Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Realize waste treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

All solid waste filling material for stabilizing dioxin incineration fly ash and preparation method thereof

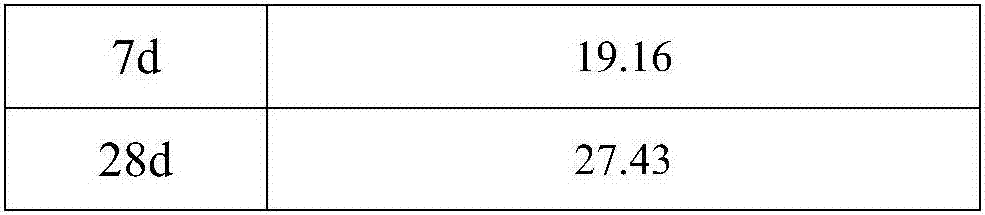

The invention provides an all solid waste filling material for stabilizing dioxin incineration fly ash and a preparation method thereof, and belongs to the technical field of solid waste utilization. The filling material comprises a cementing agent and an aggregate, and the cementing agent comprises ore slag, steel slag, industrial by-product gypsum, waste incineration fly ash and the like, and the aggregate comprises mountain sand, river sand, tailing sand or waste rocks and the like. The cementing agent is activated, and evenly mixed in a mixer, according to the weight ratio of cementing agent to aggregate of 1 / 1 to 1 / 10, 0% to 1% of a water reducing agent is added, the mass fraction of slurry is 65%-82%, and the qualified filling material can be obtained by even stirring. The cementing filling material for mines is prepared from the all solid waste system, meanwhile the dioxin-containing waste incineration fly ash can be stabilized, and the environmental problems caused by the waste incineration fly ash dioxin and a large amount of lands required for waste landfill can be solved.

Owner:北科蕴宏环保科技(北京)有限公司

Method for preparing anti-hardening granular burning-free iron-carbon microelectrolysis filler

ActiveCN103880122ARealize resource utilizationRealize waste treatmentSolid waste disposalWater/sewage treatmentWastewaterSewage treatment

The invention relates to a method for preparing anti-hardening granular burning-free iron-carbon microelectrolysis filler. The method comprises the following steps of: using scrap iron, charcoal, coal ash, cement, quick lime and clay as materials, mixing the materials respectively according to the mass fraction of 32-26%, 8-10%, 32-35%, 9-12%, 5-7% and 5-7%, granulating and curing to obtain the anti-hardening granular burning-free iron-carbon microelectrolysis filler. The particle diameter of the prepared anti-hardening granular burning-free iron-carbon microelectrolysis filler is 5-7mm. The method has the advantages that when a product is used for sewage treatment, the CODCr and the chromaticity of waste water can be reduced in shorter time, the toxicity of the waste water can be reduced and the biodegradability can be improved; in the use process, the hardening is not easy to occur, the maintenance cost is low and the usage period is long; in the preparation process, waste resources are fully utilized and a burning-free process is adopted, so that the purposes of saving energy, reducing emission and treating wastes with wastes are achieved.

Owner:SHANDONG UNIV

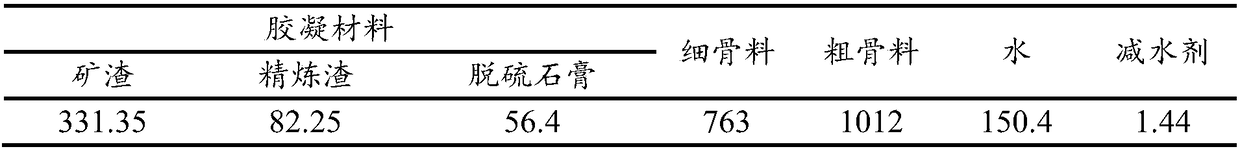

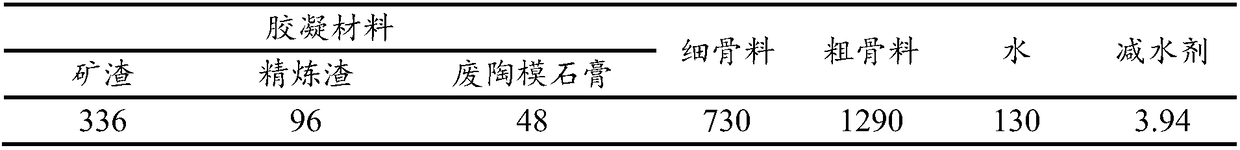

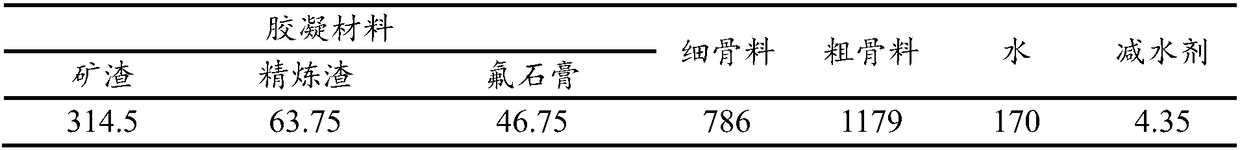

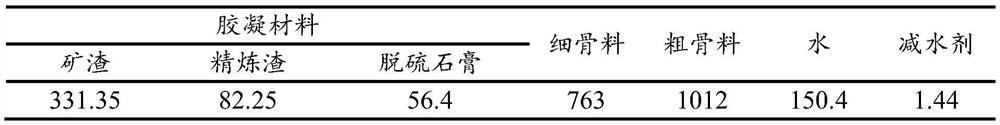

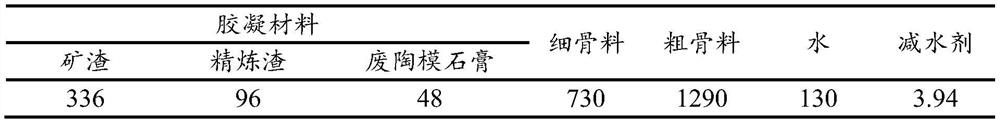

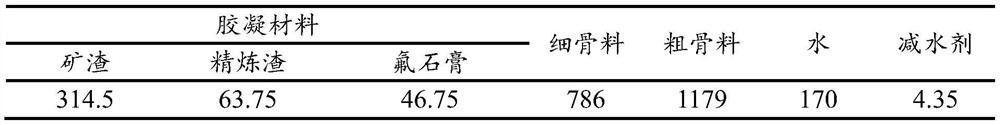

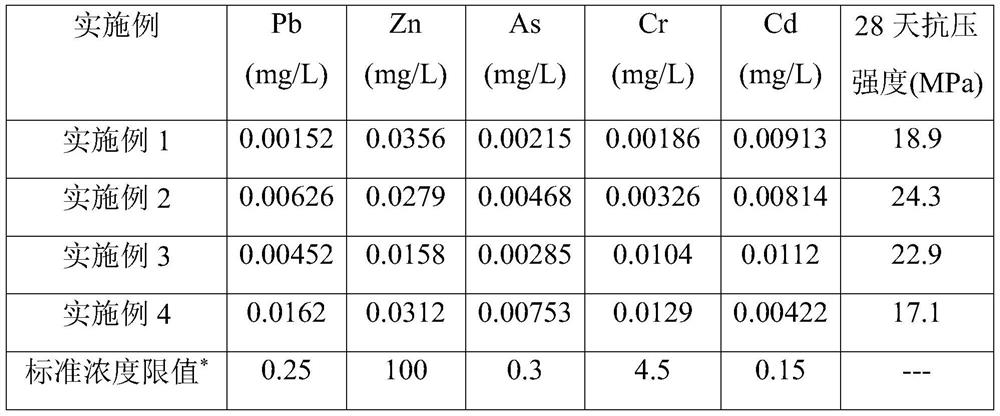

Concrete containing refining slag and preparation method of concrete

ActiveCN108358581AReduce manufacturing costReduce environmental pollutionSolid waste managementGypsumMetallurgical slag

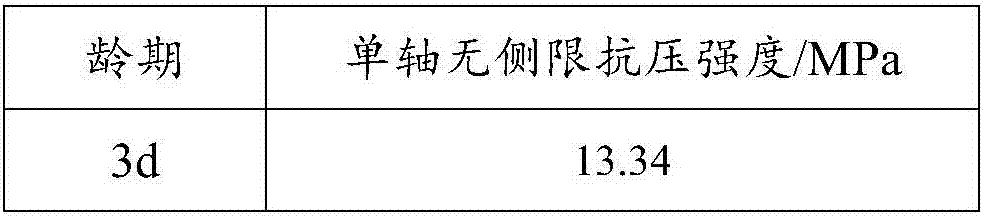

The invention provides concrete containing refining slag and a preparation method of the concrete. The preparation method comprises the following steps: firstly, grinding and uniformly mixing the following components based on dry base by mass percent: 55 to 75 percent of slag, 15 to 35 percent of the refining slag and 10 to 20 percent of industrial by-product gypsum to obtain a cementing material;secondly, adding water into 15 to 50 percent of the cementing material, 50 to 85 percent of aggregate and 0 to 3 percent of water reducing agent for uniformly stirring, and carrying out pouring molding and curing to obtain a qualified concrete material. According to the preparation method of the concrete, disclosed by the invention, the key problem of poor stability of the refining slag is solved, a whole solid waste system cementing material is prepared by playing the gelling property and the synergistic excitation effect of the slag, and further the concrete material is prepared. The metallurgical industry solid waste refining slag and the industrial by-product gypsum are cooperatively treated; the refining slag can be comprehensively utilized to the maximum extent, resource utilizationrate is improved, environmental load is reduced and the comprehensive resource utilization rate of metallurgical slag in China is obviously improved; meanwhile, the production cost of the concrete isreduced and obvious economic benefits are obtained.

Owner:UNIV OF SCI & TECH BEIJING

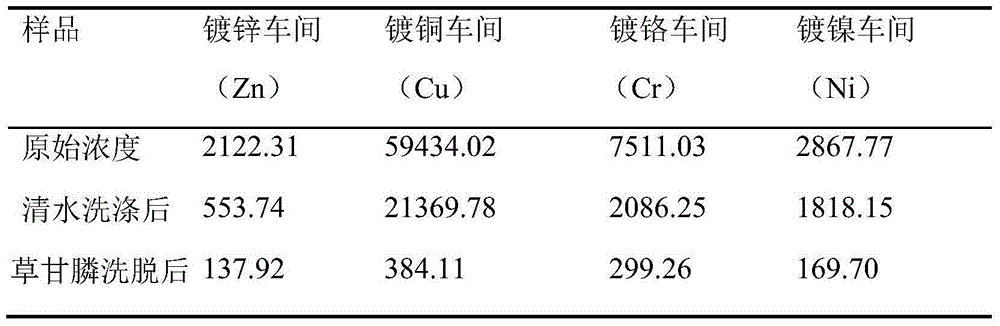

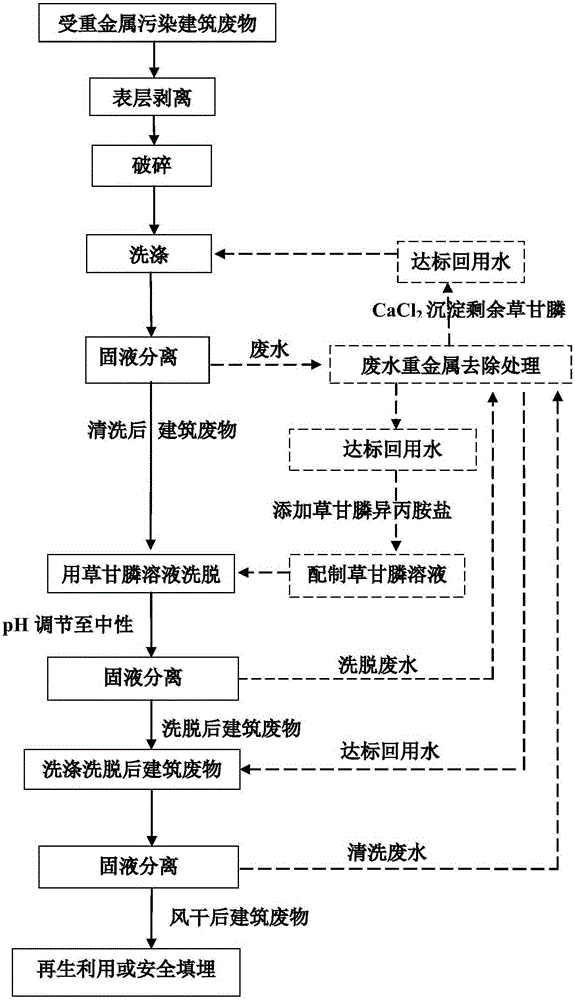

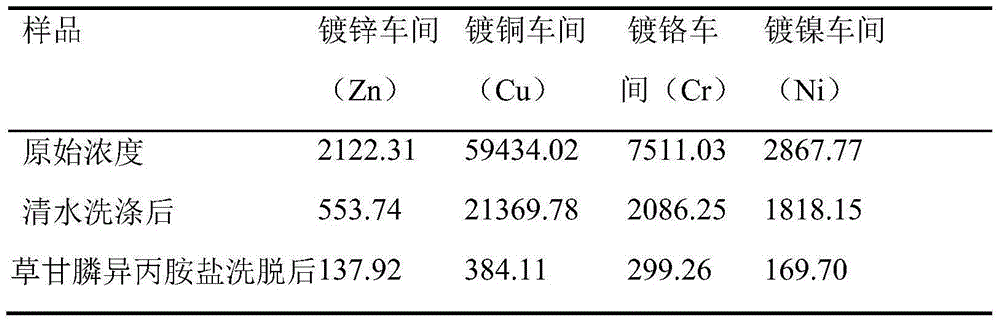

Treating method of high-concentration heavy metal polluted building waste

InactiveCN103978013AEliminate hazardsRealize waste treatmentConstruction waste recoverySolid waste disposalThree levelHigh concentration

The invention relates to a treating method of high-concentration heavy metal polluted building waste. The method includes: stripping surfaces of the building waste, smashing, washing, separating solid and liquid to obtain the cleaned building waste the water-soluble heavy metal of which is removed, adding an isopropylamine glyphosate solution into the cleaned building waste, eluting to remove the heavy metals, adjusting the pH value to be neutral, separating solid and liquid, washing the waste after elution with water and separating solid and liquid. The heavy metal contents in the building waste after air drying are lower than the three-level standard thresholds of the environmental quality standards (GB15618-1995). The building waste after air drying is subjected to a leaching test by utilization of an HJ / T229 leaching method, and the heavy metal contents in the leachate are lower than the thresholds of the standards for hazardous wastes (GB5085.3-2007). The building waste after air drying can be directly buried and stacked without pollution to the soil, and can be used as a regenerated roadbed material and a concrete aggregate. The method is simple in process and capable of completely eliminating the hazard of the polluted building waste, and has good environmental benefit, economic benefit and social benefit.

Owner:TONGJI UNIV

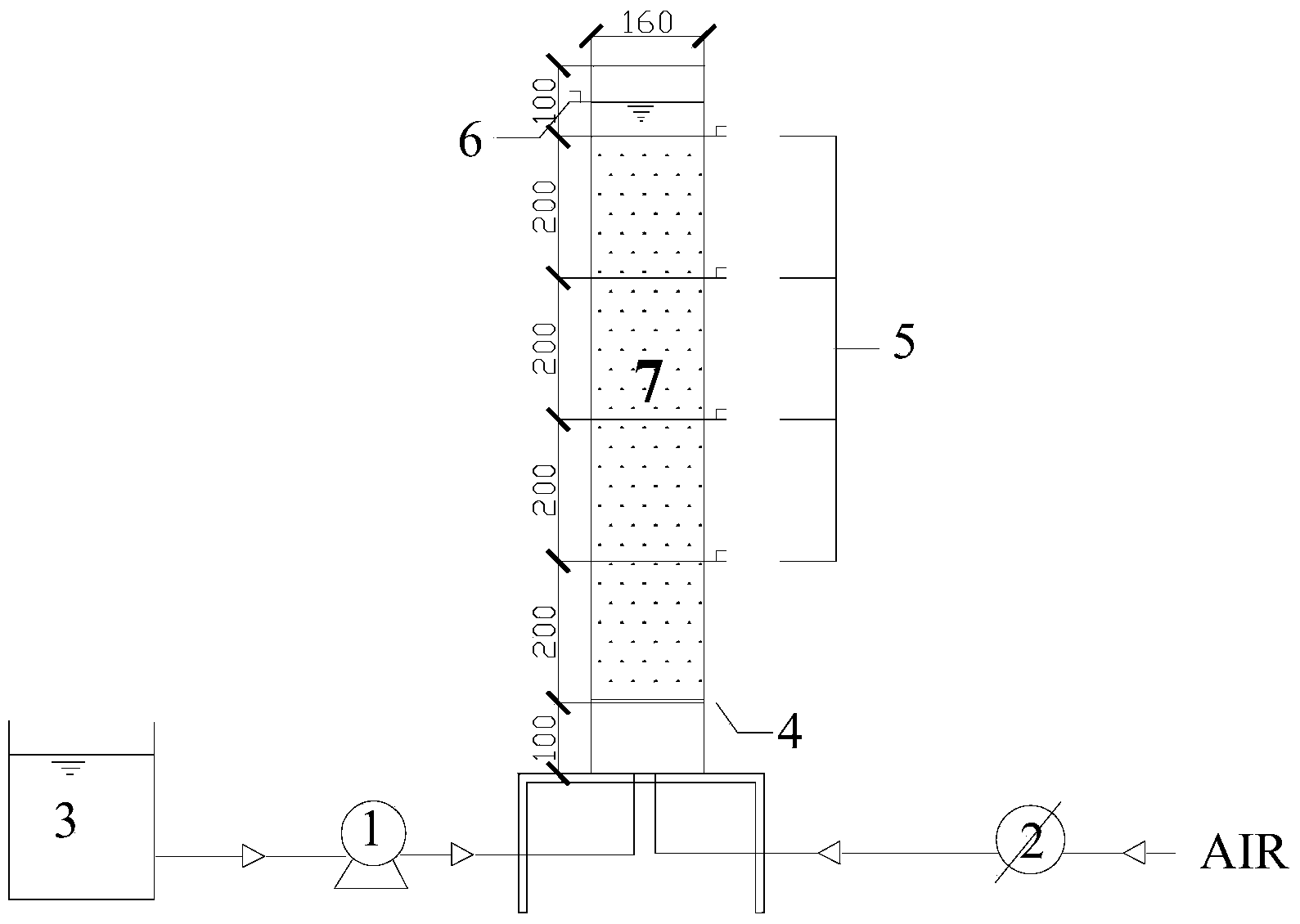

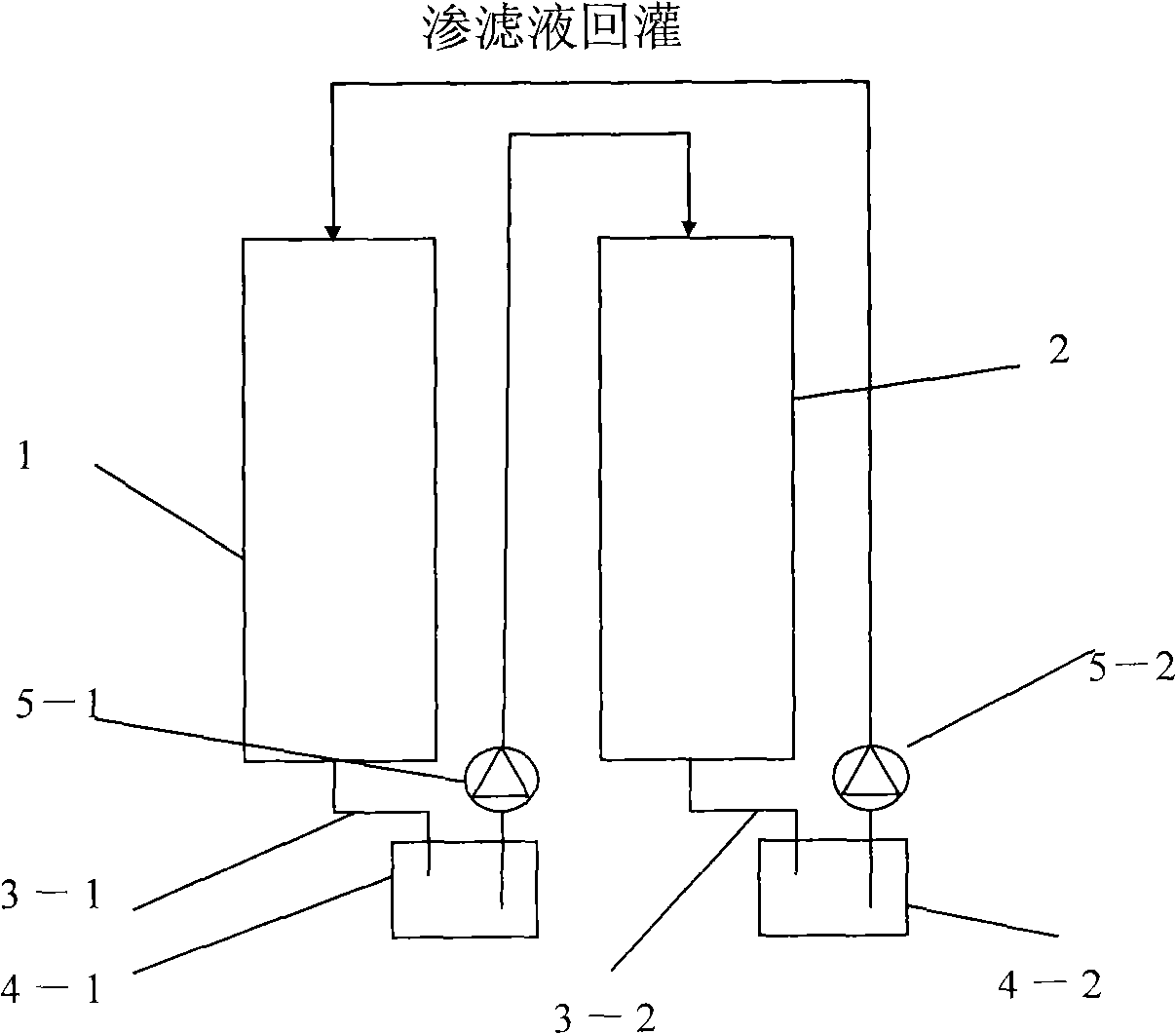

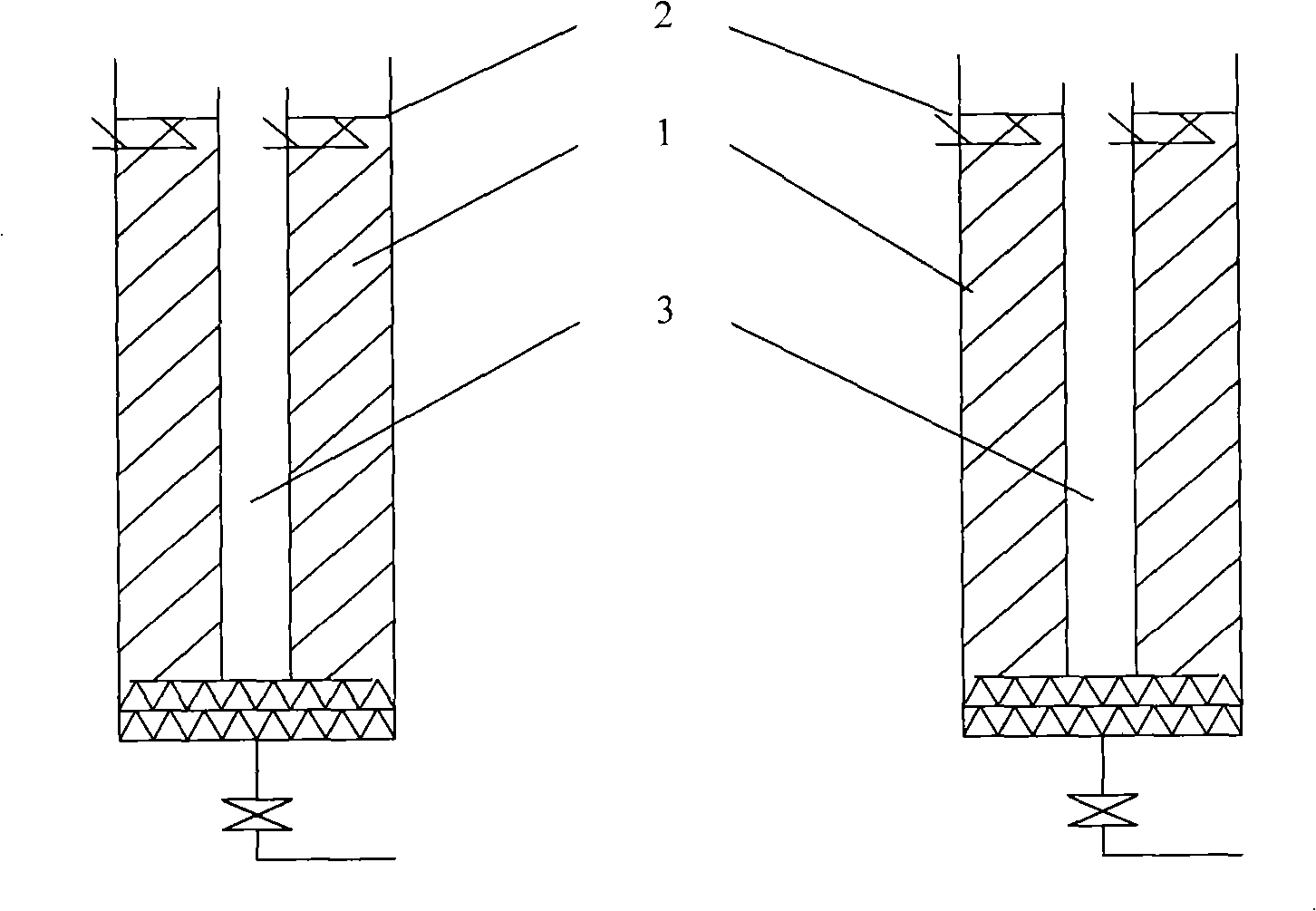

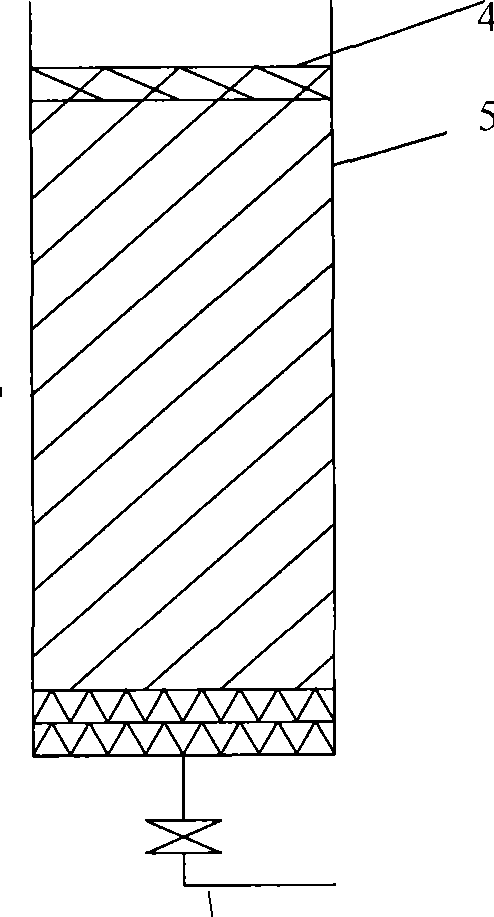

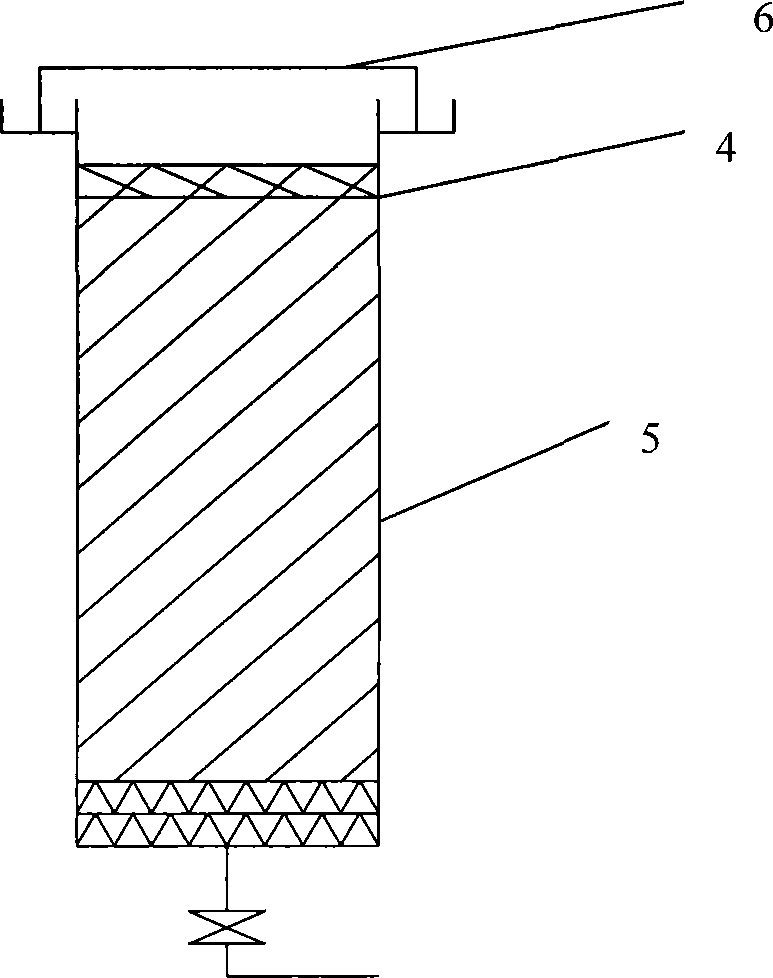

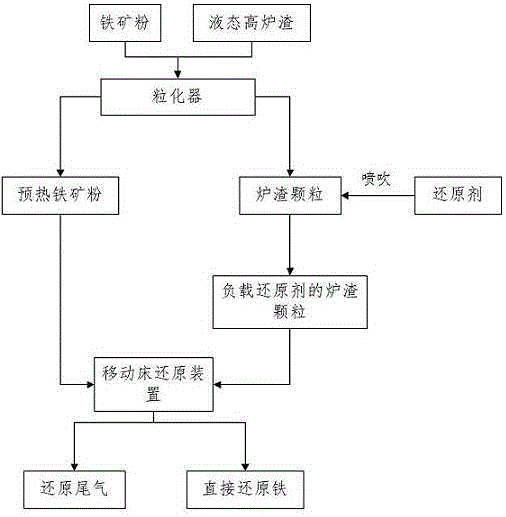

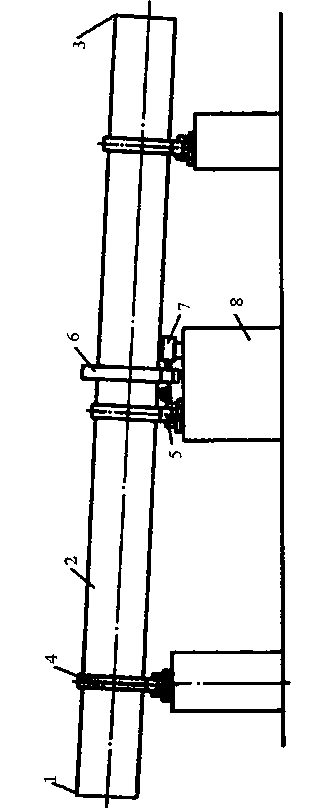

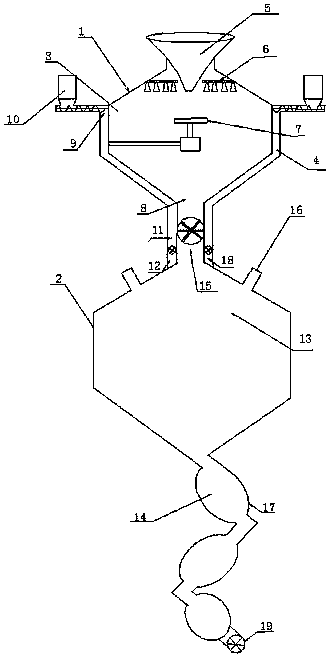

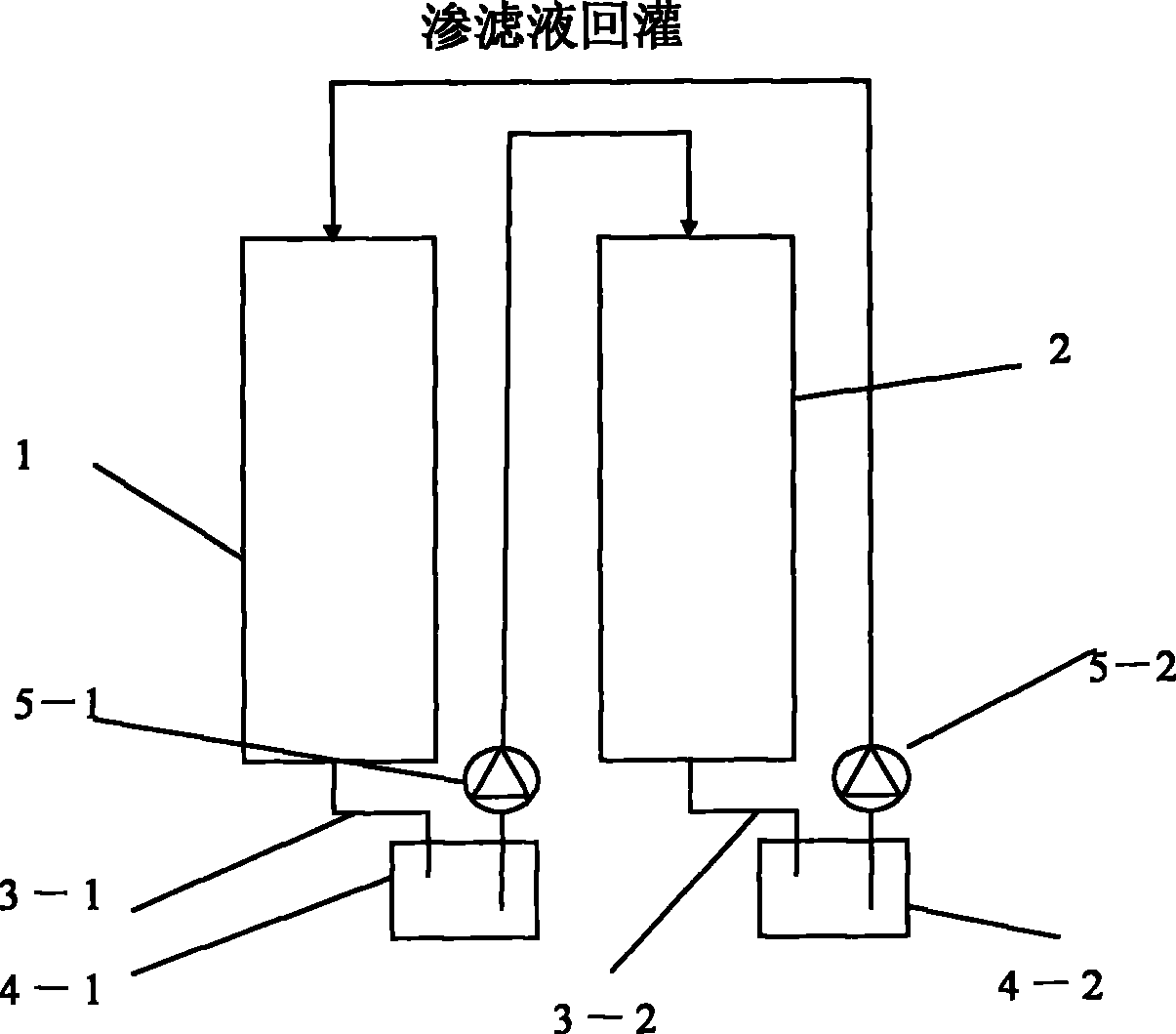

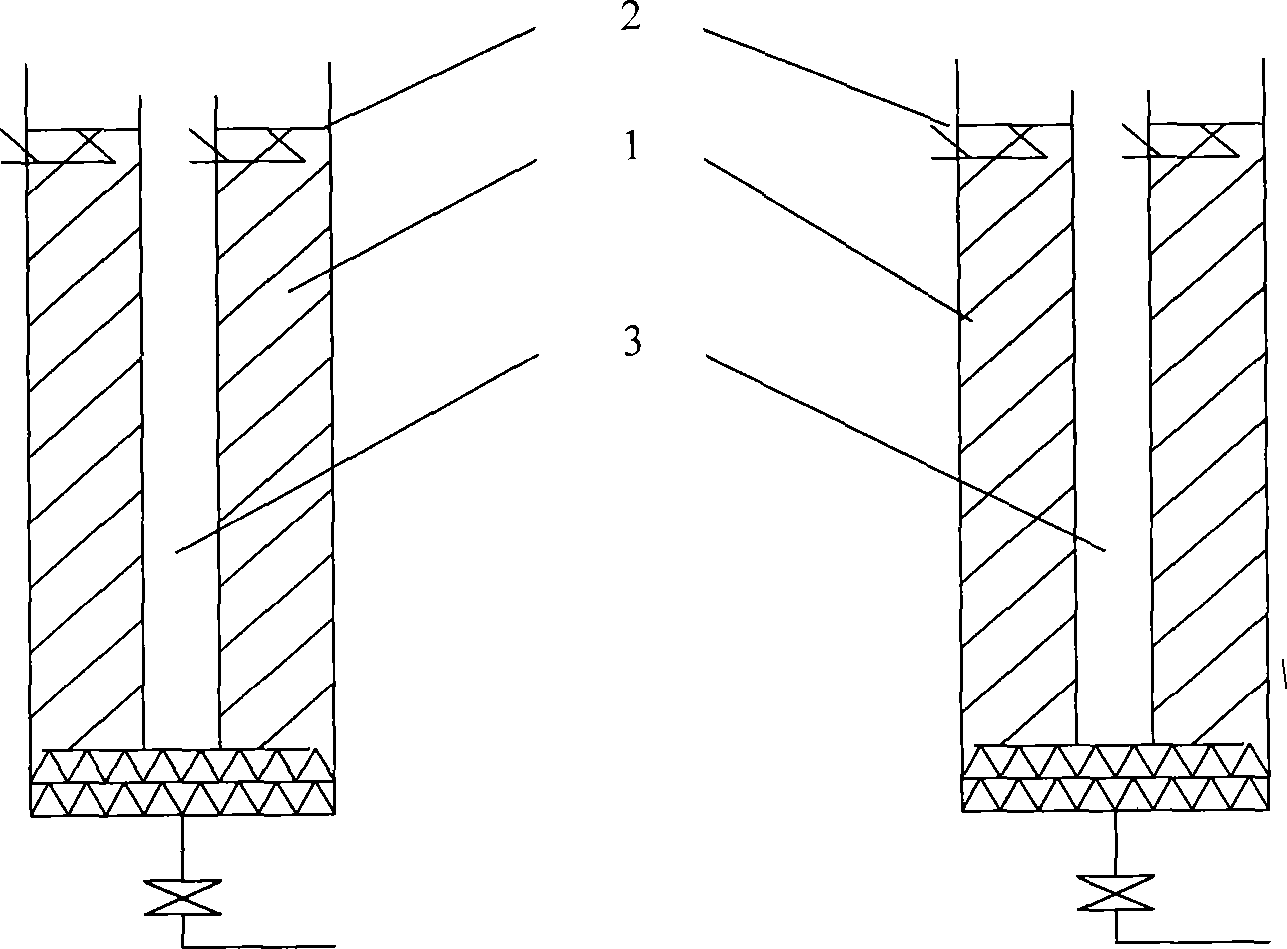

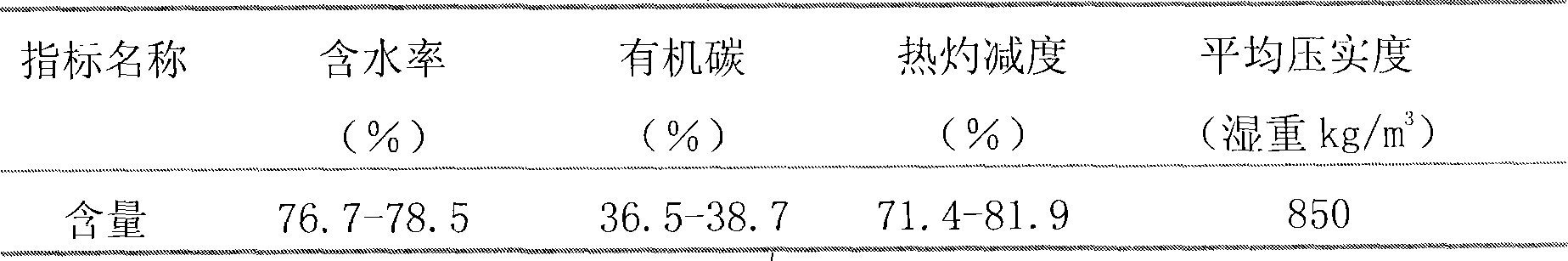

Method and special apparatus for refuse leachate disposal

InactiveCN101269856AShorten landfill cyclePromote degradationWater/sewage treatmentLeachateSustainable yield

The invention discloses a method of treating garbage seeping liquid and a special device thereof. The device of treating the garbage seeping liquid provided by the invention comprises two garbage reactors 1 connected in series and a garbage reactor 2. The garbage reactors 1 and the garbage reactor 2 comprise a pool body, a water distribution device and a vent-pipe. The top part of the pool body is open and the bottom is provided with a through hole. The water distribution device is used for leading the garbage seeping liquid towards the pool body. The vent-pipe is arranged vertically in the tank body to be used for the ventilation. The application of the device of treating the garbage seeping liquid of the invention can realize the sustainable yield of a garbage land fill filed, and achieve the zero draining purpose of the seeping liquid.

Owner:TSINGHUA UNIV

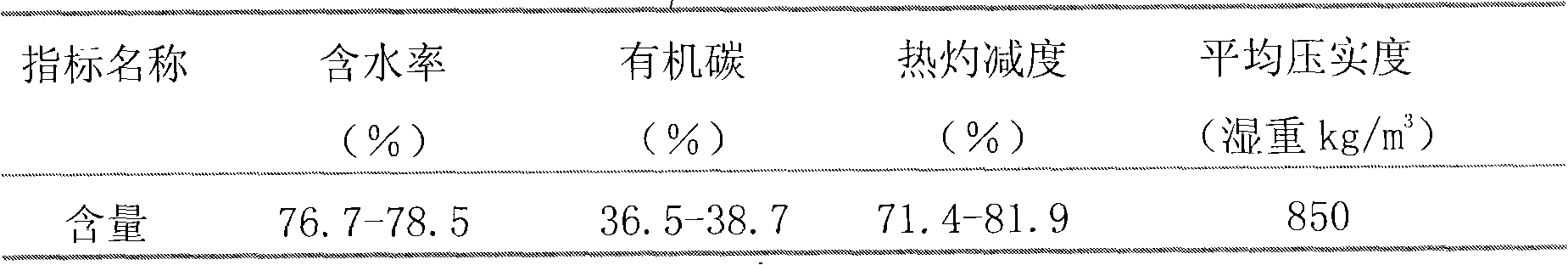

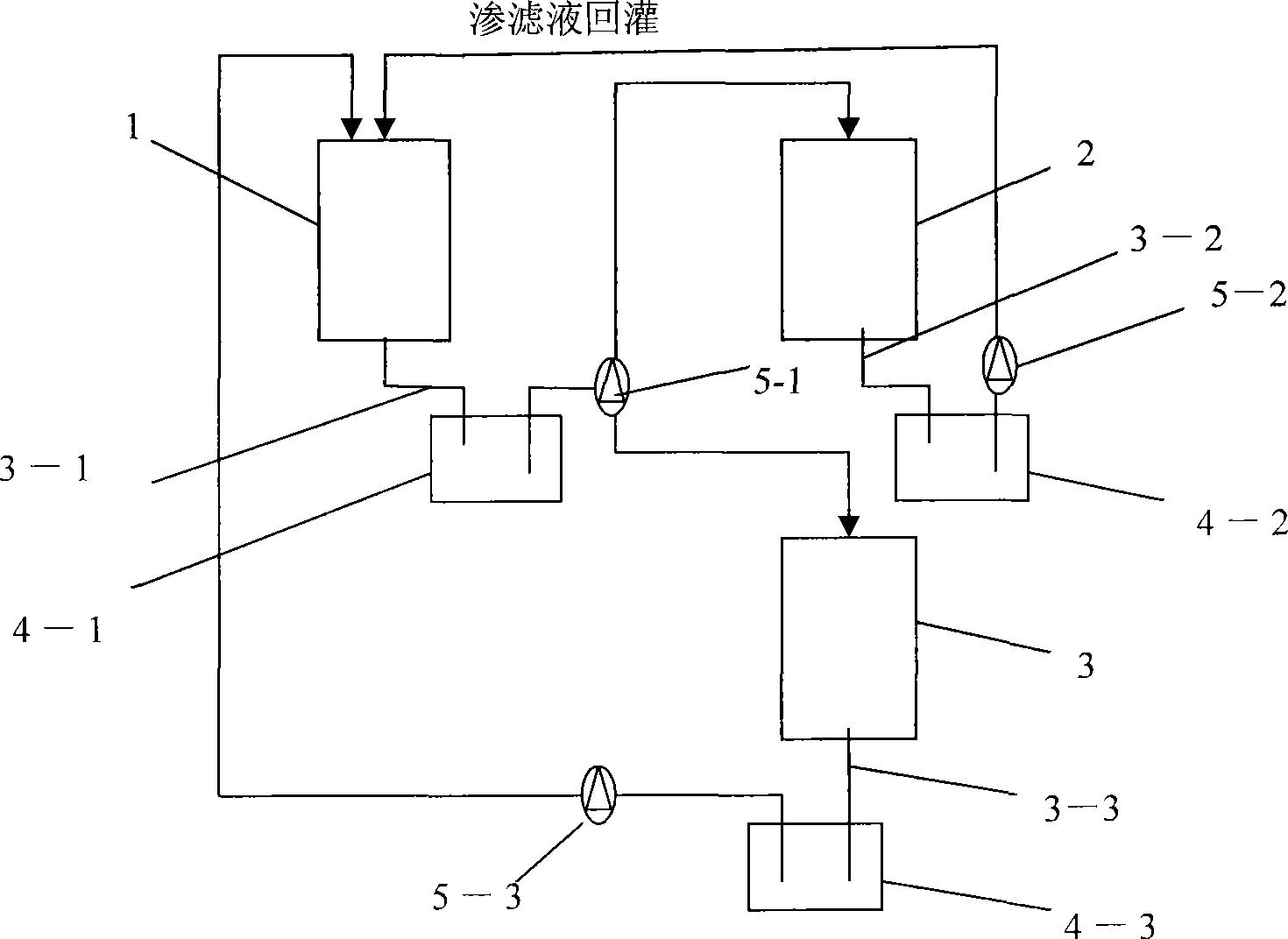

Method for processing landfill leachate and special device thereof

InactiveCN101249988AAdvantages of the treatment methodSolve processingWater/sewage treatmentFiltrationWaste site

The invention discloses a method for processing rubbish filtration and the special apparatus. The method for processing rubbish filtration has the advantages that (1) resolving the problem of blocking of the waste reactor, (2) accelerating stabilization of the rubbish for detecting and shortening the landfill waste cycle and filtration processing cycle, (3) achieving zero discharge of the filtration, (4) realizing the sustainable development of the landfill waste site, (5) can flexibly control the recharge rage.

Owner:TSINGHUA UNIV

Method for preparing soil conditioner by utilizing steel slag

The invention discloses a method for preparing a soil conditioner by utilizing steel slag, belonging to the field of comprehensive utilization of resources, and comprising the following five steps: screening, burdening, mixing, pelletizing and bagging. The method for preparing the soil conditioner by utilizing the steel slag is characterized by screening out steel slag with the size less than 3 mm, burdening 25-40 wt% of the steel slag and 75-60 wt% of vinegar residue, mixing, and utilizing a cylindrical pelletizer to carrying out pelletizing and granulating. The invention can process the steel slag in large scale, improves soil fertility, improves crop output and quality, has low manufacture cost and realizes the purpose of industrially using waste to treat waste.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

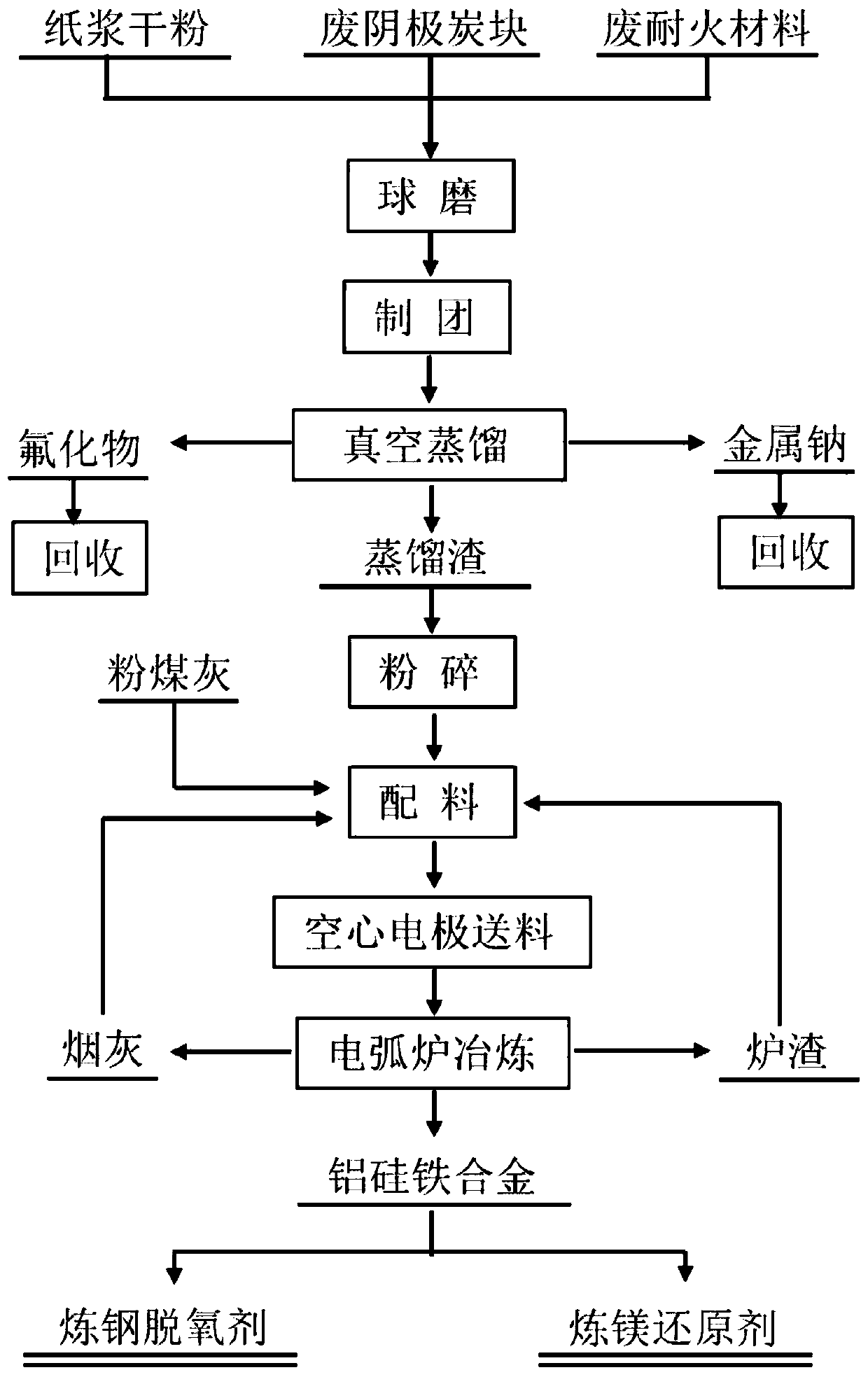

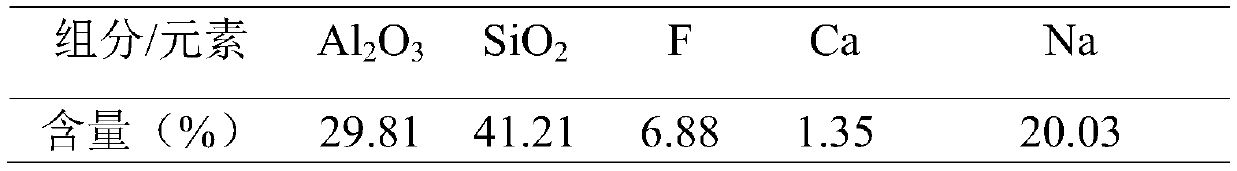

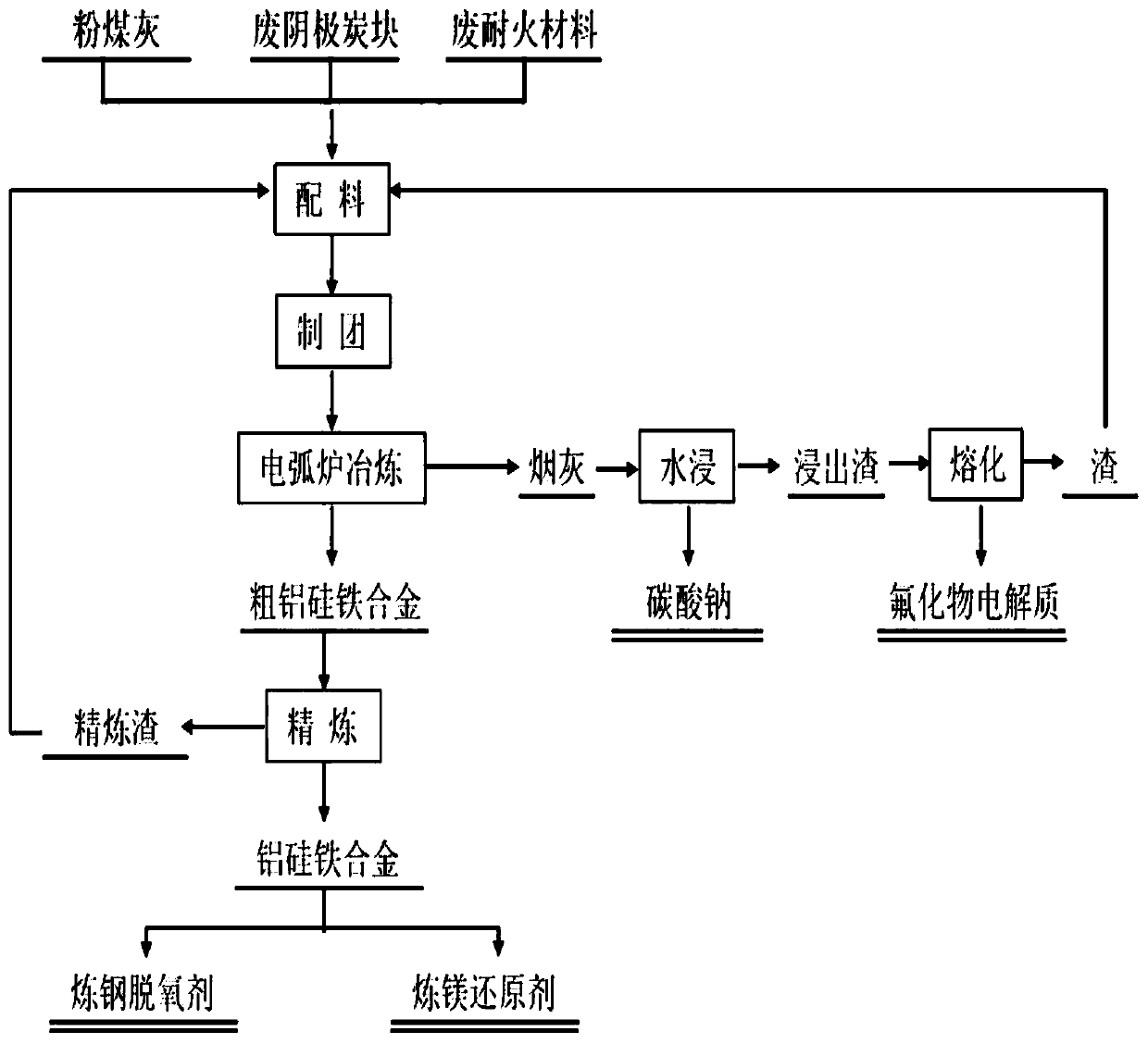

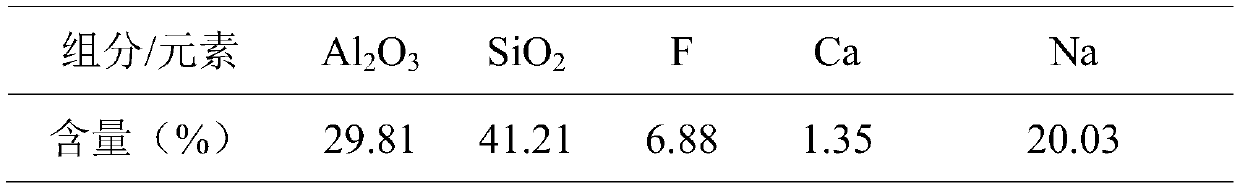

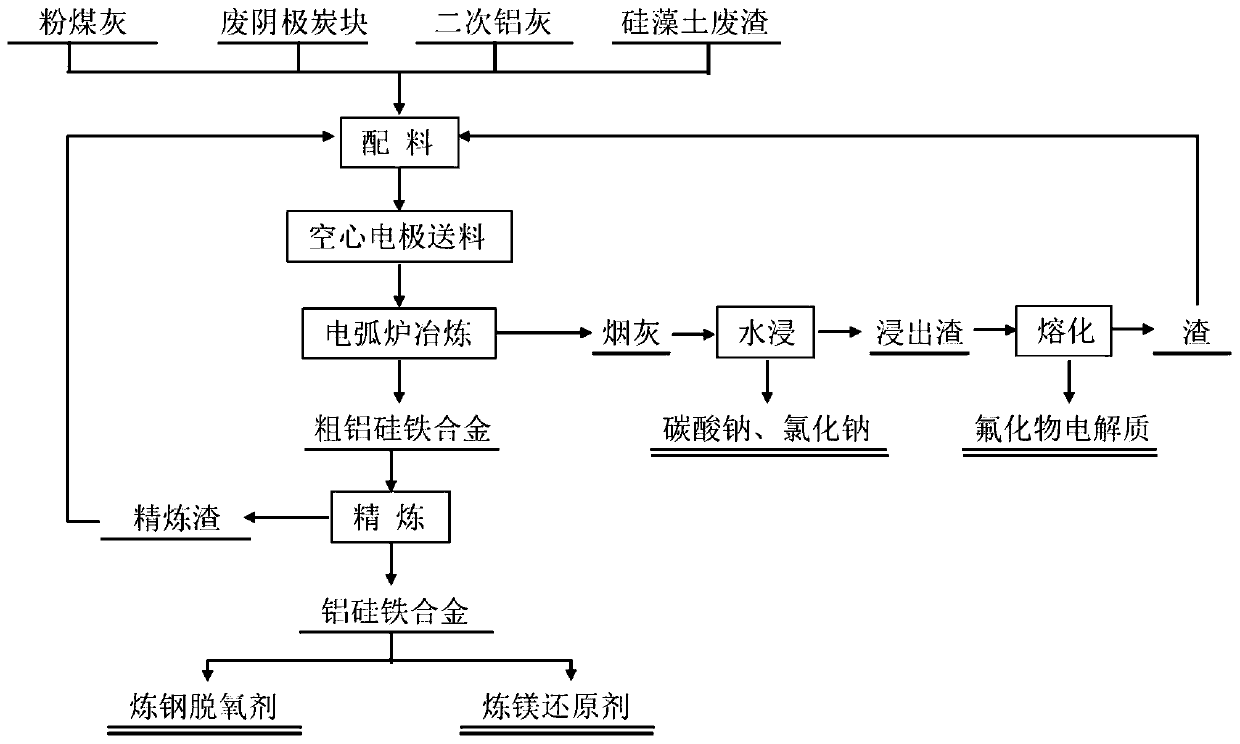

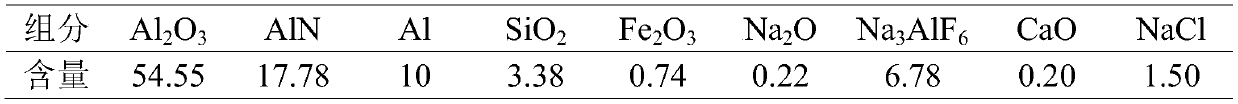

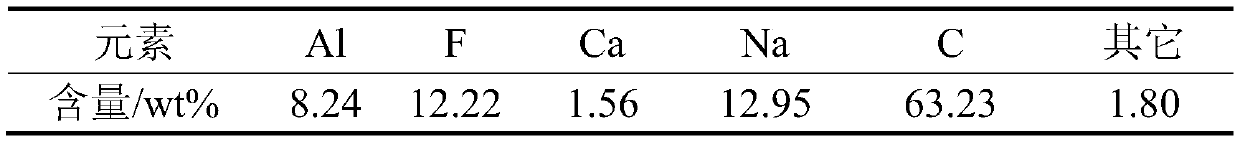

Method for preparing Al-Si-Fe alloy by preprocessing waste fireproof material and carbon thermal reduction

ActiveCN110129506ARealize high temperature volatile separationRealize resource utilizationElectric furnaceGas emission reductionElectric arc furnaceDecomposition

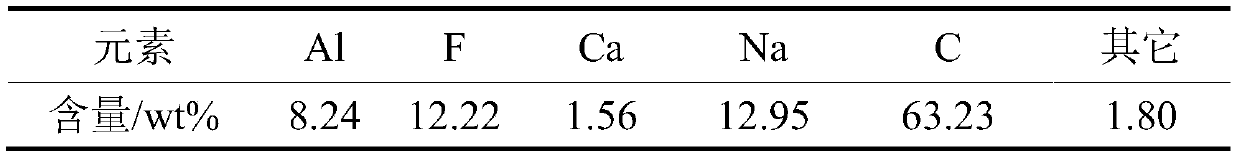

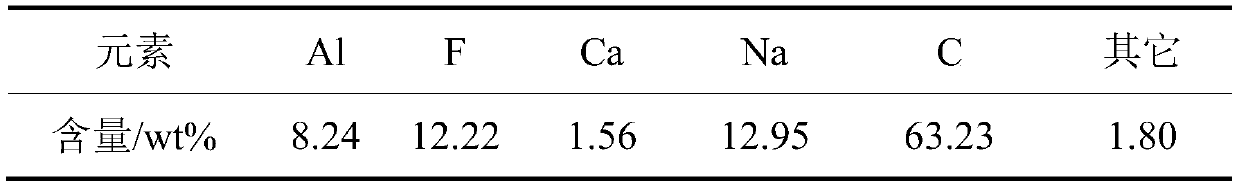

The invention provides a method for preparing an Al-Si-Fe alloy by preprocessing a waste fireproof material and carbon thermal reduction. The method for preparing the Al-Si-Fe alloy by preprocessing the waste fireproof material and carbon thermal reduction comprises the steps that the waste fireproof material, waste negative electrode carbon blocks and paper pulp dry powder are uniformly mixed andmade into powder; then the mixed material is compressed into pellets, high temperature vacuum distillation is conducted so that fluoride in the waste fireproof material and the waste negative electrode carbon blocks volatilize, then the fluoride is separated from the waste fireproof material and the waste negative electrode carbon blocks, and meanwhile, cyanide in the waste negative electrode carbon blocks is decomposed; then distillation residues are smashed and dispensed and mixed with coal ash, and fixed carbon in the waste negative electrode carbon blocks is adopted as a reducing agent inan electric arc furnace so that high temperature reduction can be conducted on a material with aluminum oxide and silicon oxide being the main components, and then the Al-Si-Fe alloy with certain components is prepared; and meanwhile, decomposition of aluminum nitride in aluminum ash and total decomposition of cyanide in the waste negative electrode carbon blocks are completed in the high temperature reduction process, and comprehensive utilization of multiple hazardous wastes and solid wastes is achieved in the same technology.

Owner:NORTHEASTERN UNIV

Method and device for treating FCC regeneration flue gas

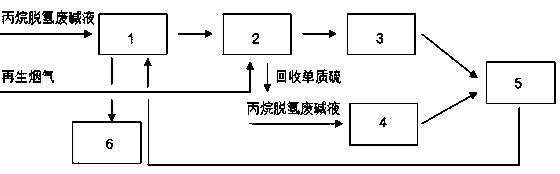

ActiveCN111097273AEfficient removalRealize waste treatmentWater treatment parameter controlGas treatmentFluid phaseFlue gas

The invention relates to a FCC regeneration flue gas treatment method which comprises the steps: (1) carrying out split-flow treatment on a waste alkali liquor, acidifying a part of the waste alkali liquor, and reacting generated gas with FCC regeneration flue gas; (2) introducing an obtained desulfurized flue gas into a cellulosic algae SS-B7 culture system in an illumination reactor, culturing for a period of time, and introducing air and / or oxygen; (3) adding solid NaOH into a rest waste alkali liquor to convert sodium hydrosulfide into sodium sulfide; (4) reacting a flue gas collected in the step (2) with the waste alkali liquor in the step (3), acidifying an obtained liquid phase in the step (1), and discharging purified gas; and (5) carrying out multiple-effect evaporation treatmenton awaste liquid collected in the step (1). According to the characteristics of propylene refining waste alkali liquid, split-flow treatment is carried out and is used for different stages of FCC regeneration flue gas treatment, SOx and NOx in the FCC regeneration flue gas can be efficiently removed, meanwhile, sulfides in the waste alkali liquid are removed, and generated sodium salt is recycled.

Owner:CHINA PETROLEUM & CHEM CORP +1

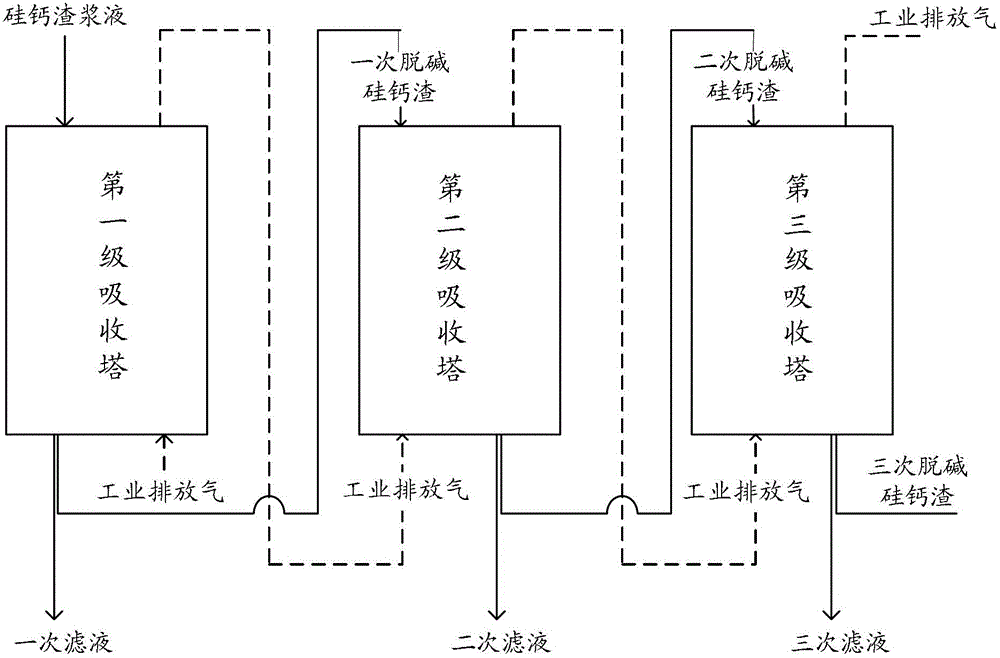

Purification method for industrial emission gas

InactiveCN103143251AStep scienceImprove absorptionDispersed particle separationAir quality improvementIndustrial wasteIndustrial emission

The invention provides a purification method for industrial emission gas. The purification method for the industrial emission gas includes the following the steps: (1) mixing silico-calcium residues into silico-calcium seriflux; and (2) enabling the silico-calcium seriflux to enter an absorption tower from top to bottom, enabling the industrial emission gas to enter the absorption tower from top to bottom, and enabling the silico-calcium seriflux to contact the industrial emission gas. The silico-calcium seriflux enters the absorption tower from top to bottom, the industrial emission gas enters the absorption tower from top to bottom, the silico-calcium seriflux and the industrial emission gas are enabled to conduct convection, full contact of the silico-calcium seriflux and the industrial emission gas is achieved, absorption effect of carbon dioxide is improved, and emission reduction of carbon dioxide is effectively achieved. The waste resource silico-calcium residues are used as raw materials to purify the industrial emission gas, and using waste to treat waste is achieved. Besides, the industrial emission gas is effectively purified, and meanwhile alkali content in the industrial waste material silico-calcium residues is reduced, and the industrial waste material silico-calcium residues are enabled to meet requirements of mixed additives and cement clinker raw materials. The purification method for the industrial emission gas possesses good social benefit and environment benefit, and meanwhile possesses good economic benefit.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT +1

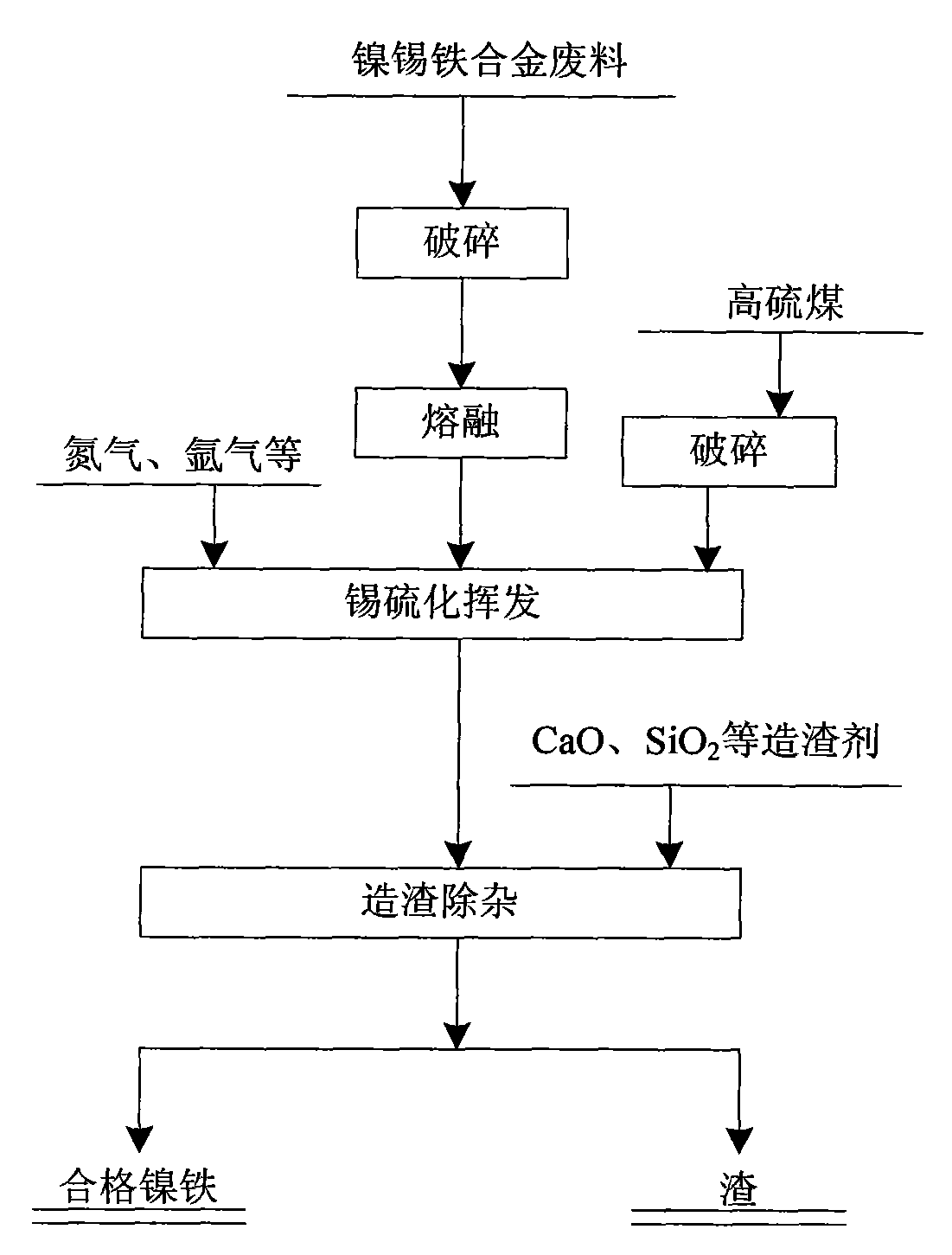

Method for Ni-Fe alloy production and Sn recovery from Ni-Sn ferroalloy scrap by high-sulfur coal sulfuration volatilization and oxidation slagging

InactiveCN104232904ARealize waste treatmentWide process applicabilityProcess efficiency improvementMolten stateMelting tank

The invention discloses a method for Ni-Fe alloy production and Sn recovery from Ni-Sn ferroalloy scrap by high-sulfur coal sulfuration volatilization and oxidation slagging. The method is characterized by comprising the process steps as follows: the Ni-Sn ferroalloy scrap is crushed to certain blockness, transferred into an intermediate frequency furnace or an electric furnace and then heated to certain temperature, a nitrogen gas spray gun is inserted into a molten pool for stirring after the material is in a molten state, and the high-sulfur coal is crushed to certain granularity and sprayed into the molten pool for a sulfuration volatilization reaction of Sn in the material; after the sulfuration reaction is finished, the high-sulfur coal is stopped from being sprayed into the furnace, certain slagging constituent is added into the molten pool for Ni-Fe liquid purification, and certain alkalinity of the molten pool is controlled in the process; after certain period, slag and Fe are completely separated, produced Ni-Fe liquid and slag are discharged from a Fe outlet and a slag outlet respectively, and resources including Ni, Fe and Sn are recovered effectively in the process. According to the method, the characteristic of high sulphur content of the high-sulfur coal is sufficiently utilized for Sn sulfidation treatment of the Ni-Sn ferroalloy scrap, the resources including Ni, Fe and Sn are recovered effectively, waste is treated by waste, the technological process is simple to operate, the production cost is lower, and broader industrial prospect is provided.

Owner:GLOBE FUTURE BEIJING TECH DEV CO LTD

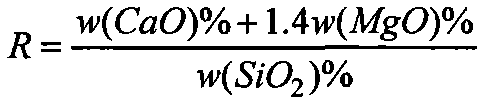

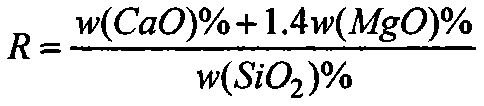

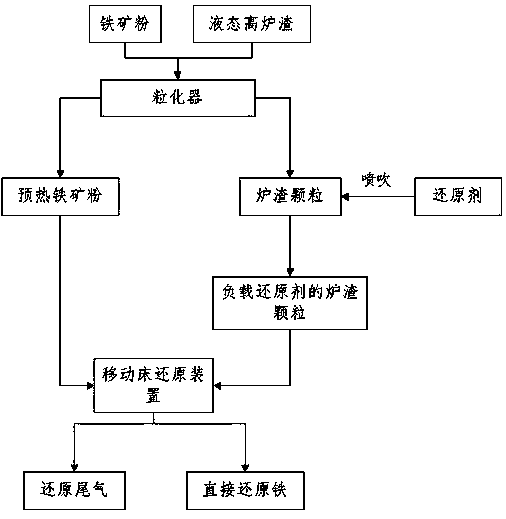

Direct-reduction ironmaking device and method based on blast furnace slag waste heat utilization

ActiveCN105779679AReduce manufacturing costImprove transfer efficiencyRecycling and recovery technologiesHearth type furnacesHeat carrierSlag

The invention provides a direct-reduction ironmaking device and method based on blast furnace slag waste heat utilization. The device comprises a granulating device and a moving bed reduction device. By means of the device, liquid blast furnace slag is made into high-temperature furnace slag granules, the granules are loaded with a reducing agent and used as a heat carrier to be in direct contact with iron ore powder, and the iron ore powder generates a direct reduction reaction for production and direct-reduction ironmaking. According to the technical scheme, waste heat of the blast furnace slag is adopted as an iron ore powder direct-reduction heat source, the furnace slag heat carrier loaded with the reducing agent is in direct contact with the iron ore powder granules, and therefore efficient heat exchange and mass transfer of the reduction reaction are achieved, the waste heat of the blast furnace slag is efficiently recycled, and low-cost and efficient production of direct-reduced iron is achieved.

Owner:光大理工环境技术研究院(青岛)有限公司

Rotary kiln

InactiveCN103528072AImprove drying efficiencyStable temperatureIncinerator apparatusActivated sludgeCombustion

The invention discloses a rotary kiln which comprises a kiln head, a kiln body, a kiln tail, rim bands, riding wheels, a big gear ring, a transmission device and a foundation. The riding wheels are arranged on the foundation through bearings, the rim bands penetrate through the kiln body in a sleeved mode and are fixedly connected to the kiln body, and the kiln body is arranged on the riding wheels through the rim bands. The big gear ring penetrates through the kiln body in a sleeved mode and fixed on the kiln body, the transmission device is arranged on the foundation, and an output end of the transmission device is in gear mesh with the big gear ring. A lifting board is arranged in the kiln body, and a kiln head cover is arranged on the kiln head. The kiln head is provided with an activated sludge feed device and a combustible waste feed device. The lifting board is an O-shaped hanging chain which is arranged on the inner wall of the kiln body. A sealing structure between the kiln head and the kiln body is in a labyrinth seal mode and a scale seal mode. The sealing structure between the kiln tail and the kiln body is in a labyrinth seal mode and a scale seal mode. A smoke outlet is formed above the kiln head cover, and a temperature measuring device is arranged on the smoke outlet. The rotary kiln is used for drying PTA process activated sludge, the combustion is sufficient, burning effects are good, sludge drying efficacy is good, energy is saved, and sealing performance is good.

Owner:YIZHENG MAORUI CHEM

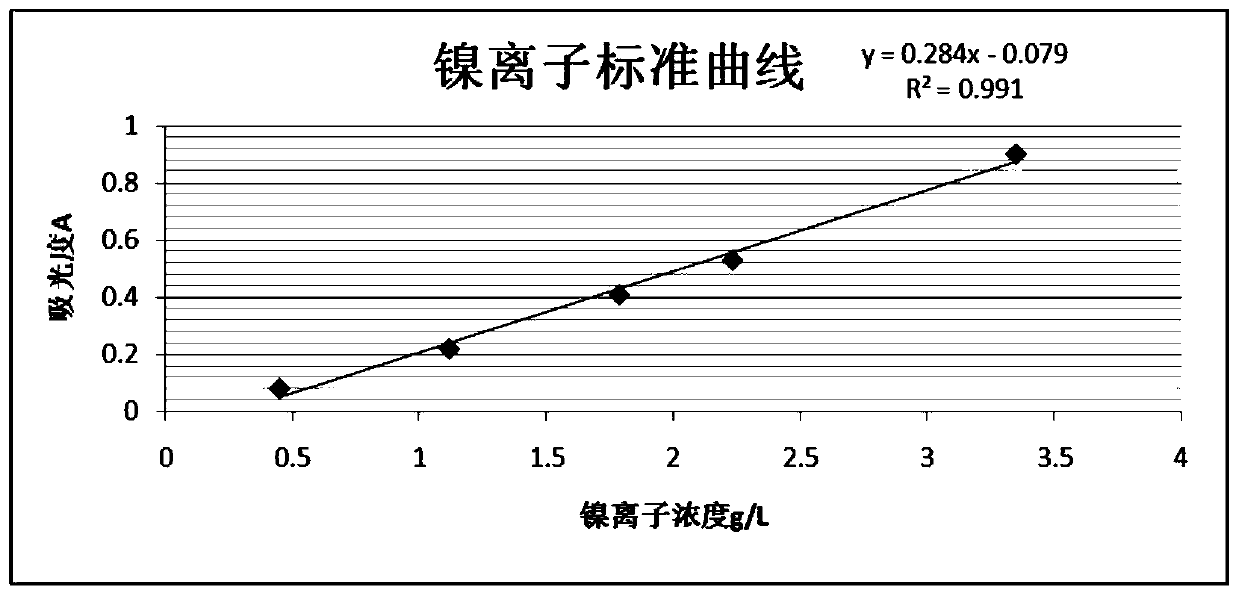

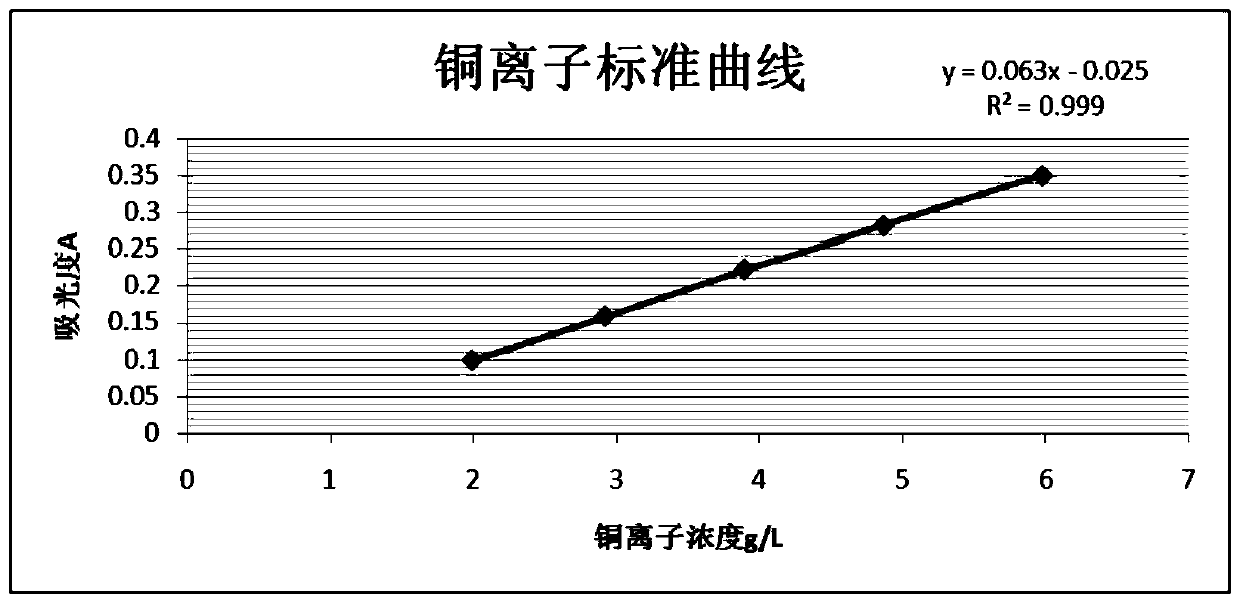

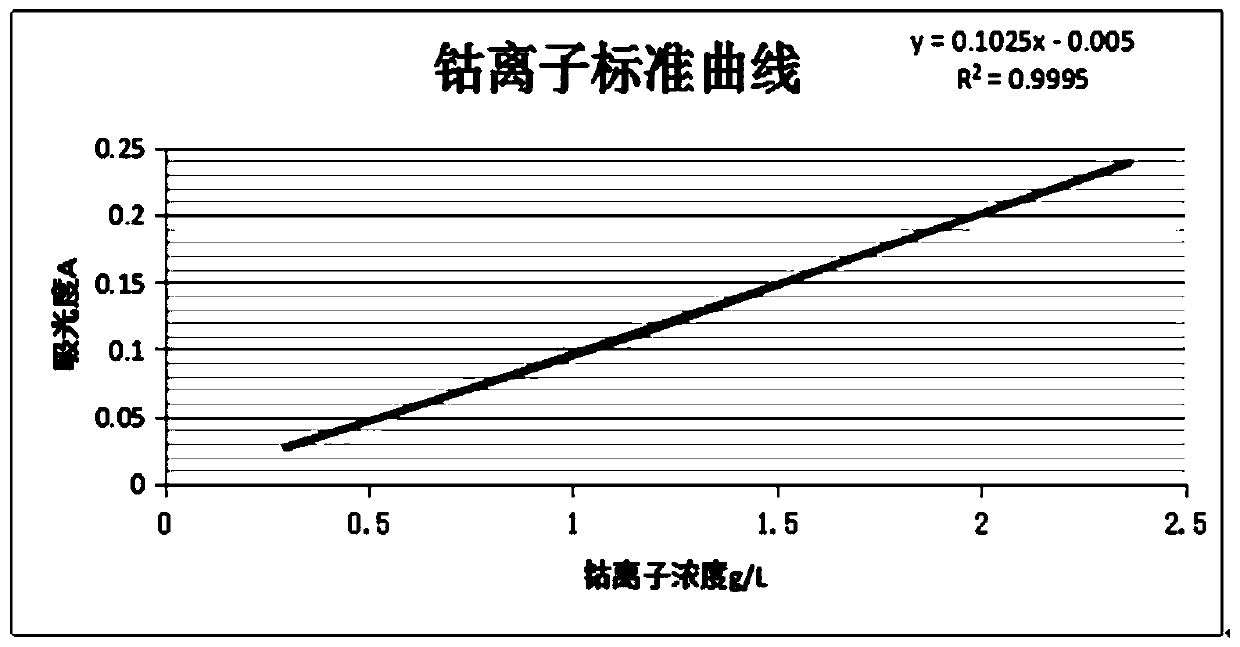

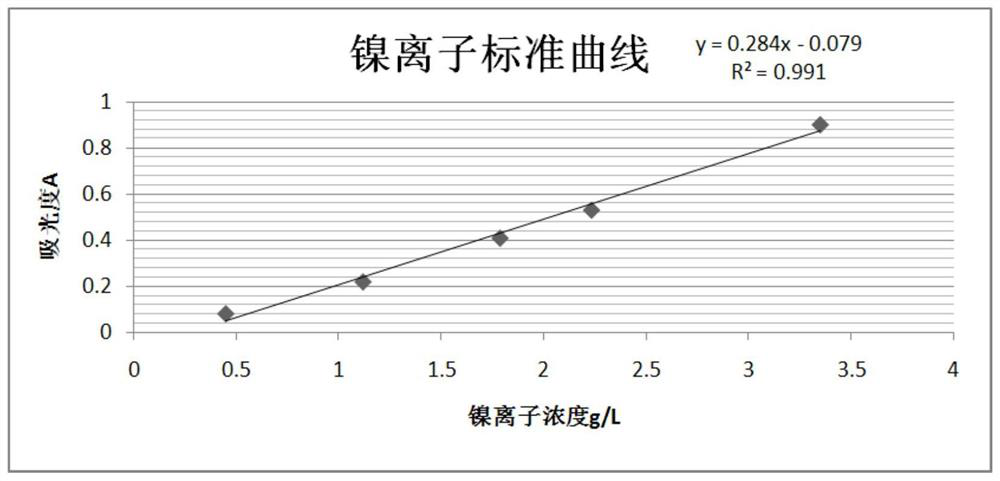

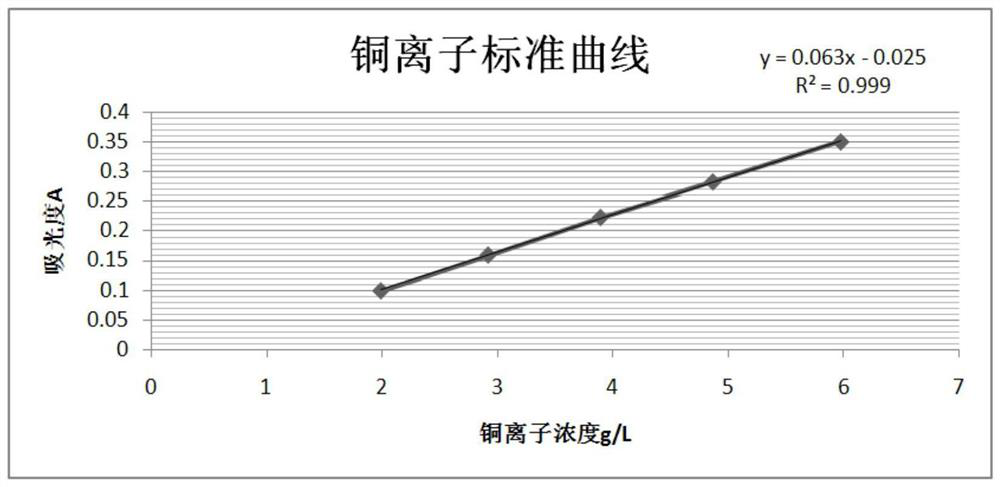

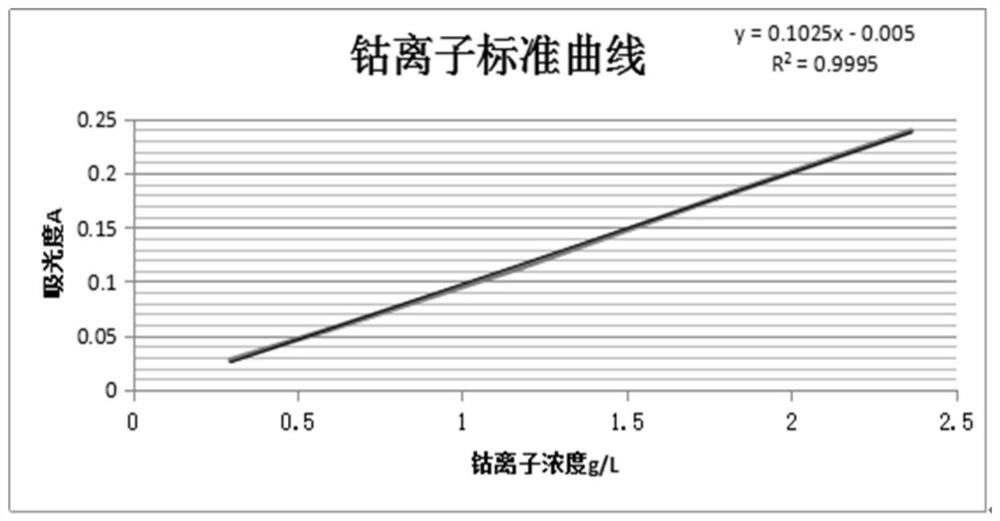

Oyster shell powder modified water treatment agent as well as preparation method and application thereof

ActiveCN109865502AImprove adsorption capacityRealize waste treatmentOther chemical processesWater contaminantsUltrasonic emulsificationOyster

The invention discloses an oyster shell powder modified water treatment agent as well as a preparation method and application thereof. The preparation method comprises the following steps: uniformly mixing oyster shell powder, polyacrylamide (PAM) and a solvent, and adding a pH adjusting agent to adjust the pH; performing ultrasonic emulsification, performing stirring heating at 50-90 DEG C for 30-150 min, performing cooling to a room temperature, performing centrifugal separation, performing drying crushing, and performing sieving to obtain modified oyster shell powder; and uniformly mixing the modified oyster shell powder and carboxymethyl cellulose sodium, performing natural drying, performing calcination at medium and low temperature, and performing cooling to obtain the oyster shell powder modified water treatment agent. The oyster shell powder modified water treatment agent provided by the invention has a faster and more efficient adsorption effect on heavy metal ions such as Ni<2+>, Co<2+> and Cu<2+>, and excellent stability and durability, effectively realizes the purpose of using waste to treat waste, belongs to high-efficiency environmentally-friendly adsorption separation materials, and has good application value.

Owner:GUANGDONG OCEAN UNIVERSITY

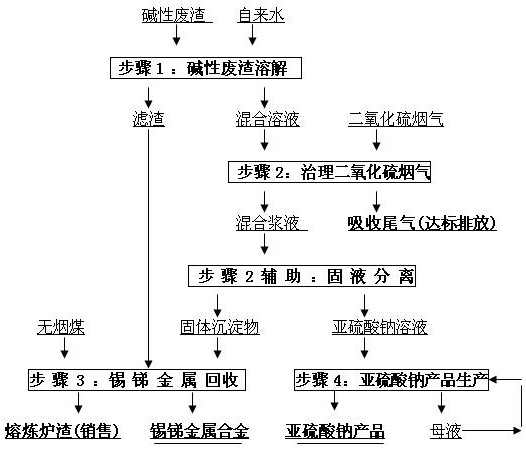

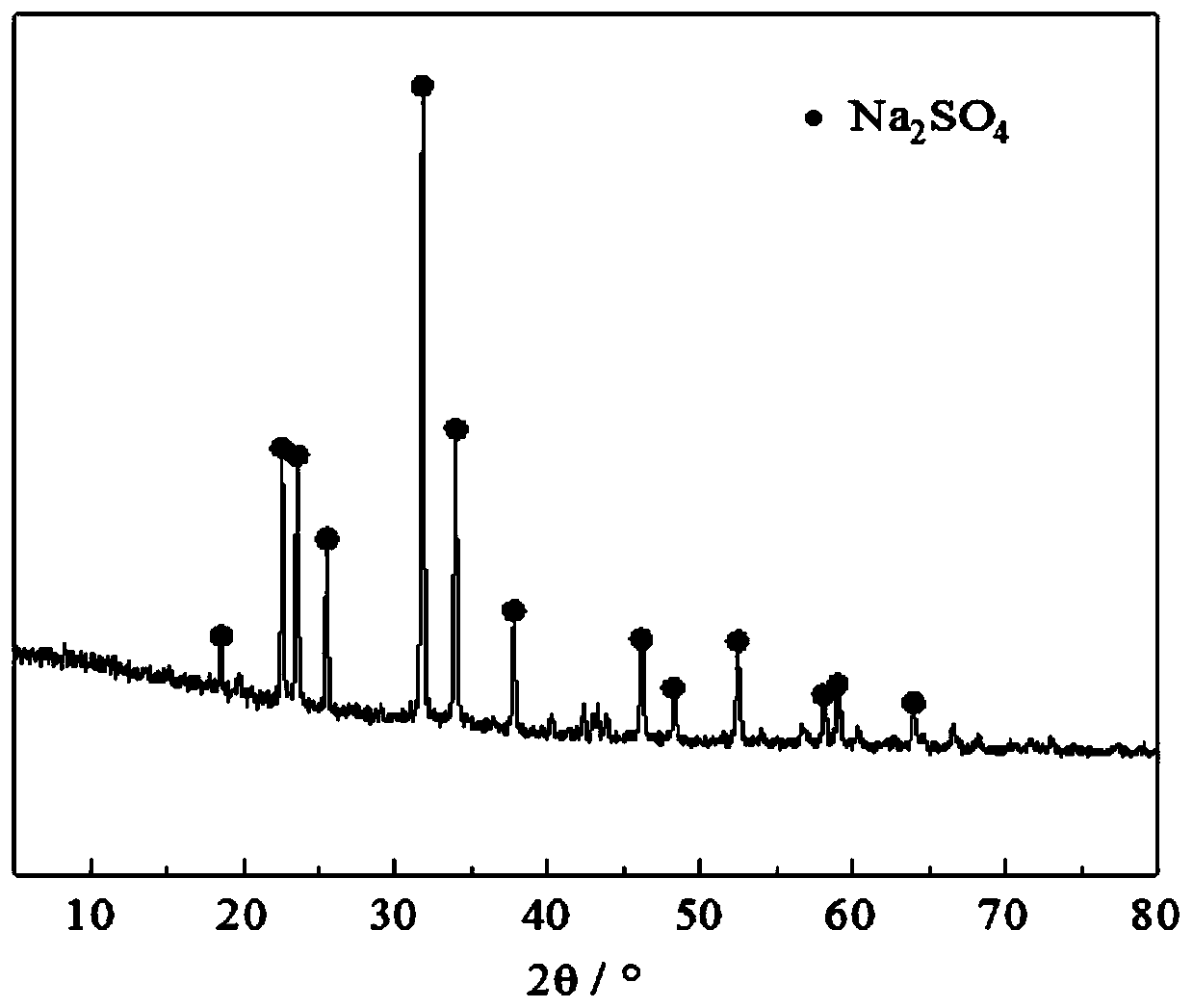

Method for treating sulfur dioxide flue gas by using alkaline waste residues and recovering tin-antimony metals and sodium sulfite crystals

InactiveCN109876630AShort processTo achieve the purpose of using alkaliDispersed particle separationAlkali metal sulfite preparationSulfite saltFiltration

The invention relates to a method for treating sulfur dioxide flue gas by using alkaline waste residues and recovering tin-antimony metals and sodium sulfite crystals. The method comprises the following steps: crushing and dissolving the alkaline waste residues, performing filtration to obtain a NaOH, Na2SnO3 and Na3SbO4 mixed solution and filter residues, carrying out an absorption reaction on the mixed solution and SO2 contained in industrially discharged flue gas in an absorption device to make the SO2 content of the flue gas reach discharge standards and obtain a mixed slurry containing Sn(OH)4 and Sb(OH)5 solid precipitates and a Na2SO3 solution, and carrying out solid-liquid separation on the slurry to obtain Sn(OH)4 and Sb(OH)5 solid precipitates and the Na2SO3 solution; and addingthe filter residues and the Sn(OH)4 and Sb(OH)5 solid precipitates to reduced coal, carrying out high-temperature reduction smelting to obtain tin-antimony metals and smelting furnace slag, and further carrying out evaporative concentration and separation on the Na2SO3 solution to obtain the sodium sulfite crystals. The method has the advantages of short process flow, high recovery rate of the tin-bismuth metals, realization of treatment of wastes with wastes, and clean and environmentally-friendly production process.

Owner:株洲湘三特环保有限公司

A treatment method for high-concentration heavy metal polluted construction waste

InactiveCN103978013BEliminate hazardsRealize waste treatmentConstruction waste recoverySolid waste disposalHigh concentrationThree level

The invention relates to a treating method of high-concentration heavy metal polluted building waste. The method includes: stripping surfaces of the building waste, smashing, washing, separating solid and liquid to obtain the cleaned building waste the water-soluble heavy metal of which is removed, adding an isopropylamine glyphosate solution into the cleaned building waste, eluting to remove the heavy metals, adjusting the pH value to be neutral, separating solid and liquid, washing the waste after elution with water and separating solid and liquid. The heavy metal contents in the building waste after air drying are lower than the three-level standard thresholds of the environmental quality standards (GB15618-1995). The building waste after air drying is subjected to a leaching test by utilization of an HJ / T229 leaching method, and the heavy metal contents in the leachate are lower than the thresholds of the standards for hazardous wastes (GB5085.3-2007). The building waste after air drying can be directly buried and stacked without pollution to the soil, and can be used as a regenerated roadbed material and a concrete aggregate. The method is simple in process and capable of completely eliminating the hazard of the polluted building waste, and has good environmental benefit, economic benefit and social benefit.

Owner:TONGJI UNIV

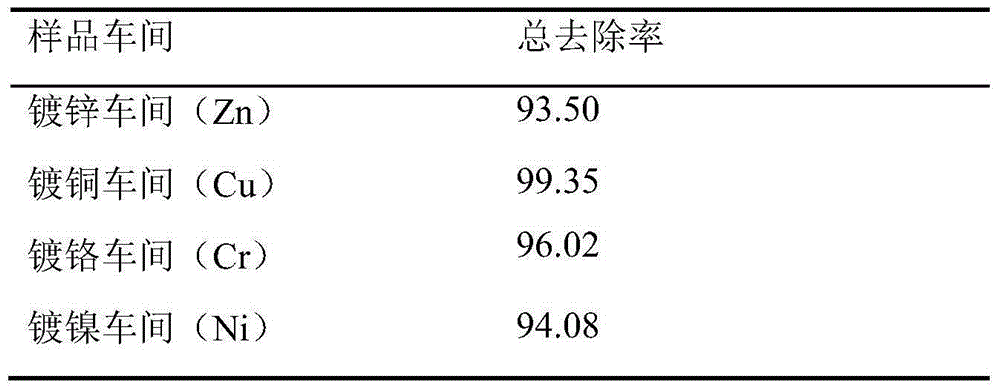

Treatment method and treatment device for FCC regeneration flue gas

ActiveCN109939550AEfficient removalRealize waste treatmentDispersed particle separationSulfur preparation/purificationSodium bisulfideFlue gas

The invention relates to a treatment method and a treatment device for FCC regeneration flue gas. The treatment method comprises the following steps: carrying out split-flow treatment on propylene refining waste alkali liquor, acidifying part of the propylene refining waste alkali liquor in an acidifying treater, and carrying out a reaction on the acidified gas and the FCC regeneration flue gas ina desulfuration reactor to recover generated single element sulfur; adding solid sodium hydroxide into the residual propylene refining waste alkali liquor, wherein sodium bisulfide in the waste alkali liquor is fully converted into sodium sulfate, oxidizing NO in the desulfurated flue gas into NO2 to react with the waste alkali liquor, a liquid phase enters the acidifying treater and purified gasis discharged; and carrying out multiple-effect evaporation on the acidified waste liquor to recover sodium salt. The treatment method can remove SOx and NOx in the FCC regeneration flue gas effectively and remove sulfides in the waste alkali liquor simultaneously to recover the generated sodium salt. The treatment device treats wastes with wastes, so that the treatment device is economical and environment-friendly.

Owner:CHINA PETROLEUM & CHEM CORP +1

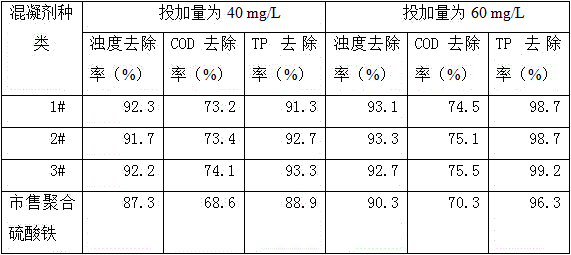

A kind of polyphosphorus ferric sulfate flocculant and its preparation method and application

ActiveCN104709992BHigh degree of polymerizationImprove stabilityWater/sewage treatment by flocculation/precipitationPhosphorus compoundsSodium bicarbonateLiquid product

The invention discloses a polymeric phosphorus ferric sulfate flocculating agent as well as a preparation method and an application thereof. The preparation method of the flocculating agent comprises the following steps: by taking an industrial byproduct namely ferrous sulfate septihydrate of titanium dioxide and waste sulfuric acid as main raw materials, adding hydrogen peroxide as an oxidant, and adding sodium dihydrogen phosphate and sodium hydrogen carbonate at the same time, and performing the steps of oxidation, hydrolysis, polymerization and ageing at normal temperature and normal pressure. The prepared product contains an active ingredient of all iron Fe<3+> with the mass content of more than or equal to 11%, the basicity is 18-25%, and the pH value is 1.4-1.6, so that the product can be widely used for feed water treatment and sewage-wastewater treatment, has a very good effect of removing turbidity, chemical oxygen demand and total phosphorus, and particularly can effectively remove soluble phosphorus and phosphorus in other forms from water and has a certain effect of removing algae and chlorophyl a from alga wastewater. The polymeric phosphorus ferric sulfate flocculating agent disclosed by the invention is simple in polymeric phosphorus ferric sulfate component and good in stability, is a liquid product, can be directly applied and is convenient to use; moreover, the preparation raw materials are low in cost, and waste utilization is realized; and the preparation process avoids generation of three wastes, and belongs to green production processes.

Owner:武汉市中润精细化学品有限公司

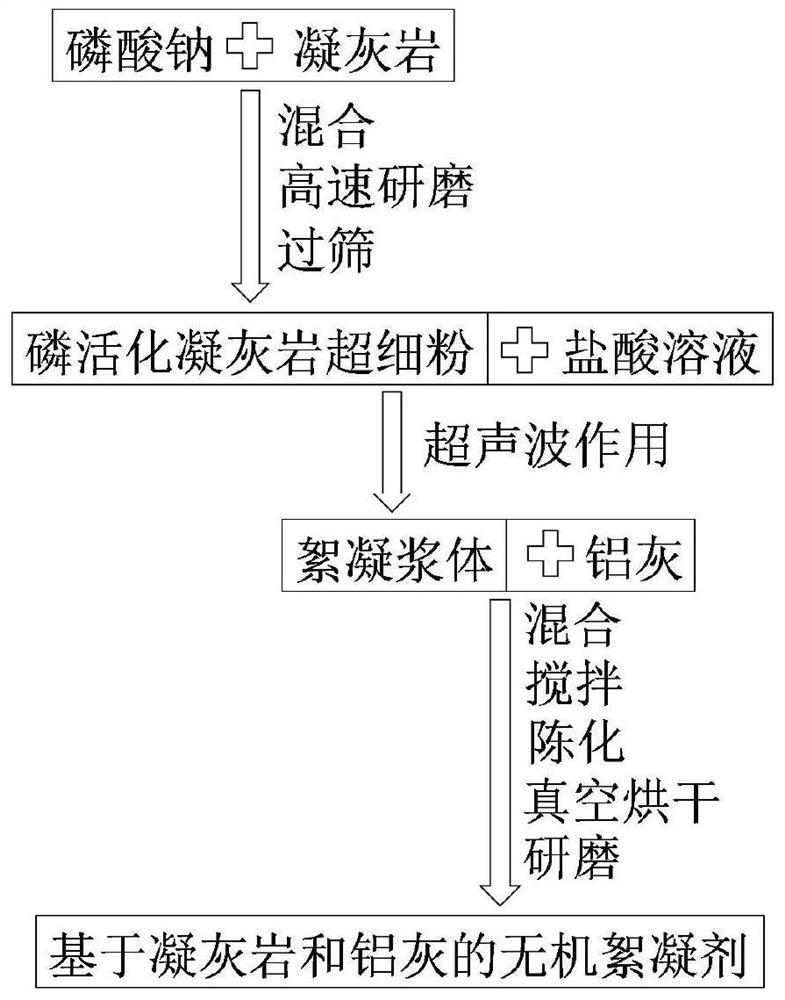

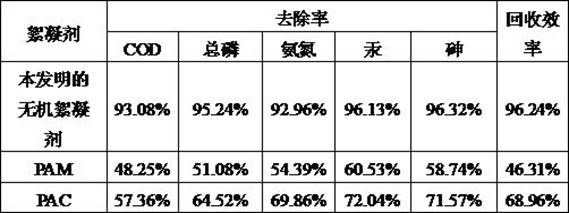

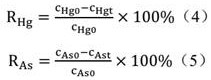

A kind of preparation method of inorganic flocculant based on tuff and aluminum ash

ActiveCN110950412BImprove recycling efficiencyEfficient removalWater treatment parameter controlWater contaminantsAluminateSodium phosphates

The invention discloses a preparation method of an inorganic flocculant based on tuff and aluminum ash, which comprises the following steps: (1) mixing, grinding and sieving sodium phosphate and tuff to obtain phosphorus-activated tuff; (2) activating the phosphorus tuff adding into hydrochloric acid solution, ultrasonic treatment to obtain flocculation slurry; (3) mixing aluminum ash and flocculation slurry, stirring, aging, drying and grinding to obtain an inorganic flocculant based on tuff and aluminum ash. Based on the chemical composition characteristics of tuff and aluminum ash itself, the invention couples and strengthens the silicon release of tuff through phosphate catalysis and ultrasonic strengthening, and fuses the silicon-aluminum-phosphorus colloid with the aluminosilicate gel through hydroxyl bridge connection and polycondensation Together, they form a flocculant, which can efficiently remove more than 96% of heavy metals, more than 93% of ammonia nitrogen, more than 93% of COD, and more than 95% of total phosphorus in domestic waste leachate, and the recovery efficiency is as high as more than 96%. Value utilization provides a new direction.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

A direct reduction ironmaking device and method based on utilization of blast furnace slag waste heat

ActiveCN105779679BReduce manufacturing costImprove transfer efficiencyRecycling and recovery technologiesHearth type furnacesHeat carrierSlag

The invention provides a direct-reduction ironmaking device and method based on blast furnace slag waste heat utilization. The device comprises a granulating device and a moving bed reduction device. By means of the device, liquid blast furnace slag is made into high-temperature furnace slag granules, the granules are loaded with a reducing agent and used as a heat carrier to be in direct contact with iron ore powder, and the iron ore powder generates a direct reduction reaction for production and direct-reduction ironmaking. According to the technical scheme, waste heat of the blast furnace slag is adopted as an iron ore powder direct-reduction heat source, the furnace slag heat carrier loaded with the reducing agent is in direct contact with the iron ore powder granules, and therefore efficient heat exchange and mass transfer of the reduction reaction are achieved, the waste heat of the blast furnace slag is efficiently recycled, and low-cost and efficient production of direct-reduced iron is achieved.

Owner:光大理工环境技术研究院(青岛)有限公司

Desulfurization and denitrification agent and preparation method and application thereof

PendingCN112604493AEasy to handleImprove the effect of desulfurization and denitrificationGas treatmentDispersed particle separationPtru catalystFlue gas

The invention provides a desulfurization and denitrification agent and a preparation method and application thereof, and the desulfurization and denitrification agent comprises the following components in parts by weight: 1-20 parts of granular waste SCR (Selective Catalytic Reduction) denitrification catalyst, 10-70 parts of granular denitrification agent, 10-70 parts of granular desulfurizing agent, 1-20 parts of granular silicate and 1-5 parts of granular combustion improver. According to the desulfurization and denitrification agent, the granular waste SCR denitrification catalyst is added, in the desulfurization and denitrification process, the granular waste SCR denitrification catalyst is converted into an effective catalyst through high temperature, and then the effective catalyst is combined with the desulfurizing agent, the denitrification agent and the combustion improver, so that the desulfurization and denitrification effects are effectively improved; while the waste SCR denitration catalyst is treated, the flue gas treatment effect is improved, and treatment of waste with waste is achieved.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

Method for producing ferrosilicon by electric arc furnace smelting waste refractory material as raw material

ActiveCN110117718BRealize high temperature volatile separationAchieve pyrolysisProcess efficiency improvementAlkali metal carbonatesElectric arc furnaceFerrosilicon

Owner:NORTHEASTERN UNIV LIAONING

Technical method for handling waste etching liquid quickly and efficiently

InactiveCN110252767AEfficient disposalRealize waste treatmentSolid waste disposalHigh concentrationPollution

The invention belongs to the technical field of waste water treatment, and particularly relates to a method for handling waste etching liquid quickly and efficiently. Waste etching liquid I, waste etching liquid II and chromium-containing waste are handled jointly; the waste etching liquid I is the mixed waste liquid of concentrated sulfuric acid and hydrogen peroxide solutions; and the waste etching liquid II is high concentration hydrogen peroxide waste solutions. With the above method, by taking advantage of the strong acidity of the waste etching liquid I and the weak reduction of the high concentration hydrogen peroxide solutions in the waste etching liquid II, chromate (with strong oxidizability under the acidic condition) existing in the form of hexavalent chromium in the chromium-containing waste is reduced to trivalent chromium; the high efficiency reaction is achieved, and the waste etching liquid is handled with the waste; and products have no secondary pollution to environment.

Owner:安徽浩悦环境科技股份有限公司

A kind of oyster shell powder modified water treatment agent and its preparation method and application

ActiveCN109865502BImprove adsorption capacityRealize waste treatmentOther chemical processesWater contaminantsCelluloseUltrasonic emulsification

The invention discloses an oyster shell powder modified water treatment agent as well as its preparation method and application. The preparation method is as follows: uniformly mix oyster shell powder, polyacrylamide (PAM) and a solvent, add a pH regulator to adjust the pH; ultrasonic emulsification, stir and heat at 50-90° C. for 30-150 minutes, cool to room temperature, and centrifuge , dried, pulverized, and sieved to obtain modified oyster shell powder; mix evenly modified oyster shell powder with sodium carboxymethyl cellulose, dry naturally, calcined at medium and low temperature, and cool to obtain The oyster shell powder modified water treatment agent. Oyster shell powder modified water treatment agent of the present invention is to Ni 2+ 、Co 2+ 、Cu 2+ Such heavy metal ions have a faster and more efficient adsorption effect, and have excellent stability and persistence, which can effectively realize the treatment of waste with waste. It is a kind of efficient and environment-friendly adsorption and separation material with good application value.

Owner:GUANGDONG OCEAN UNIVERSITY

A method for treating sulfur dioxide flue gas with alkaline waste residue and recovering tin-antimony metal and sodium sulfite crystals

InactiveCN109876630BShort processTo achieve the purpose of using alkaliDispersed particle separationAlkali metal sulfite preparationSulfite saltSlag

The invention relates to a method for treating sulfur dioxide flue gas with alkaline waste residue and recovering tin-antimony metal and sodium sulfite crystals. By crushing and dissolving alkaline waste residue and filtering, NaOH and NaOH are obtained. 2 SnO 3 、Na 3 SbO 4 Mixed solution and filter residue, SO contained in mixed solution in absorption equipment and industrial flue gas 2 The absorption reaction is carried out, so that the SO in the flue gas 2 The content reaches the emission standard, and in the process of absorption reaction, Sn(OH) 4 with Sb(OH) 5 solid precipitate and Na 2 SO 3 The mixed slurry of the solution is subjected to solid-liquid separation to obtain Sn(OH) 4 with Sb(OH) 5 solid precipitate and Na 2 SO 3 solution. Filter residue and Sn(OH) 4 with Sb(OH) 5 The solid precipitate is added to the reduced coal and subjected to high-temperature reduction smelting to obtain tin-antimony metal and smelting slag, and further deplete Na 2 SO 3 The solution was concentrated by evaporation and separated to obtain sodium sulfite crystals. The invention has the advantages of short process flow, high recovery rate of tin-antimony metal, realization of waste treatment with waste, clean and environment-friendly production process, and the like.

Owner:株洲湘三特环保有限公司

Method and special apparatus for refuse leachate disposal

InactiveCN101269856BImprove stabilityAchieve sustainable useWater/sewage treatmentLeachateSustainable yield

The invention discloses a method of treating garbage seeping liquid and a special device thereof. The device of treating the garbage seeping liquid provided by the invention comprises two garbage reactors 1 connected in series and a garbage reactor 2. The garbage reactors 1 and the garbage reactor 2 comprise a pool body, a water distribution device and a vent-pipe. The top part of the pool body is open and the bottom is provided with a through hole. The water distribution device is used for leading the garbage seeping liquid towards the pool body. The vent-pipe is arranged vertically in the tank body to be used for the ventilation. The application of the device of treating the garbage seeping liquid of the invention can realize the sustainable yield of a garbage land fill filed, and achieve the zero draining purpose of the seeping liquid.

Owner:TSINGHUA UNIV

Method for preparing ferrosilicon alloy by feeding hollow electrode with aluminum ash as raw material

ActiveCN110129565BAchieve pyrolysisEasy to cause secondary pollutionProcess efficiency improvementElectric arc furnaceFerrosilicon

Owner:NORTHEASTERN UNIV LIAONING

A kind of concrete containing refining slag and preparation method thereof

ActiveCN108358581BReduce manufacturing costRealize waste treatmentSolid waste managementMetallurgical slagEconomic benefits

The invention provides concrete containing refining slag and a preparation method of the concrete. The preparation method comprises the following steps: firstly, grinding and uniformly mixing the following components based on dry base by mass percent: 55 to 75 percent of slag, 15 to 35 percent of the refining slag and 10 to 20 percent of industrial by-product gypsum to obtain a cementing material;secondly, adding water into 15 to 50 percent of the cementing material, 50 to 85 percent of aggregate and 0 to 3 percent of water reducing agent for uniformly stirring, and carrying out pouring molding and curing to obtain a qualified concrete material. According to the preparation method of the concrete, disclosed by the invention, the key problem of poor stability of the refining slag is solved, a whole solid waste system cementing material is prepared by playing the gelling property and the synergistic excitation effect of the slag, and further the concrete material is prepared. The metallurgical industry solid waste refining slag and the industrial by-product gypsum are cooperatively treated; the refining slag can be comprehensively utilized to the maximum extent, resource utilizationrate is improved, environmental load is reduced and the comprehensive resource utilization rate of metallurgical slag in China is obviously improved; meanwhile, the production cost of the concrete isreduced and obvious economic benefits are obtained.

Owner:UNIV OF SCI & TECH BEIJING

Waste incineration fly ash all-solid waste solidification stabilization material and its solidification method

The invention provides a waste incineration fly ash all-solid waste solidification and stabilization material and a solidification method thereof, which belong to the technical field of industrial waste recycling and hazardous waste treatment and environmental protection. According to the mass percentage, the material includes 15%-40% of slag, 20%-45% of steel slag, 5%-15% of desulfurization ash, 15%-40% of calcium phosphate slag, and the raw materials are all from industrial waste slag, desulfurization ash and calcium phosphate The slag belongs to the refractory waste slag, and the comprehensive utilization rate is low. The solidification and stabilization material can solidify and stabilize the heavy metals in the fly ash by the hydration product of the gelling system and the phosphate in the calcium phosphate slag. Waste treatment has realized the harmless treatment of waste incineration fly ash and the resource utilization of industrial waste residue.

Owner:UNIV OF SCI & TECH BEIJING

Polysilicate iron/cationic starch composite flocculant and preparation method thereof

PendingCN110818048AGood flocculation effectPollution controlWater treatment parameter controlWaste water treatment from animal husbandryFlocculationSilicic acid

The invention discloses a polysilicate iron / cationic starch composite flocculant and a preparation method thereof. According to the invention, titanium dioxide waste acid, cationic starch, a sodium silicate solution, lime milk, hydrogen peroxide and an alkali are used as raw materials, a polysilicate iron flocculant is prepared by using the titanium dioxide waste acid, and the polysilicate iron and the cationic starch are compounded through a copolymerization method to successfully prepare the polysilicate iron / cationic starch composite flocculant, wherein the prepared polysilicate iron / cationic starch composite flocculant has good adsorption and flocculation effects on the turbidity, the chromaticity removal rate, the COD, the total nitrogen and the total phosphorus of breeding wastewater; and the method is simple in process and low in cost, turns titanium dioxide waste acid into wealth, treats pollution of breeding wastewater, achieves the treatment of waste with waste, and providesa new way for resource utilization of titanium dioxide waste acid.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com