Method for preparing ferrosilicon alloy by feeding hollow electrode with aluminum ash as raw material

A technology of hollow electrode and ferrosilicon alloy, which is applied in the field of electrometallurgy, can solve the problems that the utilization of resources is still in the research stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

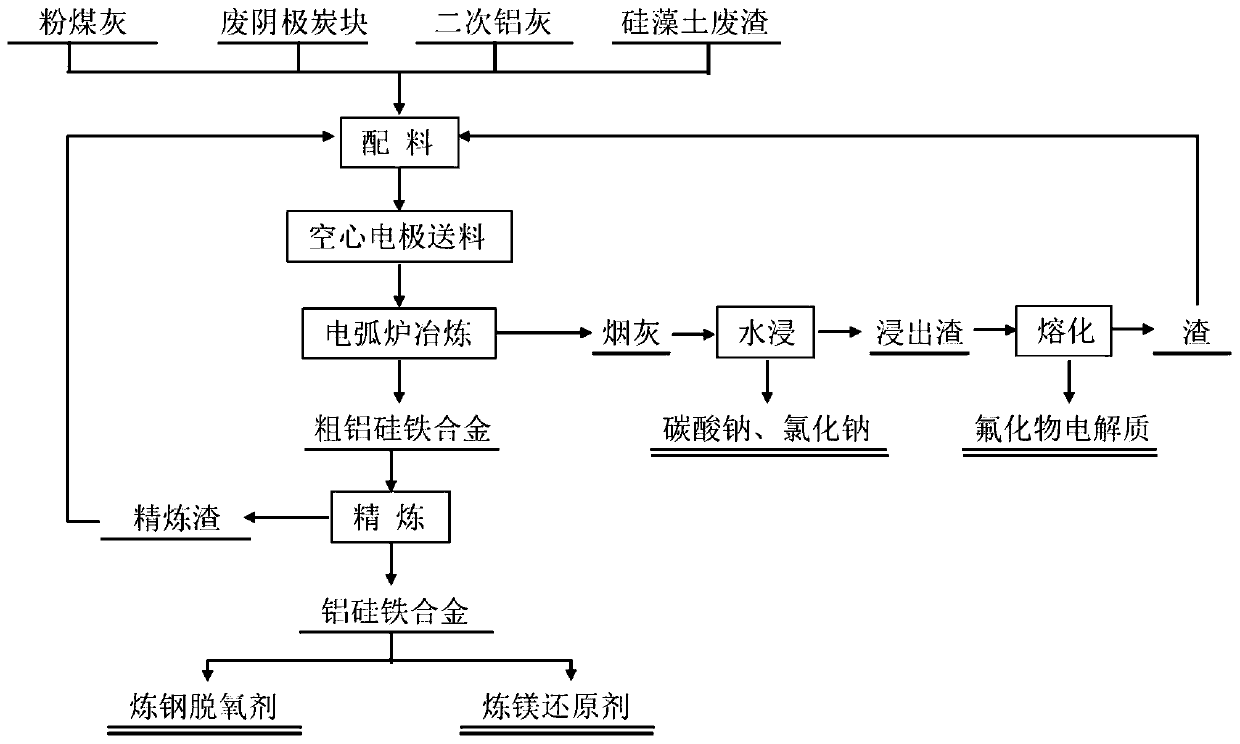

[0043] The method for preparing ferrosilicon alloy by feeding aluminum ash as a raw material hollow electrode comprises the following steps:

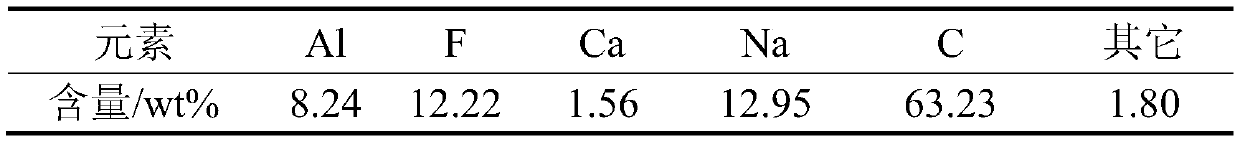

[0044] Step 1, making aluminum ash, waste cathode carbon block, fly ash and diatomite waste slag in aluminum electrolytic cell overhaul slag into powder respectively, and the particle size is all less than 100 mesh;

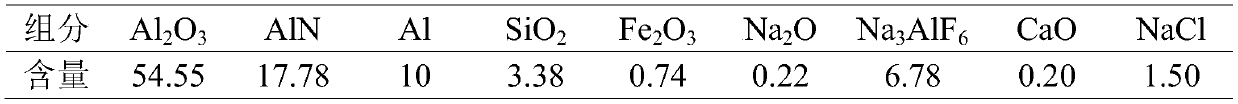

[0045] Step 2, according to the composition of the target aluminum-silicon-ferroalloy: 28% aluminum content, 61% silicon content, and the rest are iron, calcium, titanium and other trace metals, using the fixed carbon contained in the waste cathode carbon block as the reducing agent according to chemical The metering ratio is used to calculate the mass of secondary aluminum ash, spent cathode carbon block, fly ash and diatomite waste slag required for the reduction of metal oxides, wherein the metal aluminum in the secondary aluminum ash is calculated as if all of it enters the Al-Si-Fe alloy, and the nitriding All the alu...

Embodiment 2

[0049] The method for preparing ferrosilicon alloy by feeding aluminum ash as a raw material hollow electrode comprises the following steps:

[0050] Step 1, making aluminum ash, waste cathode carbon block, fly ash and diatomite waste slag in aluminum electrolytic cell overhaul slag into powder respectively, and the particle size is all less than 100 mesh;

[0051] Step 2, according to the composition of the target aluminum-silicon-ferroalloy: the aluminum content is 35%, the silicon content is 54%, and the rest is iron, calcium, titanium and other trace metals; the fixed carbon contained in the waste cathode carbon block is used as the reducing agent according to the chemical The metering ratio is used to calculate the mass of secondary aluminum ash, spent cathode carbon block, fly ash and diatomite waste slag required for the reduction of metal oxides, wherein the metal aluminum in the secondary aluminum ash is calculated as if all of it enters the Al-Si-Fe alloy, and the nit...

Embodiment 3

[0055] The method for preparing ferrosilicon alloy by feeding aluminum ash as a raw material hollow electrode comprises the following steps:

[0056] Step 1, making aluminum ash, waste cathode carbon block, fly ash and diatomite waste slag in aluminum electrolytic cell overhaul slag into powder respectively, and the particle size is all less than 100 mesh;

[0057] Step 2, according to the composition of the target aluminum-silicon-ferroalloy: 43% aluminum content, 47% silicon content, and the rest are iron, calcium, titanium and other trace metals; the fixed carbon contained in the waste cathode carbon block is used as the reducing agent according to the chemical The metering ratio is used to calculate the mass of secondary aluminum ash, spent cathode carbon block, fly ash and diatomite waste slag required for the reduction of metal oxides, wherein the metal aluminum in the secondary aluminum ash is calculated as if all of it enters the Al-Si-Fe alloy, and the nitriding All t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com