Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

142results about How to "Reduce flash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

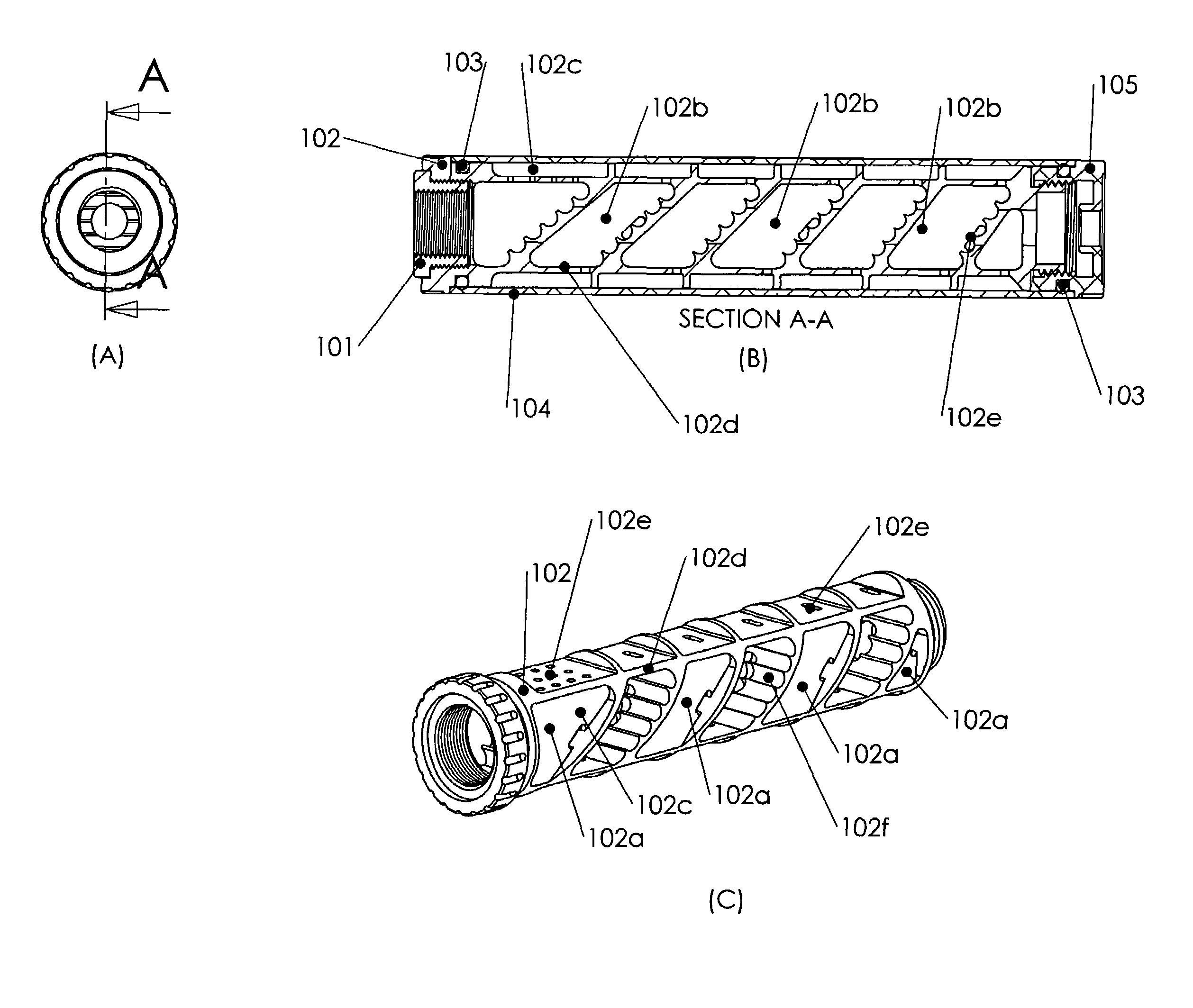

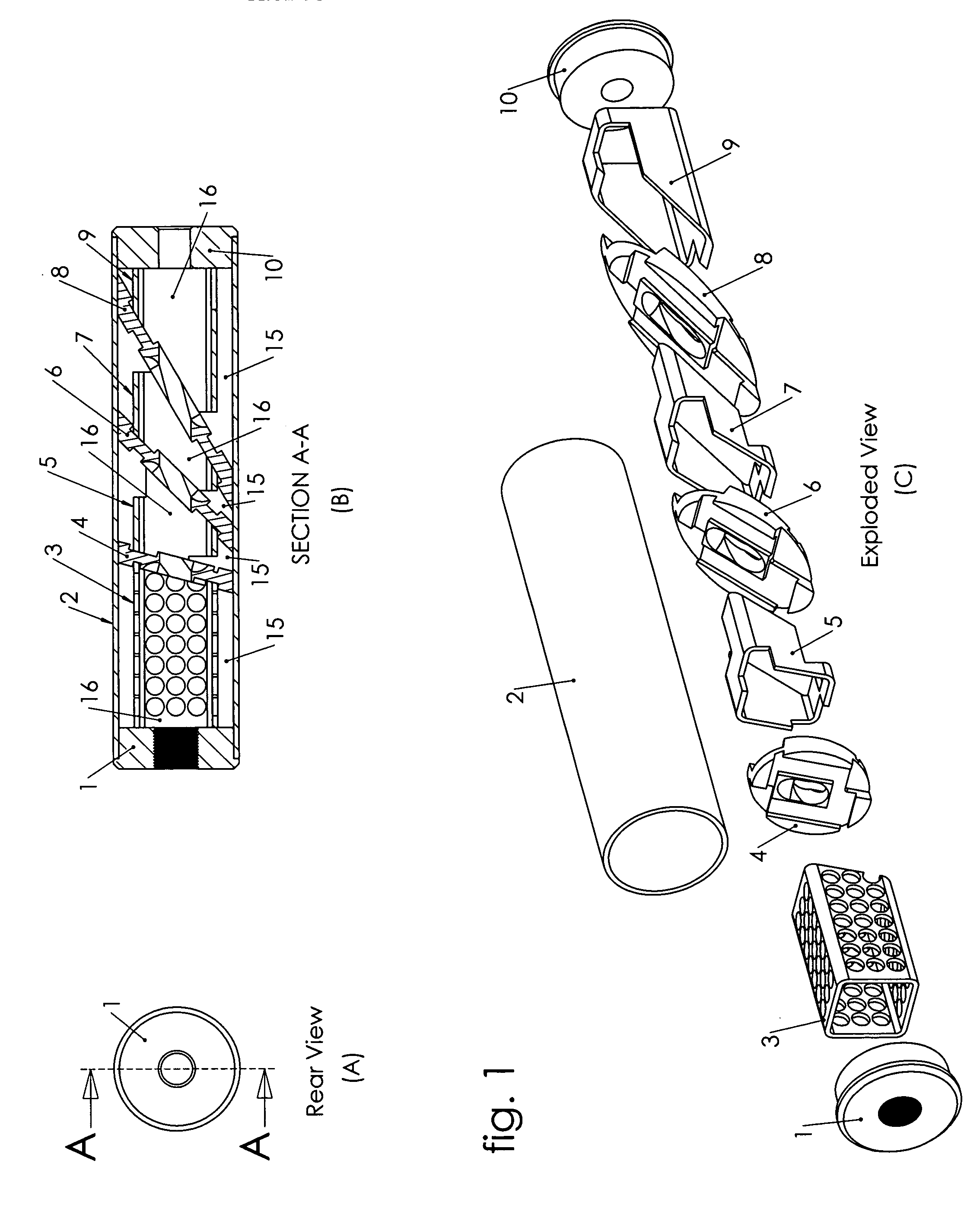

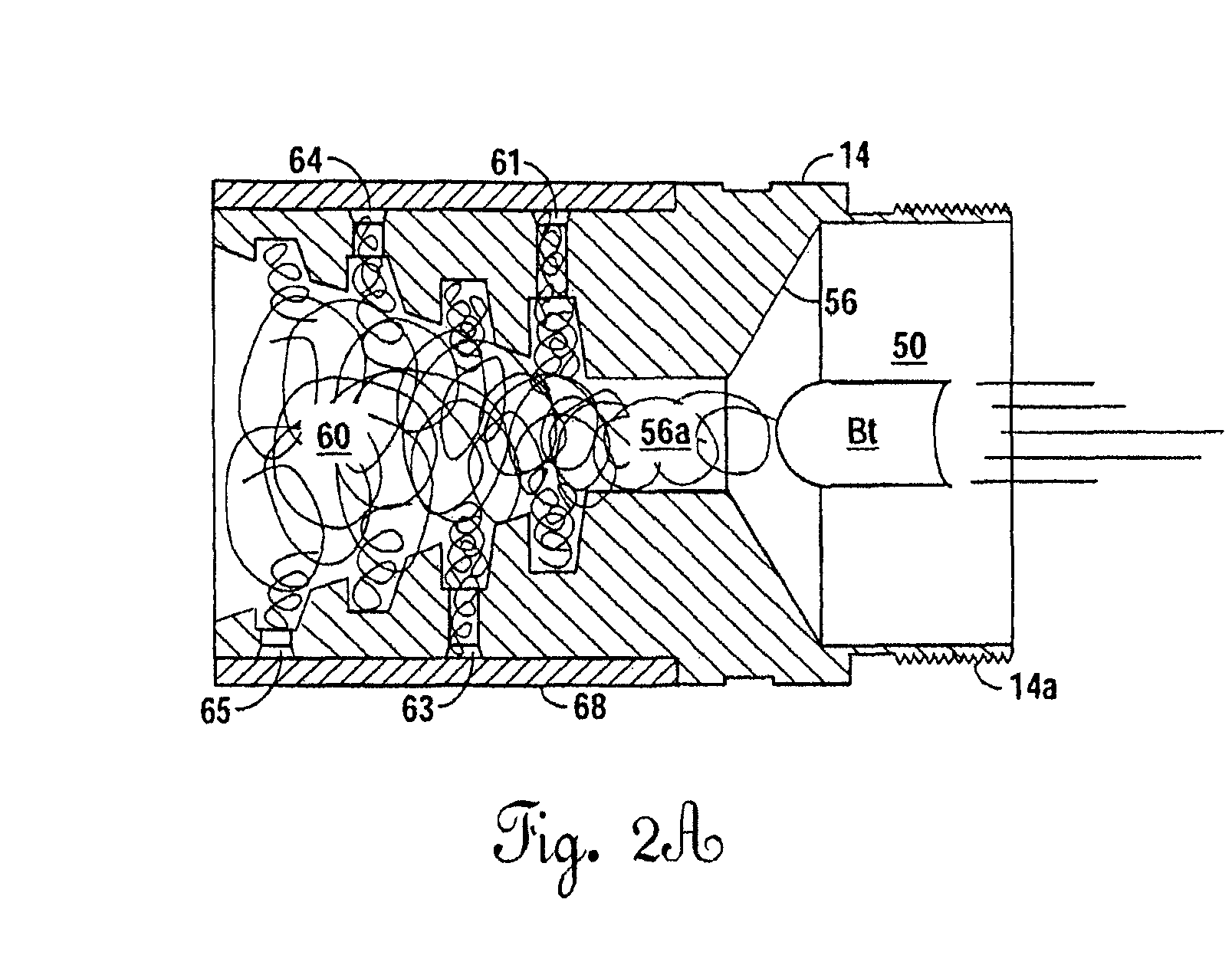

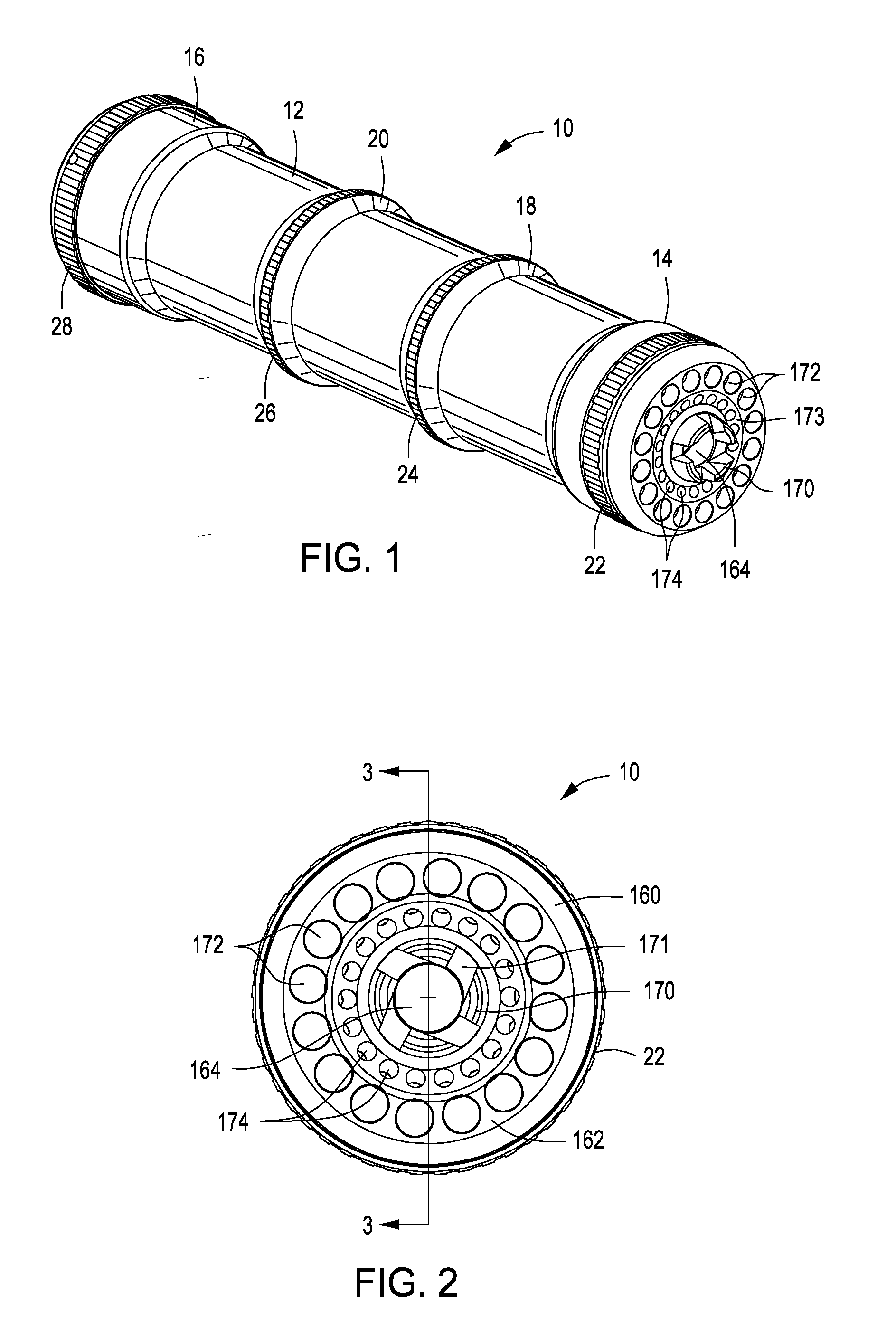

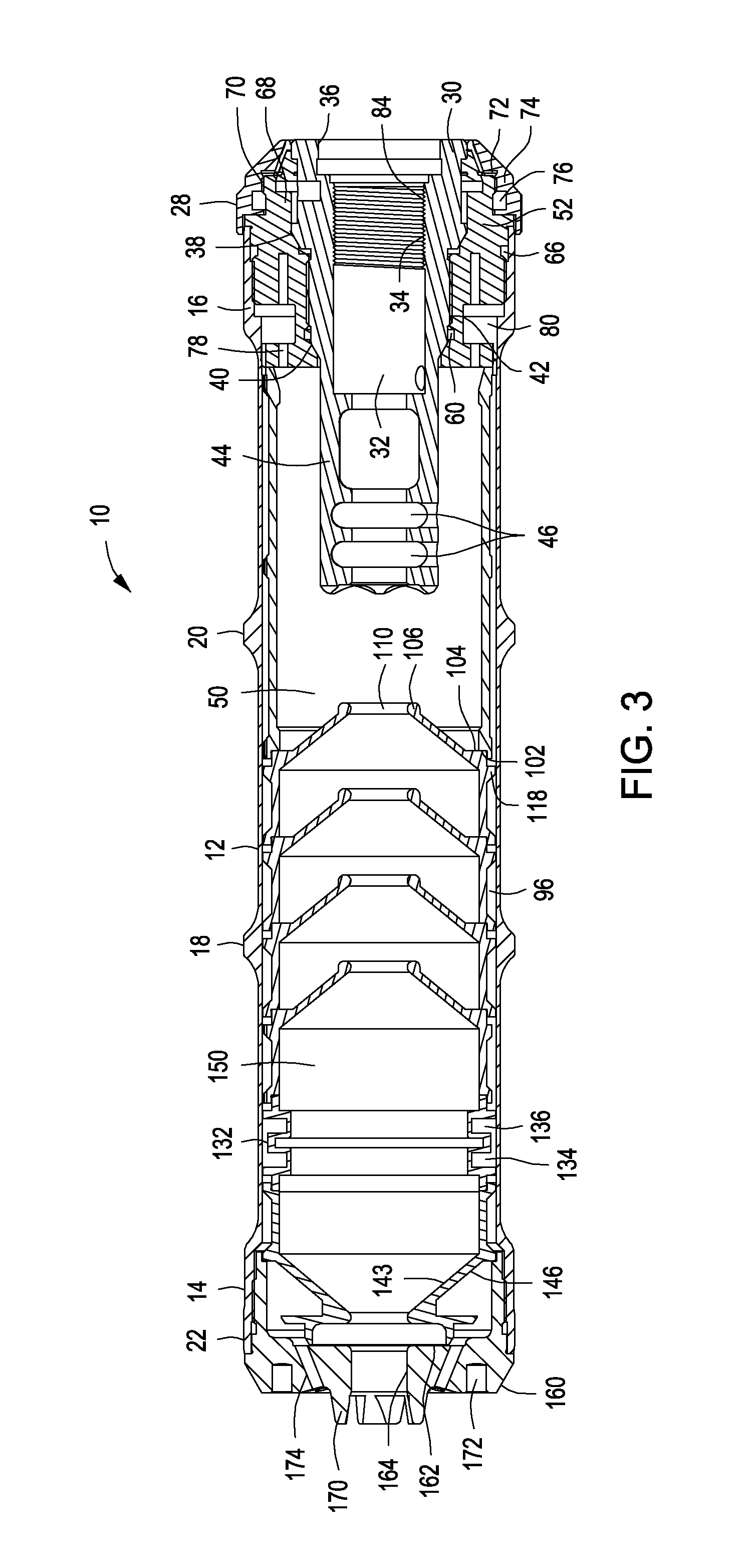

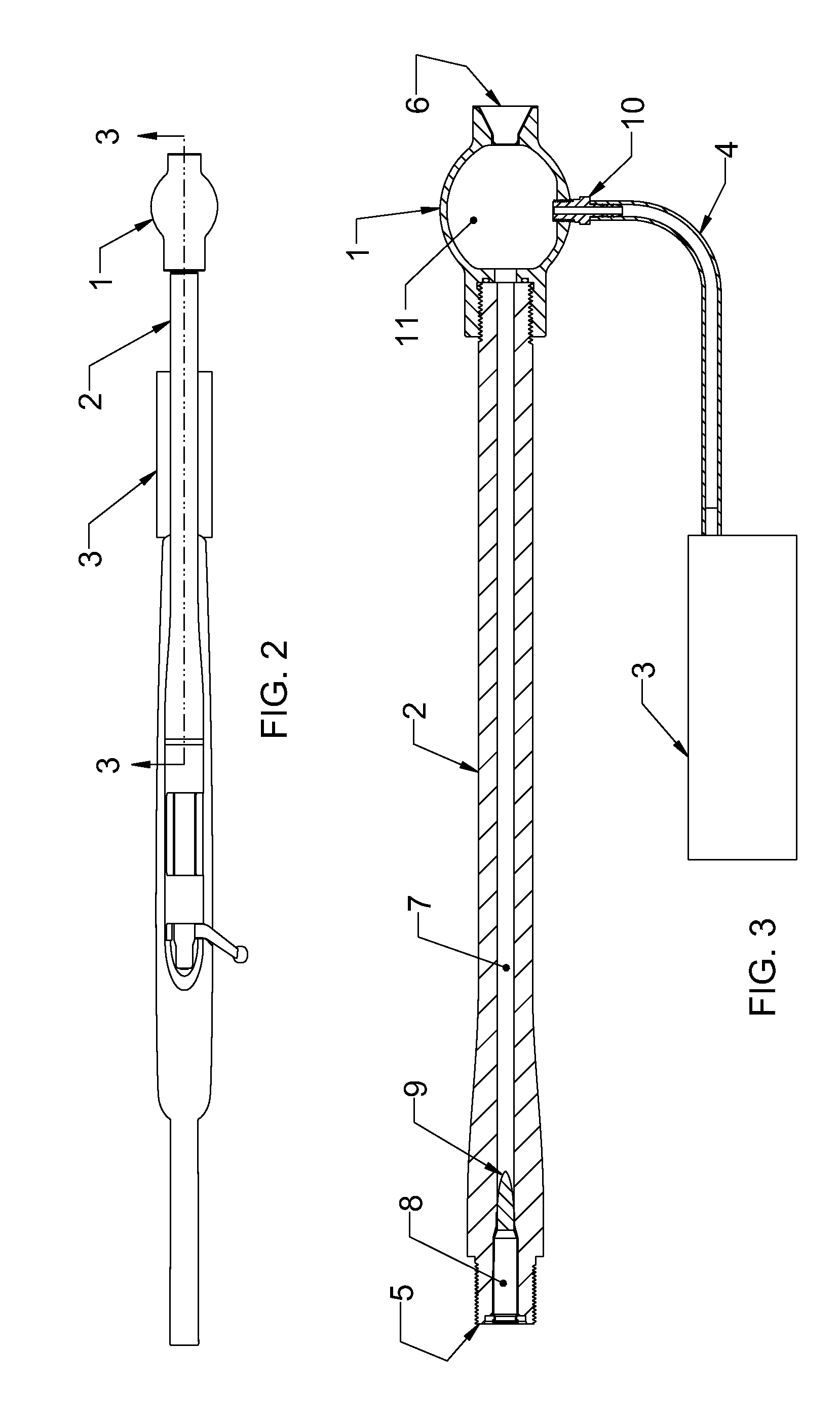

Asymmetric firearm silencer with coaxial elements

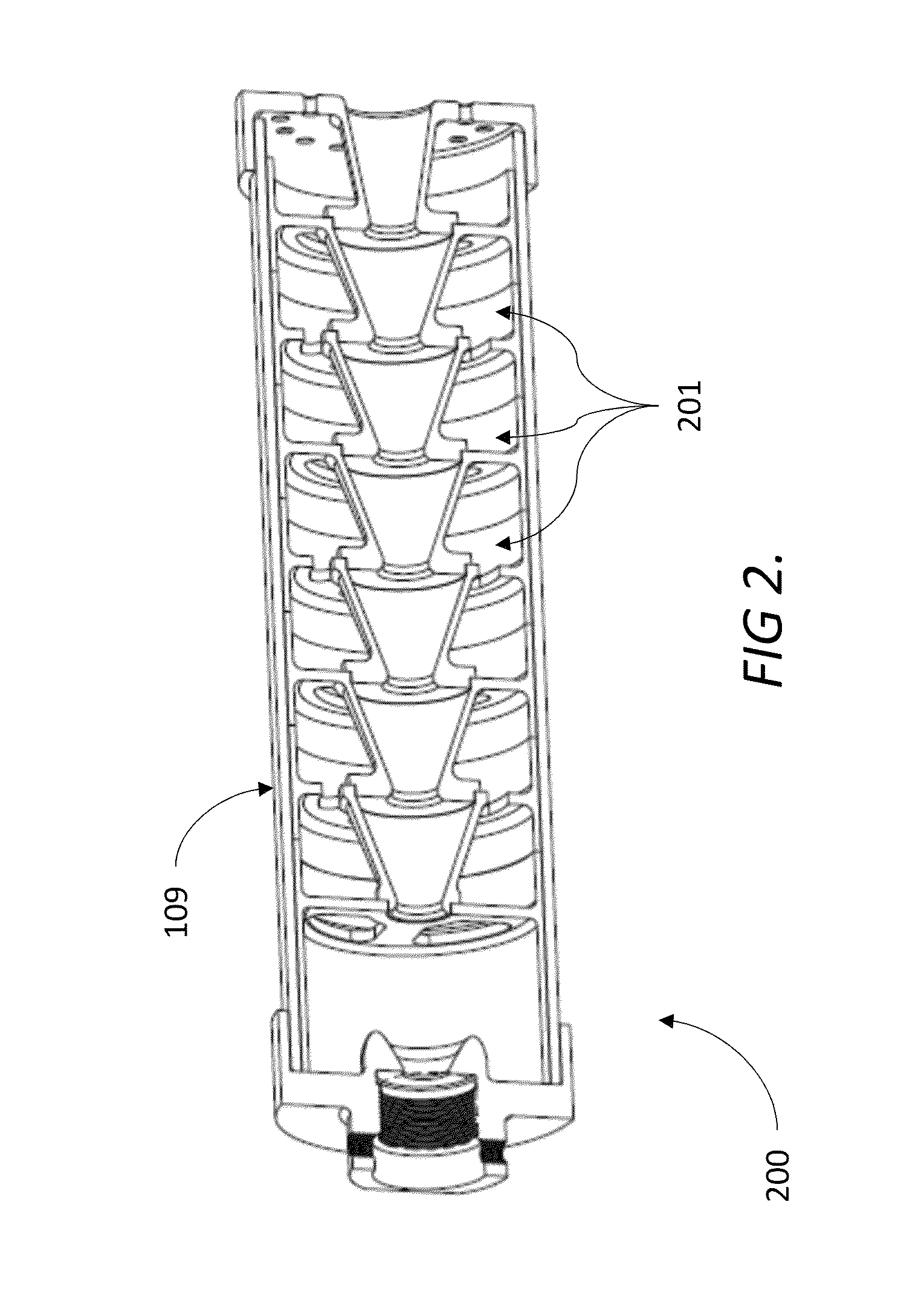

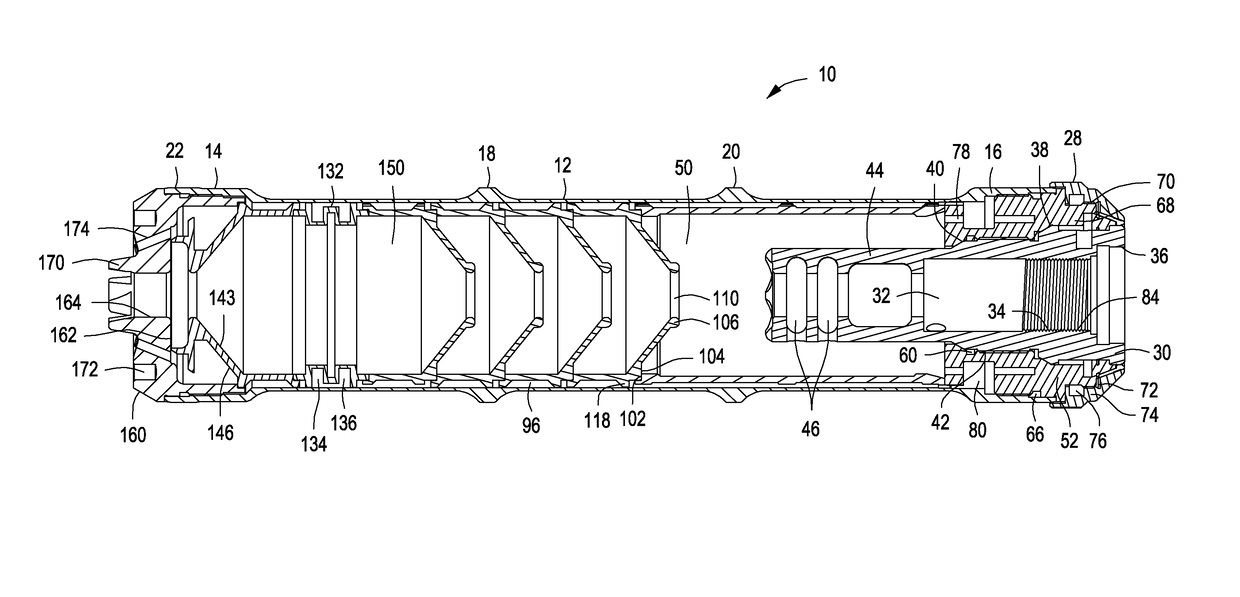

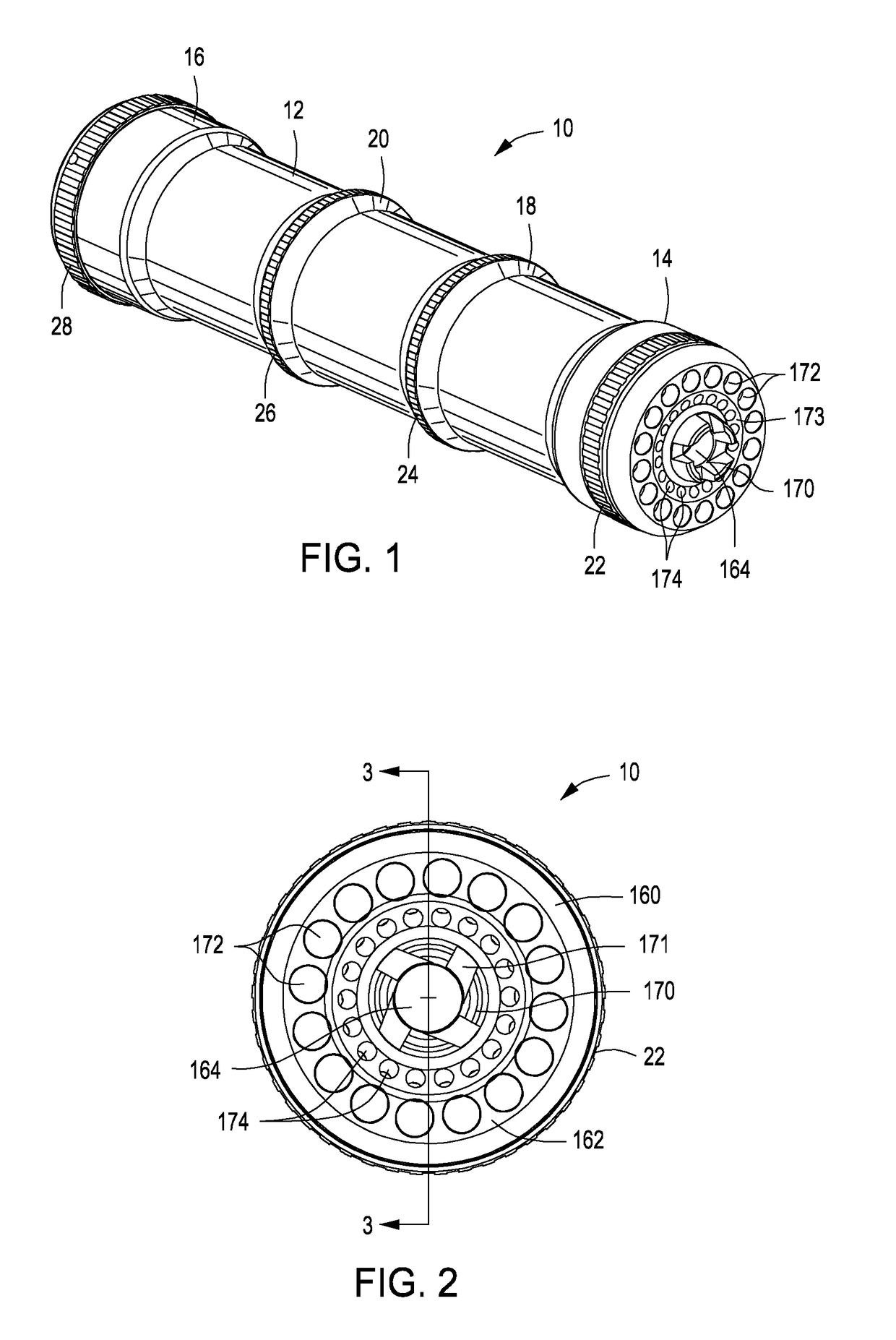

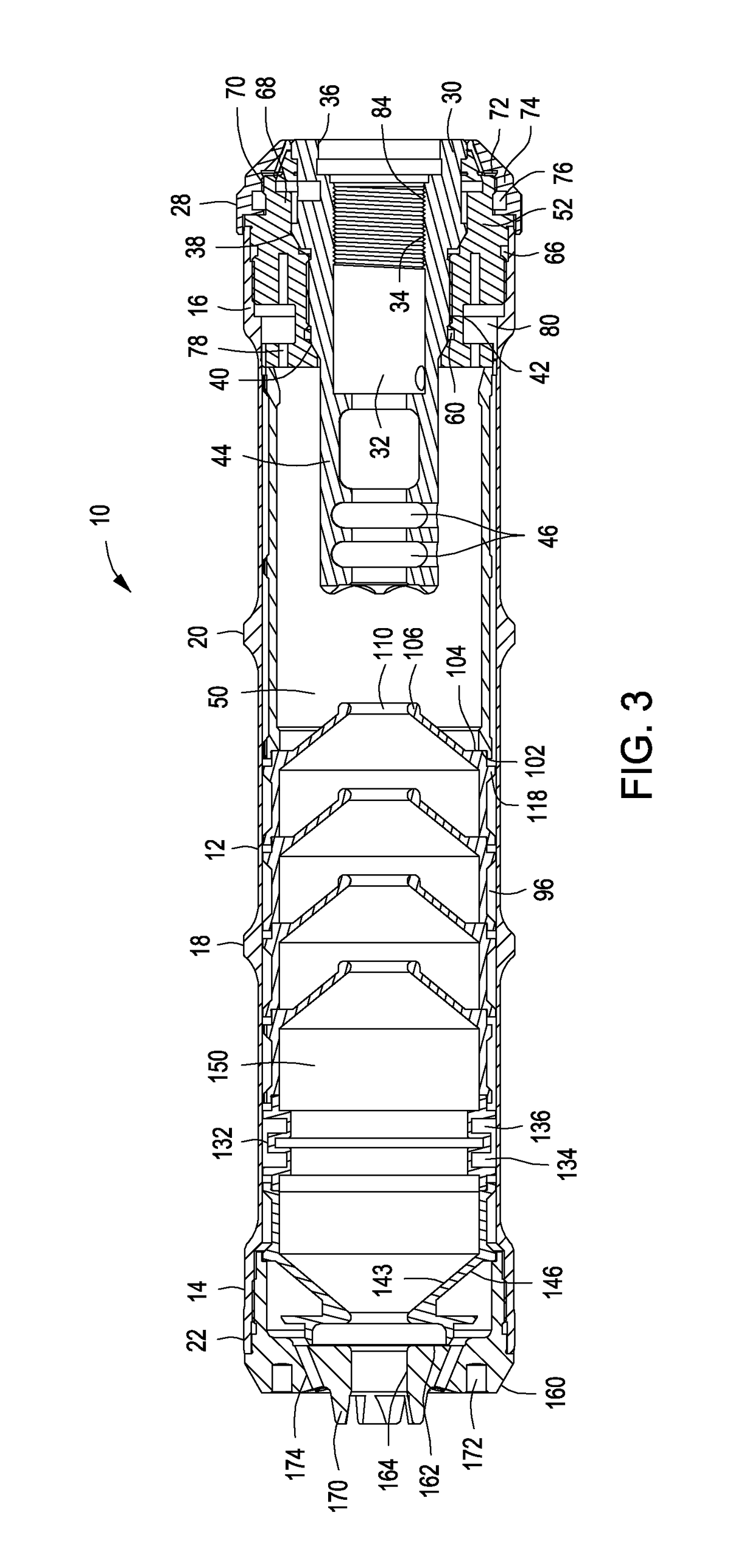

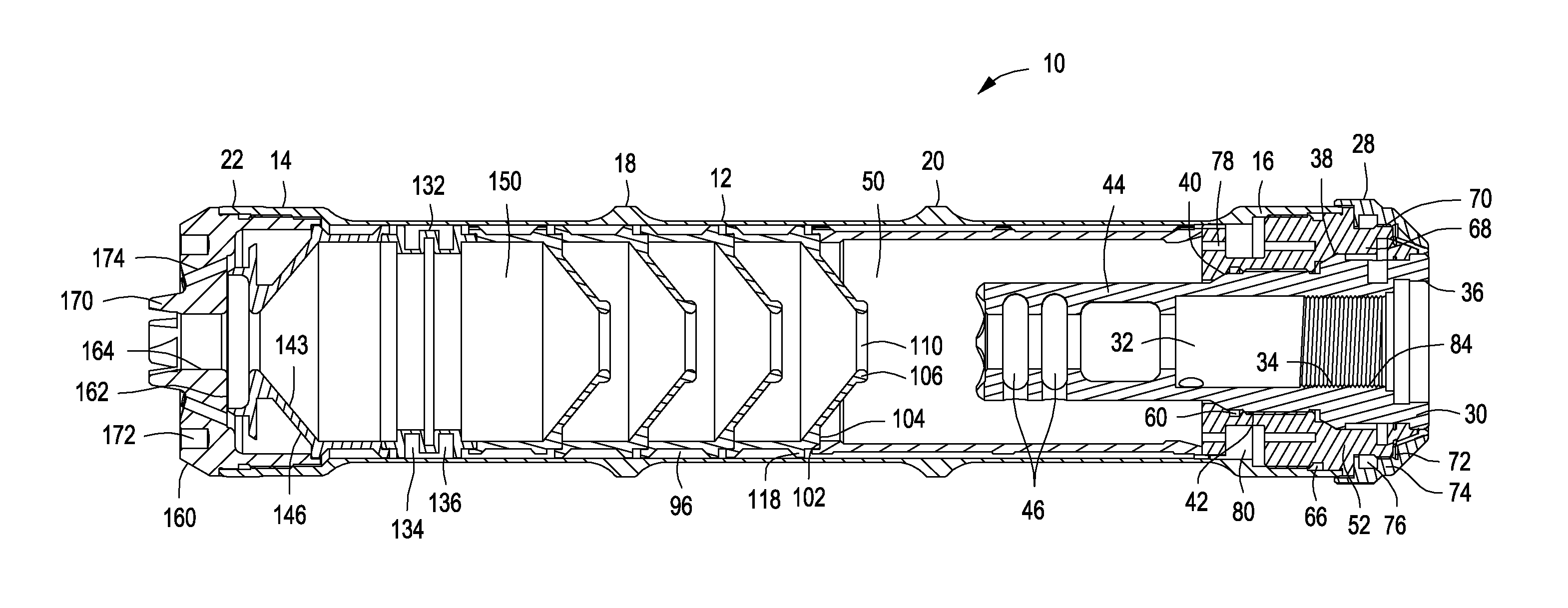

The present invention relates to a silencer for reducing muzzle blast and noise of firearms or similar devices. The present silencer has a hollow cylindrical or other shape casing comprising front and rear end caps and an opening aligned along a longitudinal axis defining a passage for a projectile and propellant gases to emerge from the muzzle opening. A plurality of serially placed baffles of symmetrical or slanted orientation and intervening coaxial spacers are positioned within the casing and define a multitude of chambers among the baffles, spacers, and outer housing. The baffles shear propellant gases away from the projectile path and through openings or ports into additional chambers formed between the spacers and outer housing. The arrangement of baffles and spacers provides flow-impeding paths, dispersion, and controlled expansion of gases and lowers gas temperature to reduce audible noise and observable signature of the muzzle blast.

Owner:JJE BRANDS LLC

Asymmetric firearm silencer with coaxial elements

ActiveUS20070107590A1High strengthReduce the soundBreech mechanismsMuzzle attachmentEngineeringMechanical engineering

The present invention relates to a silencer for reducing muzzle blast and noise of firearms or similar devices. The present silencer has a hollow cylindrical or other shape casing comprising front and rear end caps and an opening aligned along a longitudinal axis defining a passage for a projectile and propellant gases to emerge from the muzzle opening. A plurality of serially placed baffles of symmetrical or slanted orientation and intervening coaxial spacers are positioned within the casing and define a multitude of chambers among the baffles, spacers, and outer housing. The baffles shear propellant gases away from the projectile path and through openings or ports into additional chambers formed between the spacers and outer housing. The arrangement of baffles and spacers provides flow-impeding paths, dispersion, and controlled expansion of gases and lowers gas temperature to reduce audible noise and observable signature of the muzzle blast.

Owner:JJE BRANDS LLC

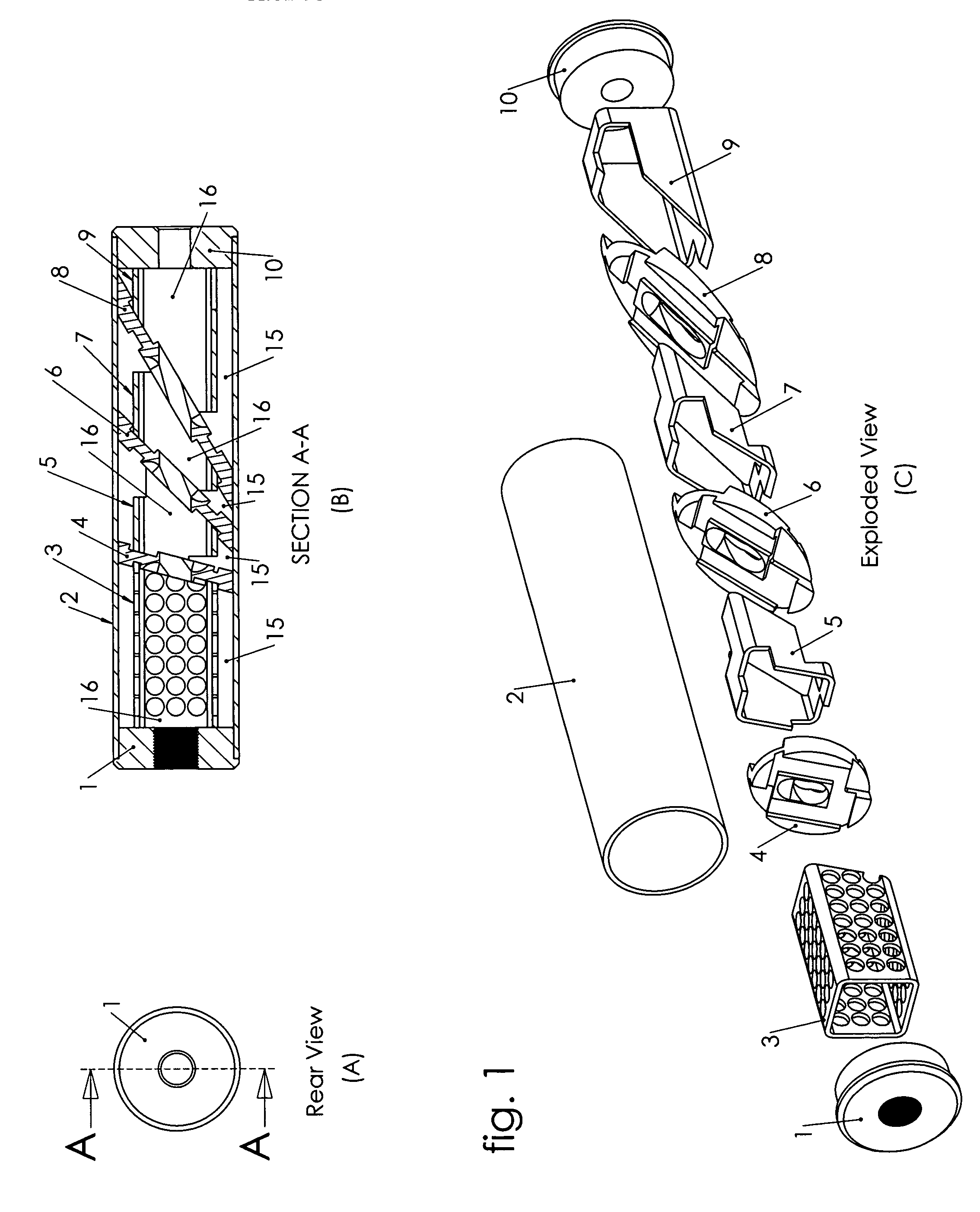

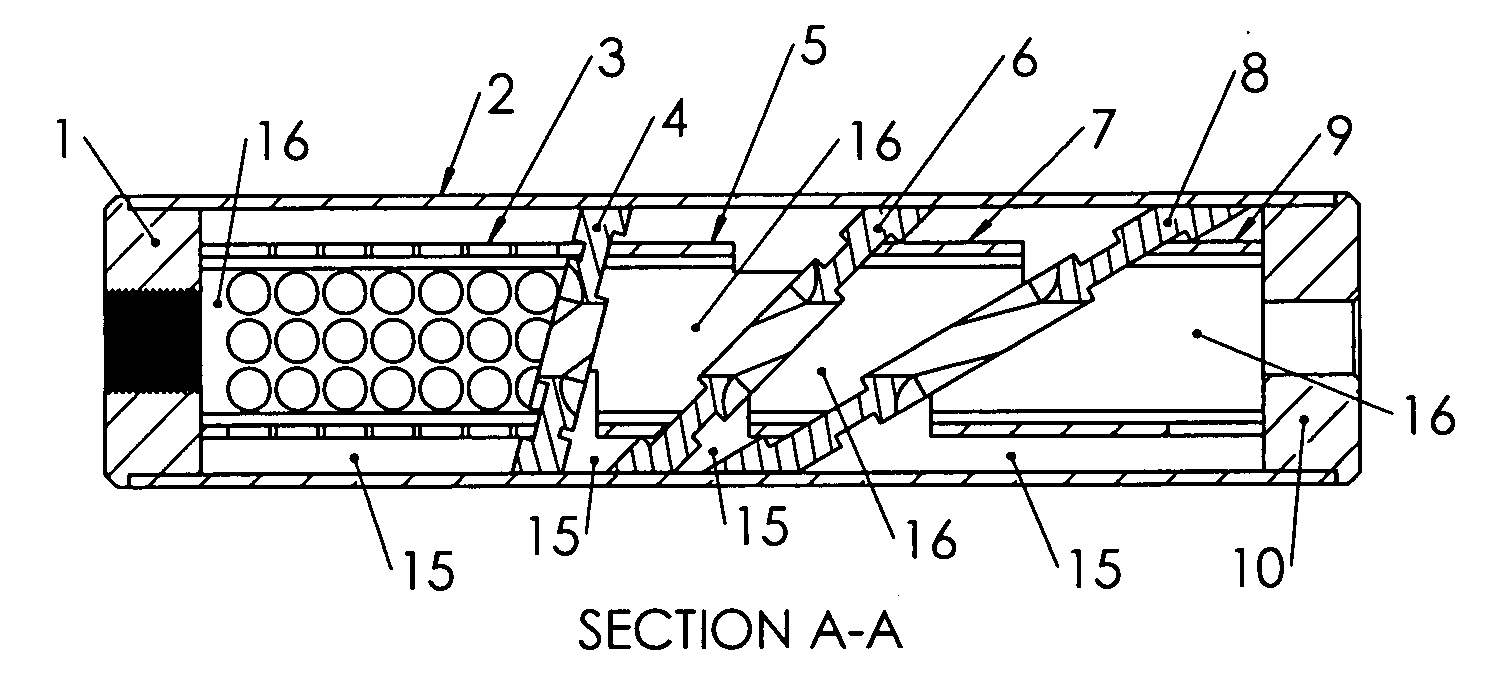

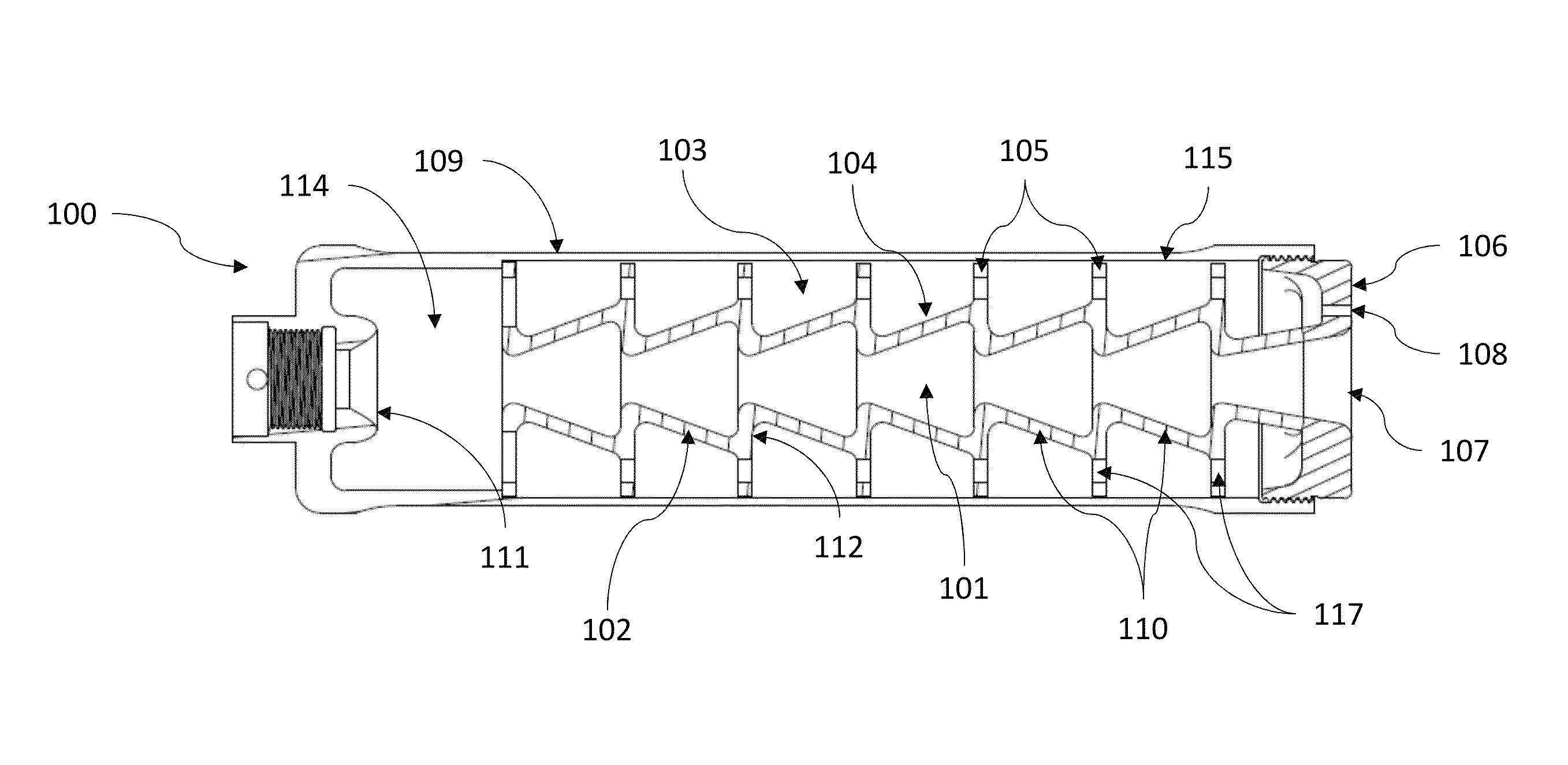

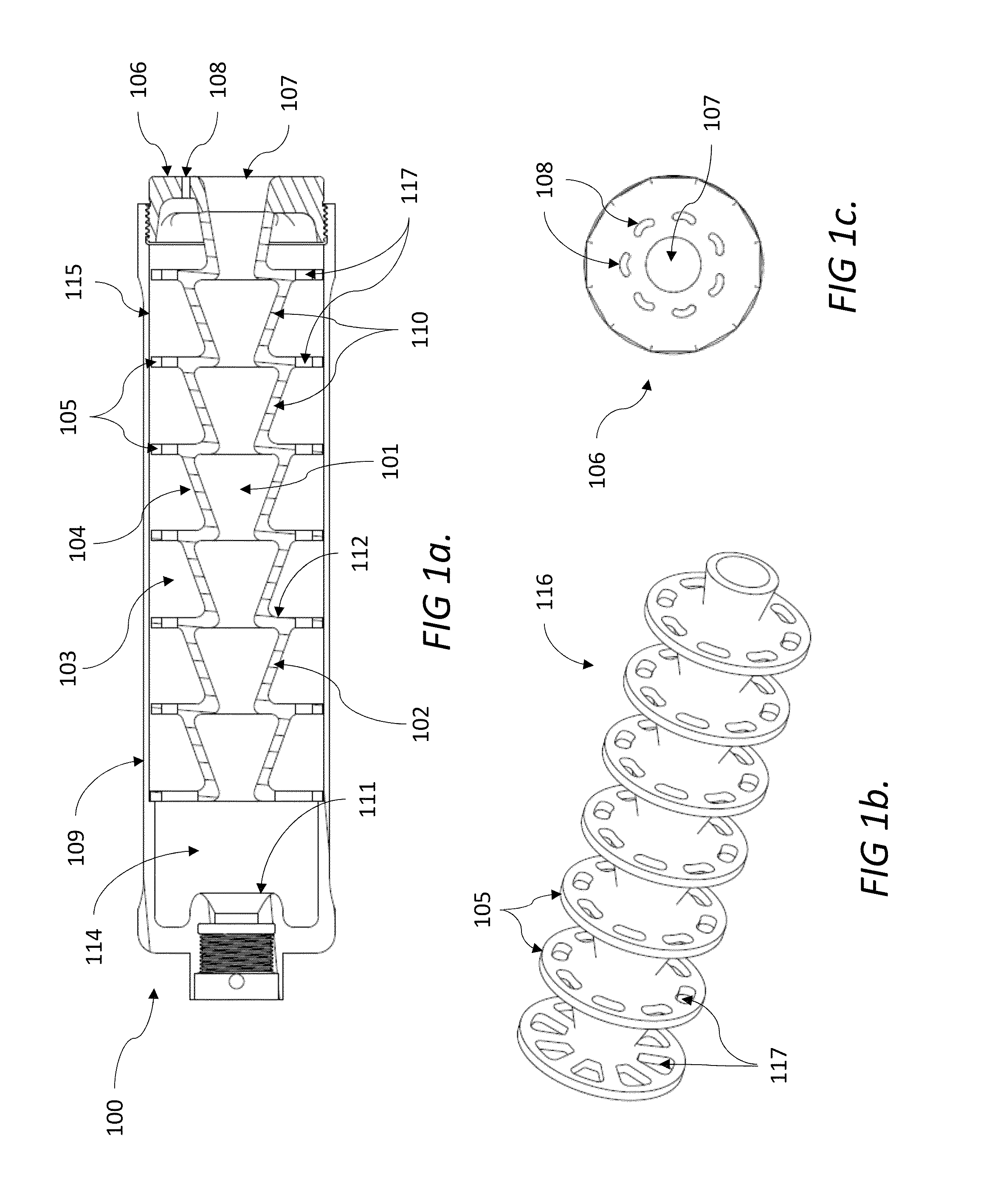

Automatic weapon suppressor

ActiveUS9347727B1Reduce heat transferLow internal surface areaWeapon componentsSuppressorEngineering

A suppressor for rapid fire weapons designed to rapidly bleed down the weapon pressure and thereby minimizing gas blowback to the operator and to the weapon's gas operating system; while also creating a shear gas flow about the exiting bullet's gas flow to mask the flash thereof. The suppressor is configured within a generally cylindrical housing, having: (1) a central core of unported K-baffles located about a central bulletway; (2) a bypass located between the cylindrical housing and the unported K-baffled central core—providing a generally forward subsonic high gas flow area to an endcap closing the cylindrical housing; (3) said endcap having a series of vent ports for the bypass, which also create a shear flow about the centrally exiting bullet; and (4) wherein the series of unported K-baffles are spaced away from the weapon's bore end to allow the propellant gasses to expand into the bypass.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Multifunctional protection composite coating material

The invention relates to multifunctional protective composite coating material, which is recombined with one layer or multilayer specific functional coating. Corrosion transformation, thermal obstructing, thermal reflecting and thermal emitting are reduced through conducting the rust protection processing for metal base plate. The coating material has the advantages of high reflectance for visible sunlight and near-infrared sunlight, strong radiation ratio in 8-13.5 mu m bands, low thermal conductivity coefficient, excellent temperature reduction effect in summers, thermal radiation property approximately to background in visible lights and infrared bands, excellent concealment effect and favorable corrosion property and the like.

Owner:陈树望 +3

Hybrid wax compositions for use in compression molded wax articles such as candles

ActiveUS20100205851A1Improve propertiesReduce flashCandlesSolid fuelsParaffin waxCompression molding

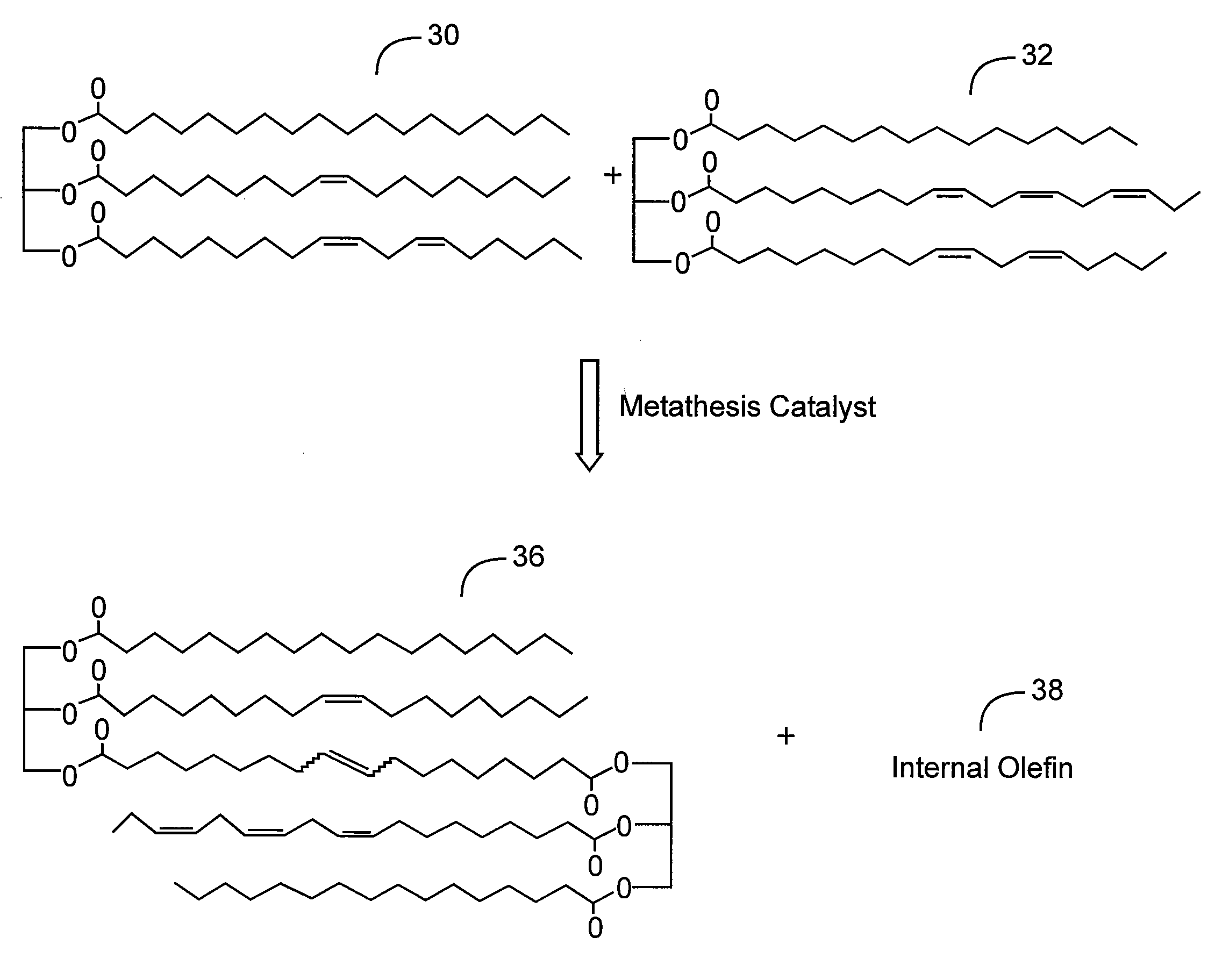

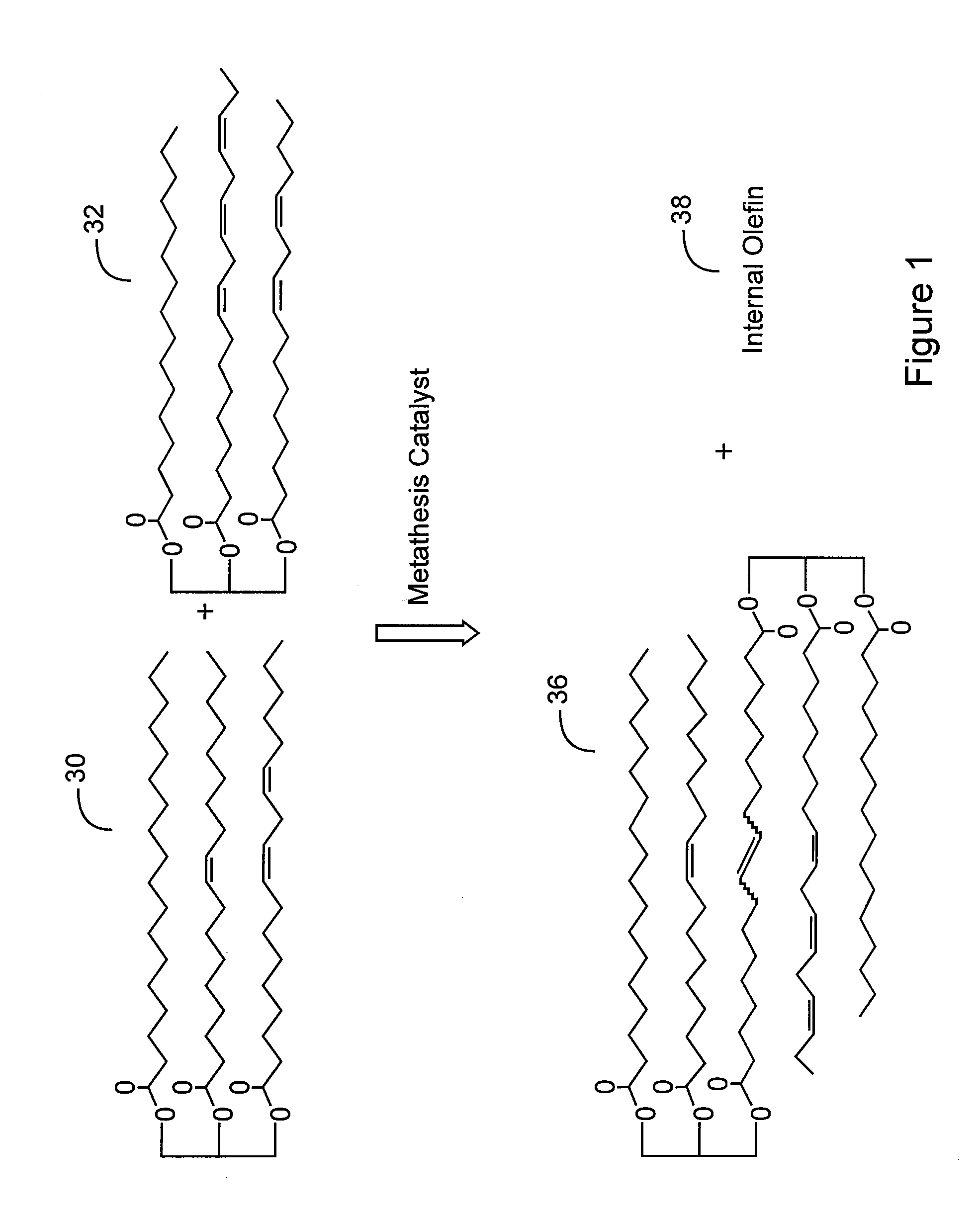

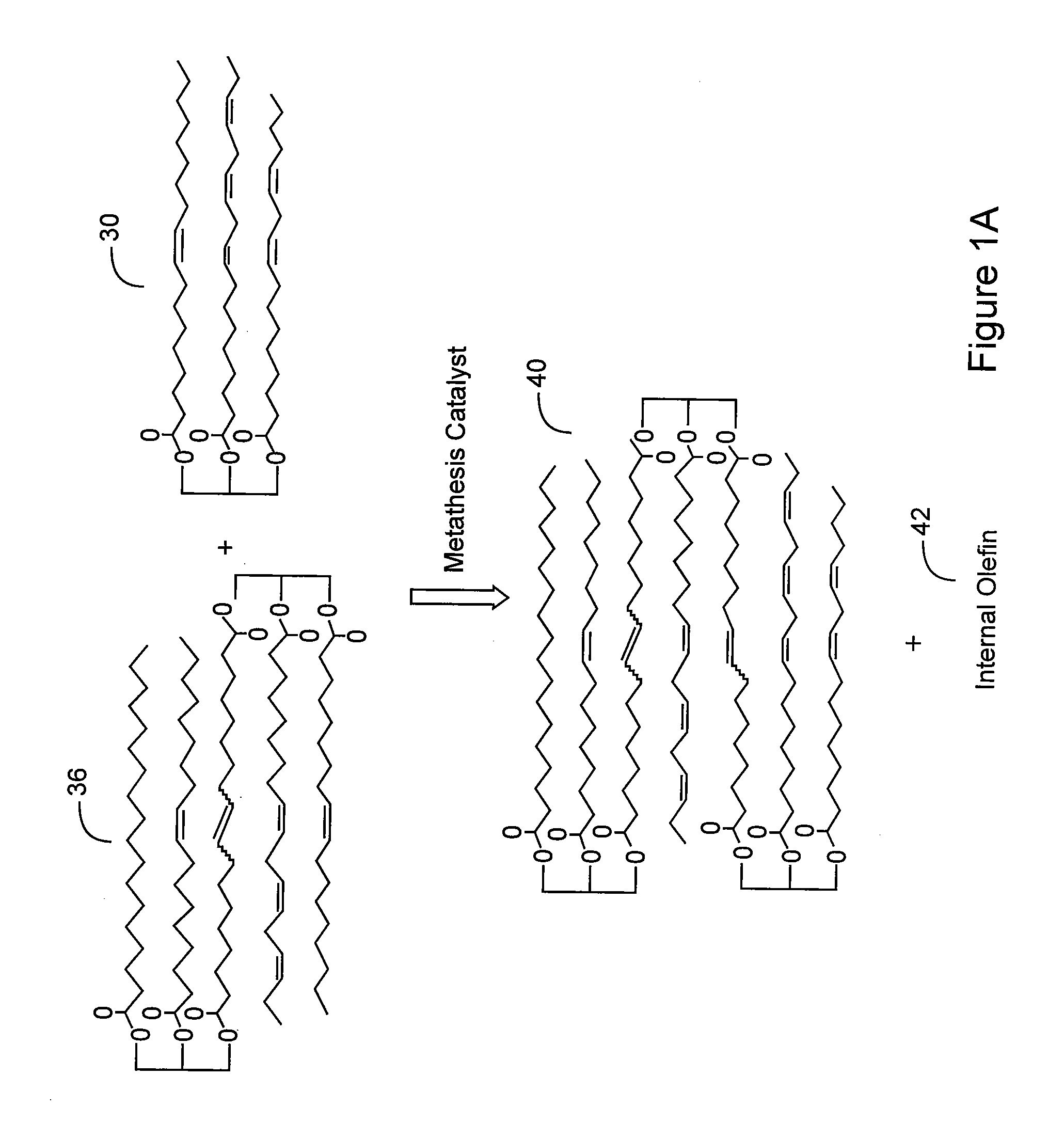

A hybrid wax compositions that are suitable for use in manufacturing wax articles (e.g., candles) by compression molding. The combination of a hydrogenated natural oil-based wax and a paraffin wax having a select distribution of hydrocarbon chain lengths provides the hybrid wax compositions with improved properties, such as improved compressive strength and improved de-molding characteristics, for example, as evidenced by reducing scarring and / or flashing. The hybrid wax compositions comprise: (a) a wax comprising a hydrogenated natural oil; and (b) a paraffin wax, wherein the paraffin wax comprises less than about 50% by weight of the hybrid wax composition, and wherein about 52% or greater of hydrocarbons in the paraffin wax have carbon chain lengths ranging from C25 to C29.

Owner:CARGILL INC

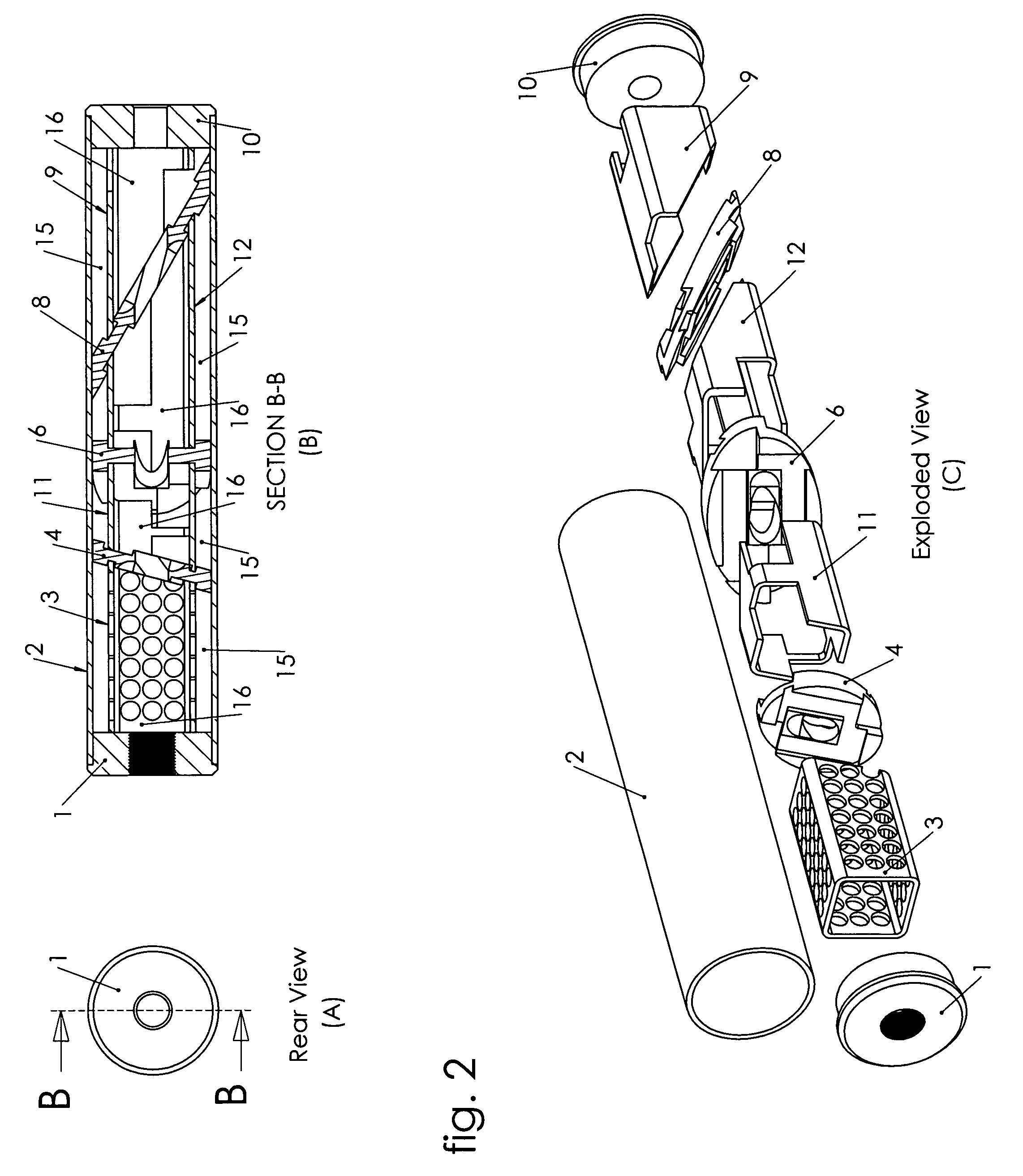

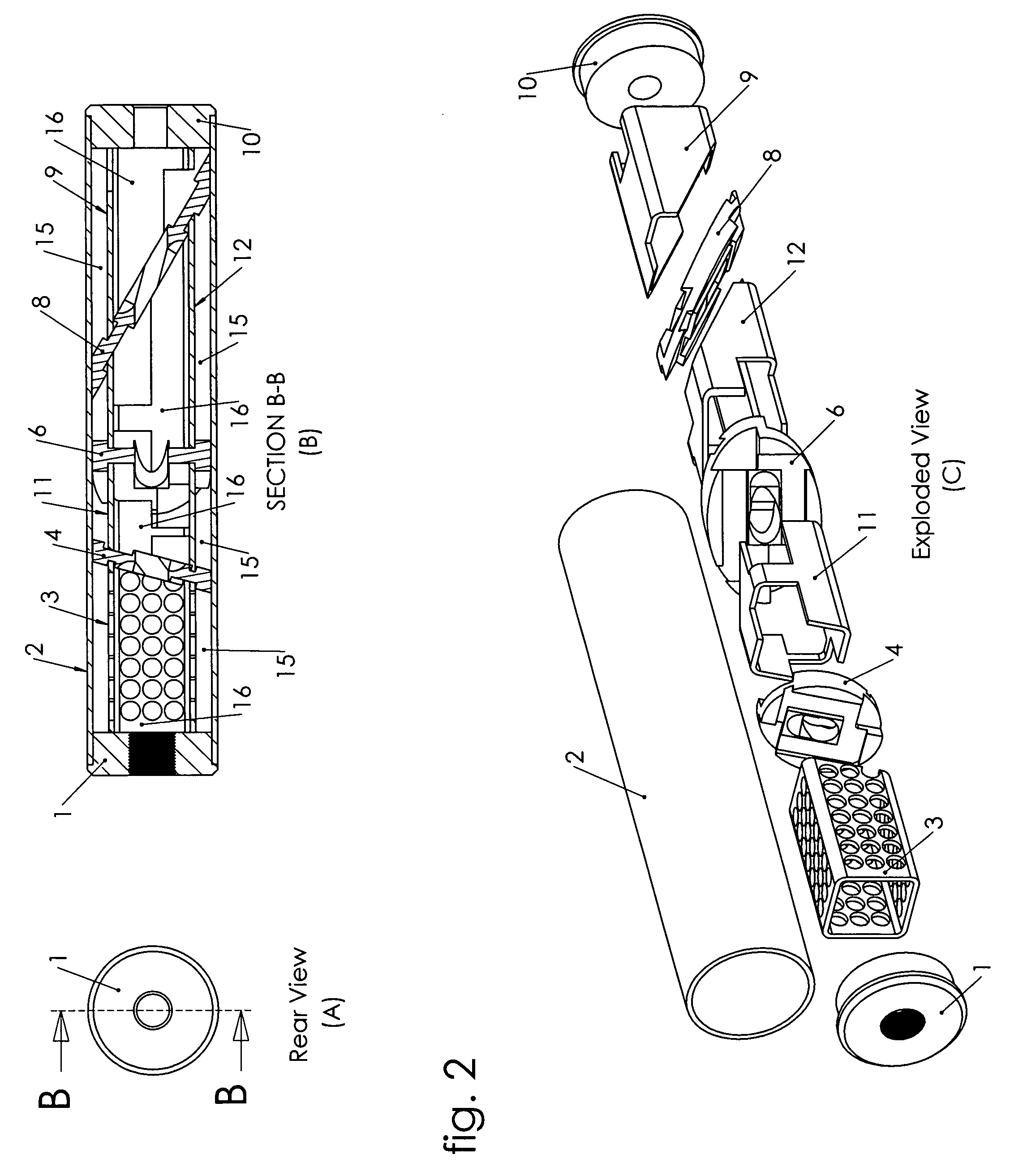

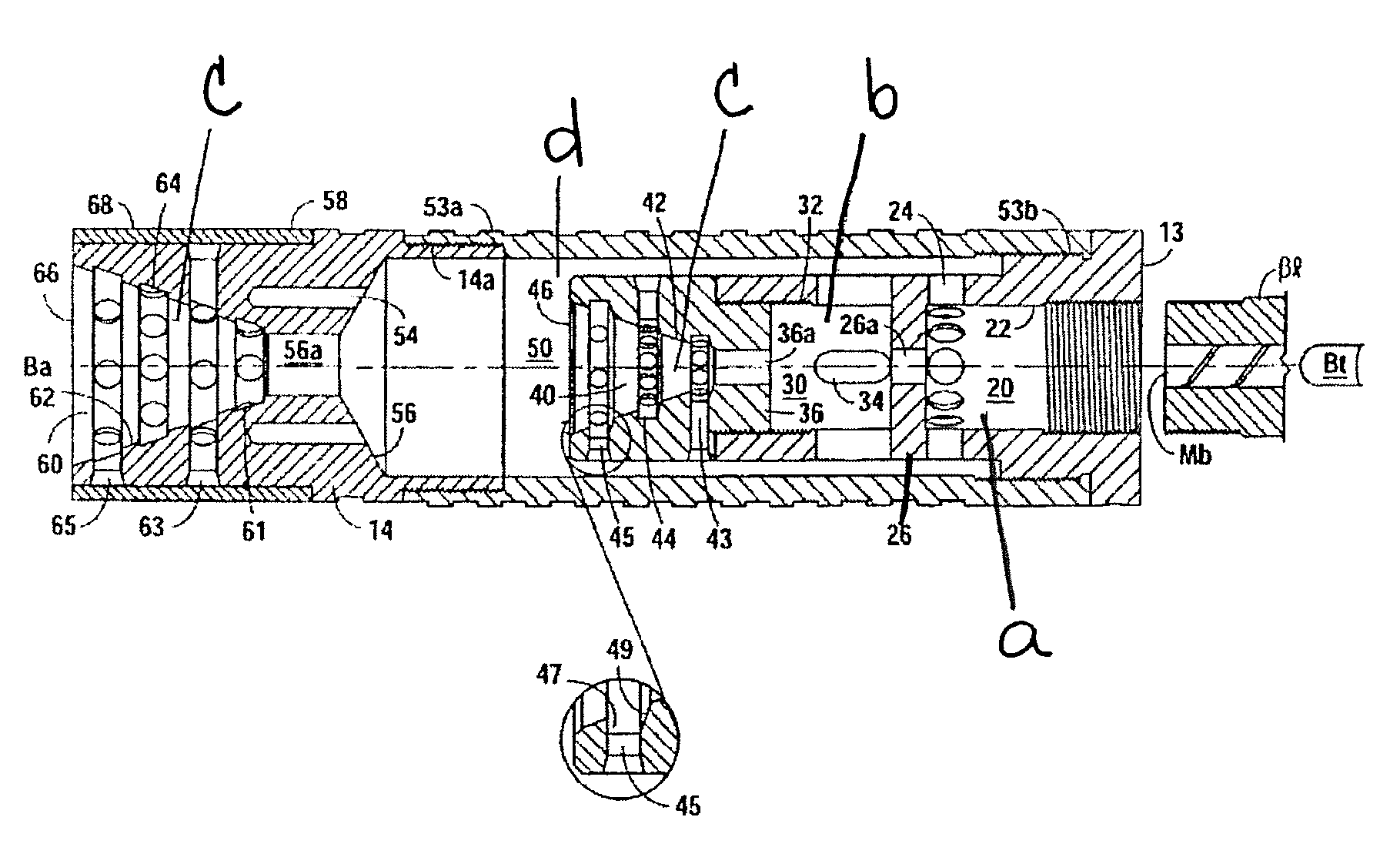

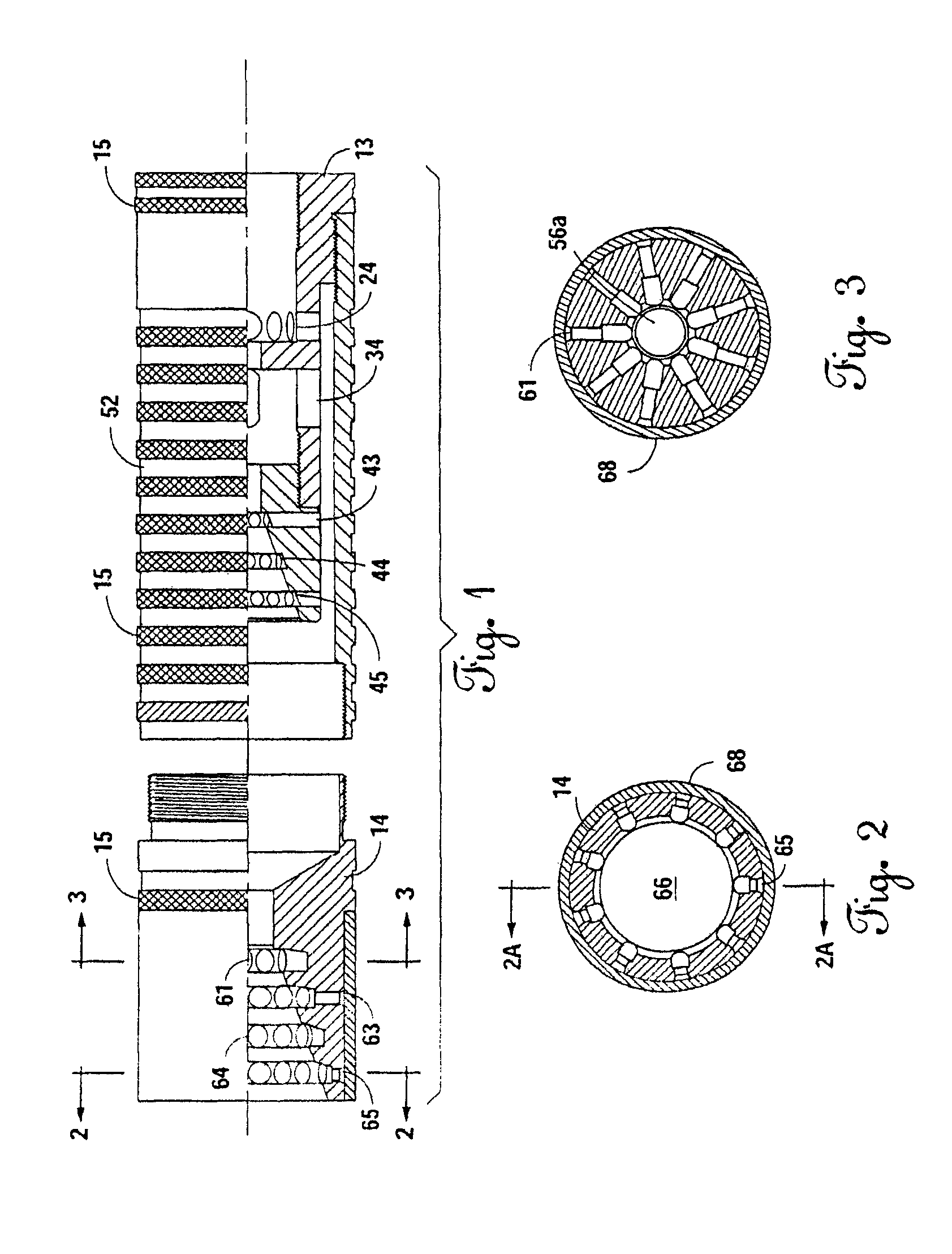

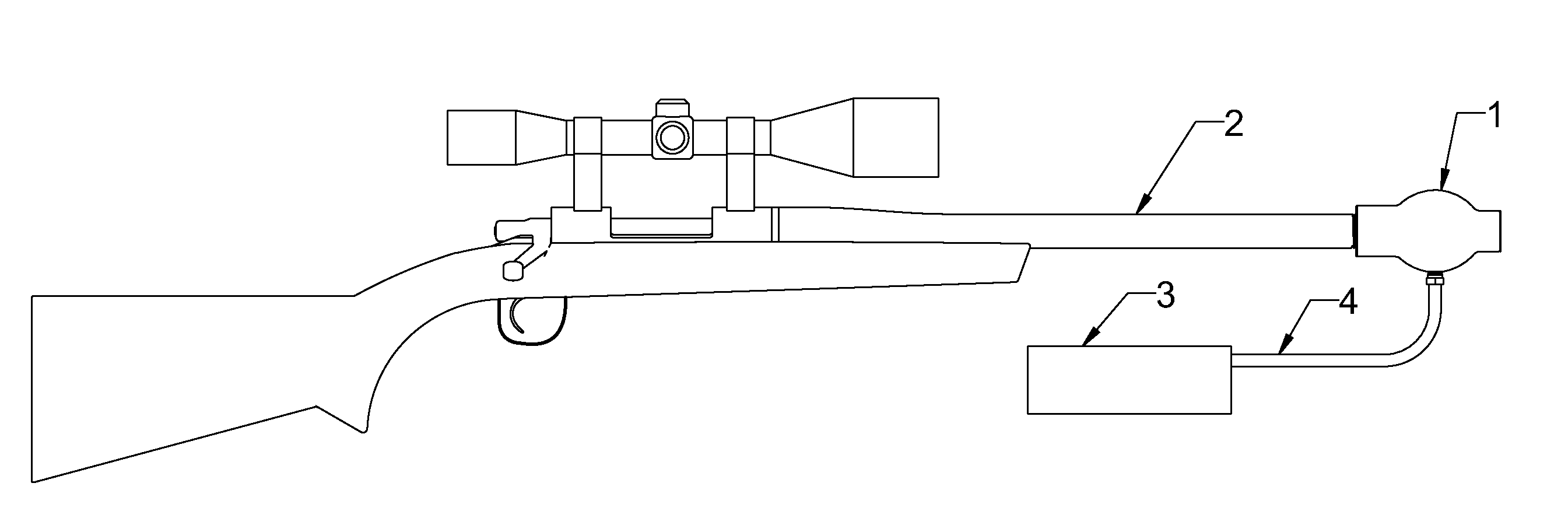

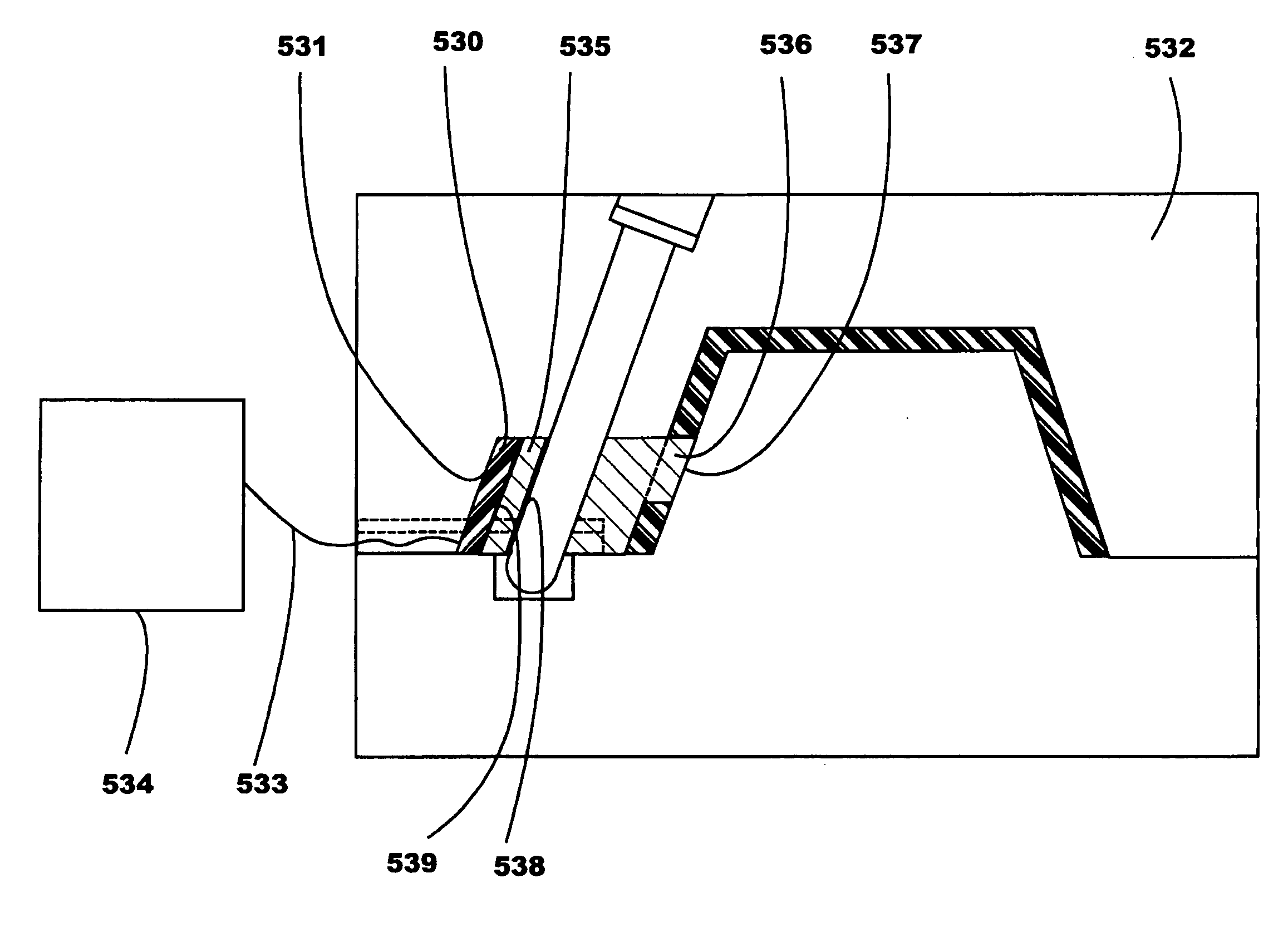

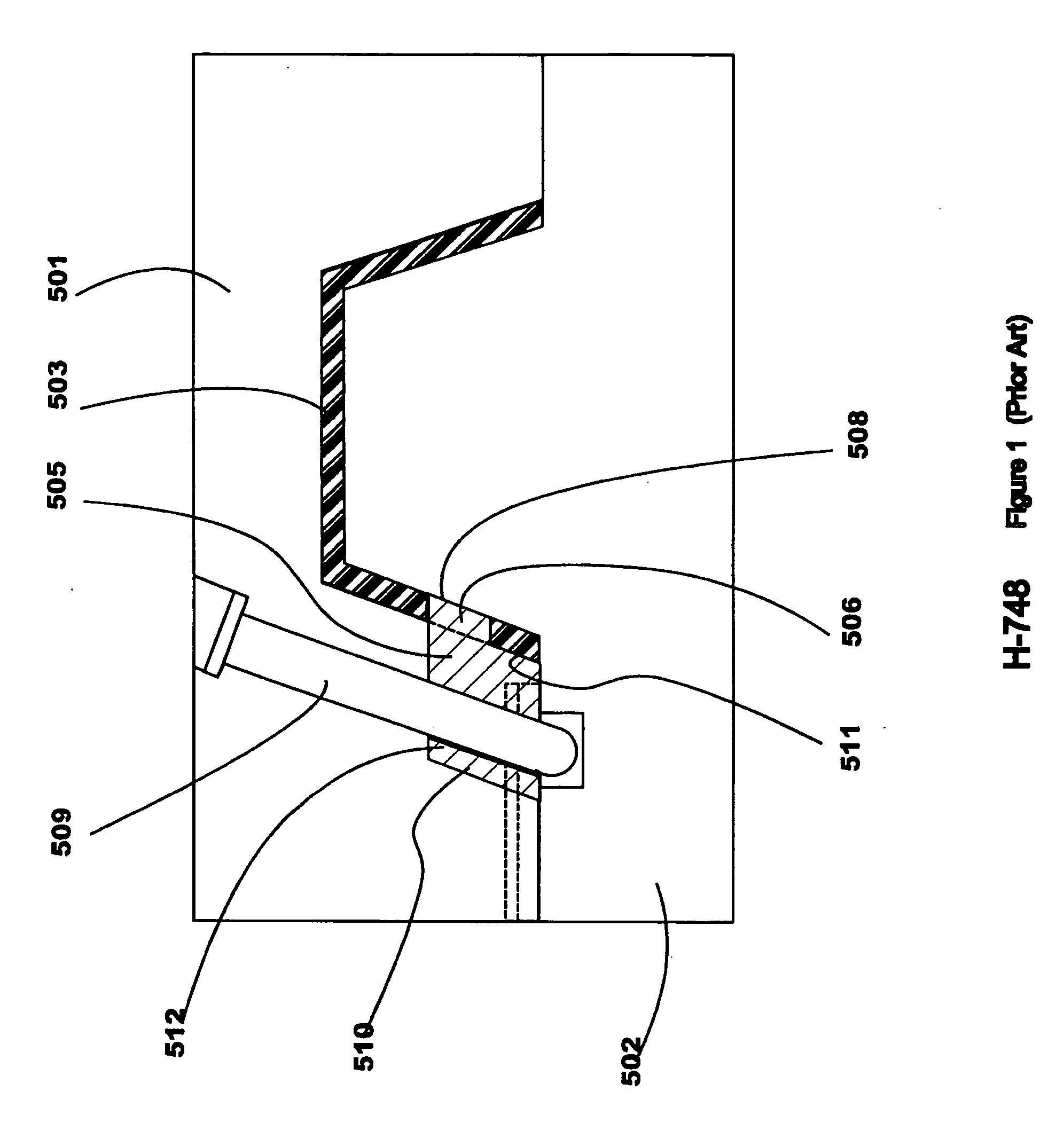

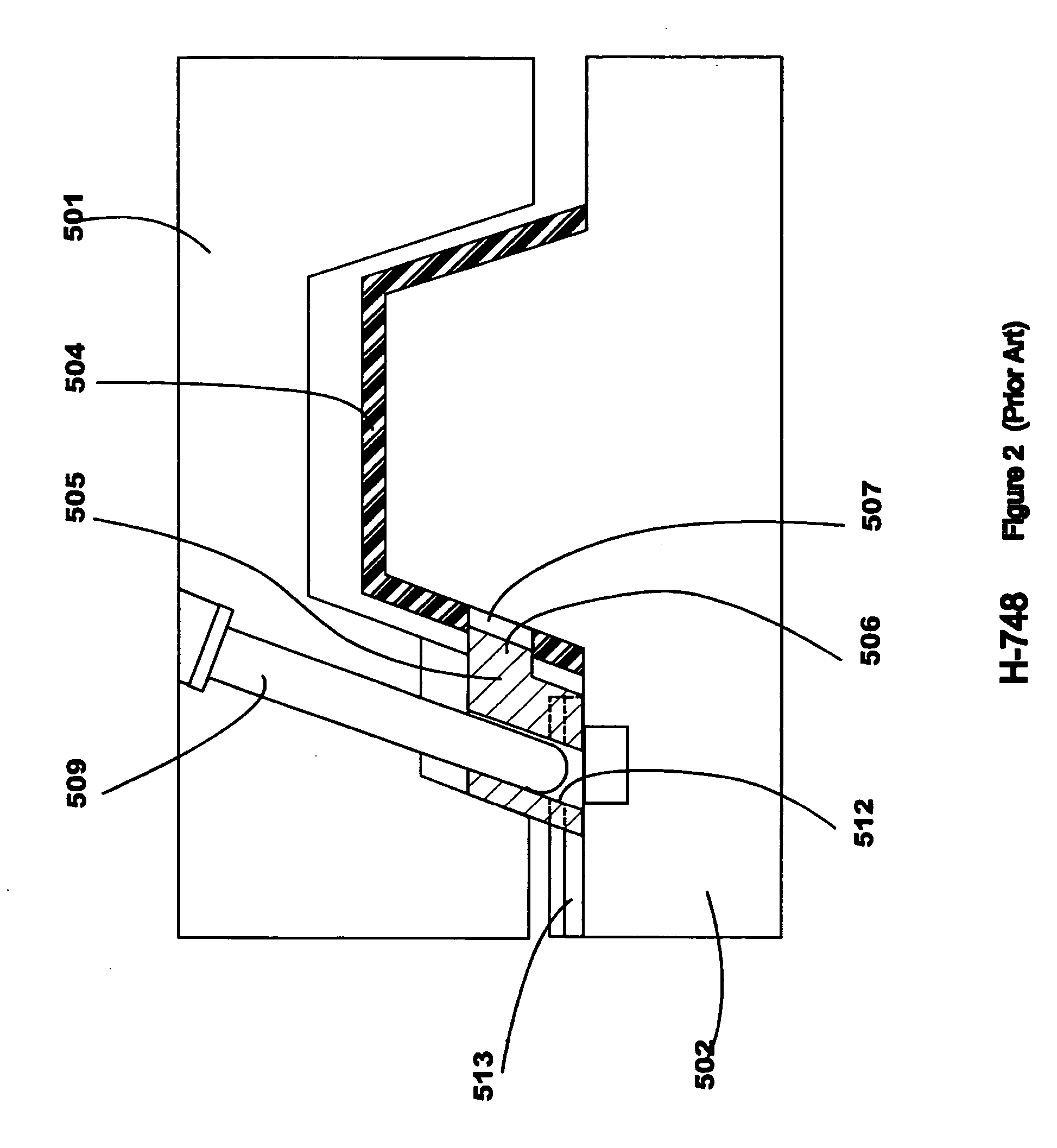

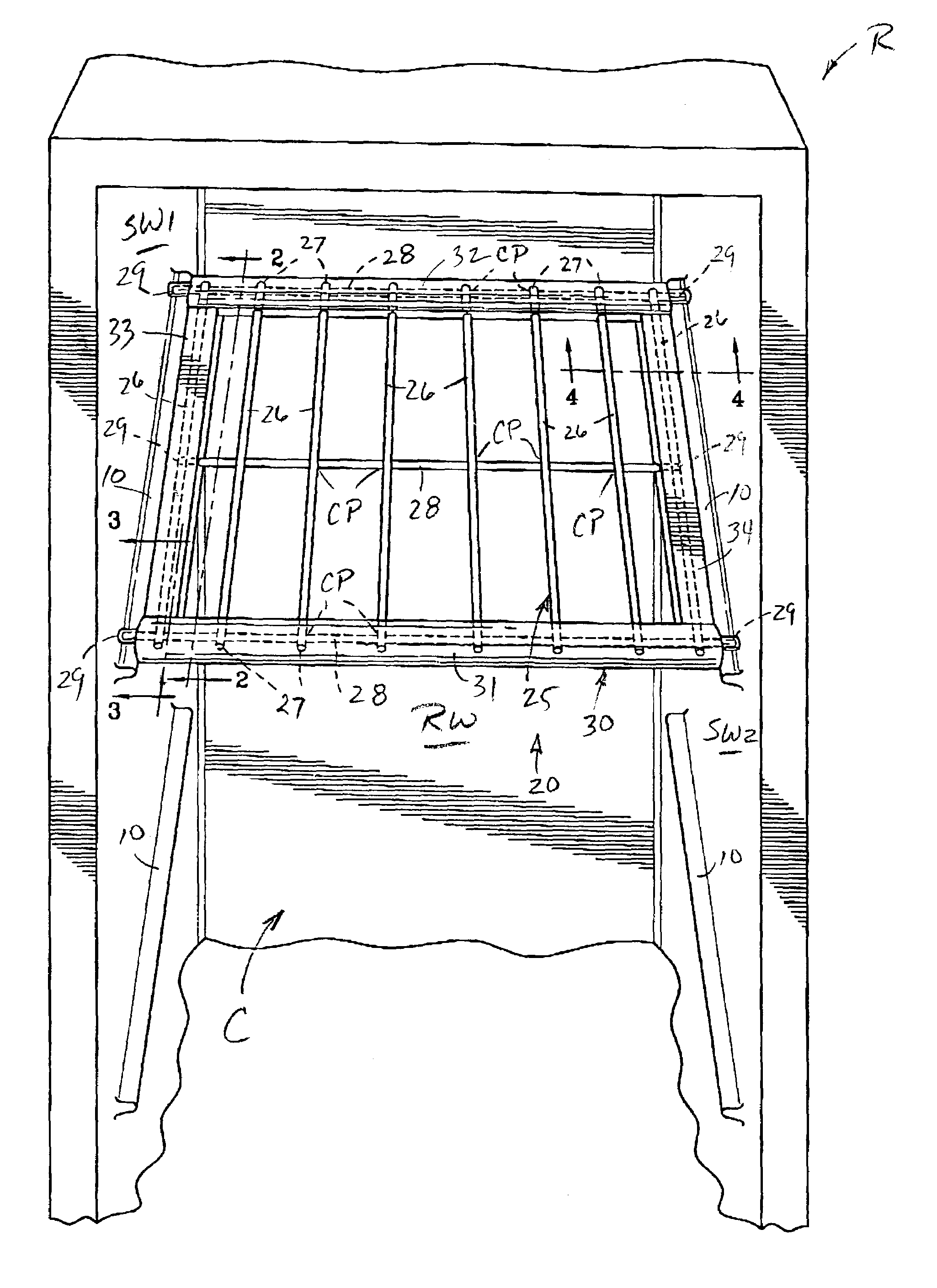

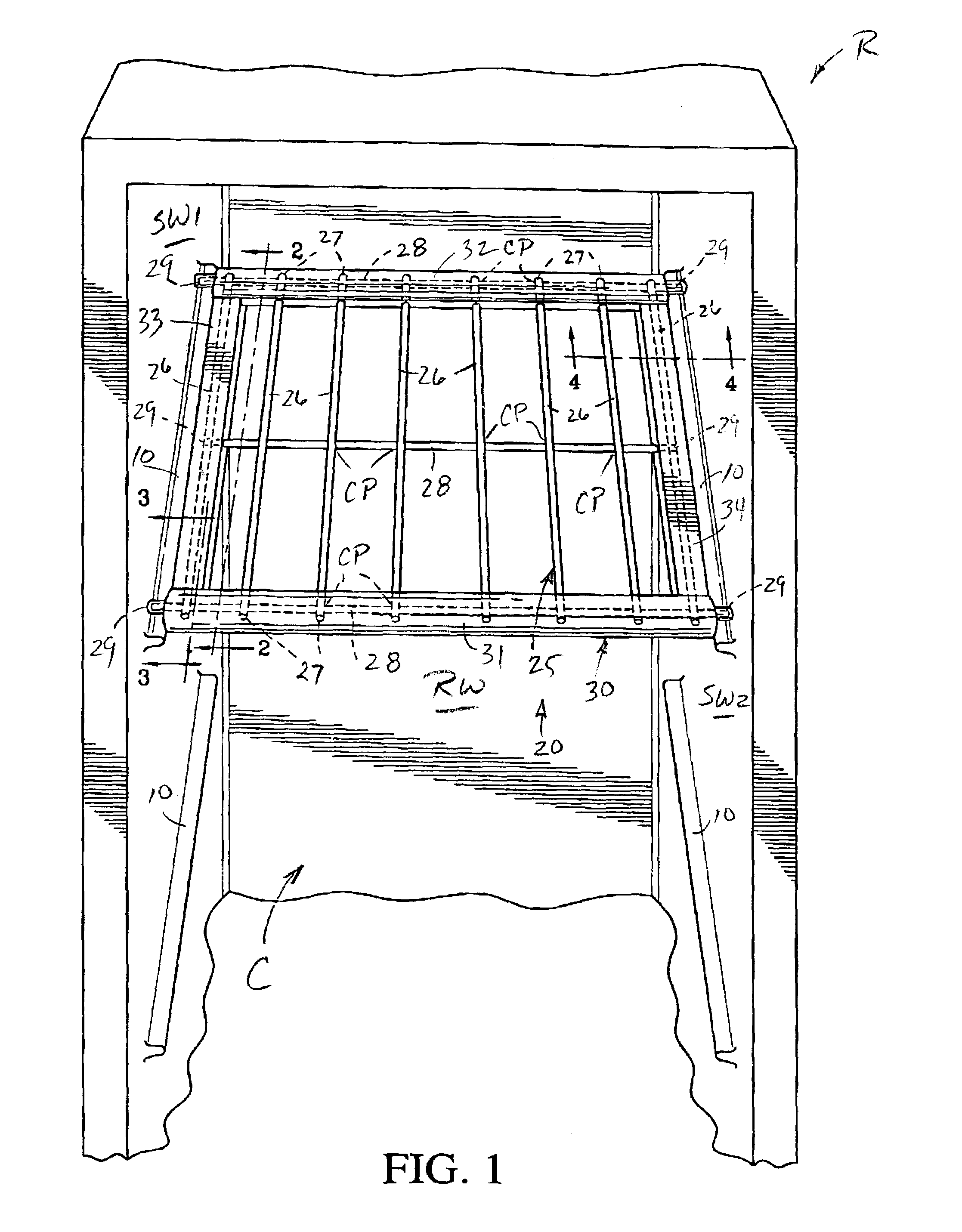

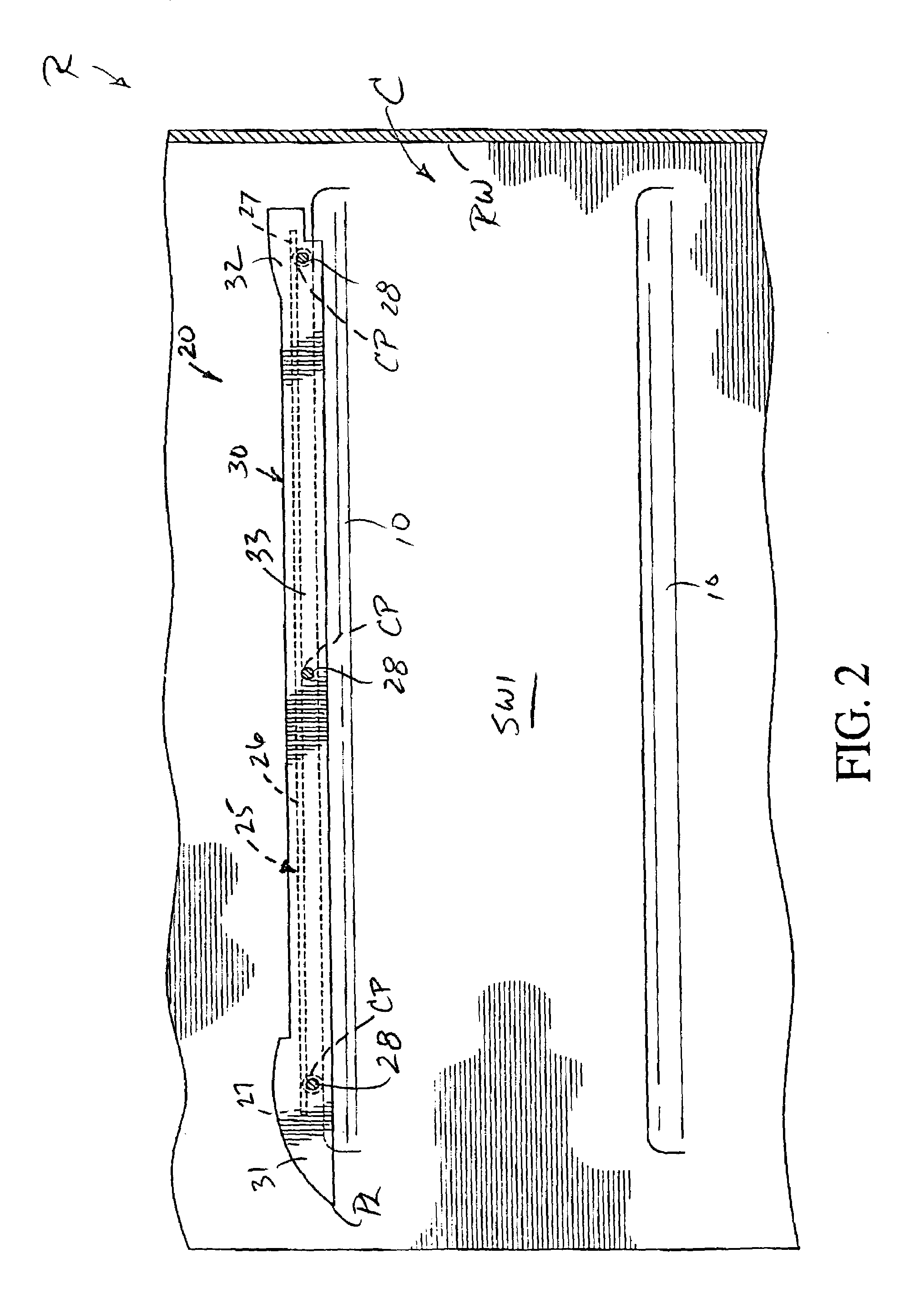

Suppressor and flash hider device for firearms having dual path gas exhaust

InactiveUS9709354B2Accelerated dissipationSpeed up the flowMuzzle attachmentSuppressorMajor and minor

A suppressor and flash hider device for firearms defines primary and secondary propellant gas paths that function simultaneously to quickly decrease gas pressure within the tubular housing of the suppressor to minimize blow-back toward the firearm user. The tubular housing has a collet-like firearm clamping system that establishes symmetrical clamping that will not tend to force the suppressor off coaxial alignment with the firearm barrel to which is mounted. A front wall mounted to the housing defines a central projectile port through which propellant gas also passes and defines an array of angularly oriented discharge passages for discharging propellant gases from the secondary propellant gas path forwardly and angularly toward gas being discharged from the projectile port of the front wall.

Owner:LARUE MARK C

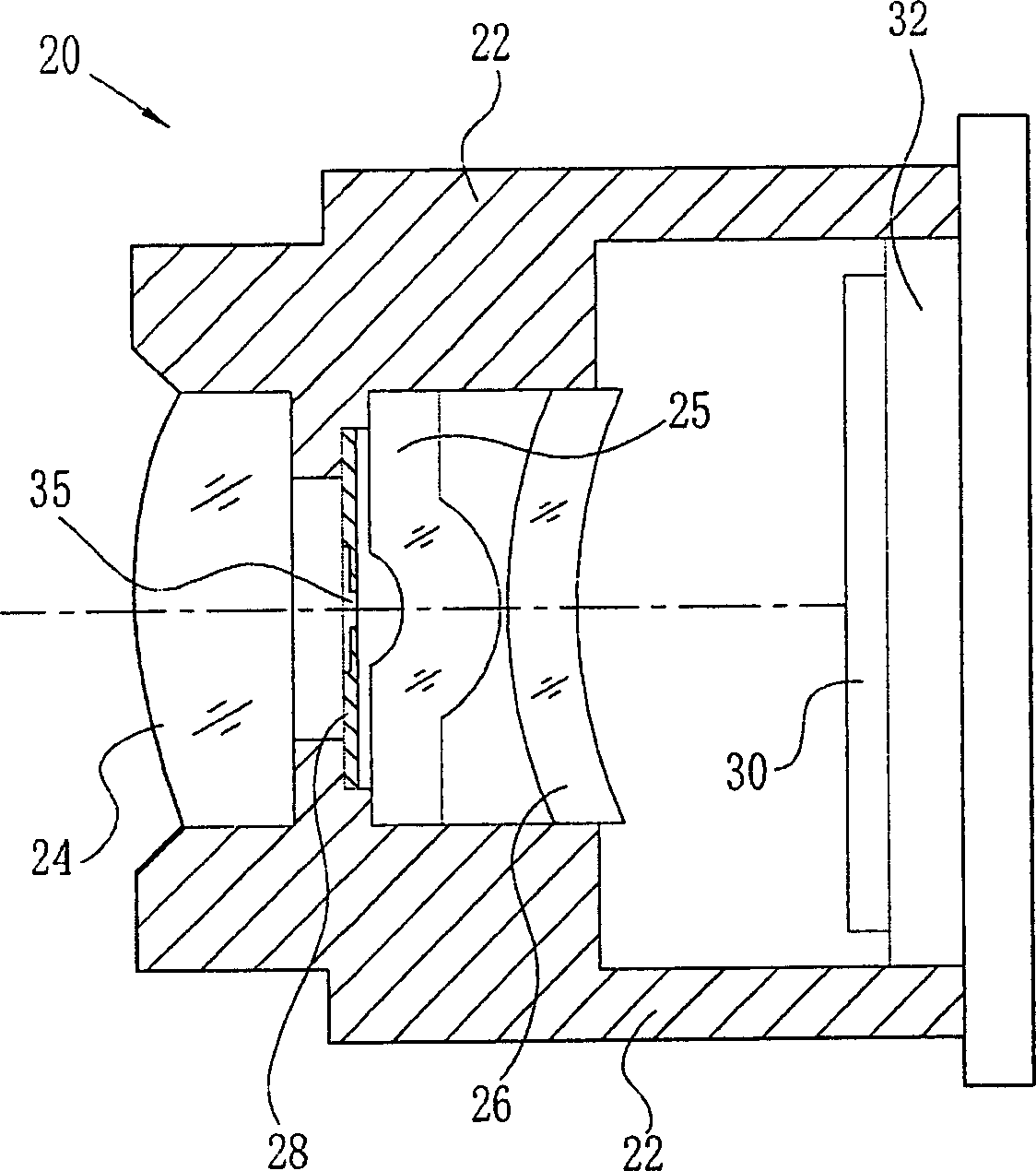

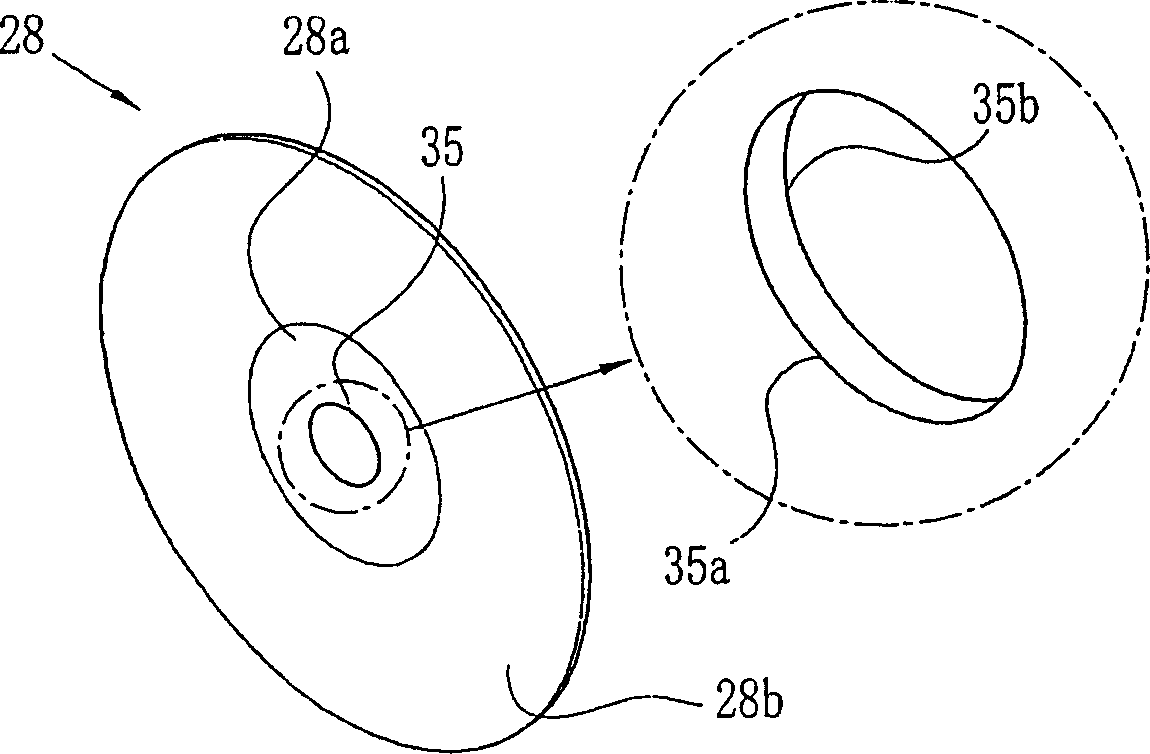

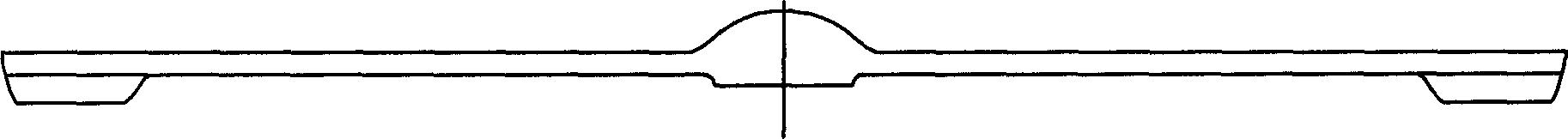

Aperture board

To provide a diaphragm plate which has sufficient strength and doesn't transmit light and suppresses the occurrence of flare and ghost. A diaphragm plate 28 is made of, for example, phosphor bronze or stainless steel. The diaphragm plate 28 comprises a first tabular portion 28a having a diaphragm aperture 35 formed therein and a second tabular portion 28b formed surrounding the periphery of the first tabular portion 28a. The first tabular portion 28a is made thinner than the second tabular portion 28b. An entrance peripheral portion 35d and an exit peripheral portion 25e are formed in an inner peripheral surface 35c of the diaphragm aperture 35. The entrance peripheral portion 35d and the exit peripheral portion 25e are formed circularly. Therefore, the diameter of the diaphragm aperture 35 is made gradually larger according as going toward an entrance 35a and an exit 35b. The inner peripheral surface 35c is coated with a paint preventing reflection of light.

Owner:FUJI PHOTO OPTICAL CO LTD

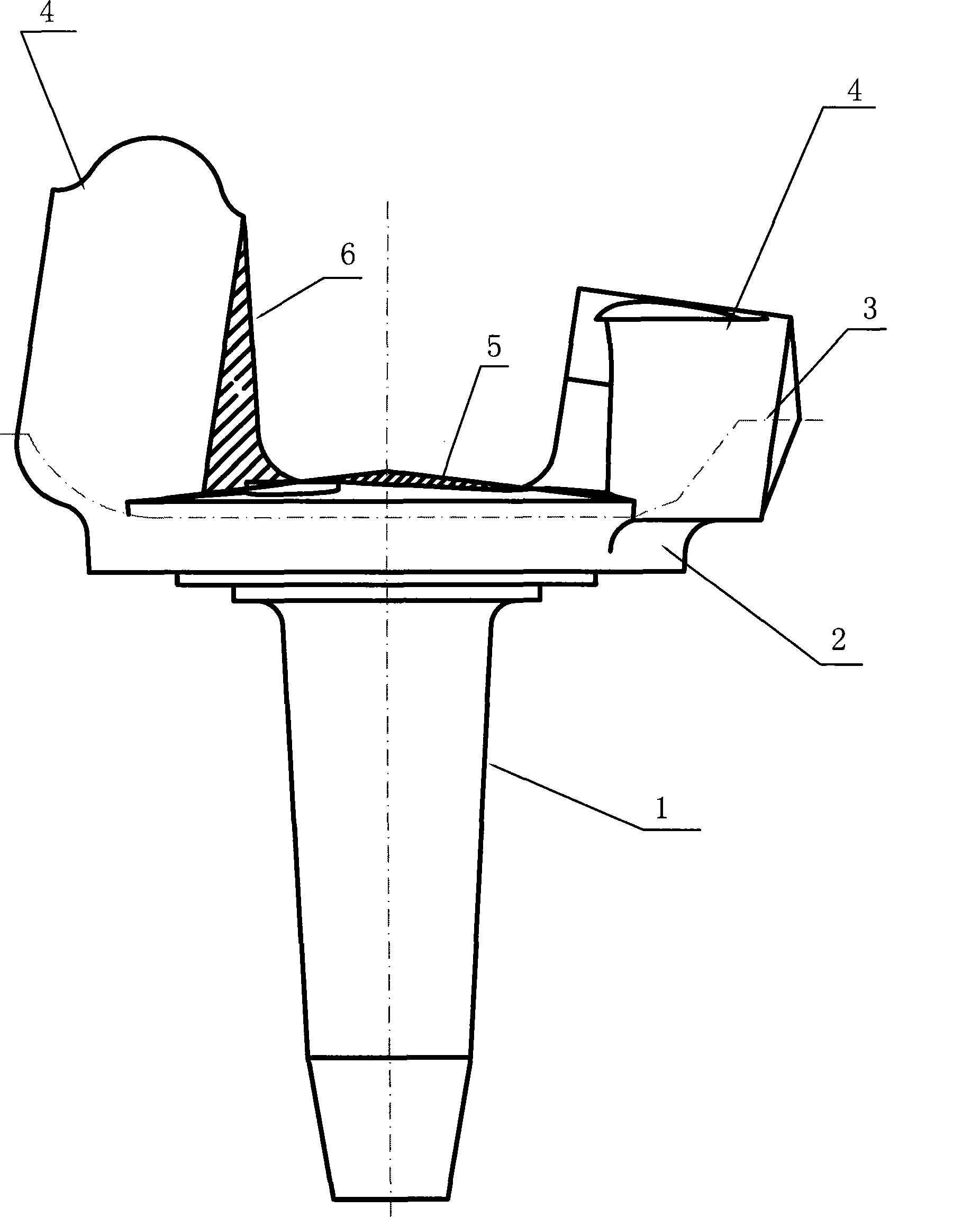

Stabilizer brake for firearm

InactiveUS9080829B1No adverse effect on bullet velocityReduce recoilMuzzle attachmentEngineeringMechanical engineering

A muzzle brake and stabilizing device is provided for a firearm having a barrel, the barrel having a barrel axis, a muzzle, and a breech end. The muzzle brake comprises walls defining a first chamber adjacent the muzzle end of the barrel, the first chamber having a substantially closed end wall and side wall through openings. Walls defining a second chamber are proximate the first chamber, the second chamber has a substantially closed end wall and side wall through openings. Walls defining a third chamber are proximate the second chamber, the third chamber with a substantially open end and having side wall through openings. Walls defining an intermediate chamber are adapted to receive gases passing through the side walls of the first, second, and third chambers, the intermediate chamber with closed side walls and a substantially closed end wall. Walls defining a fourth chamber are proximate the end wall of the intermediate chamber, the fourth chamber having a substantially open end, and side wall closed end openings.

Owner:INNOVATOR ENTERPRISES

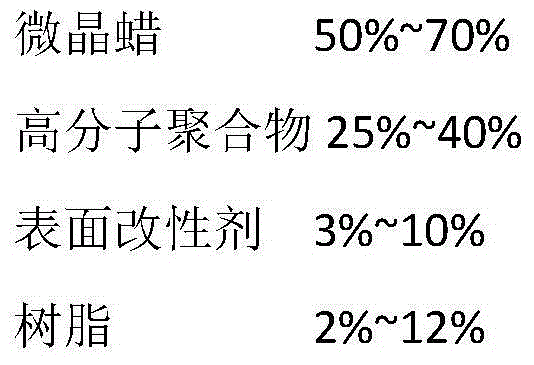

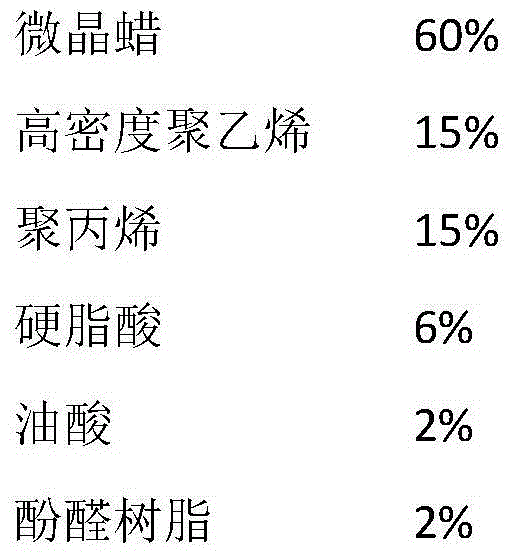

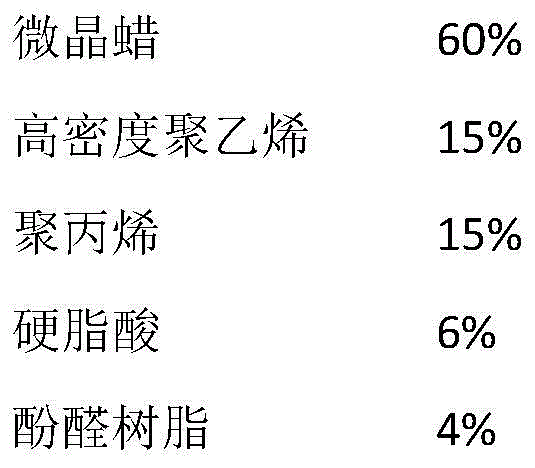

Adhesive agent for injection molding of aluminum nitride ceramic and application method of adhesive agent

The invention belongs to the technical field of ceramic material preparation and discloses an adhesive agent for injection molding of aluminum nitride ceramic and an application method of the adhesive agent. The adhesive agent comprises the following ingredients: 50-70% of microcrystalline wax, 25-40% of high polymer, 3-10% of surface modifier and 2-12% of resin. The application method of the adhesive agent comprises the following steps of mixing aluminum nitride powder and the adhesive agent, putting in a mixing mill for heating and mixing to prepare a feed, carrying out the injection molding to prepare a green body, preparing a degreased blank after degreasing, carrying out high-temperature sintering at last to form a finish product. In a sintering process, heat preservation is carried out at a specific temperature point to achieve carbon thermal reduction to further reduce an oxygen content, and then the temperature is raised to the maximum temperature for sintering and compacting. The adhesive agent has excellent liquidity and shape preserving property, and a specific carbon residue rate after thermal degreasing, and the aluminum nitride ceramic prepared by the adhesive agent has upper heat conductivity.

Owner:UNIV OF SCI & TECH BEIJING

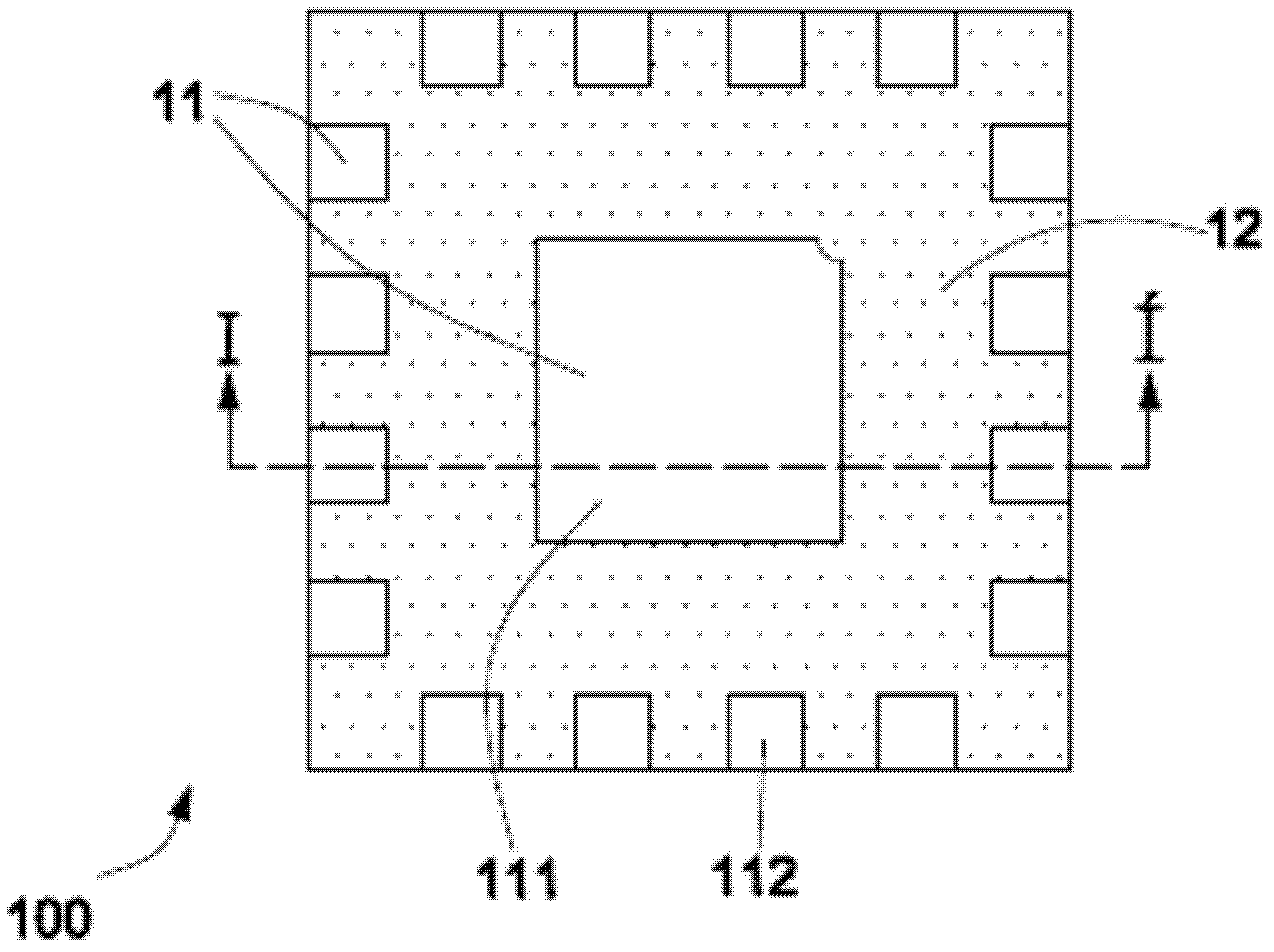

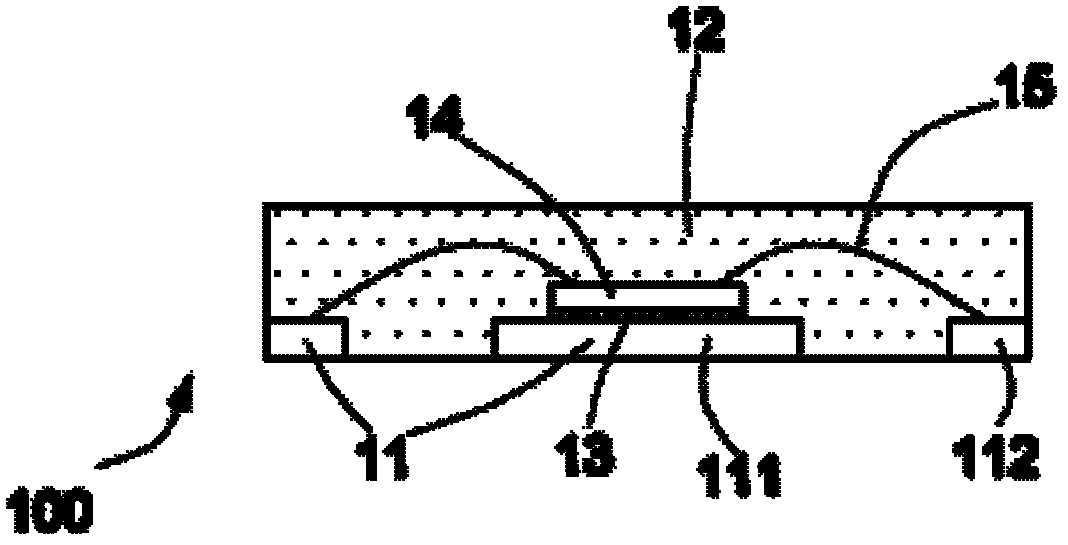

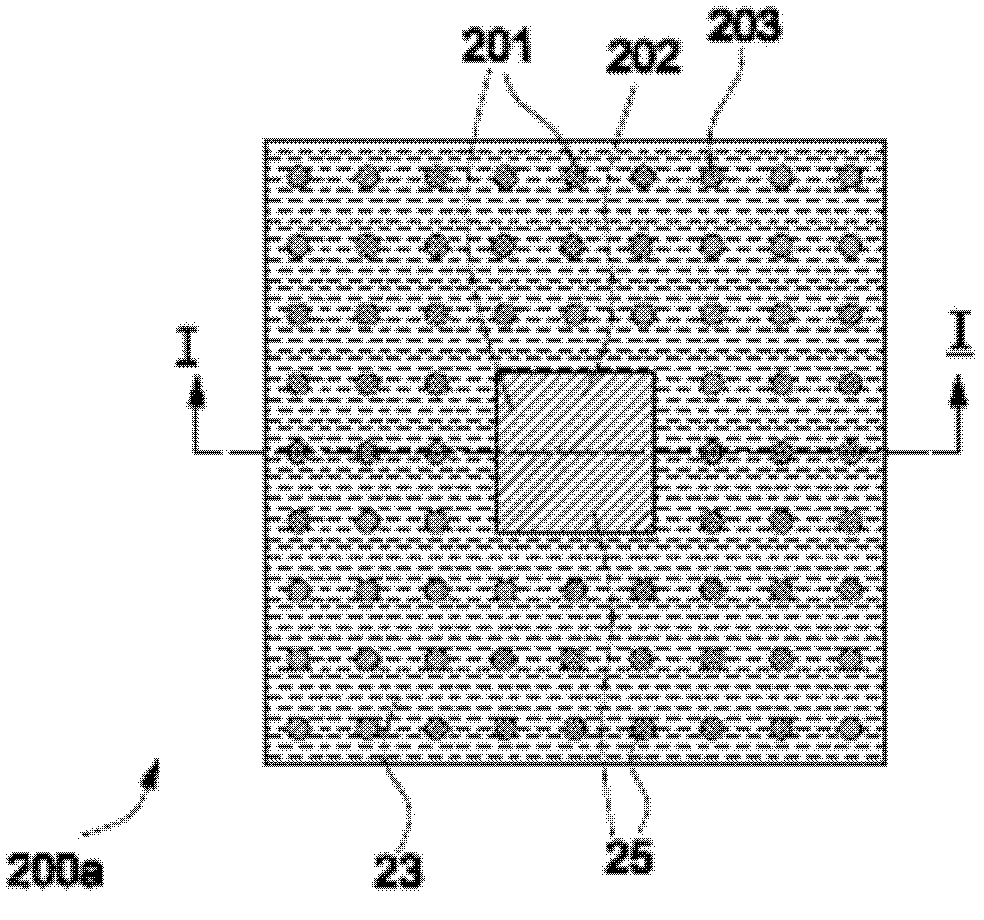

Quad flat non-lead (QFN) package with high density and manufacturing method

InactiveCN102354691AHigh I/O densityPrevent falling offSemiconductor/solid-state device detailsSolid-state devicesFilling materialsMetallic materials

The invention discloses a quad flat non-lead (QFN) package with high density and a manufacturing method. The package comprises a lead frame 201, metal material layers 25, an IC chip 27, insulating filling materials 23, bonding materials 26, metal conductors 28 and plastic package materials 29, wherein the lead frame comprises a chip carrier 202 and a plurality of leads 203 arranged in multiple circles around the chip carrier; the metal material layers are arranged on the upper and lower surfaces of the lead frame; the IC chip is arranged on a metal material layer on the upper surface of the lead frame; the insulating filling materials are arranged below stepped structures 22b of the lead frame; the bonding materials are arranged between the IC chip and the metal material layer on the upper surface of the lead frame; the IC chip is connected to the inner leads of the multiple circles of leads and the upper surface of the chip carrier respectively by the metal conductors; the plastic package materials wrap and seal the IC chip, the bonding materials, the metal conductors, partial regions of the lead frame and partial metal material layers; and the chip carrier and the outer leads exposed out of the bottom surface of a package structure, are provided with raised parts. The package and the manufacturing method have the following beneficial effects: the bottleneck of low I / O quantity is broken through and the package reliability is improved.

Owner:BEIJING UNIV OF TECH

Suppressor and flash hider device for firearms having dual path gas exhaust

InactiveUS20170030672A1Enhancing propellant gas flowAccelerated dissipationMuzzle attachmentSuppressorMajor and minor

A suppressor and flash hider device for firearms defines primary and secondary propellant gas paths that function simultaneously to quickly decrease gas pressure within the tubular housing of the suppressor to minimize blow-back toward the firearm user. The tubular housing has a collet-like firearm clamping system that establishes symmetrical clamping that will not tend to force the suppressor off coaxial alignment with the firearm barrel to which is mounted. A front wall mounted to the housing defines a central projectile port through which propellant gas also passes and defines an array of angularly oriented discharge passages for discharging propellant gases from the secondary propellant gas path forwardly and angularly toward gas being discharged from the projectile port of the front wall.

Owner:LARUE MARK C

Sound and flash suppressor for firearms

InactiveUS8397862B2Reduces sound and flash levelLower the volumeWeapon componentsSuppressorEngineering

Owner:SHAND RONNIE ALEXANDER

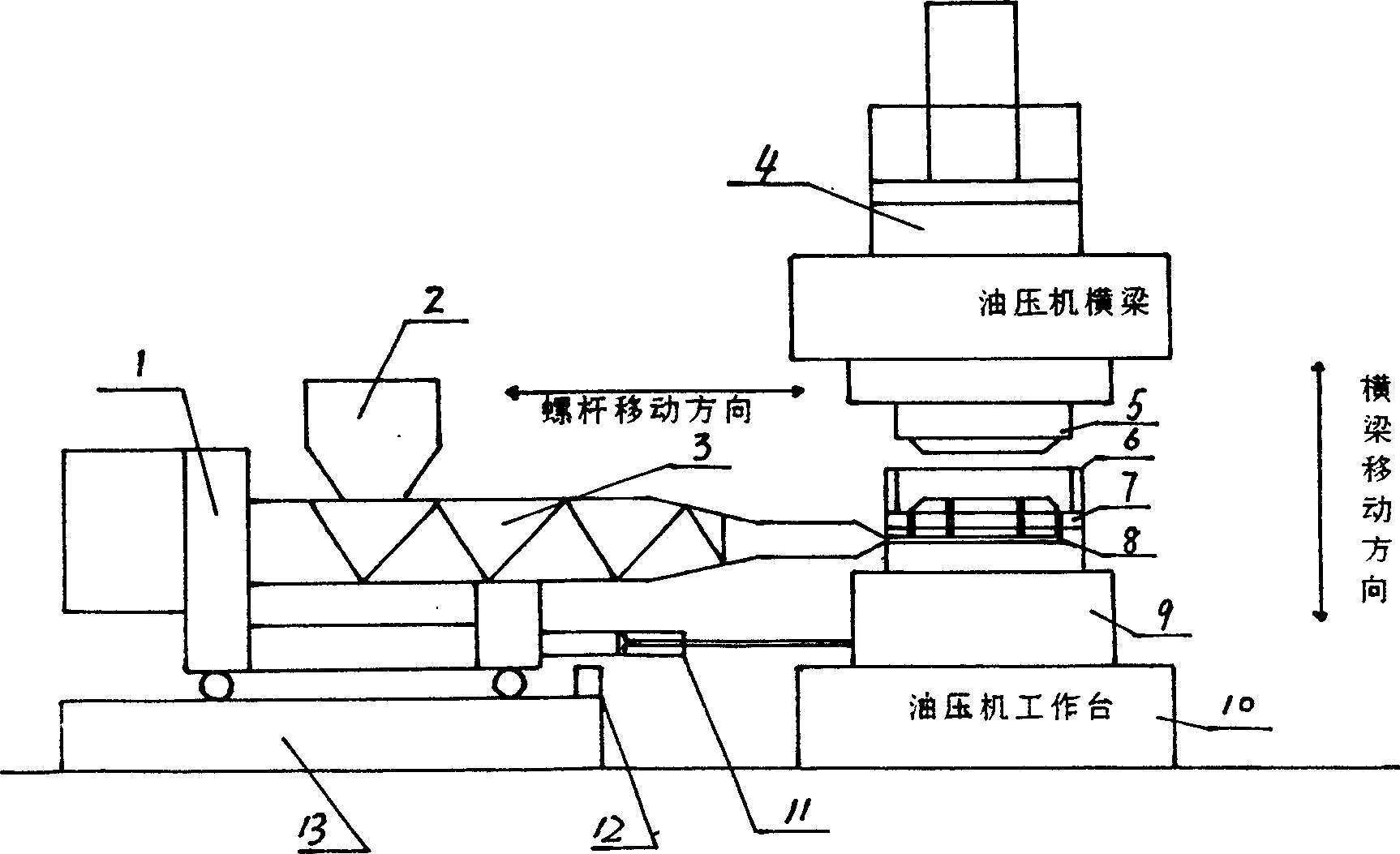

Tech. for forging forming of hook fastener flame of wagon and maould thereof

InactiveCN1792544AShorten the lengthSave materialForging/hammering/pressing machinesOther manufacturing equipments/toolsTruckRailway freight car

A technology for manufacturing the coupler tail frame of cargo train by forging includes such steps as blanking, heating, making raw coupler tail frame, die forging step by step, that is, forging one end and then another end, removing excessive edge, bending an welding. Its die set is composed of upper die with internal cavity whose length is equal to that of finished blank, and lower die with internal cavity having a central locating pit.

Owner:CHONGQING UNIV OF TECH

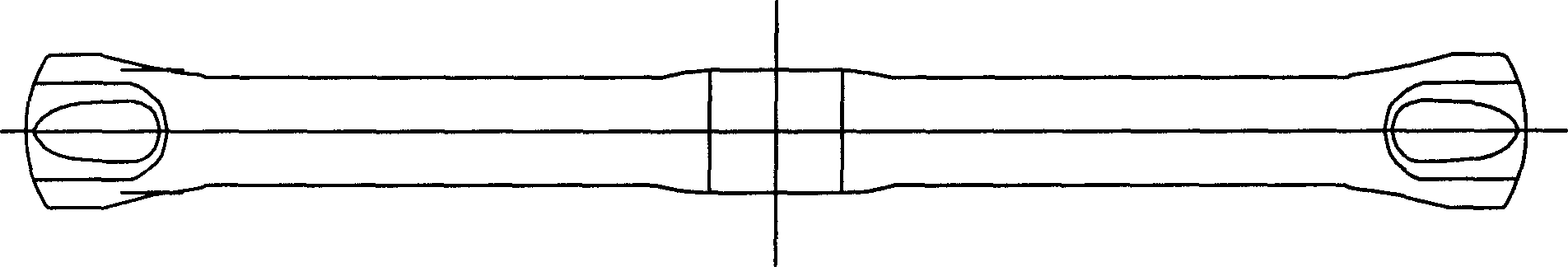

Autocar spindle fork vertical type forging technique method

InactiveCN101456056AIncrease profitEliminate machining allowanceSteering linkagesMetal-working apparatusEngineeringFlange

The invention provides a vertical type forging technology method for an automobile steering yoke. The automobile steering yoke consists of a rod part, a ring flange, and fork ears symmetrically arranged on the ring flange form a whole. The vertical type forging technology method is characterized by comprising: a. a step of vertically parting die from the ring flange of the automobile steering yoke and the yoke ears at the two sides, making the die parting surface of the vertical die parting perpendicular to the rod part, and supplementing materials into the inner part of the yoke ears of the automobile steering yoke to form a draft angle; and b. a step of performing vertical forging and forming on a forging machine, and directly forging and forming the bottom of the inner part of the fork ears. Because the die parting form is changed, the material feeding is performed on the processing position of a part, the preforming process is optimized, and the vertical forging is realized; and the die parting area is reduced, the casting fins are reduced, the utilization rate of the materials is increased by more than 20 percent, the secondary preforming step in the horizontal forging process is avoided, the forging efficiency is improved, and the production cost is lowered. The bottom of the inner part of the yoke ears is directly formed by forging so as to remove the admittance at the bottom of the inner part.

Owner:SHIYAN YIXING IND DEV

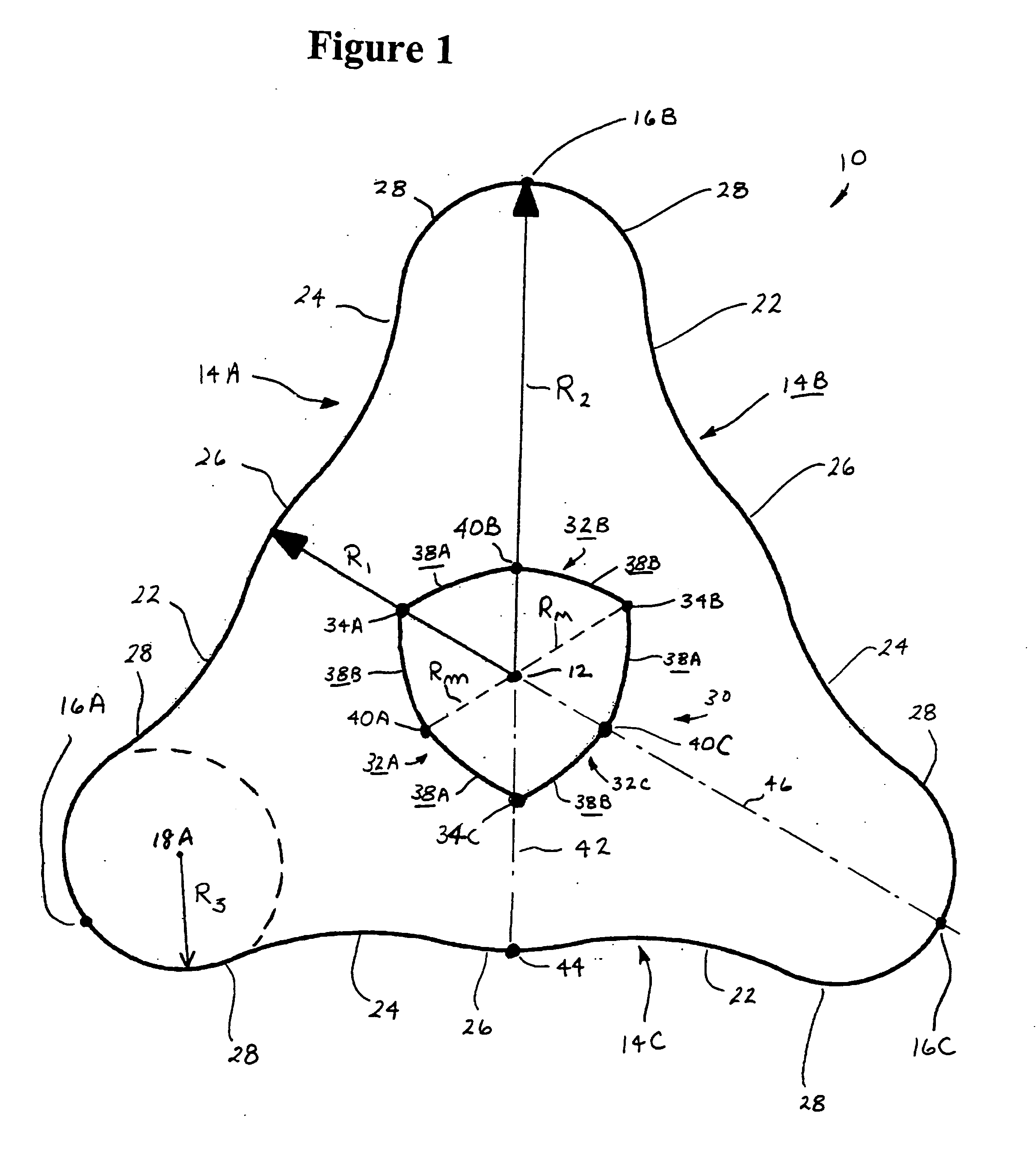

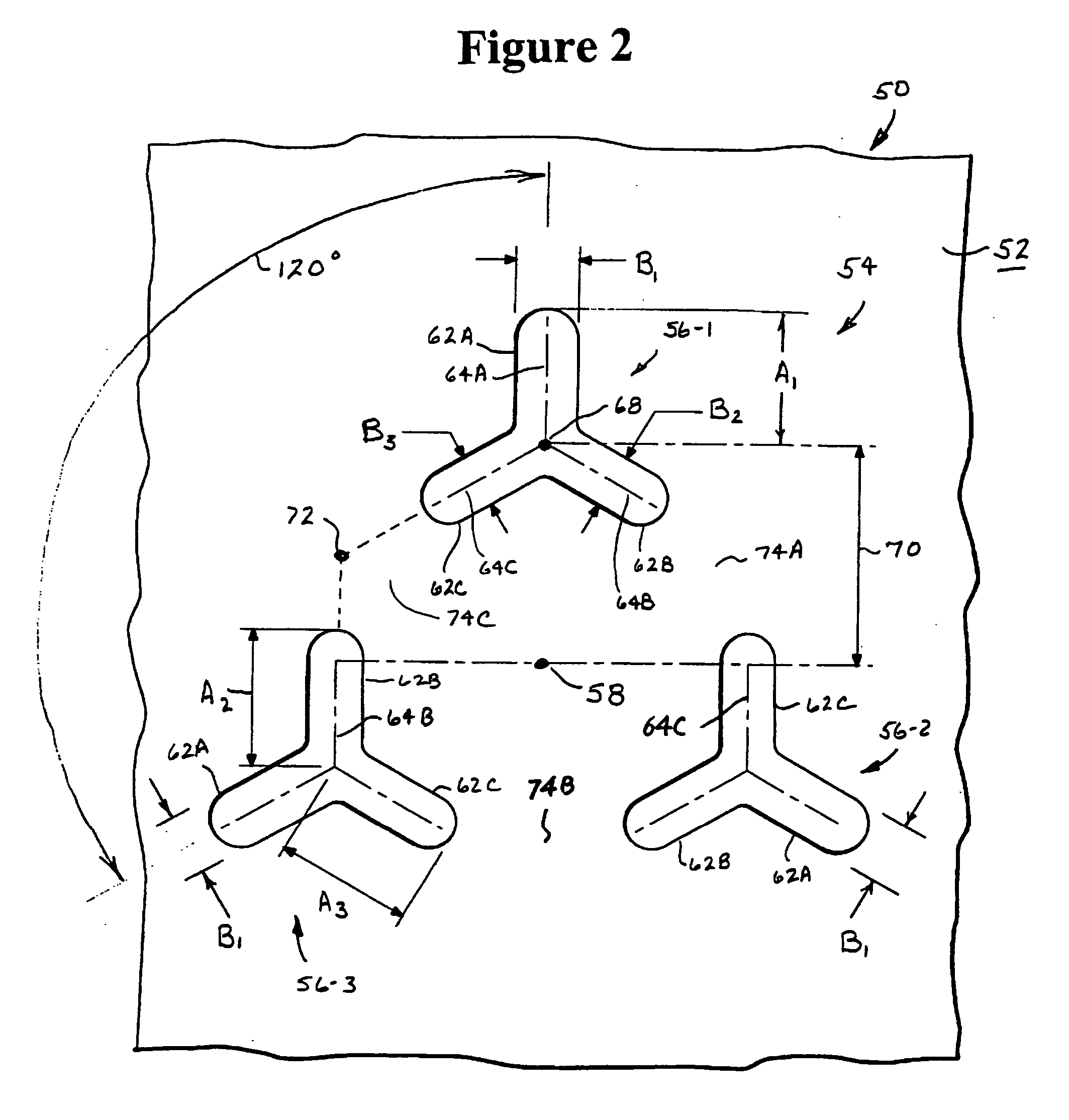

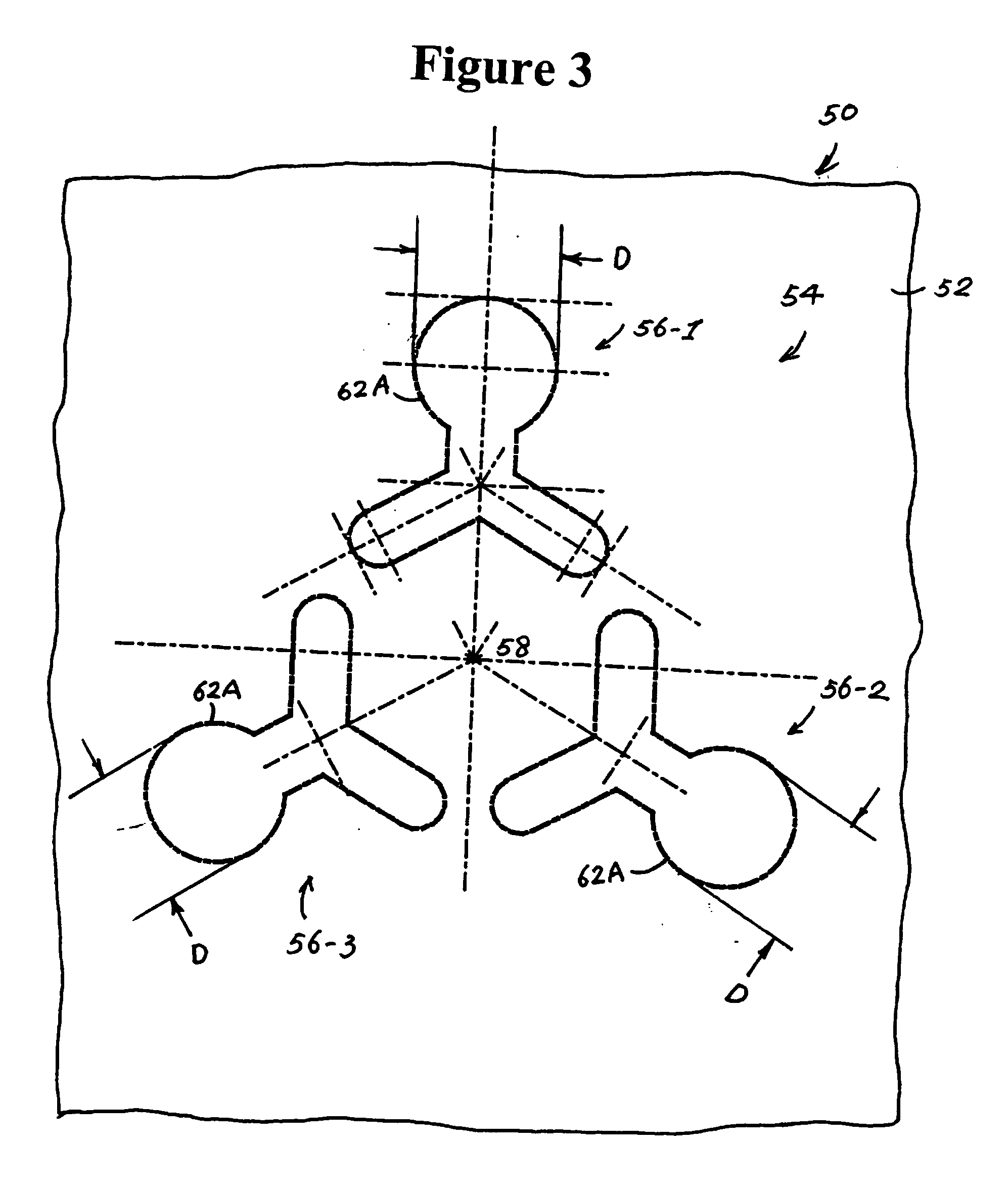

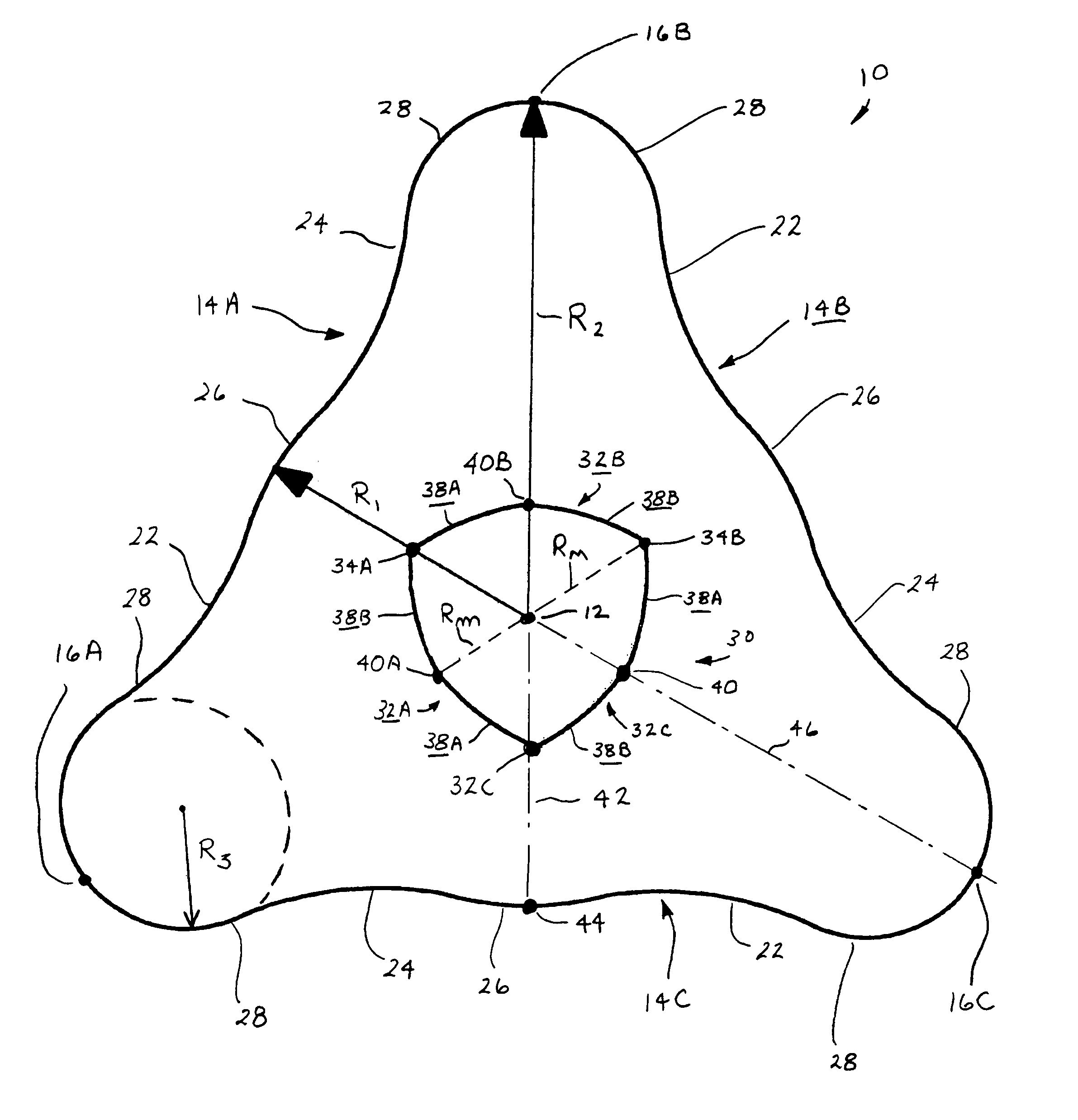

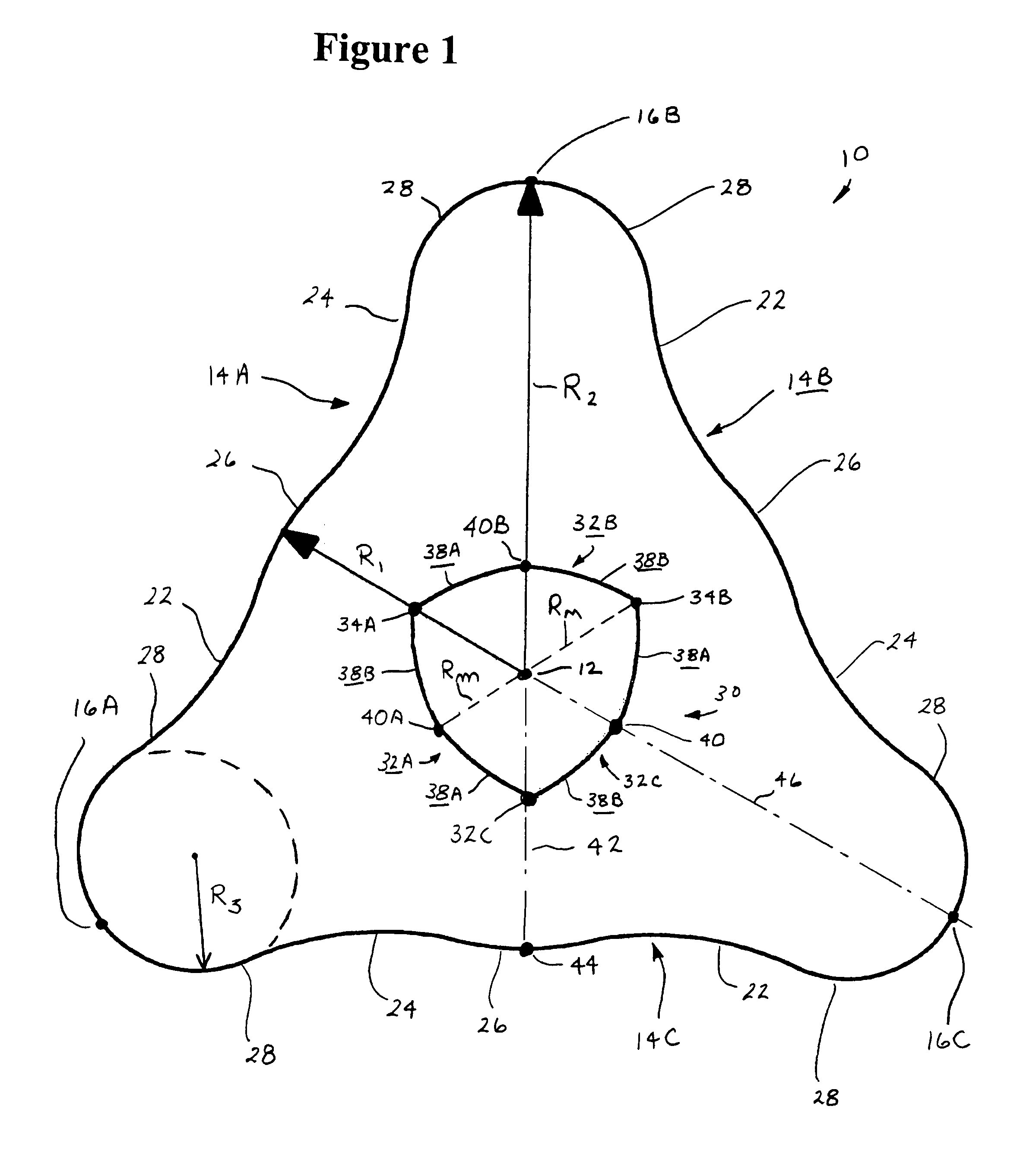

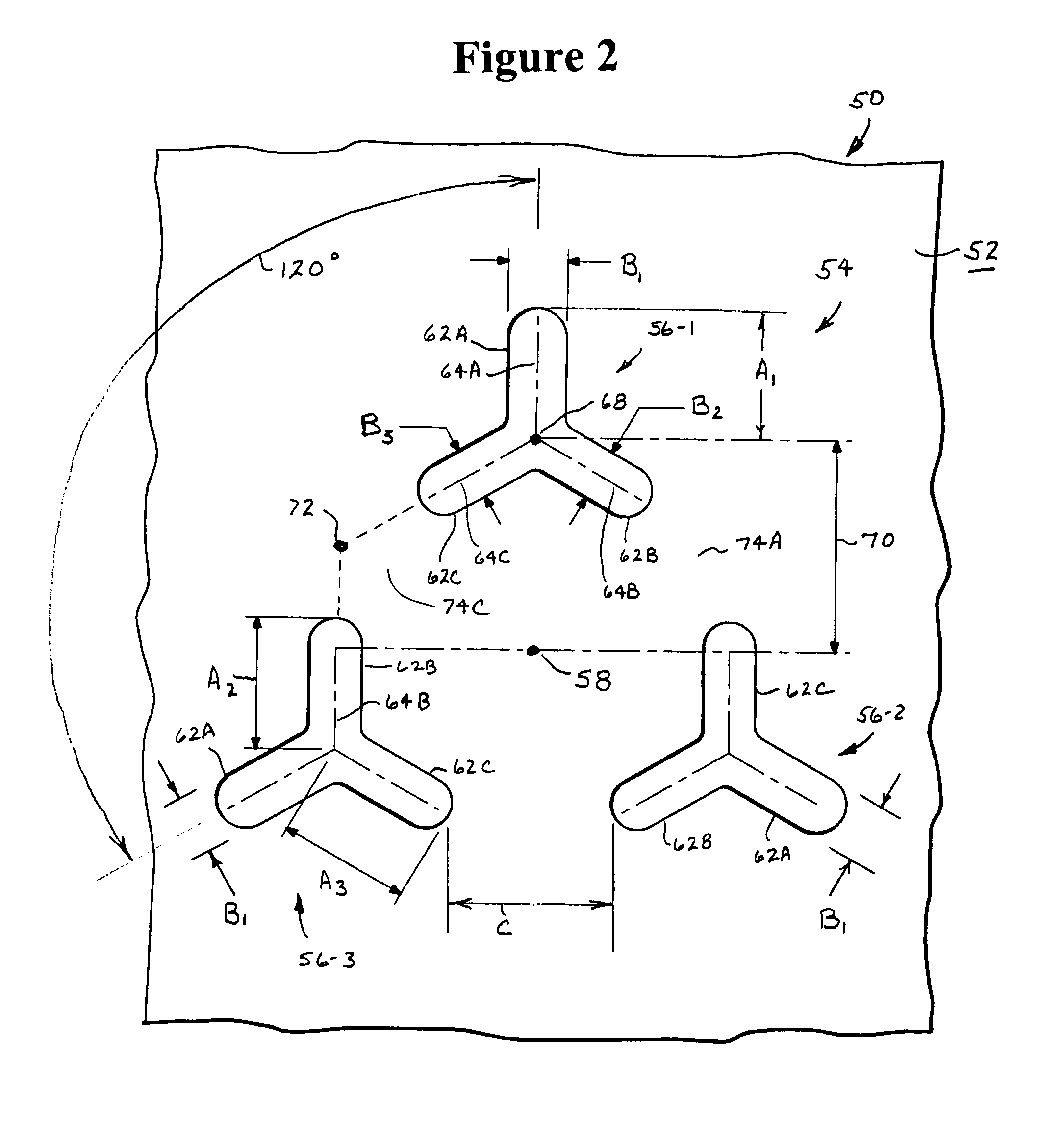

Bulked continuous filament having a three-sided exterior cross-section and a convex six-sided central void and yarn and carpet produced therefrom

ActiveUS20050266241A1Bulk is easyReduce flashLayered productsHollow filament manufactureYarnEngineering

A bulked continuous filament with a three-sided exterior configuration is characterized in that each side has a smoothly curved contour extending between a first and a second rounded tip with an inwardly extending depressed region being disposed adjacent to each tip. Generally, the filament has an exterior modification ratio in the range from about 1.4 to about 2.5, and a tip ratio in the range from about 2.0 to about 10.0. The filament generally delta-shaped void with three major apices extending centrally and axially therethrough. Each side of the void is convexly shaped and formed from a pair of facets that meet to define minor apices. The void is oriented such that each major apex extends toward the approximate midpoint of one side of the exterior of the filament and each minor apex extends toward a tip of an exterior side. The distance (RM) from the geometric center of the void to each major apex and the distance (Rm) from the geometric center of the void to each minor apex defines an apex ratio (RM / Rm) in the range from about 1.0 to about 1.55. The void occupies from about one percent (1%) to about twenty-five percent (25%) of the cross sectional area of the filament.

Owner:INV PERFORMANCE SURFACES LLC

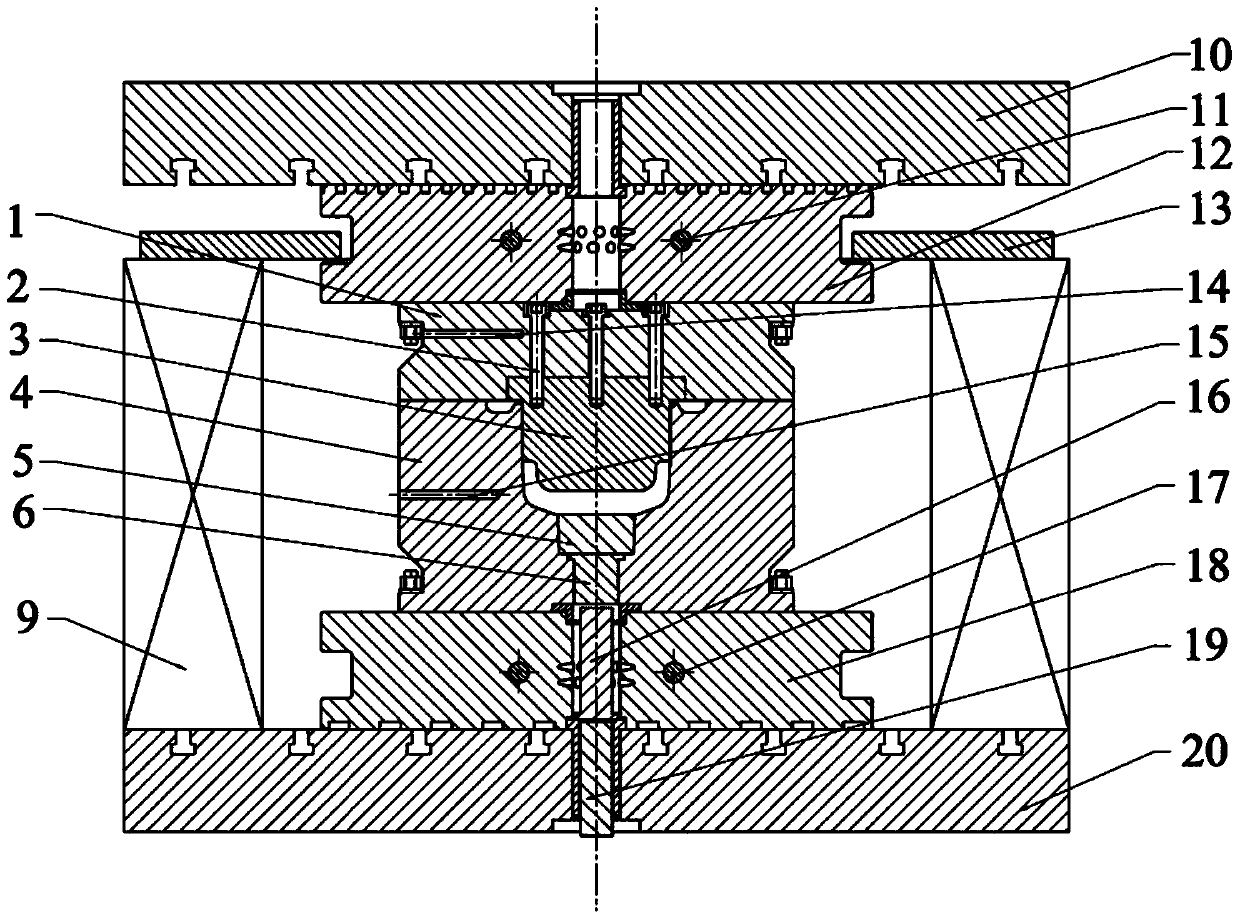

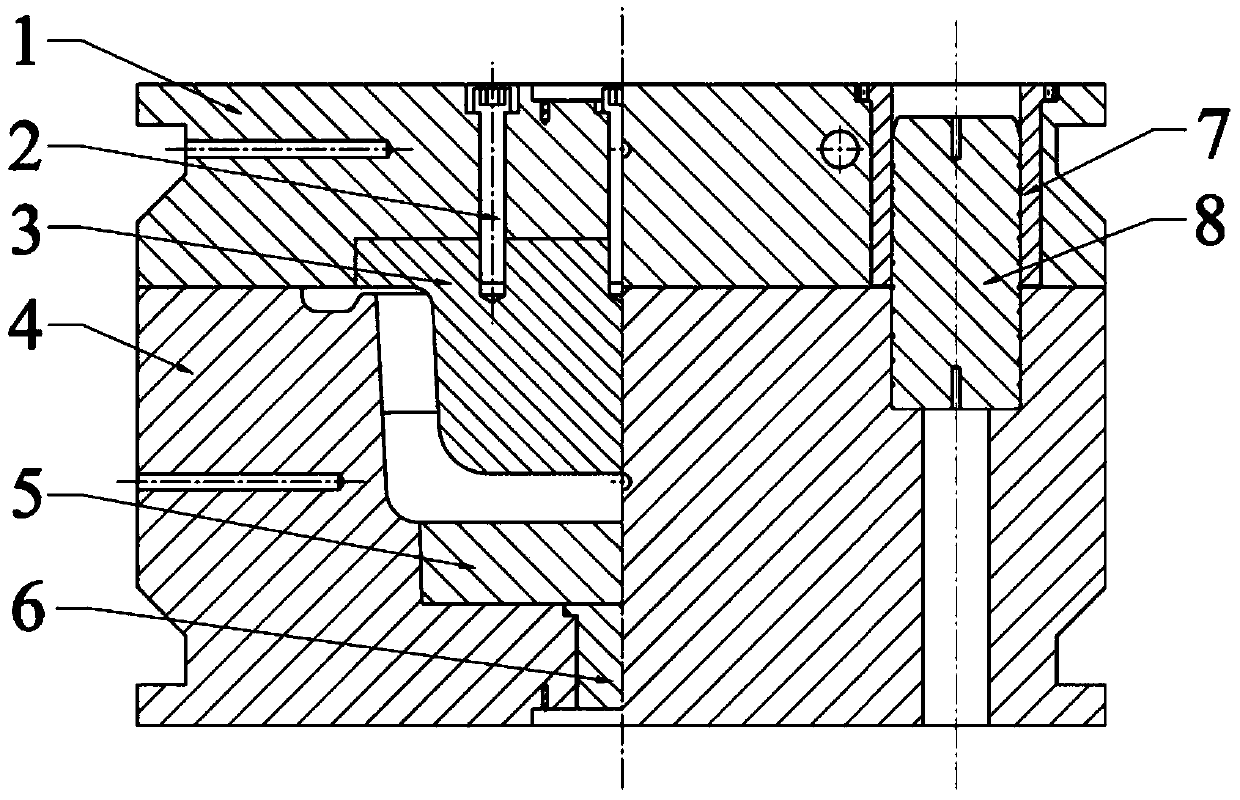

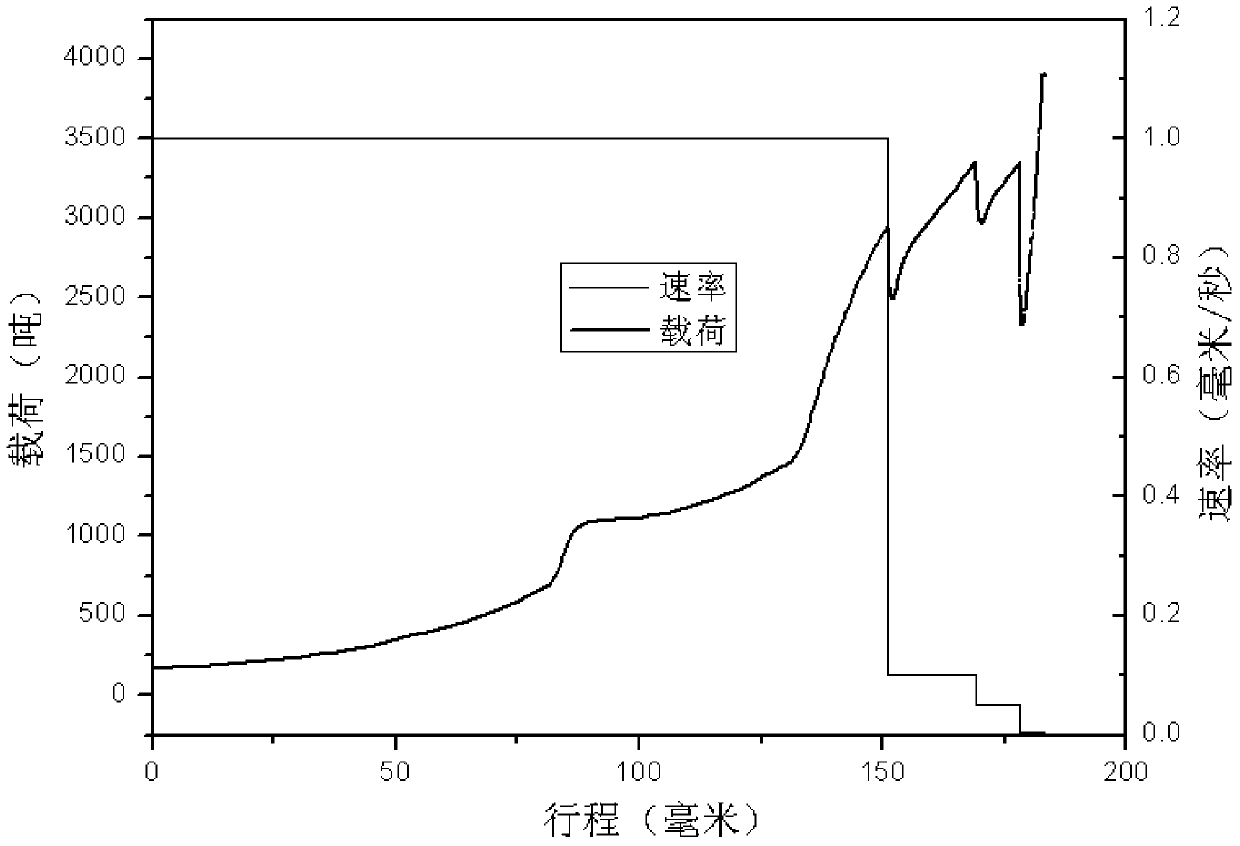

Isothermal forging die and forging technology thereof of magnesium alloy die forge piece of step type structure

InactiveCN103736894ASolve the problem of plastic deformation and easy crackingReduce flashForging/hammering/pressing machinesOpen structureClosed cavity

The invention discloses an isothermal forging die and a forging technology thereof of a magnesium alloy die forge piece of step type structure. An upper die (3) and a lower die (4) are both of semi-closed structures, and in other words, the upper die (3) and the lower die (4) are both of open structures along the length direction, and of closed structures along the width direction due to flash gutters designed on the width direction of the upper die (3) and the lower die (4). One side face along the width direction of the upper die (3) and one side face along the width direction of the lower die (4) are vertical to each other, and the upper die (3) is in clearance fit with the lower die (4) on the position where the upper die (3) and the lower die (4) vertically intersect so as to form a closed cavity. The isothermal forging die and the forging technology thereof of the magnesium alloy die forge piece of step type structure can effectively reduce forging deformation resistance, enable a forging stock to obtain good plasticity, and are high in isothermal forging production efficiency.

Owner:CENT SOUTH UNIV

Plastic filtering board or board forming process

A process for preparing the plastic filter plate or plastic plate features that its mould is controlled by hydraulic press, its heat channel is positioned at the bottom of lower mould and communicated with said lower mould, and the plasticized plastics is injected in said mould via heat channel.

Owner:ZHEJIANG LONGYUAN ENVIRONMENTAL TECH CO LTD

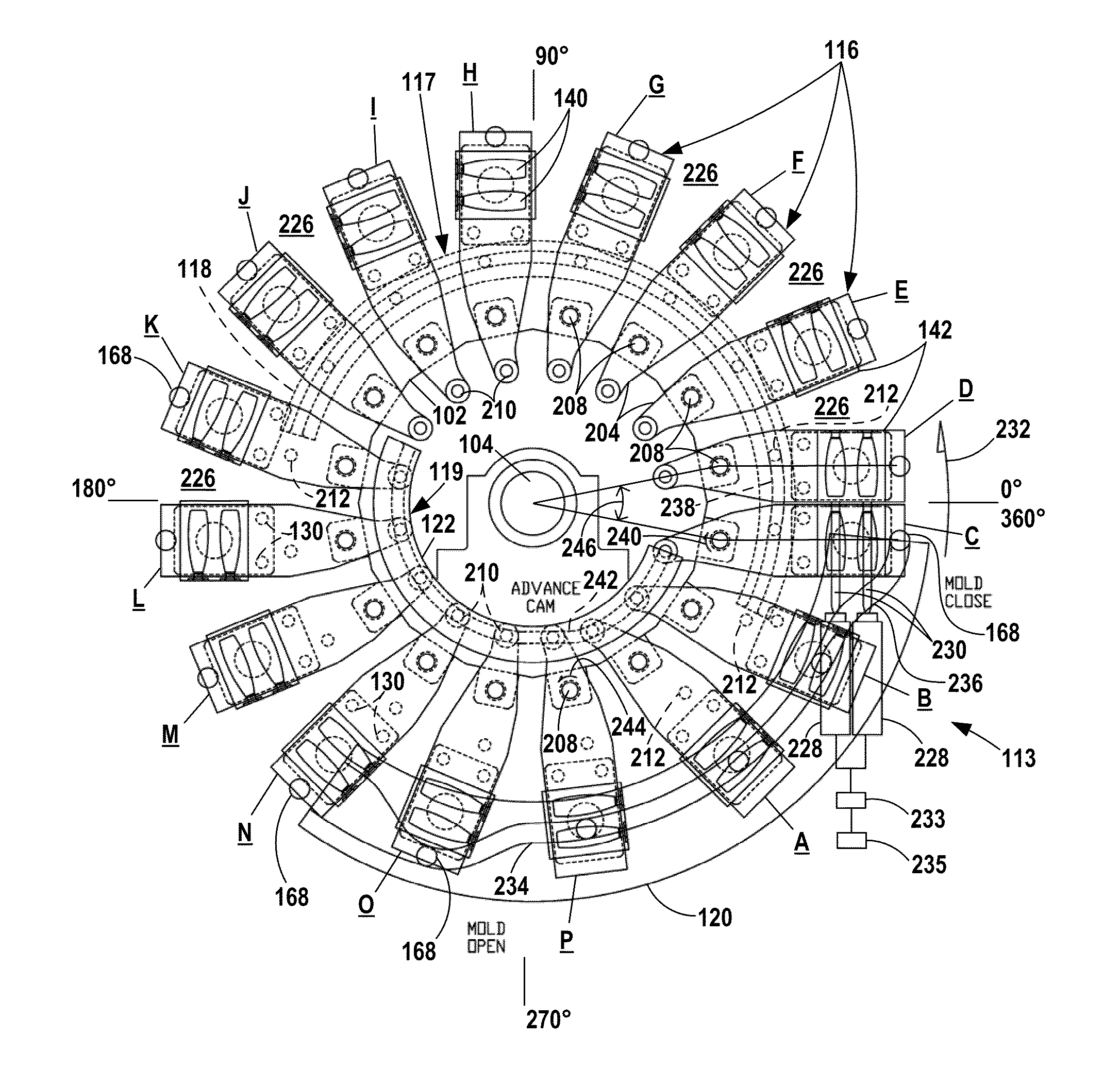

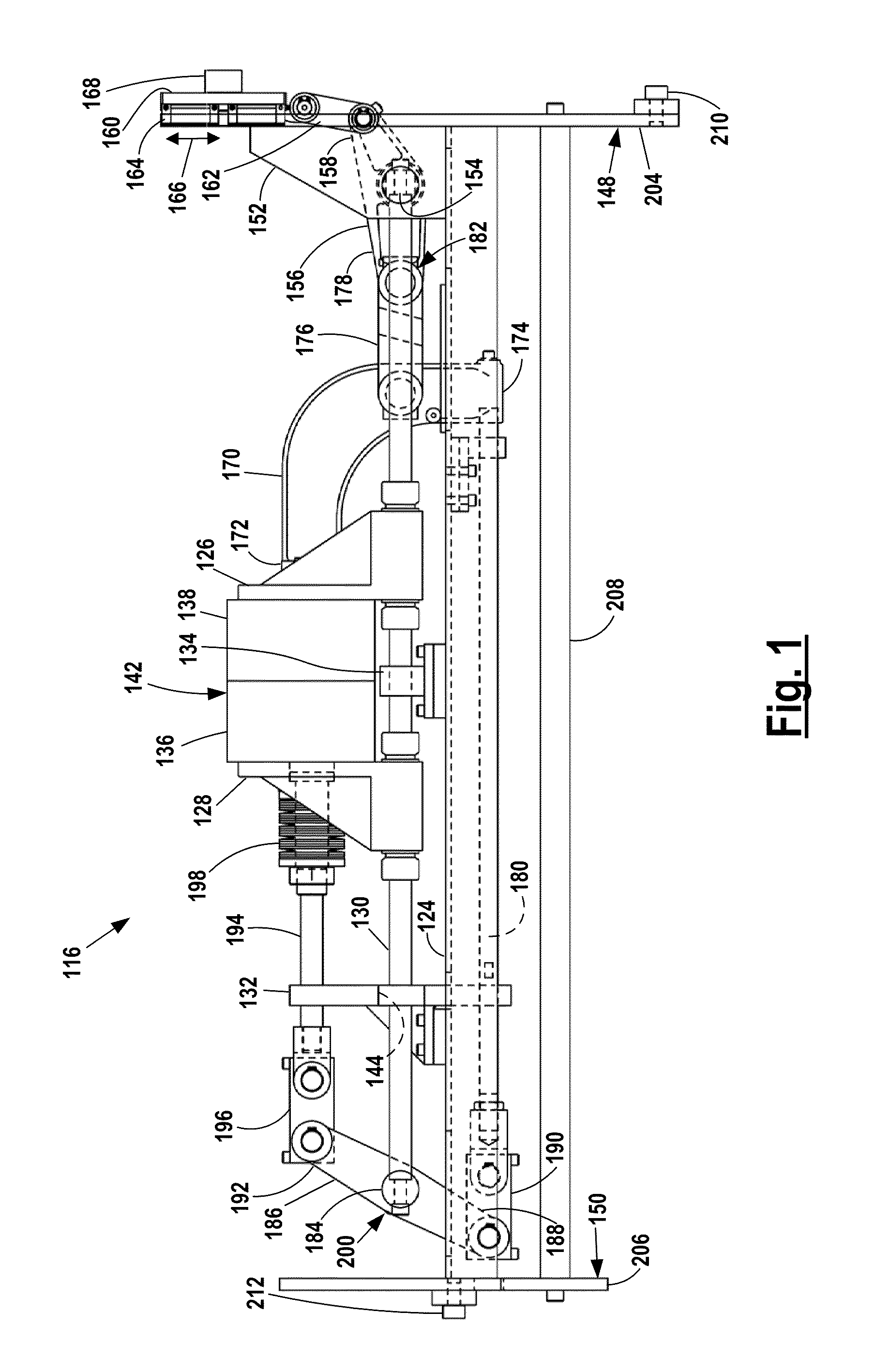

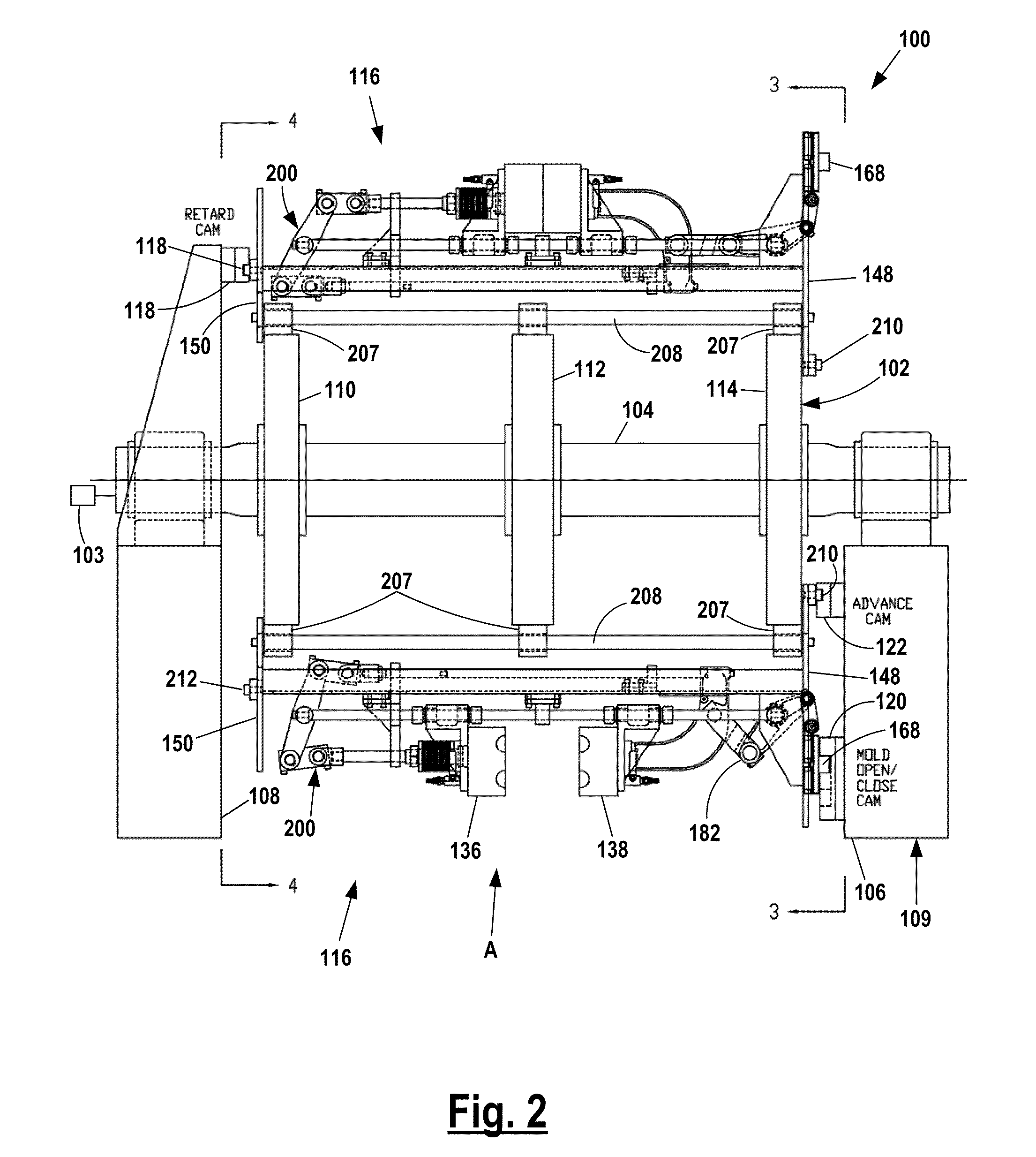

Rotary Blow Molding Machine with Movable Clamp Assemblies and Method

A continuous blow molding machine includes a mechanism for shifting molds upstream during closing to reduce between-mold flash.

Owner:GRAHAM ENG CORP

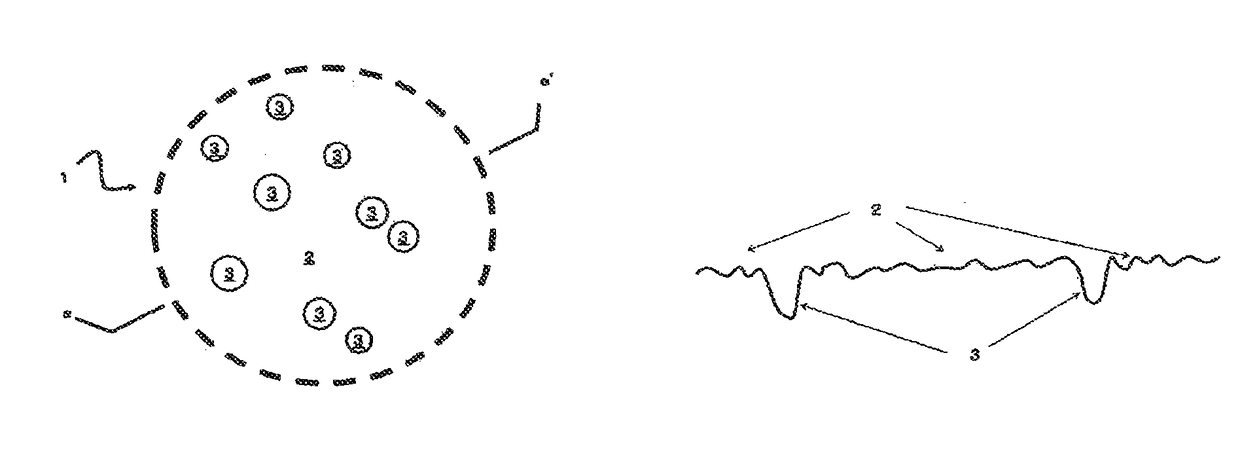

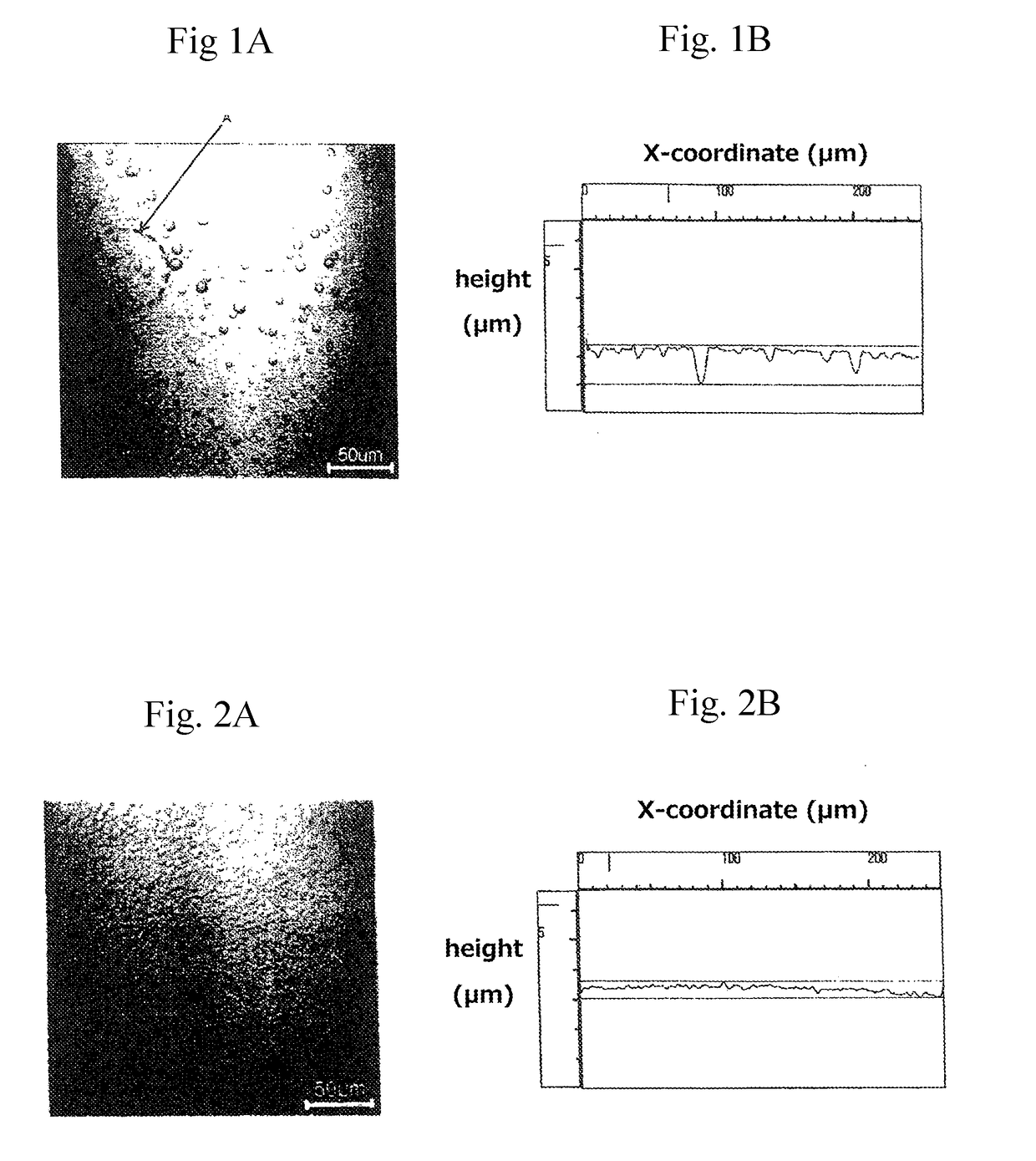

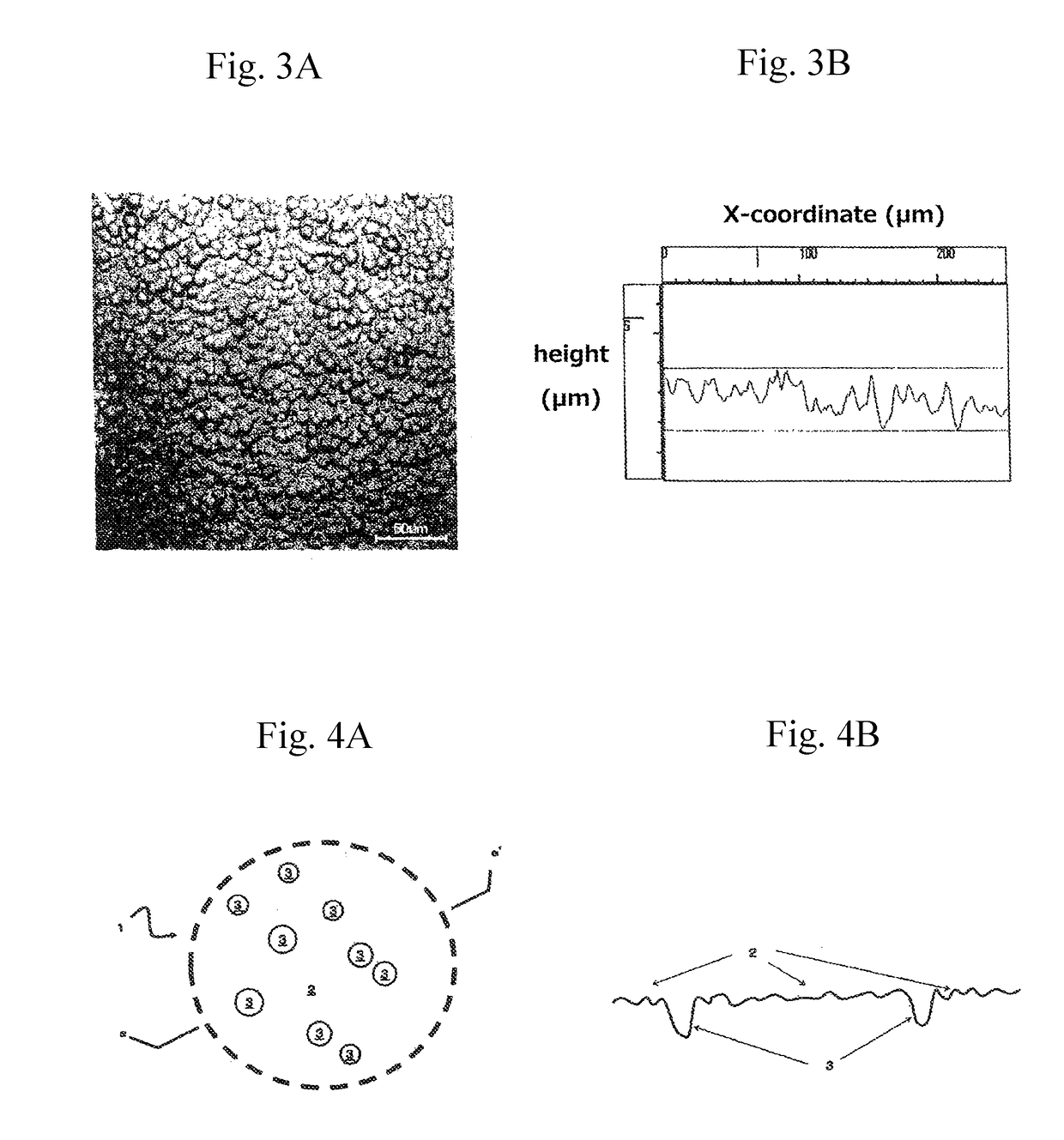

Antiglare Glass Sheet Article for Display Device and Method of Manufacturing Same

InactiveUS20170276995A1Reduce sparkleDesirable antiglare propertyOptical articlesNon-linear opticsDisplay devicePolymer science

Disclosed herein is an antiglare glass sheet article for display devices in which at least one main surface of the glass sheet is roughened. The article has a roughened surface that includes: a surface with continuous irregularities having an arithmetic average roughness (Ra) of 0.01 to 0.1 μm, and an average interval (RSm) of 1 to 20 μm; and depressions dispersed over the surface and each having a circular entrance portion measuring 3 to 20 μm in diameter, and a depth of 0.2 to 1.5 μm from the entrance portion, the roughened surface having 60 to 600 of the depressions in an observed 250 μm ×250 μm region. The article has desirable antiglare properties with reduced sparkling.

Owner:CENT GLASS CO LTD

Method and apparatus for mold component locking using active material elements

InactiveUS20050236727A1Efficient and effectiveReduce flashAuxillary shaping apparatusFood shapingElectricityEngineering

Method and apparatus for applying a force to a portion of a surface of a mold component are provided. An injection mold has a core insert, a side acting core insert, and a piezoceramic actuator. The amount of force needed for sealing a surface of said side acting core insert to a portion of a surface of said core insert is determined, and a piezoceramic actuator is actuated so as to supply the force to seal the side acting core insert against the core insert during a molding operation. A piezo-ceramic sensor may be provided to sense a force between the side acting core insert and the core insert, and to generate corresponding sense signals. Wiring structure is coupled to the piezo-ceramic sensor and is configured to carry the sense signals.

Owner:HUSKY INJECTION MOLDING SYST LTD

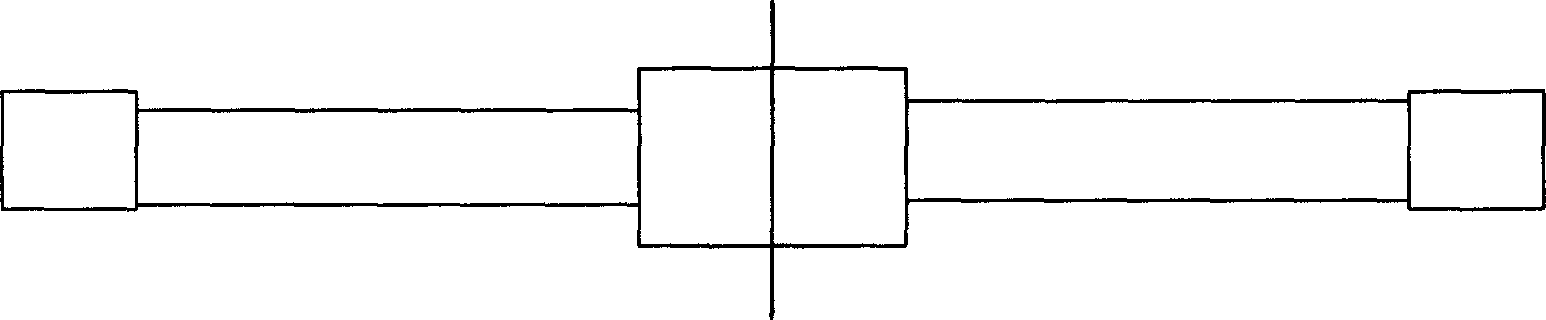

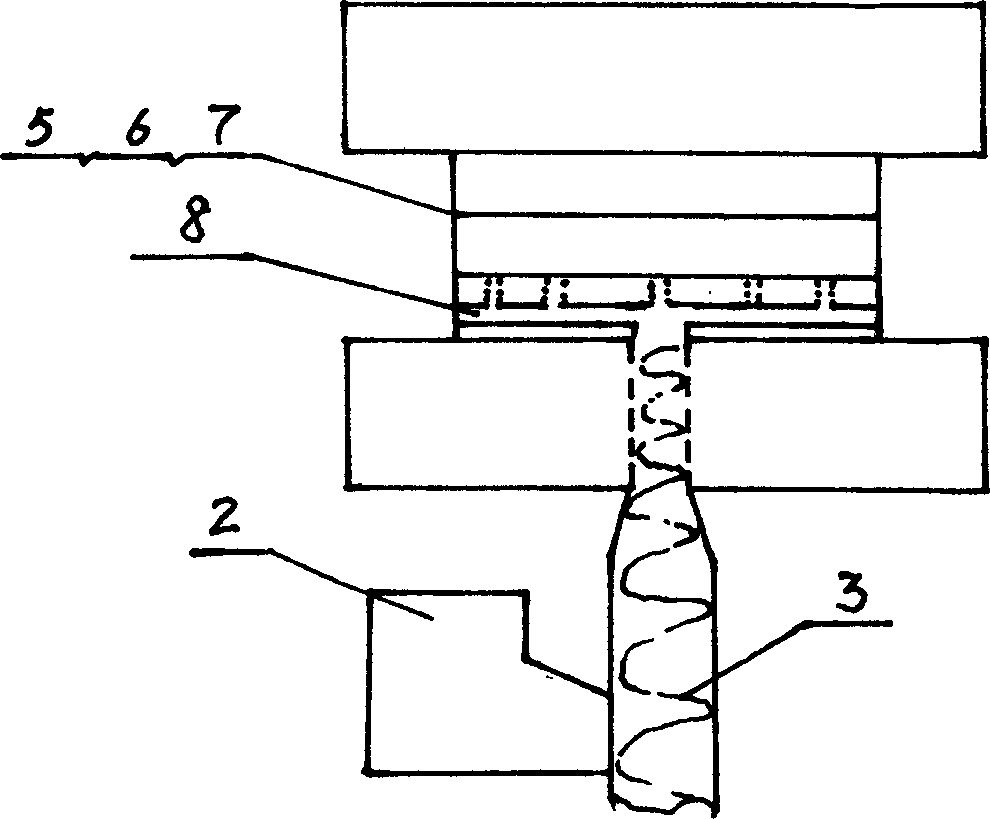

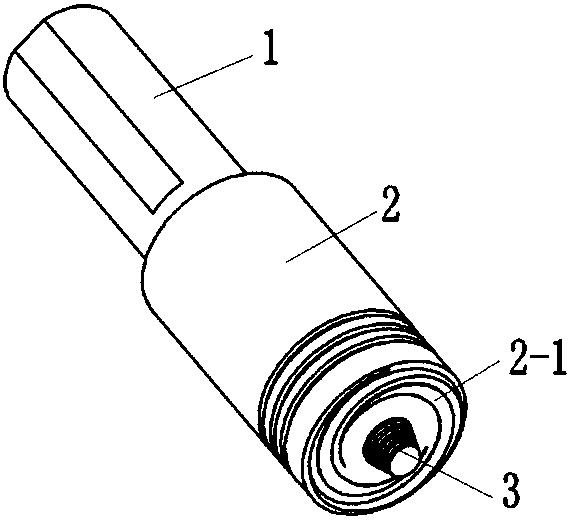

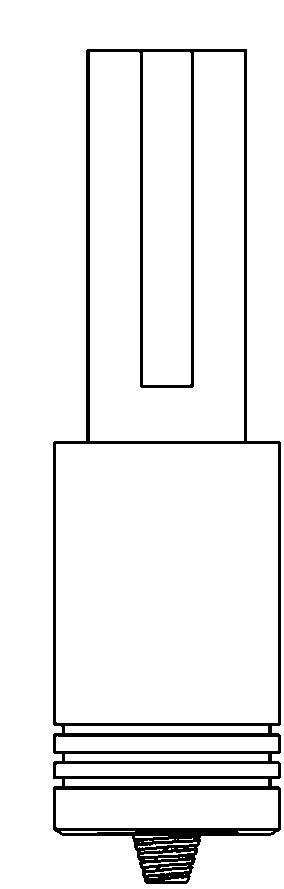

Upsetting force self-compensation stirring tool for aclinal frication stir welding and welding method

ActiveCN108031967AEasy to gatherReduce flashNon-electric welding apparatusFriction weldingEngineering

The invention relates to an upsetting force self-compensation stirring tool suitable for aclinal frication stir welding. The upsetting force self-compensation stirring tool comprises a clamping section, a cylindrical section and a stirring needle. The clamping section, the cylindrical section and the stirring needle are of an integrated structure from top to bottom. The clamping section is a cylinder, and a plane used for fastening is milled in the side face of the clamping section. The cylindrical section is a cylinder, the diameter of the cylindrical section is larger than that of the clamping section, and a heat radiating groove is formed in the circumferential direction of the cylindrical section. The lower end face of the cylindrical section is a shaft shoulder. The outer circle of the shaft shoulder is a plane and is provided with at least two archimedes screw grooves. The inner circle of the shaft shoulder is inwards concave. The inwards-concave part and the stirring needle achieve smooth transition. The stirring needle is a thick-end-up circular truncated cone. The side face of the stirring needle has a thread feature. The upsetting force self-compensation stirring tool anda conventional inwards-concave type stirring tool have a function that upsetting force self-compensation is generated for welded material along with welding, and the hole defect liable to occur to aclinal frication stir welding can be avoided effectively.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

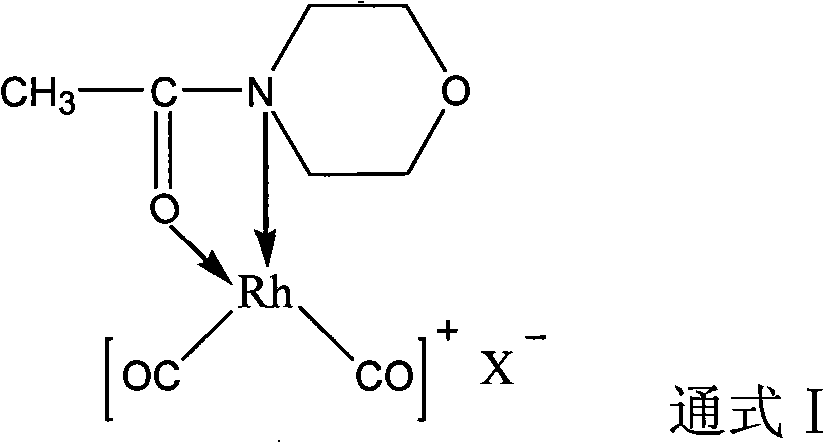

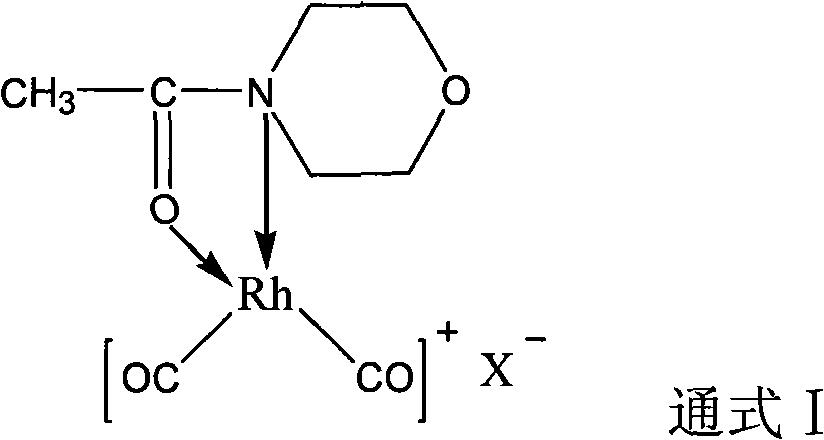

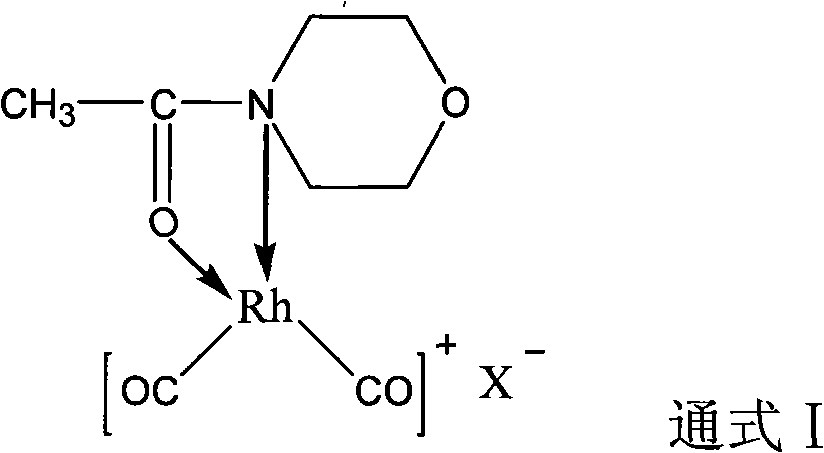

Rhodium catalyst for acetic oxide carbonyl synthesis from methyl acetate and preparation thereof

ActiveCN101279294AHigh activityImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsMetal/metal-oxides/metal-hydroxide catalystsSolubilityAcetic anhydride

The present invention discloses a rhodium catalyst for synthesizing acetic anhydride by acid methyl carbonyl, which is a cis-dicarbonyl rhodium cation structural catalyst formed by carbonyl rhodium and ligand function; the catalyst is a chelate square plane complex; the cation part of the catalyst is cis-dicarbonyl rhodium cation and the ligand is acetyl morpholine. The catalyst not only shows excellent thermal stability, but also keeps excellent catalyzing activity during the reaction of synthesizing acetic anhydride by acid methyl carbonyl; simultaneously the solubility of the catalyst species can also be increased in a reaction system, thus avoiding the addition of acetic acid and / or acetic anhydride as a catalyst solvent in the industrial production, thus effectively reducing the load of flash evaporation and evaporation and improving the manufacture efficiency of acetic anhydride synthesis by acid methyl carbonyl. The present invention also discloses a preparation method of synthesizing acetic anhydride by acid methyl carbonyl by the rhodium catalyst..

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Encapsulated wire shelf

ActiveUS7147293B2Reduce manufacturing costAvoid disadvantagesLighting and heating apparatusFurniture partsWire rodGrating

The shelf as defined by a shelf grating formed of a plurality of first and second groups of wires disposed normal to each other and having ends thereof encapsulated by an injection molded, continuous open encapsulation, rim or border. Preferably, each of four border portions of the border each encapsulate substantially the entirety of one of the wires of the two groups to afford rigidity to the wire shelf. The border includes a Class “A” upper surface between peripheral outboard and inboard parting lines or lines of flash which provides a high degree of aesthetics to the shelf when viewed from above.

Owner:GEMTRON

Bulked continuous filament having a three-sided exterior cross-section and a convex six-sided central void and yarn and carpet produced therefrom

A bulked continuous filament with a three-sided exterior configuration is characterized in that each side has a smoothly curved contour extending between a first and a second rounded tip with an inwardly extending depressed region being disposed adjacent to each tip. Generally, the filament has an exterior modification ratio in the range from about 1.4 to about 2.0, and a tip ratio in the range from about 2.0 to about 4.0. The filament generally delta-shaped void with three major apices extending centrally and axially therethrough. Each side of the void is convexly shaped and formed from a pair of facets that meet to define minor apices. The void is oriented such that each major apex extends toward the approximate midpoint of one side of the exterior of the filament and each minor apex extends toward a tip of an exterior side. The distance (RM) from the geometric center of the void to each major apex and the distance (Rm) from the geometric center of the void to each minor apex defines an apex ratio (RM / Rm) in the range from about 1.0 to about 1.55. The void occupies from about four percent (4%) to about twenty-five percent (25%) of the cross sectional area of the filament.

Owner:INV PERFORMANCE SURFACES LLC

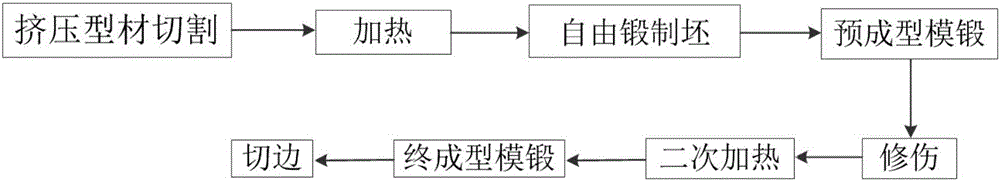

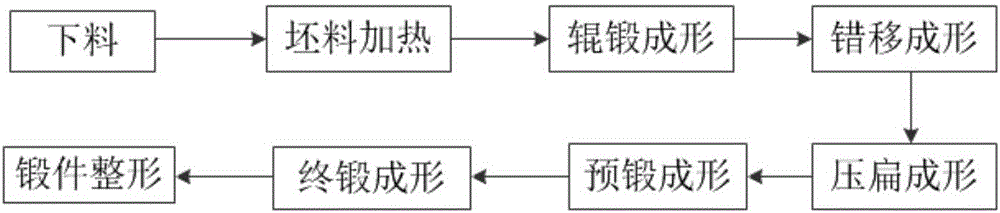

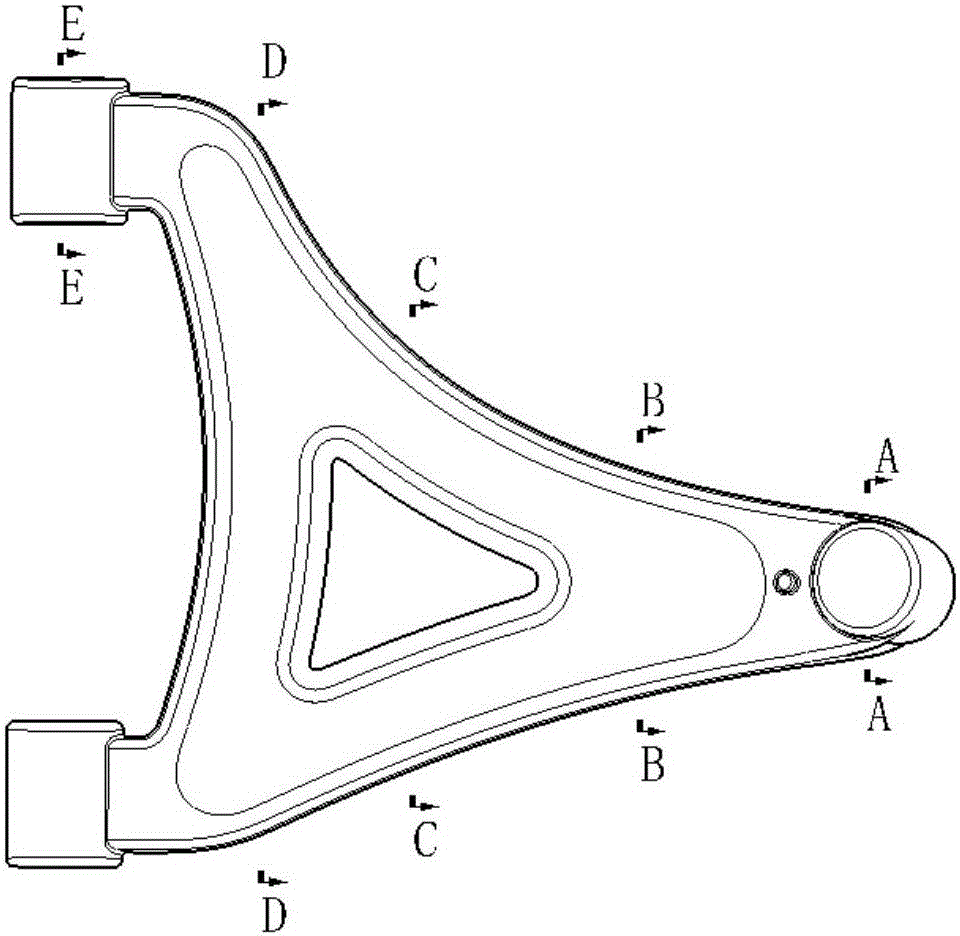

Forging forming method of triangular aluminum alloy control arm

ActiveCN106424529AAvoid Folding DefectsReduce repair workRailway componentsForging/hammering/pressing machinesControl armHeating furnace

The invention discloses a forging forming method of a triangular aluminum alloy control arm and aims at solving the problems in the prior art of low quality of a product, low material utilization ratio and low production efficiency. The forging forming method comprises the following steps: 1, blanking; 2, heating a blank: heating the blank in the first step in an electric induction heating furnace at the heating temperature of 420-480 DEG C, keeping the temperature for 5-8min to enable the blank to be uniformly heated, and finishing dynamic recrystallization after finishing forging to obtain uniform microstructures; 3, roll forgingforming: 1) calculating a roll forging pass n; 2) roll forging forming: comprising the following steps: from (1) first-pass roll forgingforming to (4) fourth-pass roll forging forming; 4, mis-shifted forming; 5, flattening forming; 6, pre-forging forming; 7, finish forging forming: carrying out finish forging forming on the basis of pre-forging forming, designing a die according to a hot forging drawing during finish forging forming, putting a pre-forging into a mold cavity of the finish forging die, and then obtaining a part in finish forging forming under the action of a press; and 8, shaping the forging.

Owner:JILIN UNIV

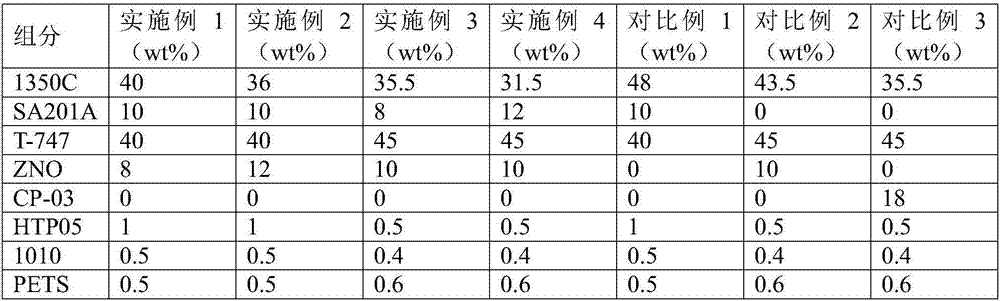

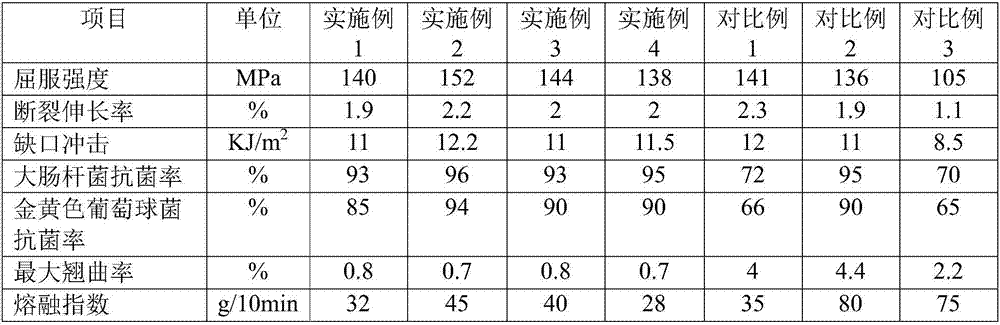

Antimicrobial low-warpage low-flash PPS composite material and preparation method thereof

The invention discloses an antimicrobial low-warpage low-flash PPS composite material and a preparation method thereof. The material is prepared from, by weight, 31.5-48% of PPS resin, 6-12% of PPE resin, 40-45% of glass fibers, 8-12% of antimicrobial agent, 0.5-1% of nucleating agent, 0.4-0.5% of antioxidant and 0.5-0.6% of lubricating agent. An engineering plastic, namely PPS, serves as a main body, the PPE resin, the glass fibers, the antimicrobial agent, the nucleating agent the antioxidant and the lubricating agent are added, the raw materials are mixed together and melted through a double-screw extruder, and then the antimicrobial low-warpage low-flash PPS composite material which is capable of meeting the antimicrobial requirements of household appliances is prepared. The material has the advantages of being antimicrobial, low in warpage and low in flash on the basis of ensuring the original excellent mechanical performance, heat resistance, fire resistance and electrical performance of PPS.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

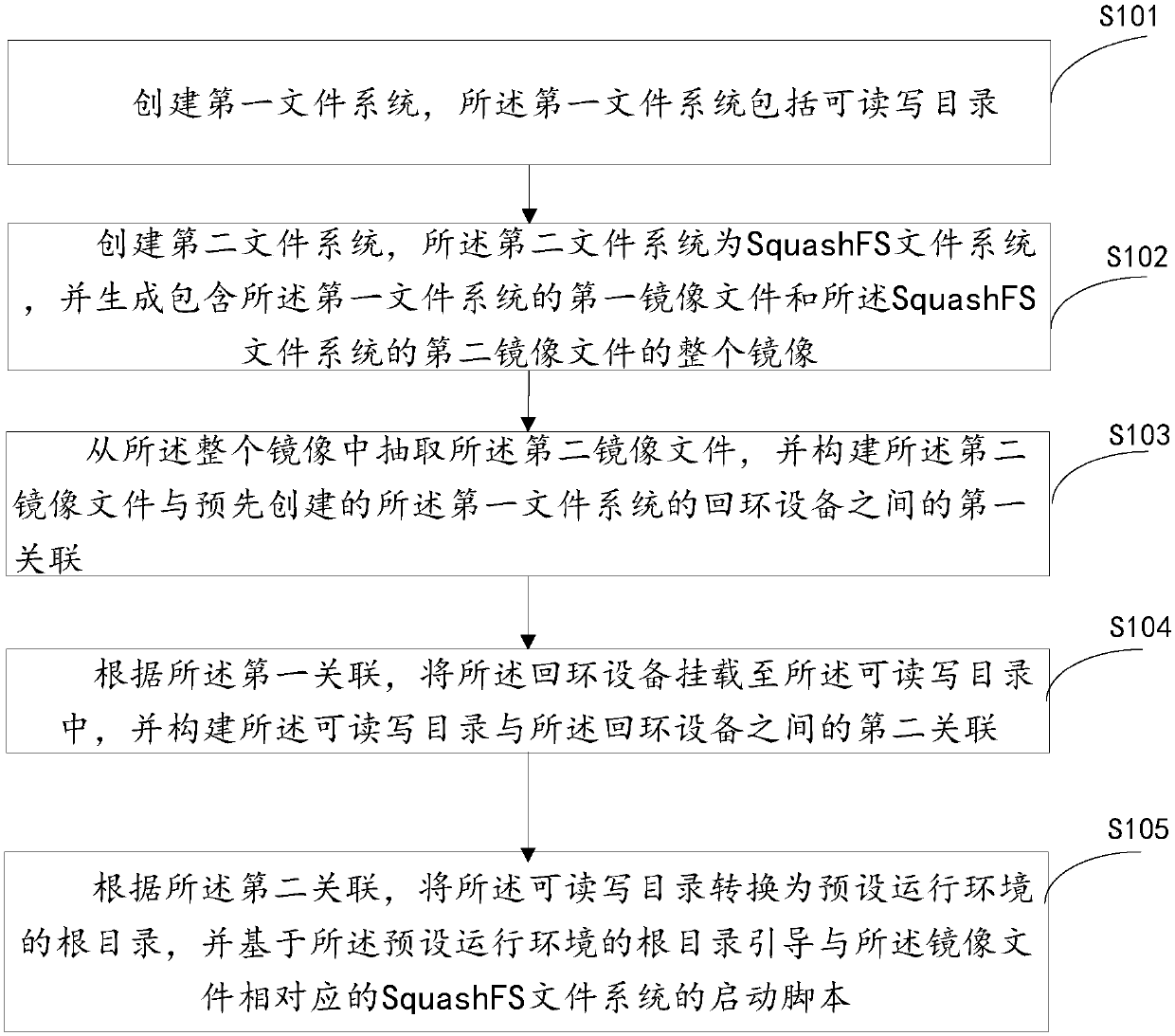

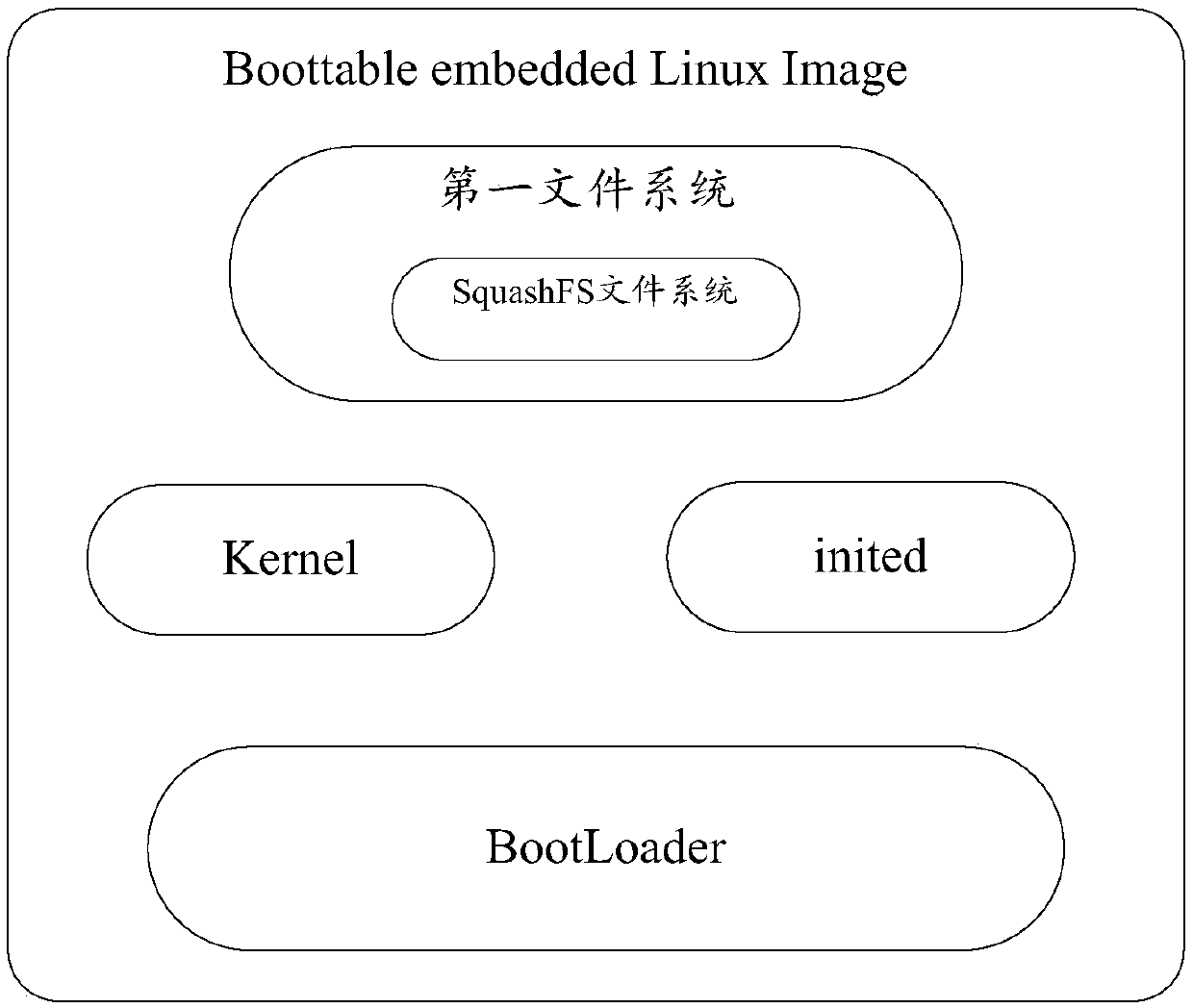

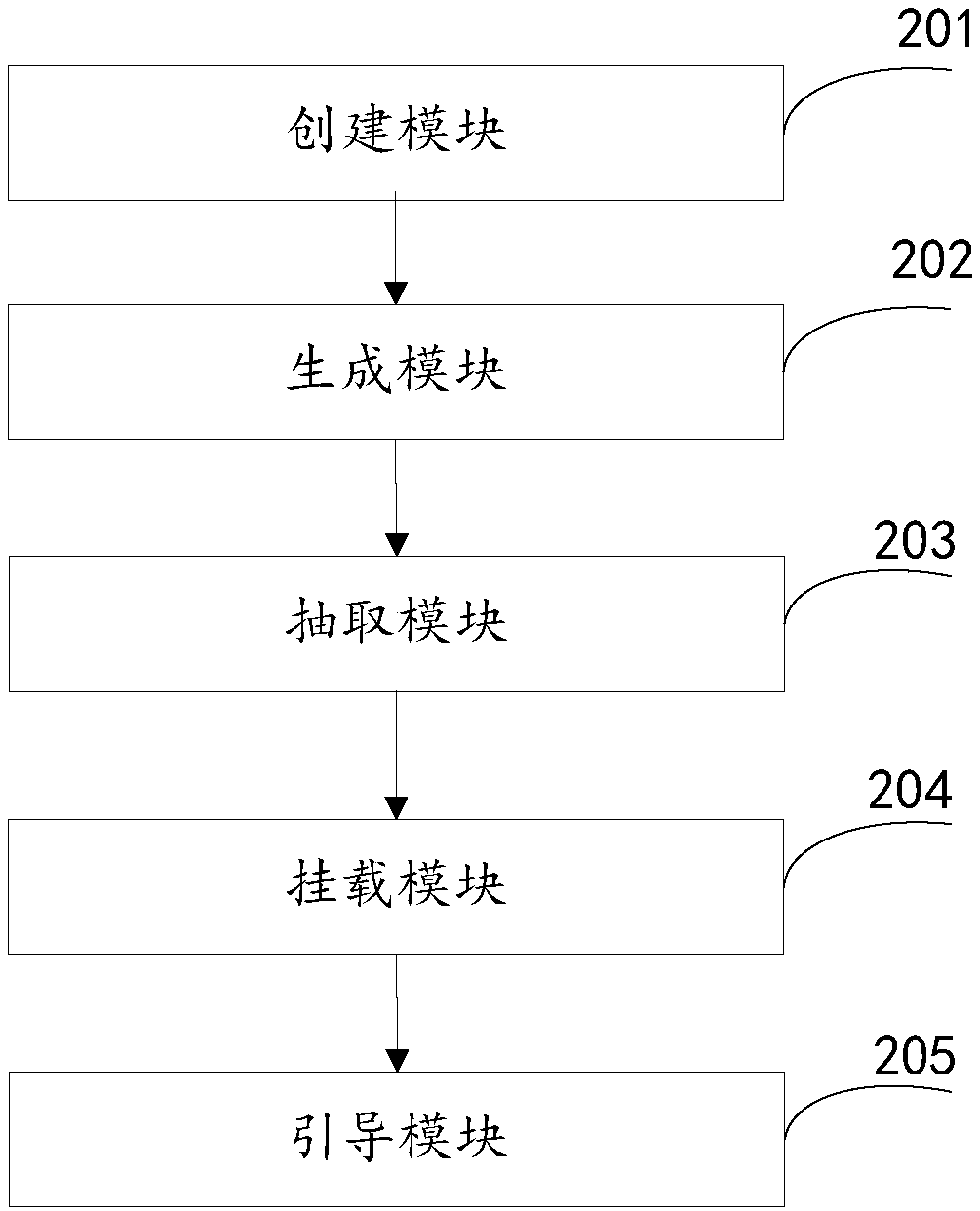

Boot file system mounting method and apparatus

InactiveCN107562483AReduce sizeReduce consumptionResource allocationBootstrappingResource consumptionMirror image

The invention discloses a boot file system mounting method and apparatus. The method comprises the steps of creating a first file system; creating a second file system, and generating a whole mirror image; extracting a second mirror image file from the whole mirror image, and establishing a first correlation between the second mirror image file and a pre-created loopback device of the first file system; according to the first correlation, mounting the loopback device to a read-write directory, and establishing a second correlation between the read-write directory and the loopback device; and according to the second correlation, converting the read-write directory into a root directory of a preset running environment, and based on the root directory of the preset running environment, booting a startup script. The technical problem of relatively high resource consumption due to occupation of relatively large flash memory and running memory in a method in the prior art is solved.

Owner:BOWEI TECH

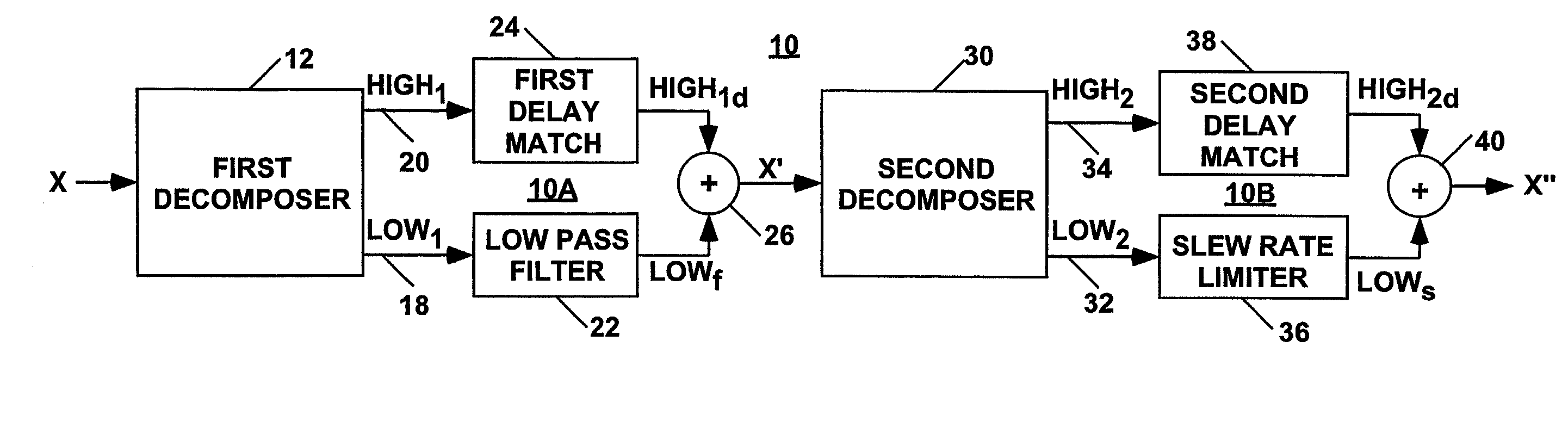

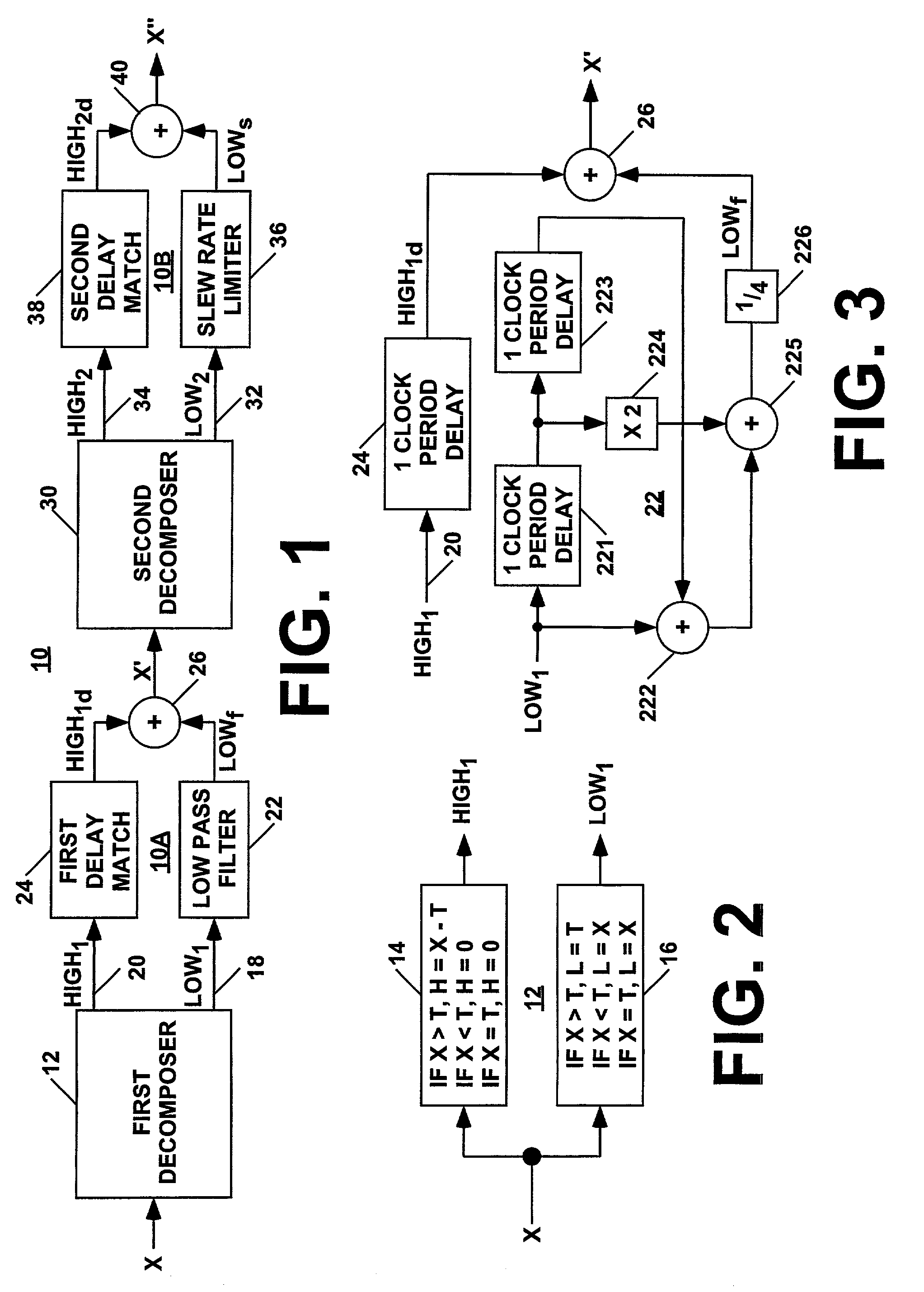

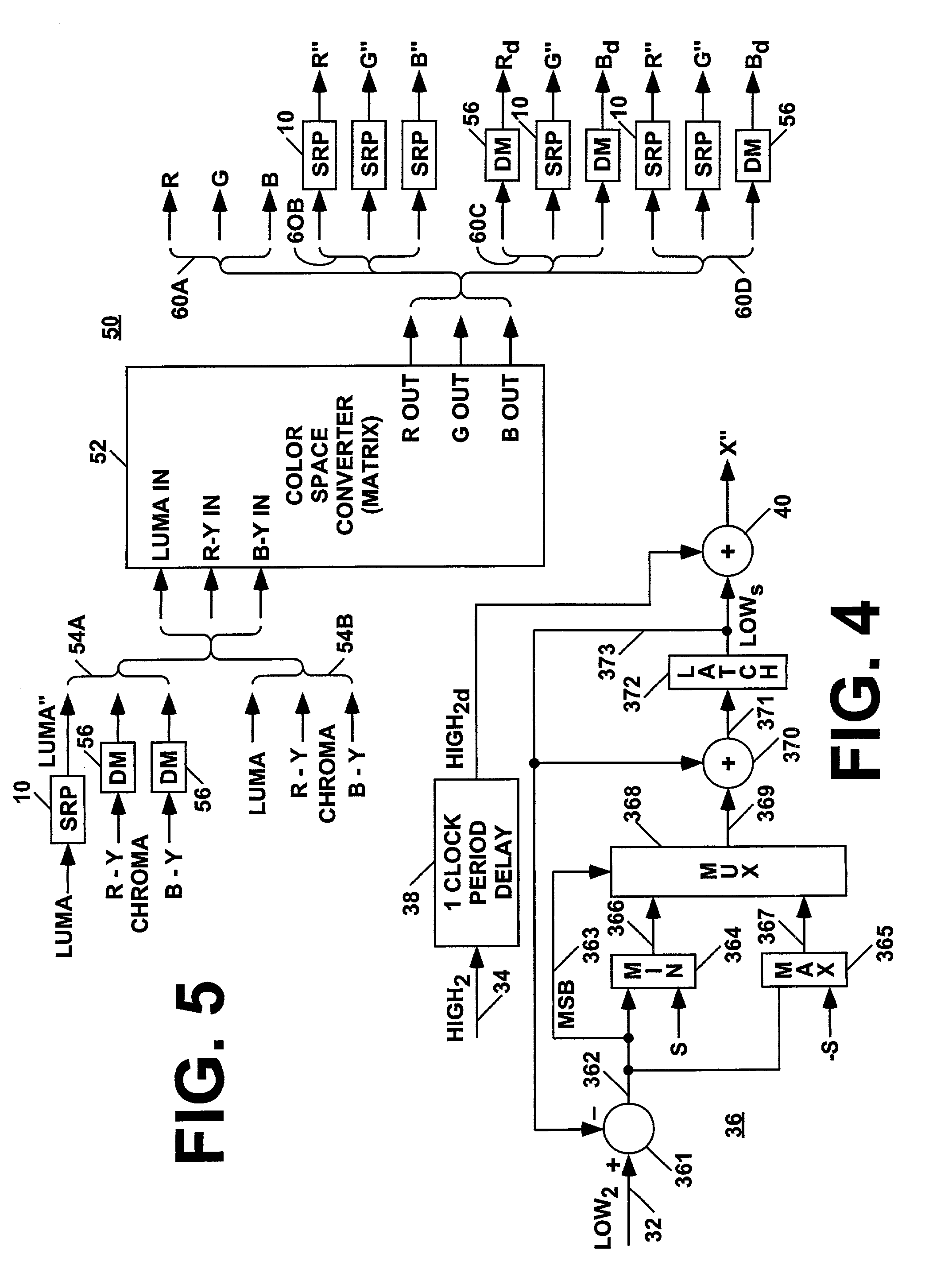

Reducing sparkle artifacts with low brightness processing

InactiveUS20020126080A1Without degrading high definition sharpnessIncrease brightnessTelevision system detailsColor signal processing circuitsSlew rateComputer science

A method for reducing sparkle artifacts in a liquid crystal imager, comprises the steps of: low pass filtering only a first lower brightness level signal component of a video signal; and, slew rate limiting only a second lower brightness level signal component of the video signal having the low pass filtered signal component, the video signal having the low pass filtered and the slew rate limited signal components being less likely to result in sparkle artifacts in the imager. Brightness thresholds for defining the lower brightness level signal components and slew rate limits can be selected in accordance with transitions between lower and higher level gain portions of a gamma table associated with the imager, for example an LCOS imager.

Owner:INTERDIGITAL CE PATENT HLDG

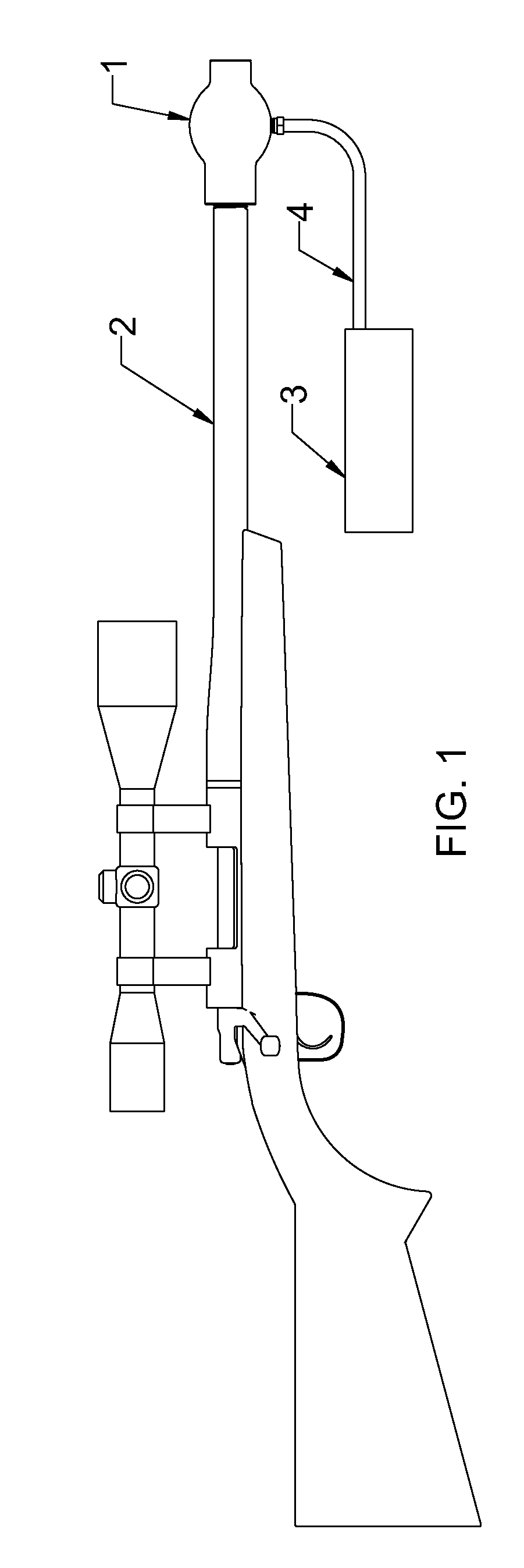

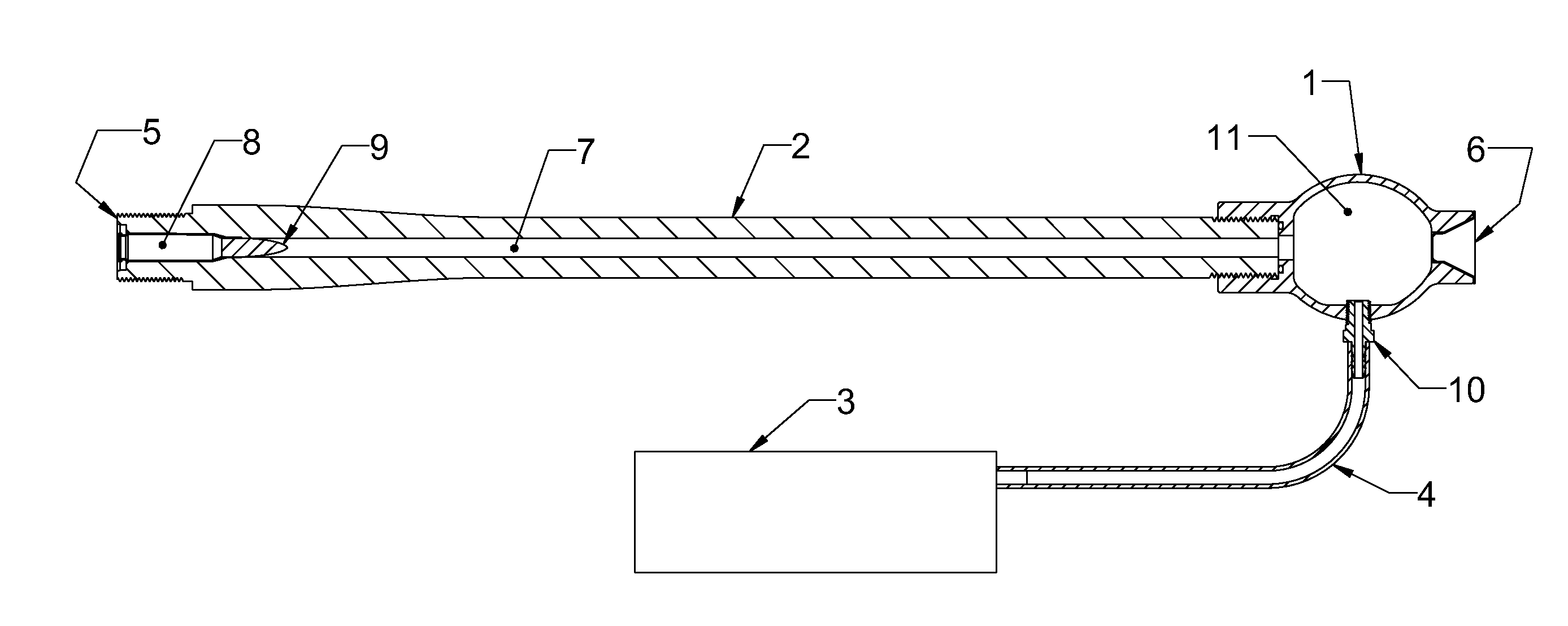

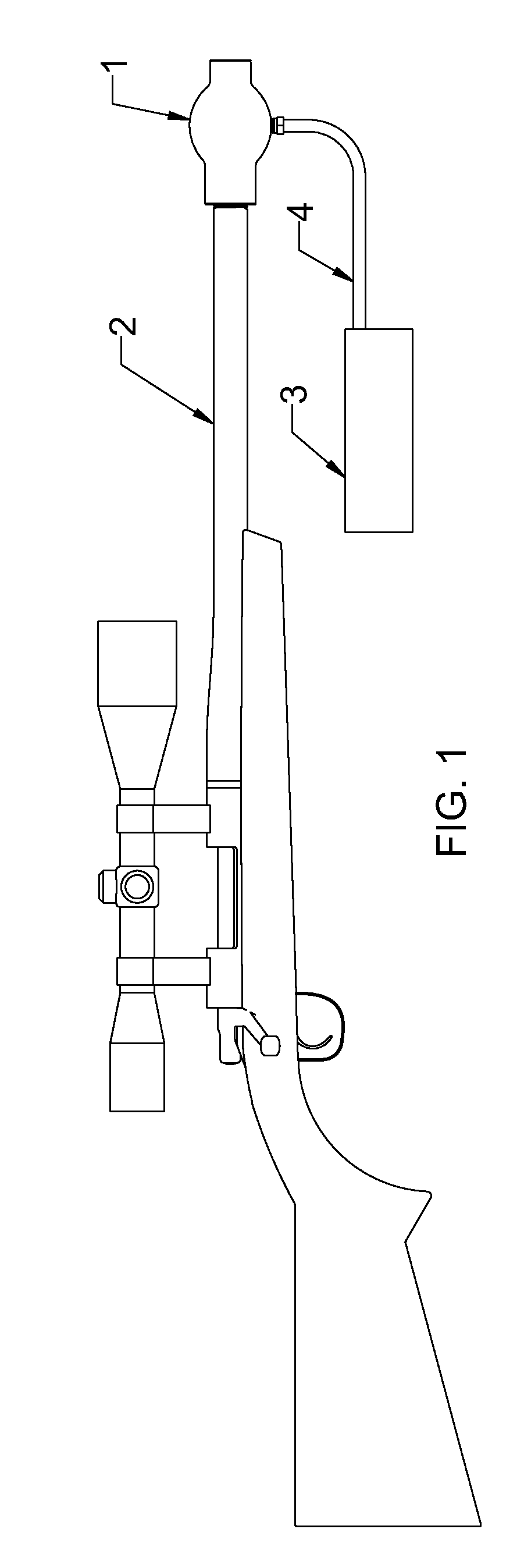

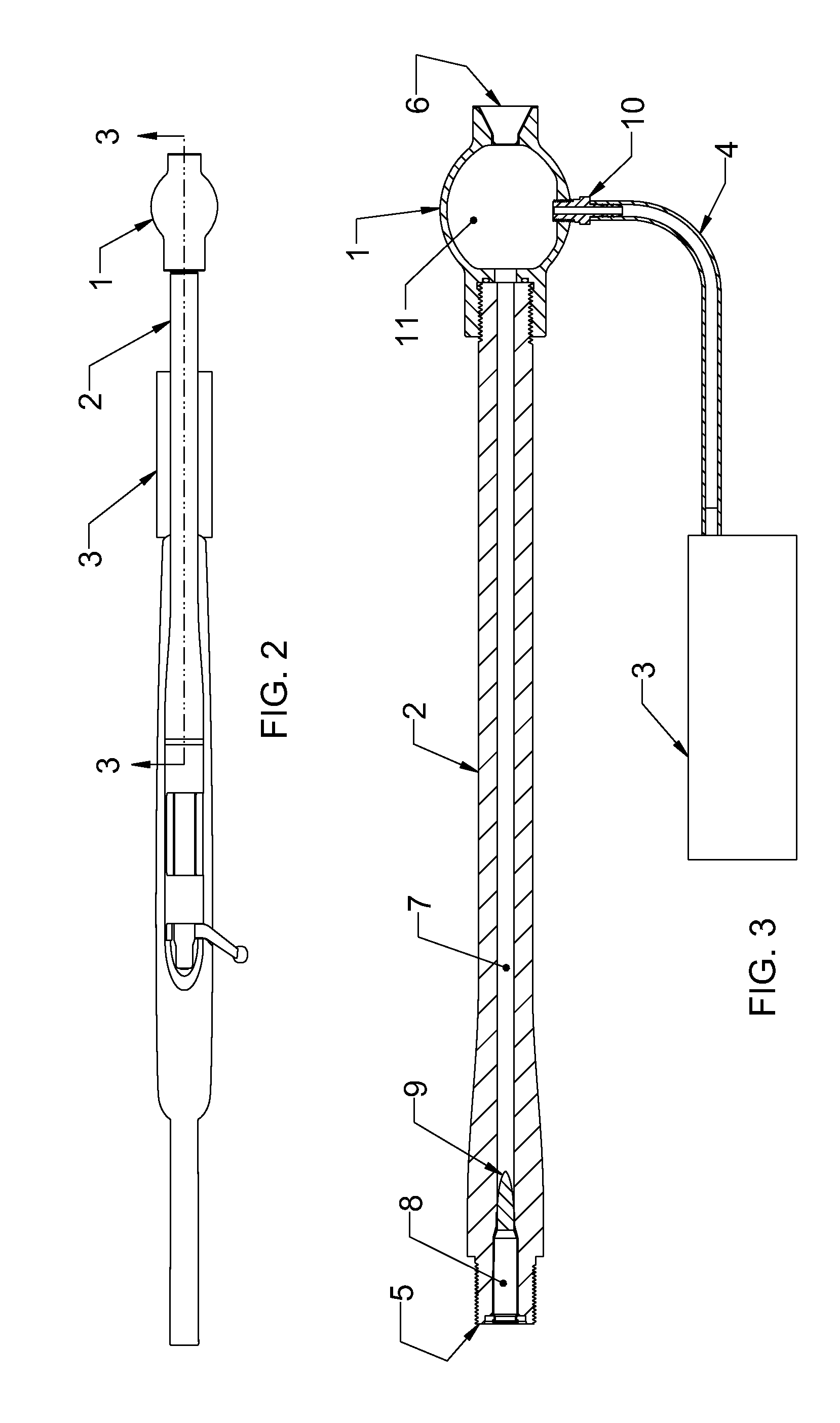

Sound and Flash Suppressor for Firearms

InactiveUS20120080261A1Reduces sound and flash levelLower the volumeWeapon componentsSuppressorEngineering

A gun silencer comprises and outer tube having and single inner vacuum chamber or multiple vacuum chambers that creates a vacuum enclosed volume for the gases to expand into, so the pressure of the gas that exits the suppressor is reduced significantly; therefore, the sound of the gun firing is more silent than conventional silencers. Prior to firing the gun, a vacuum seal is placed at the exit orifice of the suppressor and a vacuum is created inside of the suppressor with the use of a vacuum pump. The inner vacuum chamber reduces the pressure wave caused at the end of the firearm's barrel. When the firearm is discharged the gases fill the vacuum chamber instead of exiting at normal atmospheric pressure level. As the bullet continues its travel through the distal end of the suppressor, it will perforate the vacuum seal and continue its flight path.

Owner:SHAND RONNIE ALEXANDER

Casting forming process for large wind power planetary carrier

ActiveCN107790641ASmall size deviationEasy to operateFoundry mouldsFoundry coresElectricityEconomic benefits

The invention discloses a casting forming process for a large wind power planetary carrier casting. The planetary carrier casting comprises an upper annular plate and a lower annular plate which are vertically connected with triangular vertical columns, and a parting face of the planetary carrier casting is arranged on the interfaces of the upper annular plate and the triangular vertical columns;a first sand core and a second sand core are arranged between the upper annular plate and the lower annular plate, a triangular air outlet channel is formed in the outer sides of the sand cores, and vertical air outlet channels are formed in the centers of the sand cores; open risers are arranged right above the intersections of the upper annular plate and the triangular vertical columns, blinderrisers are arranged on the lower annular plate, and external chills are arranged under the lower annular plate. Pouring is carried out by adopting combined pouring mode of bottom-back pouring gates and stepped pouring gates. The planetary carrier produced by the method is good in forming and qualified in size, the matric structure of the casting is compact, joint parts of the triangular verticalcolumns and the upper annular plate and the lower annular plate has no crack defect, the other parts only need to undergo modification repair welding, the production cost of the casting is reduced, and higher economic benefits are achieved.

Owner:兰州兰石铸锻有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com