Method for preparing anti-hardening granular burning-free iron-carbon microelectrolysis filler

An iron-carbon micro-electrolysis, anti-hardening technology, applied in chemical instruments and methods, solid waste removal, water/sludge/sewage treatment, etc. Biodegradability, reduced energy consumption, reduced CODCr and toxicity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

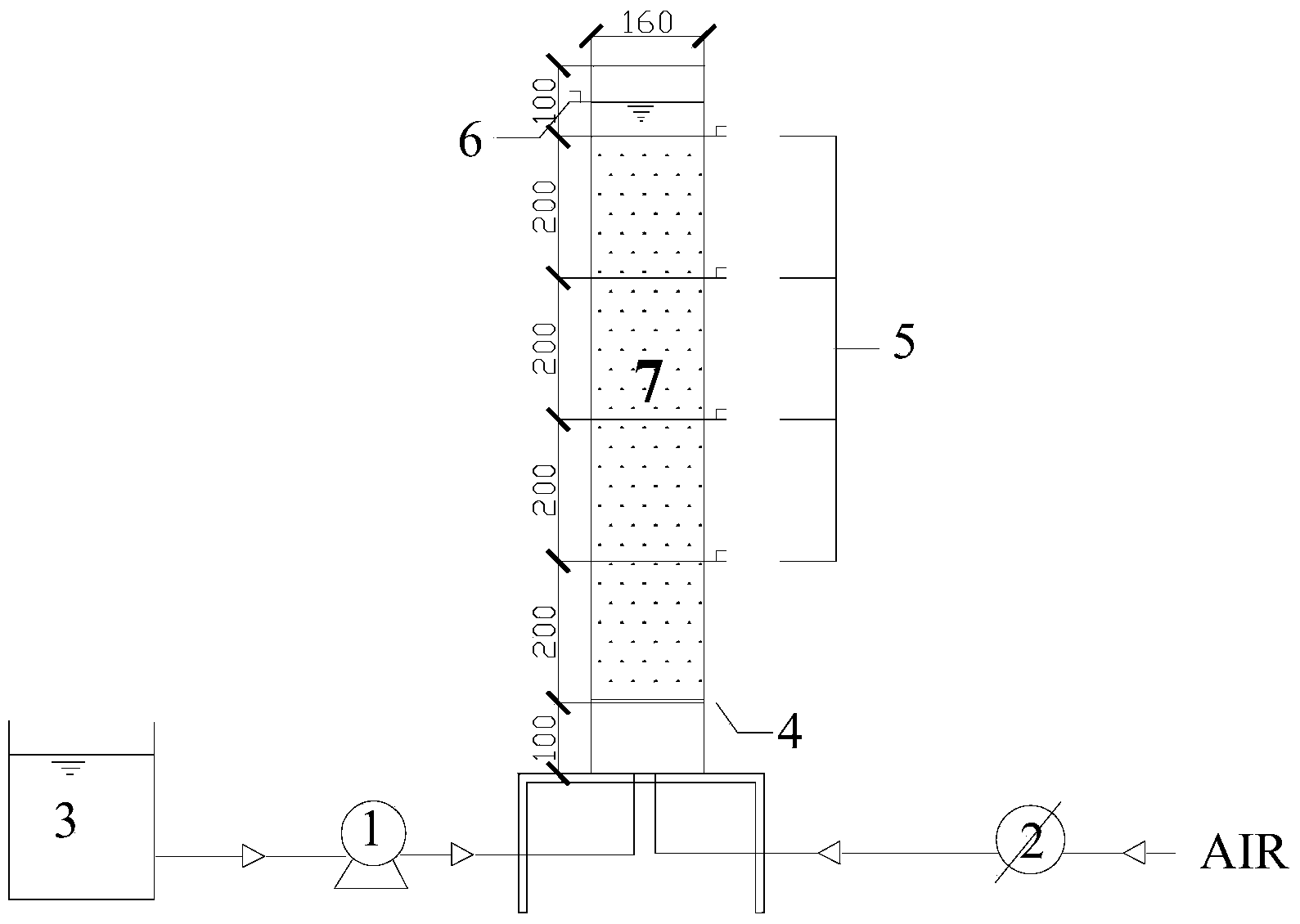

Image

Examples

Embodiment 1

[0032] A method for preparing anti-hardening granular unburned iron-carbon micro-electrolytic filler, comprising the following steps:

[0033] (1) Iron filings, charcoal, fly ash, cement, quicklime, and clay were dried at 105°C for 2 hours, then pulverized, and passed through a 100-mesh sieve;

[0034](2) Mix the pretreated raw materials in step (1) according to the mass fraction of iron filings 36%, charcoal 9%, fly ash 33%, cement 10%, quicklime 6%, clay 6%, and place in Roll in a disc-type ball forming machine, and spray the binder diluent during the rolling process (water glass solution with a modulus of 2.5-2.8 plus water to dilute 2 times) to assist in ball granulation; pass through a 5-6 mesh sieve, The screened raw meal balls with a particle size of 5-7 mm were placed in a dry and ventilated place and dried at room temperature for 20 hours to obtain raw meal balls;

[0035] (3) Curing the dried raw meal balls obtained in step (2) with water vapor at 105°C for 45 minut...

Embodiment 2

[0038] A method for preparing anti-hardening granular unburned iron-carbon micro-electrolytic filler, comprising the following steps:

[0039] (1) Iron filings, charcoal, fly ash, cement, quicklime, and clay were dried at 110°C for 1 hour, then pulverized, and passed through a 100-mesh sieve;

[0040] (2) Mix the pretreated raw materials in step (1) according to the mass fraction of iron filings 32%, charcoal 8%, fly ash 35%, cement 11%, quicklime 7%, clay 7%, and place in Roll in a disc-type ball forming machine, and spray the binder diluent during the rolling process (water glass solution with a modulus of 2.5-2.8 plus water to dilute 3 times) to assist in ball granulation; pass through a 5-6 mesh sieve, The screened raw meal balls with a particle size of 5-7 mm were placed in a dry and ventilated place and dried at room temperature for 24 hours to obtain raw meal balls;

[0041] (3) Curing the dried raw meal balls obtained in step (2) with water vapor at 110°C for 30 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com