Breach simulation method for high energy pipeline leakage monitoring test in nuclear power plant

A technology of high-energy pipelines and simulation methods, applied in nuclear power generation, nuclear reactor monitoring, nuclear engineering, etc., can solve problems such as engineering impracticability, achieve the effects of reducing test losses, shortening construction periods, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

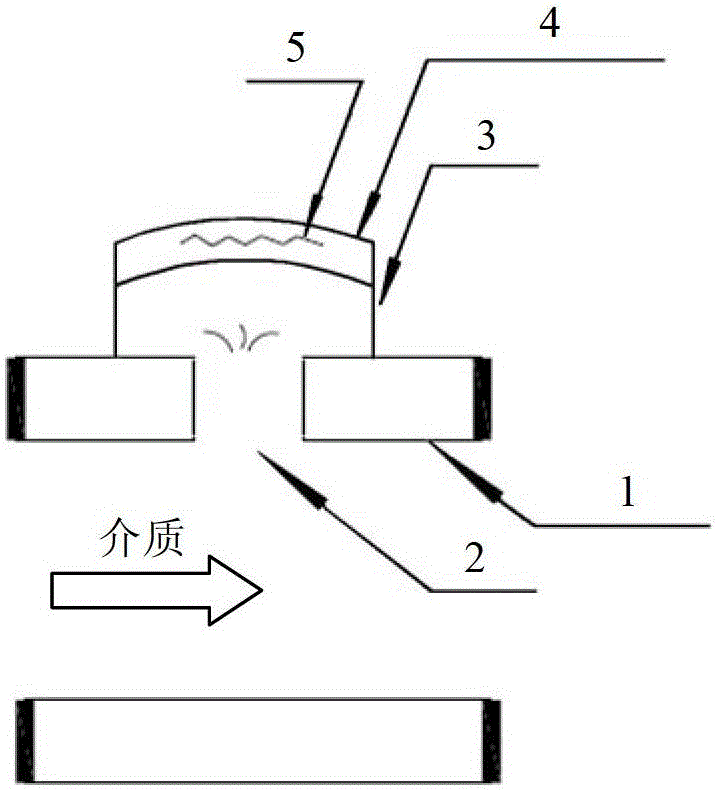

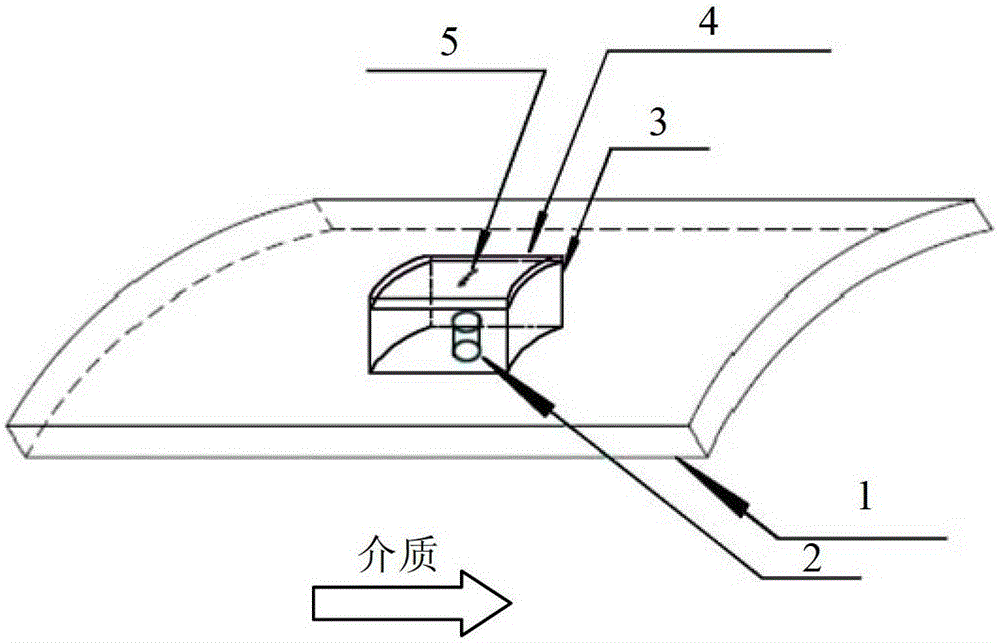

[0040] This embodiment adopts the expansion slot scheme, such as Picture 1-1 , Figure 1-2 As shown, on the wall of the test straight pipeline 1 (acoustic emission leakage monitoring test bench test pipeline), an expansion hole 2 of a certain size is opened, and one end of the expansion groove 3 is welded to the outer wall of the test straight pipeline 1, and the other end is welded to the leak hole The simulated test piece 4 is provided with a simulated breach 5 on the simulated test piece of leakage breach.

[0041] Expansion hole: The area of the expansion hole is required to be as large as possible (such as Φ50mm, the specific size can be determined according to the leakage requirement of the breach and the outer diameter of the test straight pipe), so as to ensure that when the medium in the pipeline leaks, it will not cause obvious flow of the medium near the expansion hole , so as to trigger noise signal interference.

[0042]Expansion groove: the size of the expans...

Embodiment 2

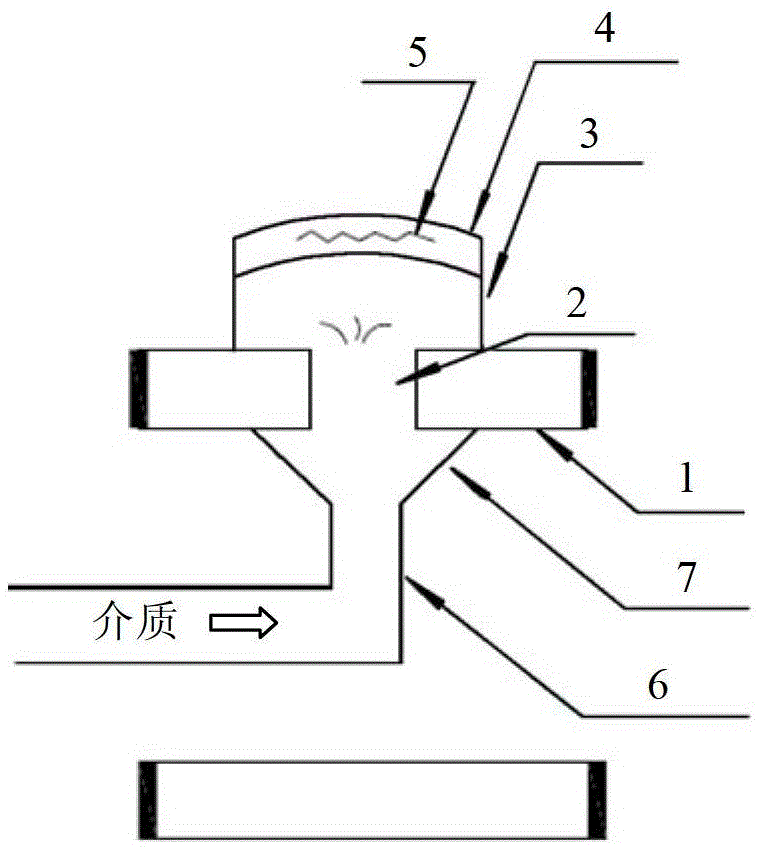

[0050] This embodiment adopts the solution of expansion tank + medium delivery pipeline, such as diagram 2-1 , Figure 2-2 As shown, compared with Embodiment 1, the design of this embodiment only adds the medium delivery pipeline 6, and the design requirements of other main components remain unchanged.

[0051] Medium delivery pipeline: the thin pipeline 6 that can meet the highest temperature and highest pressure of the high-energy pipeline can be selected to transport the medium to the expansion hole, and the narrow pipeline is welded with the tapered deflector 7 at the expansion hole on the inner wall of the test straight pipeline 1 (The shape of the deflector can be changed according to specific conditions) connection.

[0052] By adopting the expansion tank + medium delivery pipeline solution, while retaining the functions of Example 1, the requirement for the supply of test medium can be reduced. For the larger size of the actual pipeline, this scheme is not only diff...

Embodiment 3

[0054] Such as Figure 3-1 As shown, in this embodiment, a simulated breach 8 is directly preset on the test straight pipe 1, and the form of the breach can be processed and preset with reference to Example 1 according to requirements.

[0055] This scheme is suitable for the situation where the actual pipeline size is small, it is not difficult to simulate the actual pipeline size to process the breach, and the leakage breach form is unique. This scheme simulates the actual pipeline leakage as much as possible to reduce the impact on the acoustic emission detection signal. If there are a large number of leakage simulation breaches, which involves pipe replacement or cutting, this solution is not recommended.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com