Plastic filtering board or board forming process

A technology of plate forming and filter plate, which is applied in the field of filter plate forming process of filter press, can solve the problems of filter plate strength, invariable quality, unsatisfactory thermal insulation effect of the material tank, long time of material tank moving process, etc., so as to shorten Material consumption, good heat preservation effect, effect of reducing formula types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

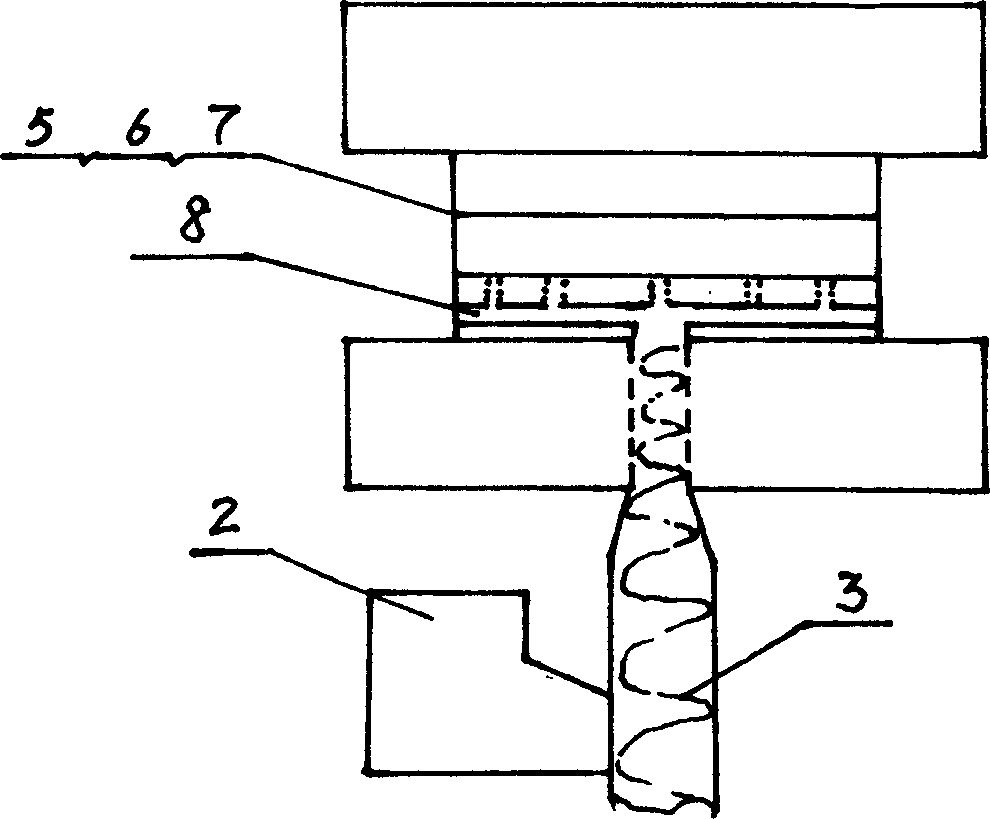

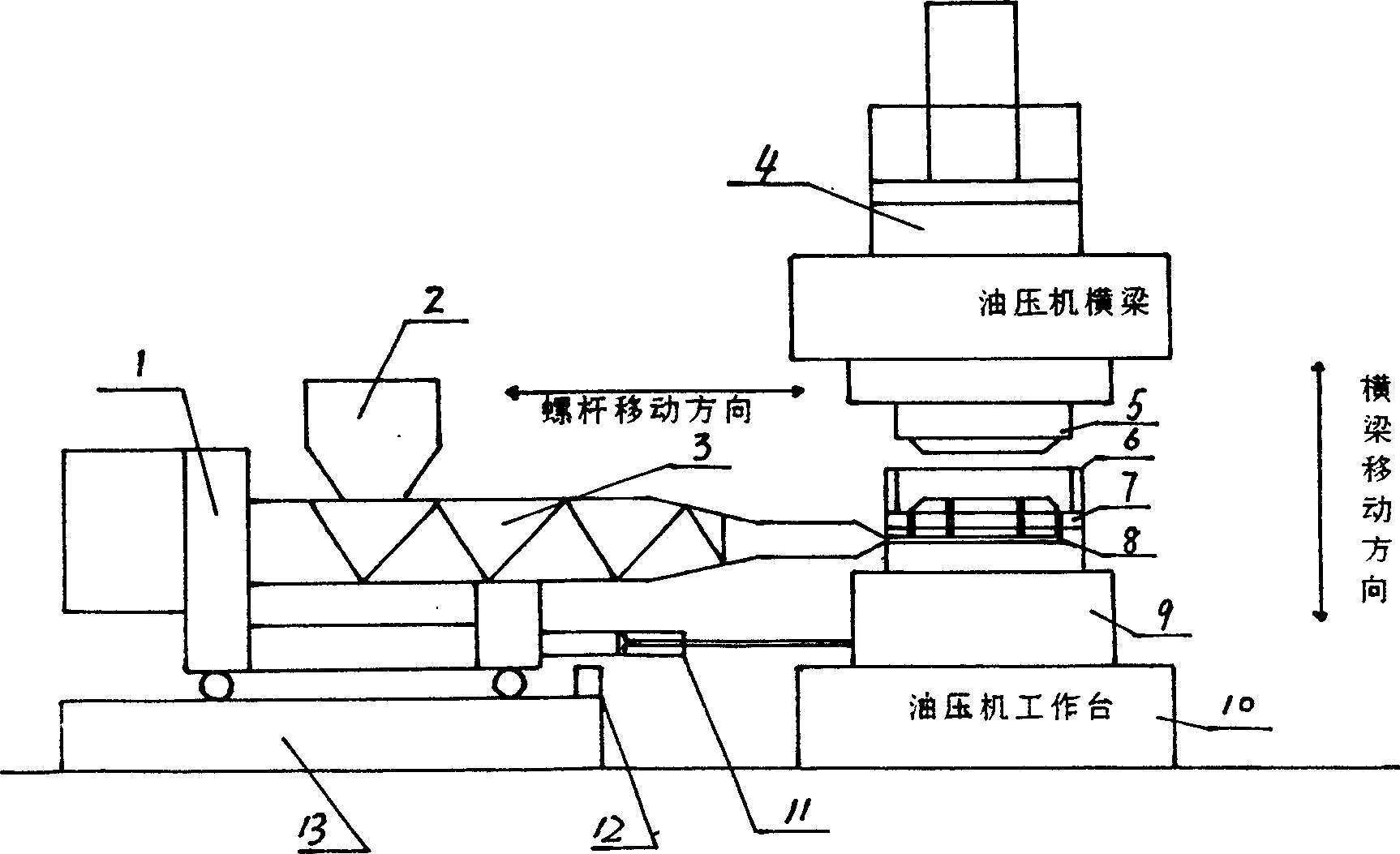

[0010] Embodiment 1: with reference to attached figure 1 . New plastic filter plate or plate forming process, the hot runner port of the hot runner plastic filter plate forming mold or hot runner plate forming mold is located on the upper or bottom or side of the hot runner plastic filter plate forming mold or hot runner plate forming mold, the injection molding machine The outlet of the injection molding mechanism is aligned with the hot runner mouth. After the plastic raw material is heated and plasticized by the injection molding mechanism, the outlet is injected into the cavity of the mold through the hot runner in the hot runner plastic filter plate forming mold or the hot runner plate forming mold. , After cooling and shaping, the mold can be opened to take out the filter plate or plate. When the hot runner opening of the hot runner plastic filter plate forming mold or the hot runner plate forming mold is located on the upper part of the forming mold, the outlet of the ...

Embodiment 2

[0011] Embodiment 2: Novel plastic filter plate or plate molding process, the hot runner mouth of the hot runner plastic filter plate forming mold or the hot runner plate forming mold is located at the top or bottom or side of the hot runner plastic filter plate forming mold or the hot runner plate forming mold , the discharge port of the injection molding mechanism is aligned with the hot runner port, and the hydraulic press is closed. After the plastic raw material is heated and plasticized by the injection molding device, the discharge port is injected into the mold through the hot runner in the hot runner plastic filter plate forming mold or the hot runner plate forming mold. After forming in the cavity, cooling and setting, the hydraulic press can open the mold to take out the filter plate or plate. The filter plate or plate forming mold is located in the hydraulic press and is clamped and opened by the hydraulic press. The hot runner device is located on the upper or bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com