Epoxy resin composition capable of being quickly thickened and fiber reinforced composite material semi-cured material thereof

A reinforced composite material and epoxy resin technology, applied in the field of fiber-reinforced thermosetting resin composite materials, can solve the problems of inability to meet the environmental protection requirements of composite parts, poor unsaturated SMC strength, low impact strength, etc., and achieve low production costs , high production efficiency, good mechanical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The raw materials of the rapid thickening epoxy resin composition are added to the mixing device in order according to the weight and mixed evenly. First, 100 parts of the low-viscosity liquid bisphenol A epoxy resin, 0.75 parts of the defoamer, and 0.75 parts of the sizing agent are sequentially added , 6 parts of curing agent dicyandiamide 100S, 4 parts of organic urea accelerator UR500 are added to the mixing device and mixed evenly to obtain a fast-curing epoxy resin component; then 3 parts of epoxy thickener DETA are added to the mixing device and mixed evenly, That is, a rapidly thickening epoxy resin composition is obtained.

[0055] The quick-thickening epoxy resin composition is put into a drying room at 35°C for 20hrs, and the epoxy thickener amine-based active hydrogen cross-links with the epoxy functional group of the epoxy resin to increase the viscosity of the epoxy resin composition. Complete to obtain semi-solid semi-cured epoxy resin.

[0056] The thic...

Embodiment 2~10

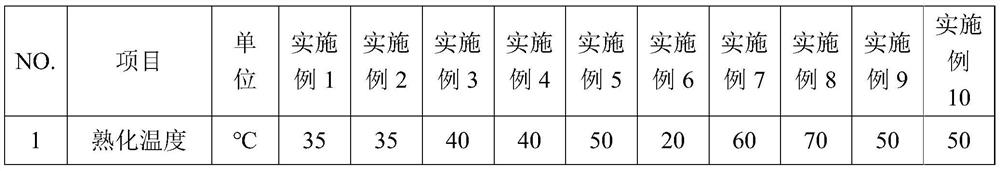

[0061] The preparation method of the rapidly thickening epoxy resin composition, the preparation of the curing thickening, and the resin-cured casting body are the same as in Example 1, and the weight of each component of the rapidly thickening epoxy resin composition is shown in Table 1; The characteristics of the thickened epoxy resin composition, the properties of the resin-cured cast body and the Tg test are the same as in Example 1, and the test results are shown in Table 2.

[0062] As shown in Table 1 and Table 2, the initial viscosity at 25°C after mixing of the rapidly thickening epoxy resin composition of Examples 1-10 is 5-50 pa.s, and the epoxy resin composition can be controlled at 30-60°C Viscosity ≤ 1000mPa.s, low initial viscosity of epoxy resin is conducive to infiltration of reinforcing fibers; aging at 30-70°C for 1-200hrs reacts and thickens, so that the viscosity of the epoxy resin composition at 70°C increases to 10-5000Pa.s, The thickened semi-cured epox...

Embodiment 11

[0064] The rapidly thickening epoxy resin composition mixed in Example 3 is poured into the scraping groove of the SMC sheet machine, and the epoxy resin is evenly coated on the upper and lower carrier films with a scraper to form an epoxy resin paste film; Surface density is 300g / m 2 ELG recycled chopped carbon fiber felt is placed on the lower epoxy resin paste film, and then the upper epoxy resin film is covered on the surface of the carbon fiber felt. After extrusion and exhaust, the epoxy resin is fully infiltrated into the carbon fiber to form a chopped carbon fiber. Felt resin composite sheet, and then rolled and packaged; the chopped carbon fiber felt resin composite sheet that is rolled and packaged is cured in a drying room at 35°C for 20hrs, so that the epoxy resin composition is reacted and thickened to obtain a chopped carbon fiber felt prepreg . The epoxy chopped carbon fiber felt prepreg is prepared, the carbon fiber felt is infiltrated with epoxy resin, the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com