Biomass pyrolysis system and method for pyrolyzing biomass

A biomass pyrolysis and biomass technology, applied in the chemical industry, can solve the problems of difficulty in realizing high-value production of biomass resources, increasing system operating costs, and unstable product quality, achieving high energy utilization and low operating costs. , the effect of efficient pyrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

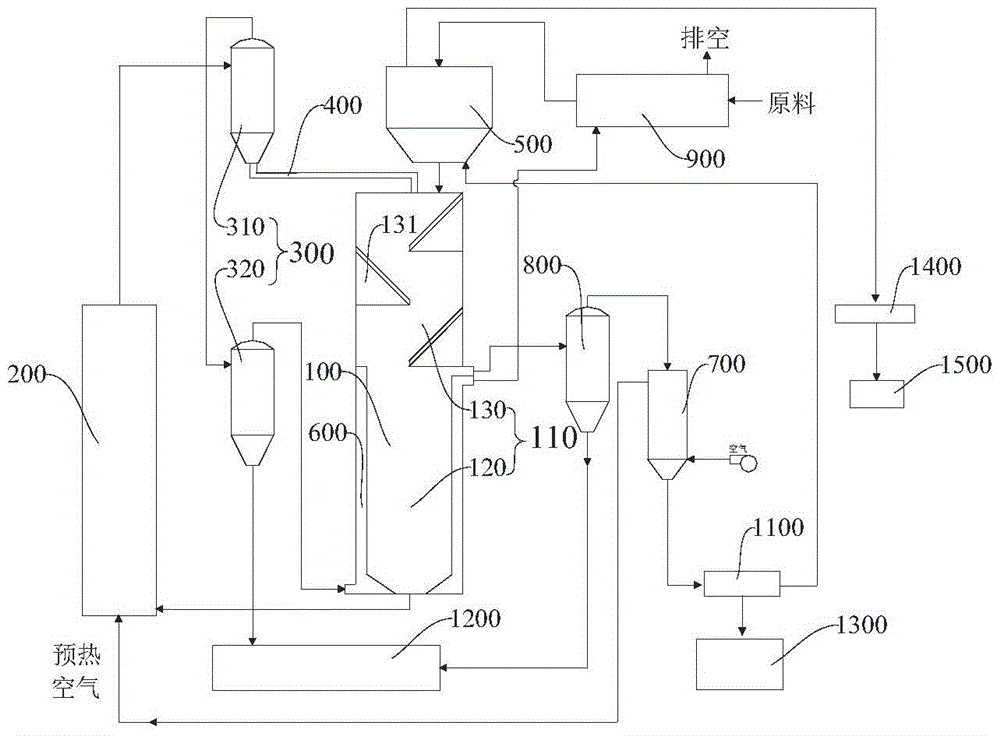

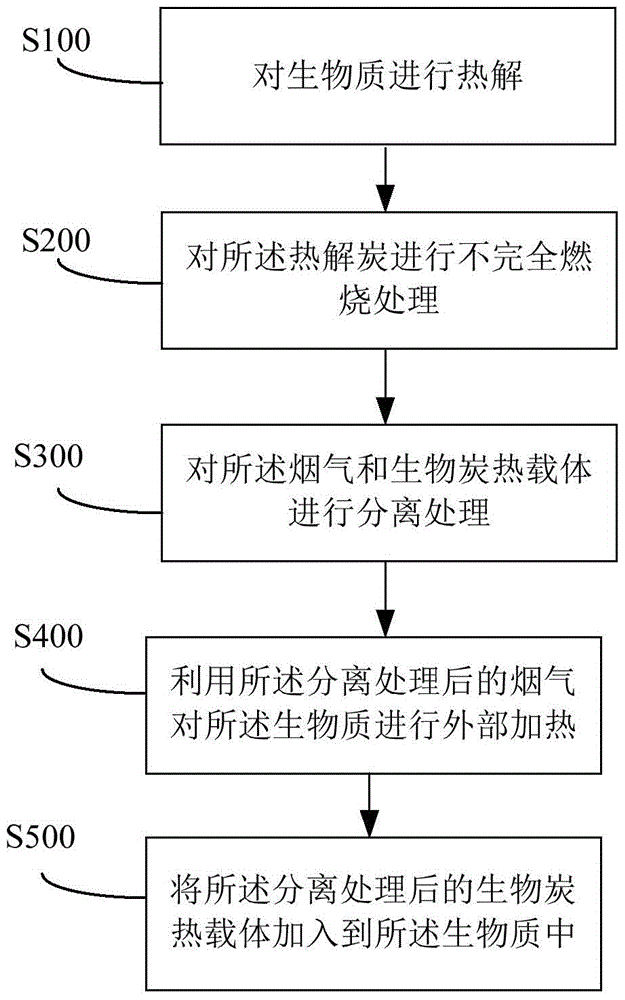

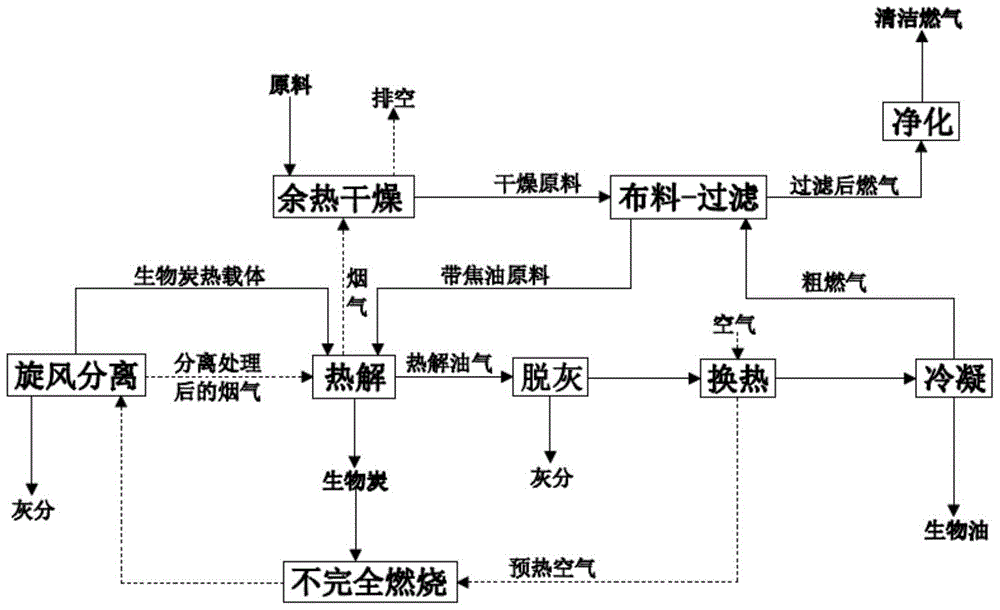

[0059] Utilize the device of the present invention, the structural representation of device is as figure 1 As shown, wood chips are used as raw materials to produce bio-oil and gas, and the pyrolysis process is as follows image 3 As shown, the specific steps are as follows:

[0060] (1) Taking wood chips with a particle size of 2-3cm and a water content of less than 20% as an example, the wood chips first enter the rotary kiln dryer for material drying at a drying temperature of 150-200°C, and the dried wood chips enter the silo ;

[0061] (2) The dry sawdust and the biochar heat carrier enter the pyrolysis furnace through the raw material inlet and the heat carrier inlet respectively at a ratio of 5:1, and after being fully mixed by the mixing slide, they enter the pyrolysis zone evenly and start pyrolysis;

[0062] (3) The obtained pyrolytic charcoal (500-550°C) is mixed with preheated air (200-300°C) and enters the combustion riser for incomplete combustion, and the prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com