Emulsion type epoxy curing agent and preparation method thereof

An epoxy curing agent, emulsion type technology, applied in epoxy resin coatings, coatings, etc., can solve the problems of reducing the water resistance, corrosion resistance and instability of the coating film, achieve fast drying speed, easy room temperature curing, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Synthesis of emulsion type epoxy curing agent:

[0032] Step 1: Under nitrogen protection, add 54g of monofunctional polyetheramine (Hunsman M-1000) with a molecular weight of 1000 to a 500mL three-necked flask, add 246g of liquid epoxy resin E54, raise the temperature to 90°C, and start the stirring reaction After 2h, a yellow and transparent intermediate product can be obtained.

[0033] Step 2: Add 50 g of DMDC into a 500 mL three-necked flask, then slowly add 70 g of the above-mentioned intermediate product into the flask, and stir and react at 60° C. for 6 h.

[0034] Step 3: Add 3g of C 12 -C 14 Alkyl glycidyl ether was added to the above reaction, and the reaction was stirred at 60°C for 2h.

[0035] Step 4: Add 110g of deionized water dropwise into the flask under high-speed stirring, control the emulsification temperature at 50°C, and rotate at 1000r / min, stir and disperse to obtain the milky white target emulsion-type epoxy curing agent.

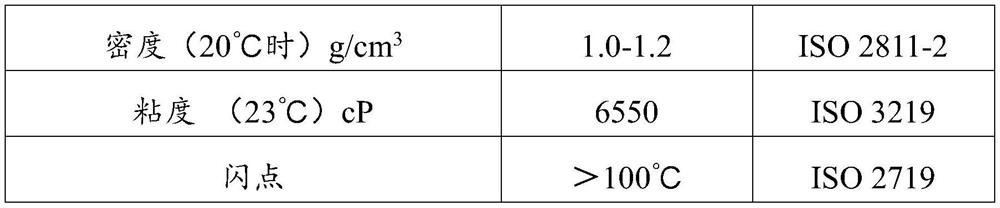

[0036] The perfo...

Embodiment 2

[0040] Synthesis of emulsion type epoxy curing agent:

[0041] Step 1: Under nitrogen protection, add 60g of difunctional polyetheramine (ED-600) with a molecular weight of 600 to a 500mL three-necked flask, add 240g of liquid epoxy resin E54, heat up to 125°C, and start stirring for 3.5 hours. A yellow transparent intermediate was obtained.

[0042] Step 2: Add 6g of TETA and 30g of MXDA into a 500mL three-necked flask, then slowly add 80g of the above-mentioned intermediate product into the flask, and stir and react at 60°C for 5h.

[0043] The third step: 5 g of C12-C14 alkyl glycidyl ether was added, and stirred and reacted at 80° C. for 2 h.

[0044] Step 4: Add 121g of deionized water dropwise into the flask under high-speed stirring, control the emulsification temperature at 60°C, and rotate at 1000r / min, stir and disperse to obtain the milky white target emulsion-type epoxy curing agent.

[0045] The performance parameters of the products prepared in this embodiment ...

Embodiment 3

[0049] Synthesis of emulsion type epoxy curing agent:

[0050] Step 1: Under nitrogen protection, add 62g of monofunctional polyetheramine (Hunsman M-2070) with a molecular weight of 2000 to a 500mL three-necked flask, add 238g of liquid epoxy resin E51, raise the temperature to 150°C, and start the stirring reaction After 4h, a yellow and transparent intermediate product can be obtained.

[0051] Step 2: Add 30g of IPDA and 10g of PACM into a 500mL three-neck flask, then slowly add 70g of the above-mentioned intermediate product into the flask, and stir and react at 60°C for 5h.

[0052] The third step: 3g of butyl glycidyl ether (C 7 h 14 o 2 ) was added, and the reaction was stirred at 60°C for 2h.

[0053] Step 4: Add 90g of deionized water dropwise into the flask under high-speed stirring, control the emulsification temperature at 70°C, and rotate at 1500r / min, stir and disperse to obtain the milky white target emulsion-type epoxy curing agent.

[0054] The performan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com