Concrete containing refining slag and preparation method of concrete

A technology of refining slag and concrete, which is applied in the field of solid waste resource utilization and building materials, can solve problems such as the consumption of refining slag, the waste of refining slag hydraulic gelation, and the lack of in-depth research on the stability of refining slag. The effect of reducing environmental pollution and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

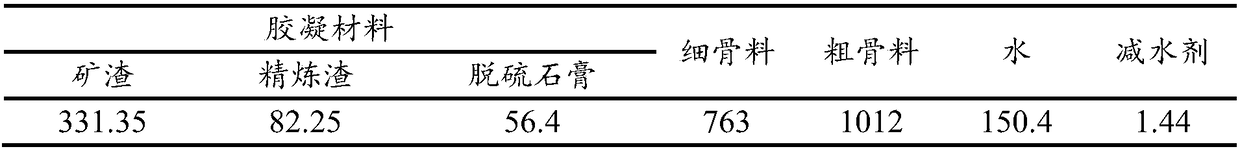

[0034] A kind of concrete, the cementitious material is prepared from the following raw materials in mass percentage: slag 70.5%, refining slag 17.5%, desulfurization gypsum 12%, the three are mixed and ground to a specific surface area of 560m 2 / kg; In concrete, cementitious material accounts for 19.6%, aggregate accounts for 74%, and water reducing agent accounts for 0.06%.

[0035] The concrete mix ratio is shown in the following table: (amount of concrete material per cubic meter: kg / m 3 )

[0036]

[0037] Coarse aggregate is mine waste rock, fine aggregate is tailings sand, and water reducer is solid polycarboxylate high-efficiency water reducer.

[0038] The stability test of cementitious materials is carried out in accordance with GB / T 1346-2011 "Cement Standard Consistency Water Consumption, Setting Time, and Stability Test Methods". The ratio of the stability test refers to the "cementation material" part in the above table, and the cake test method and the R...

Embodiment 2

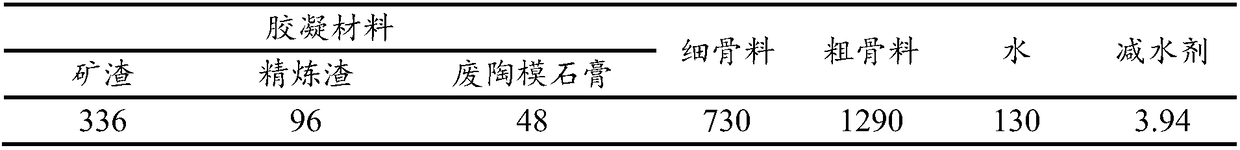

[0041] A kind of concrete, the cementitious material is prepared from the following raw materials in mass percentage: 70% of slag, 20% of refining slag, 10% of waste pottery mold gypsum, and the three are mixed and ground to a specific surface area of 650m 2 / kg; In concrete, cementitious material accounts for 18.2%, aggregate accounts for 76.7%, and water reducing agent accounts for 0.15%.

[0042] The concrete mix ratio is as follows: (amount of concrete material per cubic meter: kg / m 3 )

[0043]

[0044] Coarse aggregate is mine waste rock, fine aggregate is tailings sand, and water reducer is solid polycarboxylate high-efficiency water reducer.

[0045] The stability test of cementitious materials is carried out in accordance with GB / T 1346-2011 "Cement Standard Consistency Water Consumption, Setting Time, and Stability Test Methods". The ratio of the stability test refers to the "cementation material" part in the above table, and the cake test method and the Rayleig...

Embodiment 3

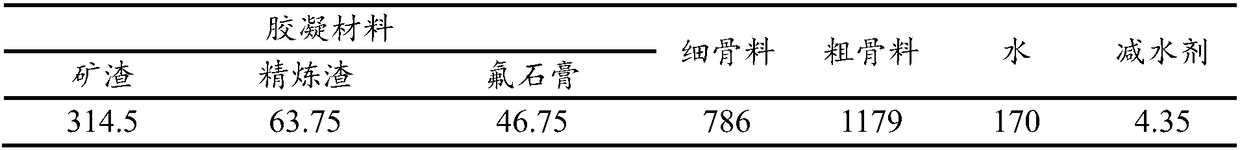

[0048] A kind of concrete, the cementitious material is prepared from the following raw materials in mass percentage: slag 74%, refining slag 15%, fluorine gypsum 11%, the three are mixed and ground to a specific surface area of 550m 2 / kg; In concrete, cementitious material accounts for 16.6%, aggregate accounts for 76.7%, and water reducing agent accounts for 0.17%.

[0049] The concrete mix ratio is as follows: (amount of concrete material per cubic meter: kg / m 3 )

[0050]

[0051] The coarse aggregate is limestone stones, the fine aggregate is quartz river sand, and the water reducer is naphthalene-based high-efficiency water reducer.

[0052] The stability test of cementitious materials is carried out in accordance with GB / T 1346-2011 "Cement Standard Consistency Water Consumption, Setting Time, and Stability Test Methods". The ratio of the stability test refers to the "cementation material" part in the above table, and the cake test method and the Rayleigh method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com