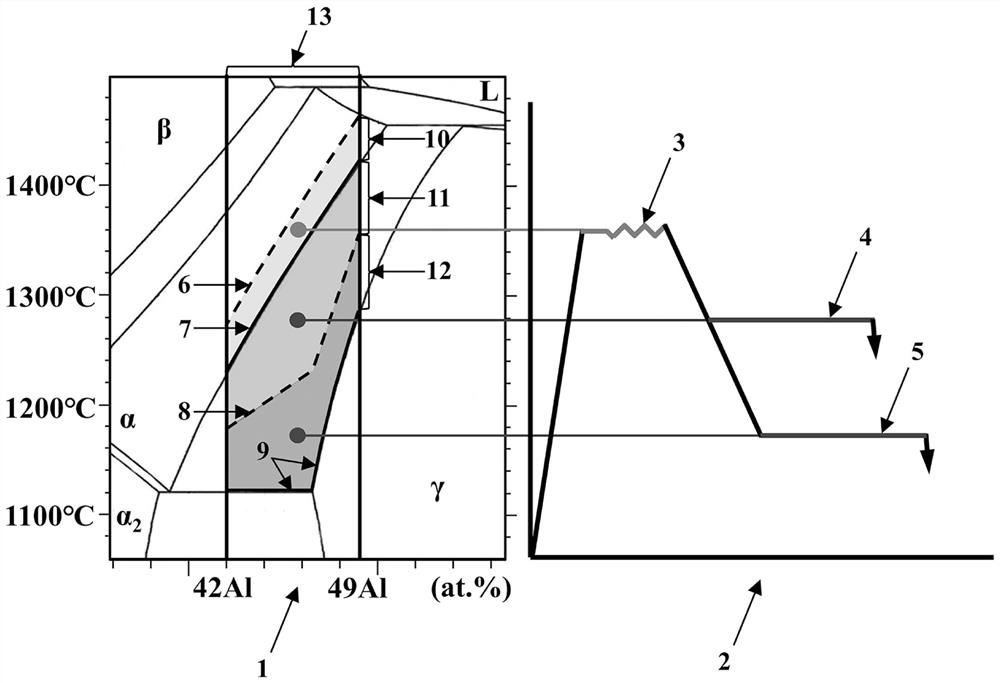

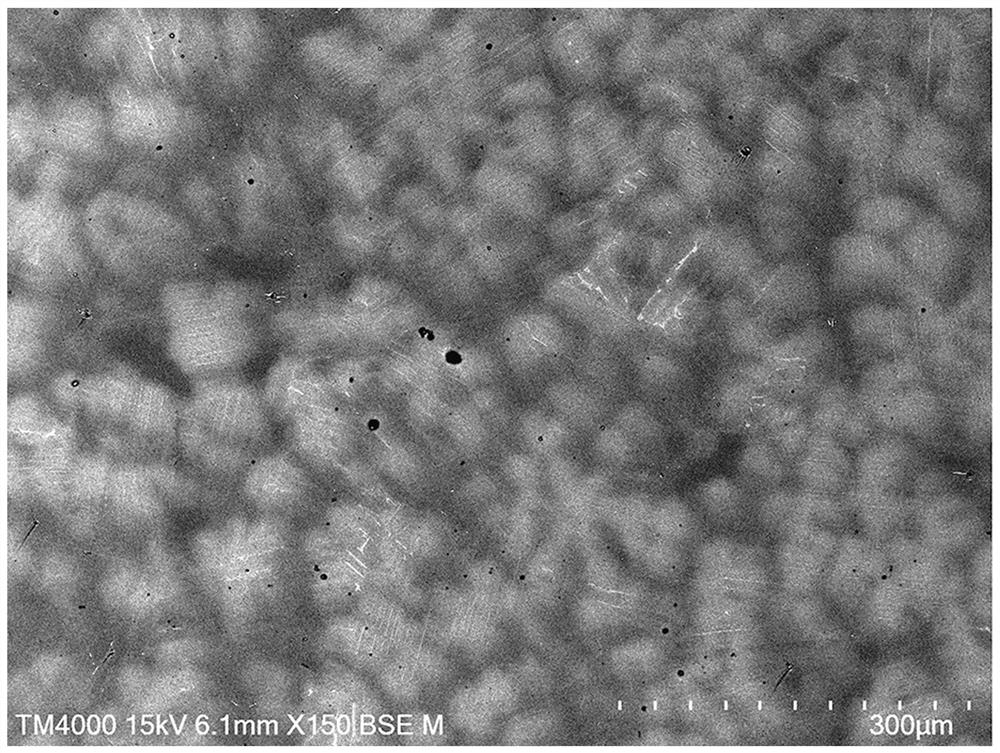

[0053] This example is a deformation heat treatment method for obtaining a fine-grained full-lamellar structure of TiAl alloy by using pre-deformation treatment and isothermal heat treatment in combination, and Ti-48.5Al-4Nb-2Cr-0.3(Fe, C, N) Alloy as an example, to be described in detail.

[0054] The Ti-48.5Al-4Nb-2Cr-0.3 (Fe, C, N) alloy is obtained by vacuum electrode self-consumption + water-cooled copper crucible induction melting centrifugal casting method, and the α of the composition alloy is obtained by metallography and differential thermal analysis. The temperature range of the single-phase region is 80°C, the temperature at the junction of the α single-phase region and the α+γ two-phase region, that is, the Tα temperature is 1390°C, the temperature range of the α+γ two-phase region is 130°C, and the Tγ temperature is 1260°C. like image 3 As shown, its microstructure is composed of coarse lamellar clusters with an average size greater than 300 μm and γ grains, an...

Embodiment 2

[0060] This embodiment is a deformation heat treatment method for obtaining TiAl alloy fine-grained near-lamellar layers by combining pre-deformation treatment and isothermal heat treatment, and taking Ti-47Al-2Nb-2Cr-0.2(C, N) alloy as an example, be described in detail.

[0061]The Ti-47Al-2Nb-2Cr-0.2(C, N) alloy is obtained by vacuum electrode self-consumption + water-cooled copper crucible induction melting gravity casting method, and the α single phase of the composition alloy is obtained by metallographic method and differential thermal analysis method The temperature range of the zone is 130°C, the temperature at the junction of the α single-phase zone and the α+γ two-phase zone, that is, the Tα temperature is 1340°C, the temperature range of the α+γ two-phase zone is 200°C, and the Tγ temperature is 1140°C. like Figure 5 As shown, its microstructure is completely composed of coarse lamellar clusters with an average size of more than 500 μm, which belongs to the full ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com