Rotary kiln

A technology of rotary kiln and kiln body, applied in the field of rotary kiln, can solve the problems of total weight of rotary kiln body, unsatisfactory sealing effect, energy waste, etc., to avoid adhesion and lifting plate, reduce natural gas consumption, save energy energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further described below in conjunction with embodiment.

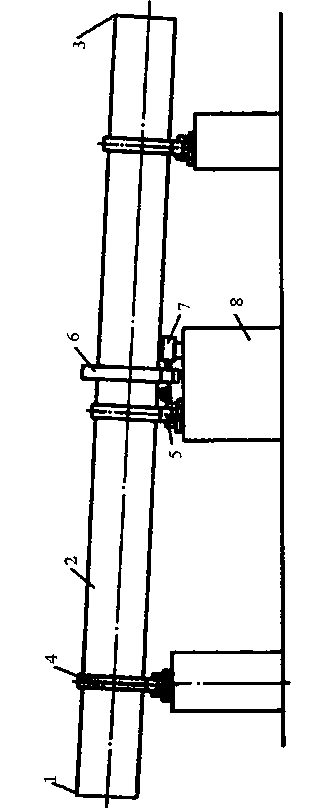

[0019] A rotary kiln, including a kiln head 1, a kiln body 2, a kiln tail 3, a wheel belt 4, a supporting wheel 5, a large ring gear 6, a transmission device 7, a foundation 8, a burner, an automatic powder sprayer and a secondary air inlet device.

[0020] The supporting wheel 5 is set on the foundation 8 through bearings. The wheel belt 4 is sheathed and fixedly connected to the kiln body 2 . The kiln body 2 is set on the support roller 5 through the tire belt 4 .

[0021] The supporting roller 5 is set on the foundation 8 through the bearing, the tire belt 4 is sheathed and fixedly connected to the kiln body 2, and the kiln body 2 is set on the supporting roller 5 through the tire belt 4.

[0022] The kiln body 2 is fitted with a fixed ring gear 6 . The transmission device 7 is arranged on the foundation 8, and the output end of the transmission device 7 meshes with the gear of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com