Slag-metal reaction simulation test device and method for continuous casting crystallizer covering slag

A continuous casting mold and simulation test technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of weakening and difficulty in the degree of slag-gold reaction, and achieve the effect of reducing test losses and wide applicability of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

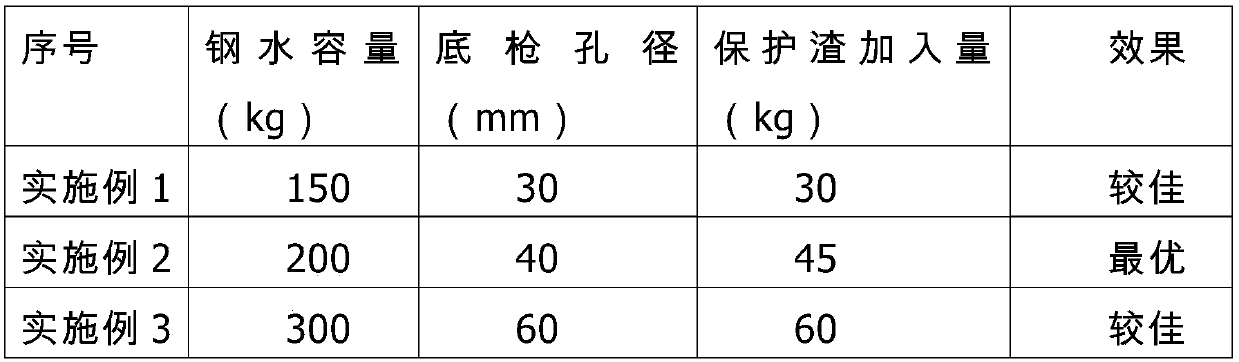

Embodiment 1

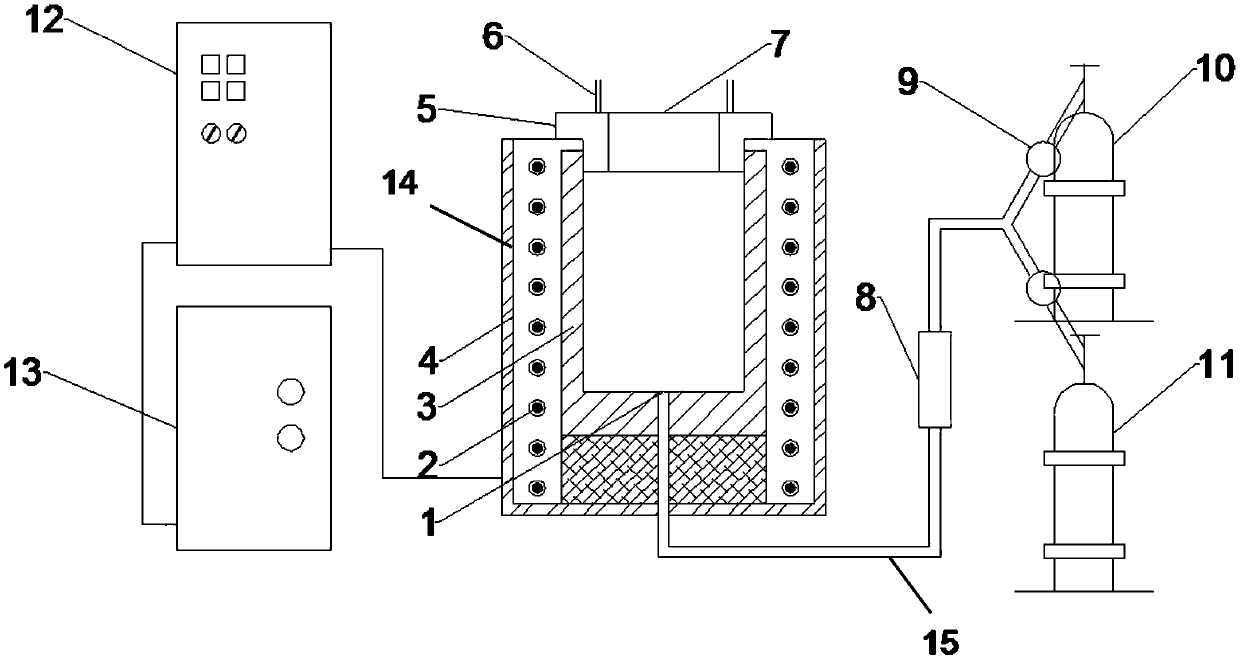

[0051] The layout of the medium frequency induction furnace is attached figure 1 , using a graphite crucible 3 with a hole in the bottom, with a capacity of 150kg of molten steel; installing a bottom gun 1, the selected bottom gun 1 has an aperture of 30mm, and is connected to Ar or nitrogen, and the argon and nitrogen can be switched freely; the top of the crucible is covered with a furnace roof cover , the external protective gas blowpipe 15 of the cover plate is blown into the furnace to form a protective atmosphere in the furnace by setting the air blowing hole groove inside;

[0052] According to the quality of molten steel for smelting, steel blocks of moderate size are added to the graphite crucible 3 in batches. The steel block is melted by electricity, the top cover and the bottom gun 1 are sprayed with argon, and the induction furnace is turned on to increase the power to melt the steel block rapidly;

[0053] After the molten steel is melted, take the original stee...

Embodiment 2

[0058] The layout of the medium frequency induction furnace is attached figure 1 , use a graphite crucible 3 with a hole in the bottom, with a molten steel capacity of 200kg; install a bottom gun 1, the selected bottom gun 1 has an aperture of 40mm, and connect to Ar or nitrogen, and the argon and nitrogen can be switched freely; the top of the crucible covers the furnace roof cover , the external protective gas blowpipe 15 of the cover plate is blown into the furnace to form a protective atmosphere in the furnace by setting the air blowing hole groove inside;

[0059] According to the quality of molten steel for smelting, steel blocks of moderate size are added to the crucible in batches. The steel block is melted by electricity, the top cover and the bottom gun 1 are sprayed with argon, and the induction furnace is turned on to increase the power to melt the steel block rapidly;

[0060] After the molten steel is melted, take the original steel sample with a sample spoon. ...

Embodiment 3

[0065] The layout of the medium frequency induction furnace is attached figure 1 , use a graphite crucible 3 with a hole in the bottom, with a molten steel capacity of 300kg; install a bottom gun 1, the selected bottom gun 1 has an aperture of 60mm, and connect to Ar or nitrogen, and the argon and nitrogen can be switched freely; the top of the crucible covers the furnace roof cover , the external protective gas blowpipe 15 of the cover plate is blown into the furnace to form a protective atmosphere in the furnace by setting the air blowing hole groove inside;

[0066] According to the quality of molten steel for smelting, steel blocks of moderate size are added to the crucible in batches. The steel block is melted by electricity, the top cover and the bottom gun 1 are sprayed with argon, and the induction furnace is turned on to increase the power to melt the steel block rapidly;

[0067] After the molten steel is melted, take the original steel sample with a sample spoon. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com