Device and process method for preparing fertilizers by using kitchen waste

A technology for preparing food waste and fertilizers, which is applied in the field of resource treatment and effective utilization of food waste, and can solve the problems of harmful organic matter and heavy metal pollution, reduction, harmlessness, and low degree of resource utilization , poor storage, transportation, and collection of food waste, etc., to achieve the effects of good product technical indicators, high equipment mechanization and automation, and low heavy metal content in products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The schematic embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

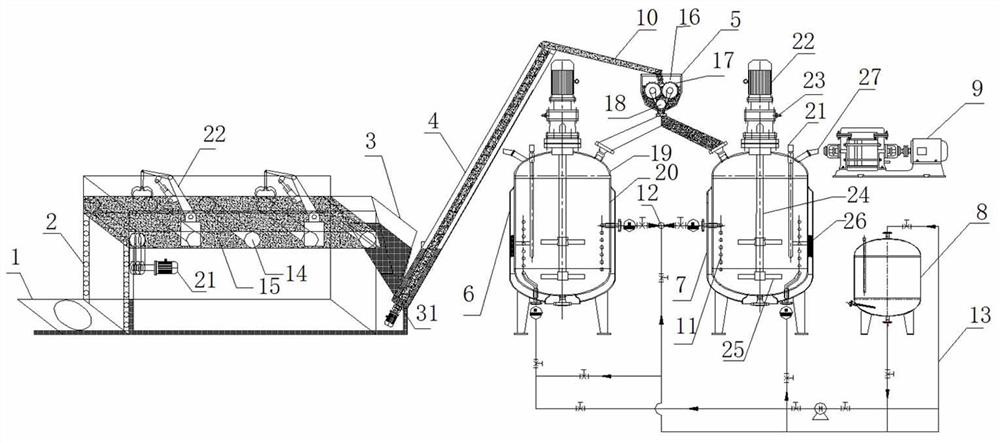

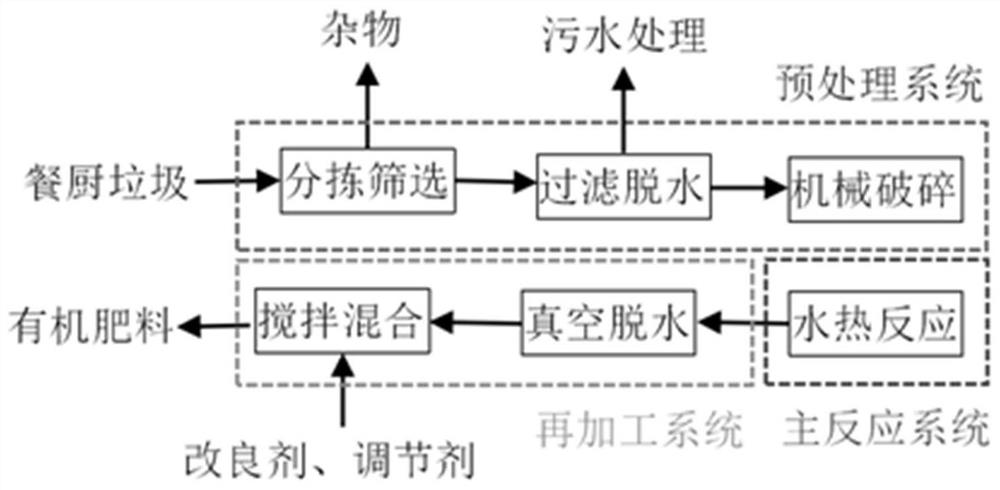

[0024] Such as Figure 1-2 The device and process method for preparing fertilizer from food waste are shown; the process flow of organic fertilizer from food waste is as follows: figure 2 As shown, it includes garbage sorting-dehydration-crushing-reaction-dehydration-regulation and other processes, and finally produces high-quality and cheap fertilizers, realizing the maximum resource utilization of kitchen waste.

[0025] Such as Figure 1-2As shown, the device for preparing fertilizer from kitchen waste in this embodiment includes a pretreatment system, a main reaction system and a reprocessing system. The pretreatment system includes a lifting platform 1, a sorting platform 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com