Continuous uniform fine foaming machine for producing plasterboards

A foaming machine and gypsum board technology, applied in clay preparation equipment, chemical instruments and methods, cement mixing equipment, etc., can solve the problems of difficult flow rate adjustment and control, uneven foam diameter, large consumption of foaming agent, etc. , to achieve precise adjustment and control, less consumption of foaming agent, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

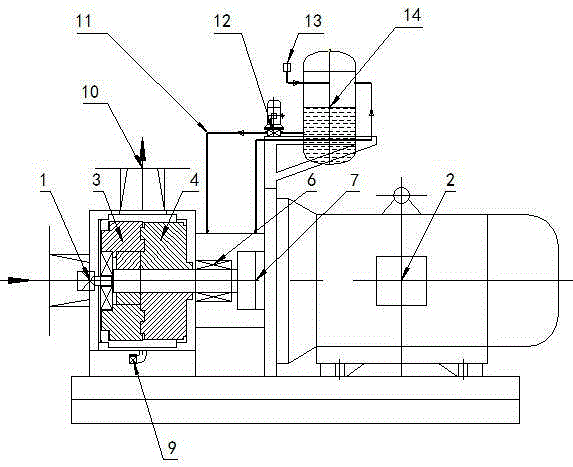

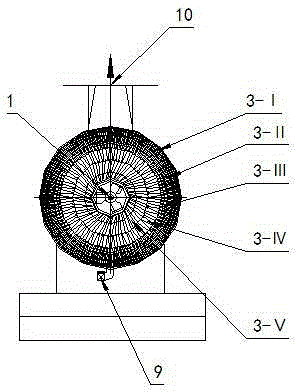

[0011] Such as figure 1 , 2 As shown, the continuous uniform gypsum board fine foaming machine includes a foaming machine body 1, a stator mechanism 3 and a rotor mechanism 4 are arranged inside the foaming cavity of the foaming machine body 1, and the rotor mechanism 4 is driven by a frequency conversion motor 2 to drive the rotation, the stator mechanism 3 is formed by combining several layers of stators from outside to inside, and the rotor mechanism 4 is formed by combining several layers of rotors respectively paired with the stator mechanism 3 .

[0012] The stator mechanism 3 and the rotor mechanism 4 are arranged alternately by several layers of toothed discs paired with each other, and the gap between the innermost layer and the outermost layer of the toothed discs gradually decreases.

[0013] In this embodiment, the foaming machine body 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com