Position adjusting system for heliostat cleaning equipment

A technology for cleaning equipment and adjusting systems, which is applied to cleaning methods and appliances, smoke and dust removal, control devices, etc. It can solve problems such as low production efficiency, high labor intensity, and insignificant cleaning effect, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the purpose, technical solution and advantages of the present invention clearer, the invention will be clearly and completely described below in conjunction with the accompanying drawings and specific embodiments.

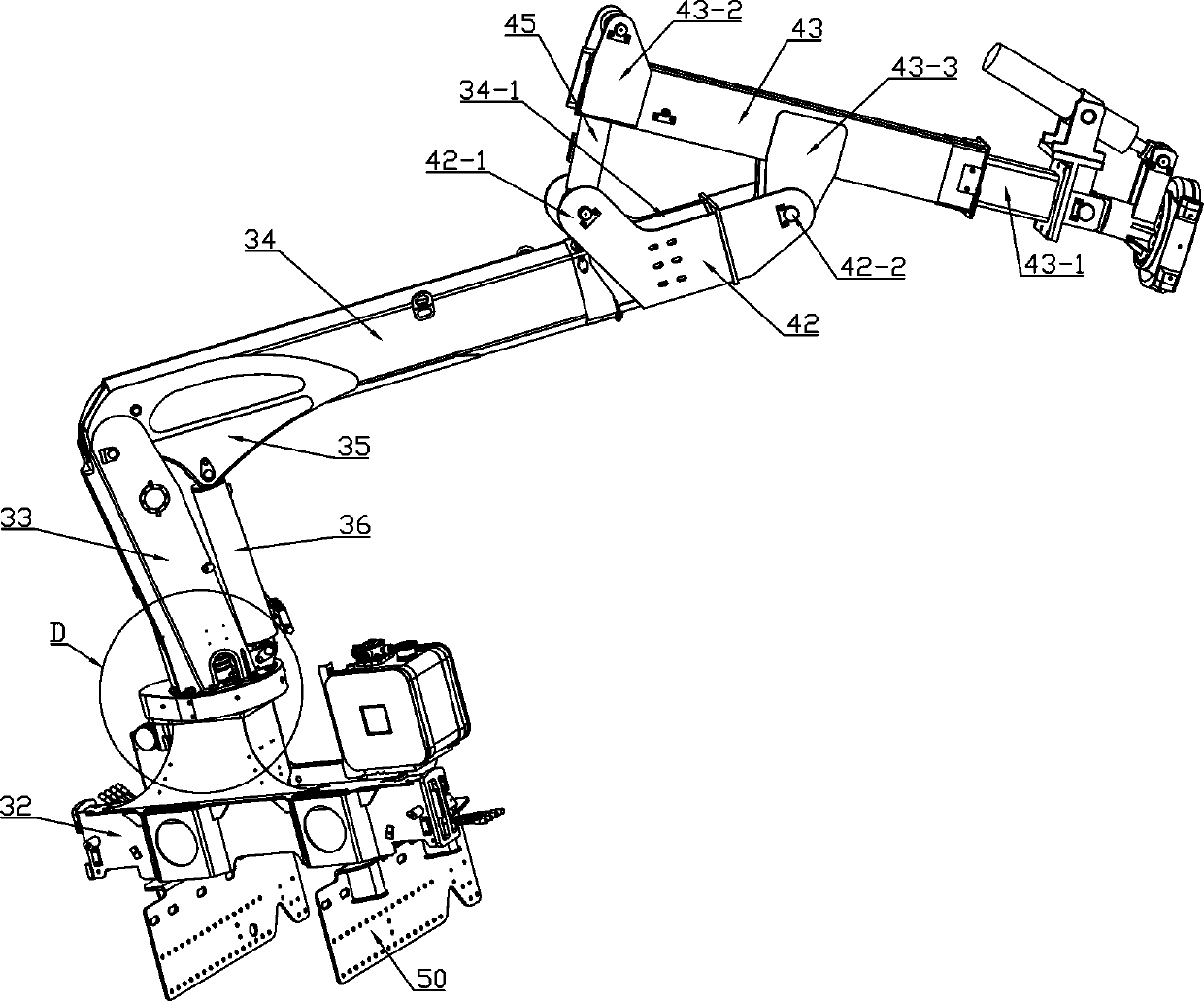

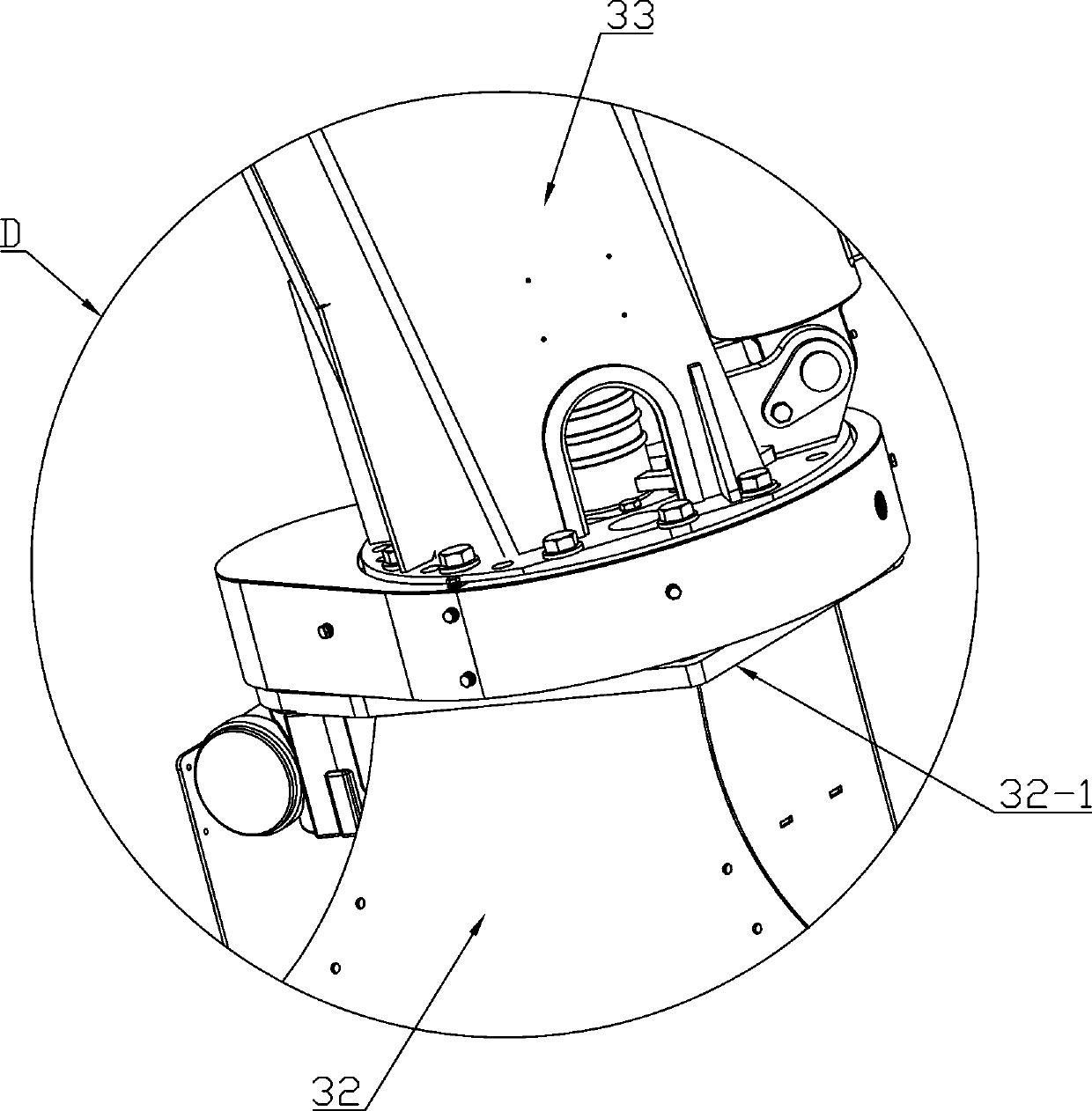

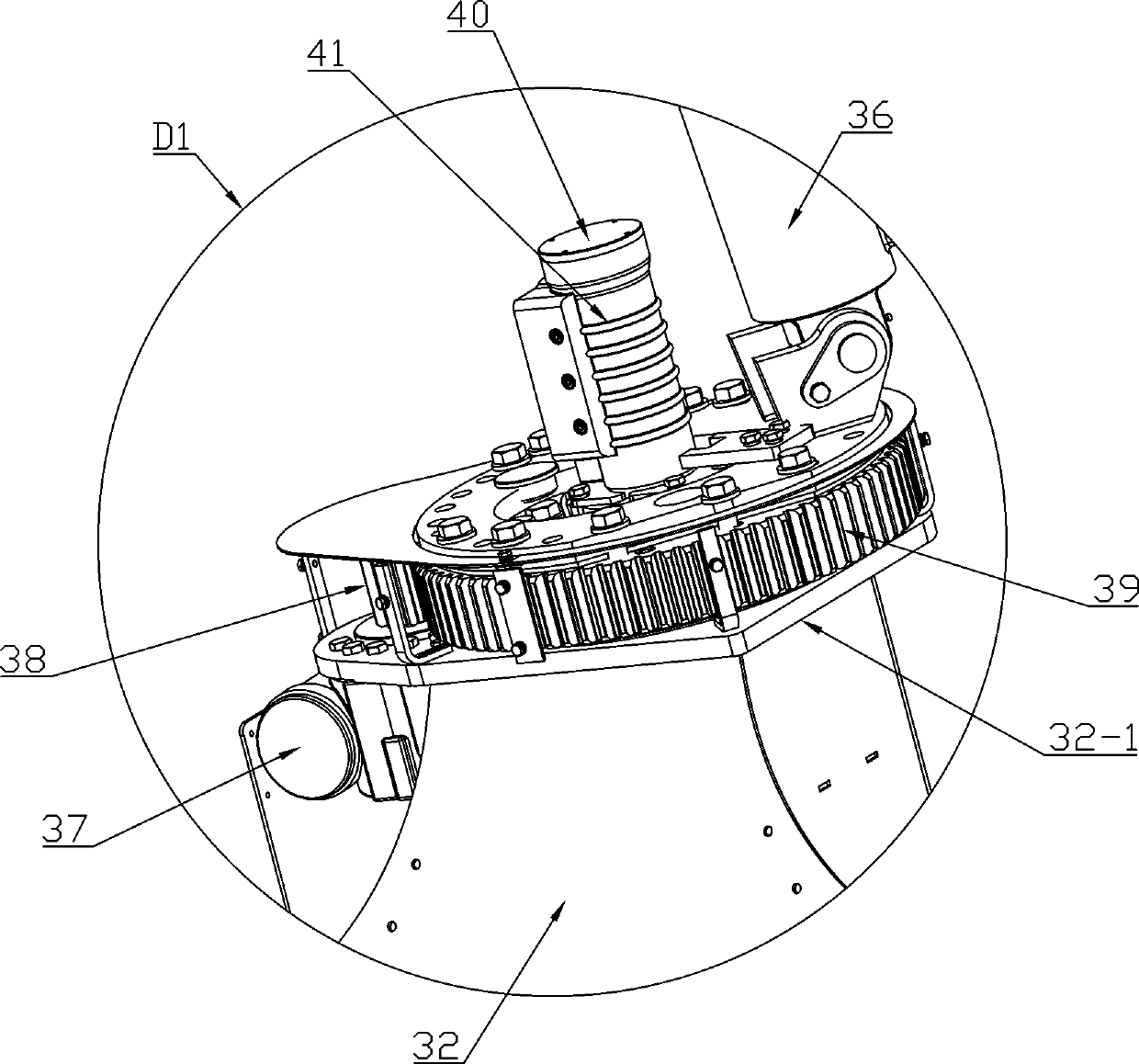

[0047] Such as Figure 1-19 A position adjustment system for heliostat cleaning equipment is shown, which includes:

[0048] A position adjustment system for heliostat cleaning equipment, which includes a multi-degree-of-freedom adjustable hydraulic boom 29 provided on the chassis of a cleaning vehicle 31, an adjustment device provided on a frame one 1, and a hydraulic boom 29 provided on the cleaning vehicle 31. The distance detection device near the side of the mirror surface of the heliostat 30 and the parallelism detection device arranged on the frame one 1, wherein the frame one 1 is connected to the hydraulic boom 29 through the connection seat 2 in the upper middle part of the frame one. The frame mounting positions 48 are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com