Modal fiber napping splitting agent with skin-core structure and preparation method of modal fiber napping splitting agent

A technology of modal fiber and skin-core structure, which is applied in fiber processing, plant fiber, textiles and papermaking, etc., can solve the problems of operator safety hazards, fabric strength reduction, damage to the inner wall of the machine cylinder, etc., to achieve a small impact on fiber strength and prevent Color point, strong effect with little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

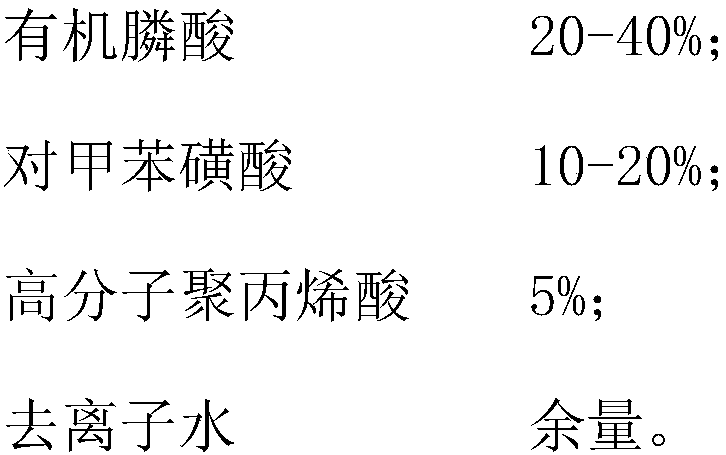

[0030] A sheath-core structure modal fiber raising fiber opening agent is composed of the following components in mass percentage:

[0031]

[0032] The molecular weight of the polymer polyacrylic acid is 2000-6000.

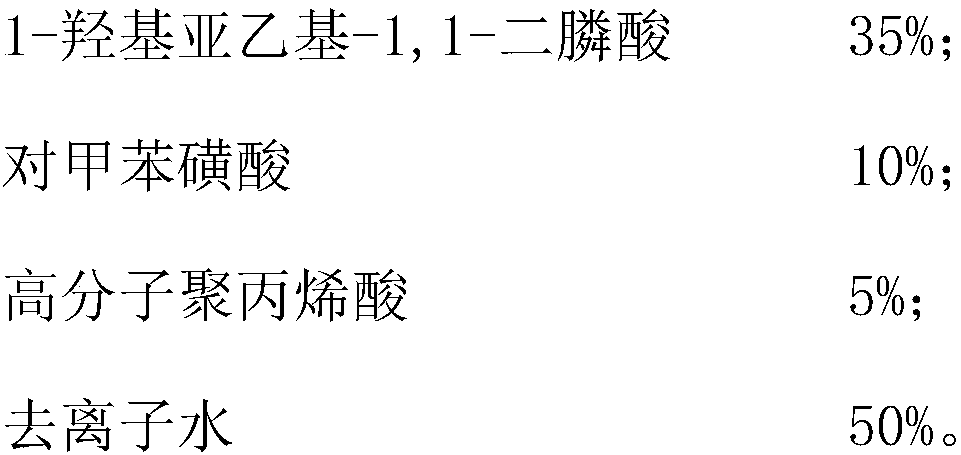

[0033] A preparation method of a fiber-opening agent for modal fibers with a skin-core structure, comprising the following steps: first, add 1-hydroxyethylidene-1,1-diphosphonic acid and p-toluenesulfonic acid in proportion to deionized water and stir evenly to form a mixed liquid, then add polymer polyacrylic acid in proportion to the mixed liquid and stir evenly to make a fiber opener.

Embodiment 2

[0035] A skin-core structure Modal fiber raising fiber opening agent, which is composed of the following components in mass percentage:

[0036]

[0037] The molecular weight of the polymer polyacrylic acid is 2000-6000.

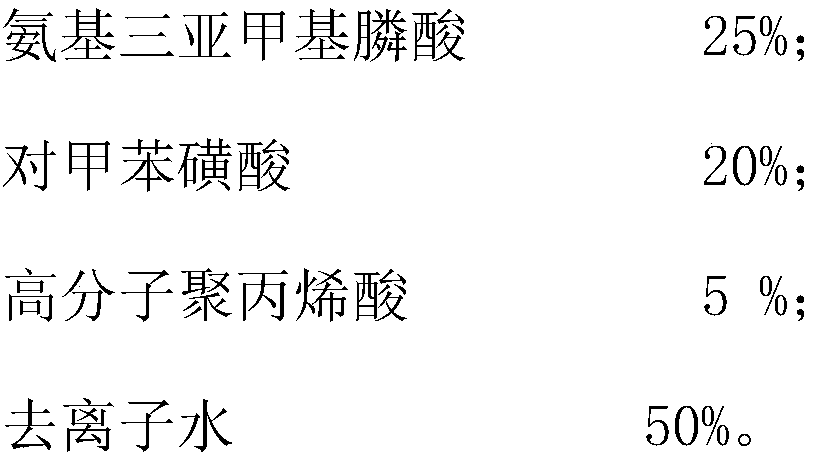

[0038] A method for preparing a skin-core structure modal fiber raising fiber opener, comprising the following steps: first, add amino trimethylene phosphonic acid and p-toluene sulfonic acid in proportion to deionized water and stir to form a mixed liquid, and then add the mixed liquid Add high-molecular polyacrylic acid in proportion and stir evenly to make fiber opener.

Embodiment 3

[0040] A sheath-core structure modal fiber raising fiber opening agent is composed of the following components in mass percentage:

[0041]

[0042] The molecular weight of the polymer polyacrylic acid is 2000-6000.

[0043] A preparation method of a skin-core structure modal fiber raising fiber opener, comprising the following steps: firstly add ethylenediaminetetramethylenephosphonic acid and p-toluenesulfonic acid in proportion to deionized water and stir to form a mixed solution, and then Add high-molecular polyacrylic acid in proportion to the mixed liquid and stir evenly to make a fiber opener.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com